Tool Time

21 Engine-Building Tools for Under $100

From the February, 2009 issue of Chevy High Performance

By Scott Crouse

Photography by Scott Crouse

http://www.chevyhiperformance.com/techa ... ewall.html

|

|http://www.wizardswarehouse.com/products/tools

http://garage.grumpysperformance.com/index.php?threads/starter-tool-set.6032/

148 0505 Tools 22 Z

Torque it, stretch it, compress it--these are just a few of the exercises that engine builders encounter when assembling a high-performance engine. The process of building a bullet requires the skills to set up internal engine clearances and demands a legion of tools that can be costly to average enthusiasts. While engine building and the skilled steps involved are a story of their own, this month's chronicle takes a look at some of the tools needed to assemble a Chevrolet powerplant. Every month, CHP delivers attainable and affordable stout engine combinations, but that pile of parts is only as good as the person assembling them. In order to construct a home-built bullet on a budget, we chose 21 reasonably priced items for less than $100. If high-performance garage tinkering gets your heart pumping, then make room in the toolbox. This year's wish list could be a long one.

148 0505 Tools 01 Z

1. Deck Bridge

Powerhouse Products

$19

PN POW101310

The internal timing of the crankshaft, camshaft, and piston location all play vital roles in determining the characteristics of the engine's power curve. In order to put each of these parts into the proper timing sequence, the number 1 piston must be measured at its top dead center (TDC) point with a dial indicator that is connected to a deck bridge. The piston location allows the engine builder to determine when the engine's firing sequence will occur. In order to use the dial indicator/deck bridge tool correctly, the dial indicator reading tip must be placed on the center of the piston to experience as little piston rock as possible. While turning the engine over by hand, the dial indicator will reveal the piston's TDC point, which will allow the builder to set the internal timing of the engine by installing the timing chain at a desired location.

148 0505 Tools 02 Z

2. Magnetic Base Dial Indicator

Powerhouse Products

$39.95 (magnetic base stand)

$29.95 (dial indicator only)

PN POW151140; PN POW151100

Accurately measuring lifter rise, piston movement, or any other oscillating part can be tough without the help of a dial indicator. Powerhouse Products offers a dial indicator by itself, as well as a magnetic base designed to hold the indicator in innumerable positions. Whether it's degreeing internal timing, lining up bellhousings, or simply checking rocker roll, a magnetic-base dial indicator is a must-have tool when it comes to engine assembly.

148 0505 Tools 03 Z

3. Crankshaft Turning Socket

Powerhouse Products

$14.95 SBC

$29.95 BBC

PN POW102050; PN POW103055

Whether it's connecting the rods to the crankshaft or adjusting the valves, a rotating assembly is constantly being turned over. Using the balancer bolt to turn over a rotating assembly will eventually become a problem, which is why Powerhouse Products offers its crankshaft turning socket. The small-block piece is cast aluminum and works well with a 2- to 3-inch extension; the big-block Pro crankshaft turning socket is constructed of hardened steel in order to turn over the biggest engines. When engine maintenance and assembly lay ahead, a crankshaft turning socket is the only way to go. TIP: When turning an engine over by hand, it's easier to do so once the spark plugs have been removed. This allows compressed air to escape from each cylinder and drastically reduce rotating resistance.

148 0505 Tools 04 Z

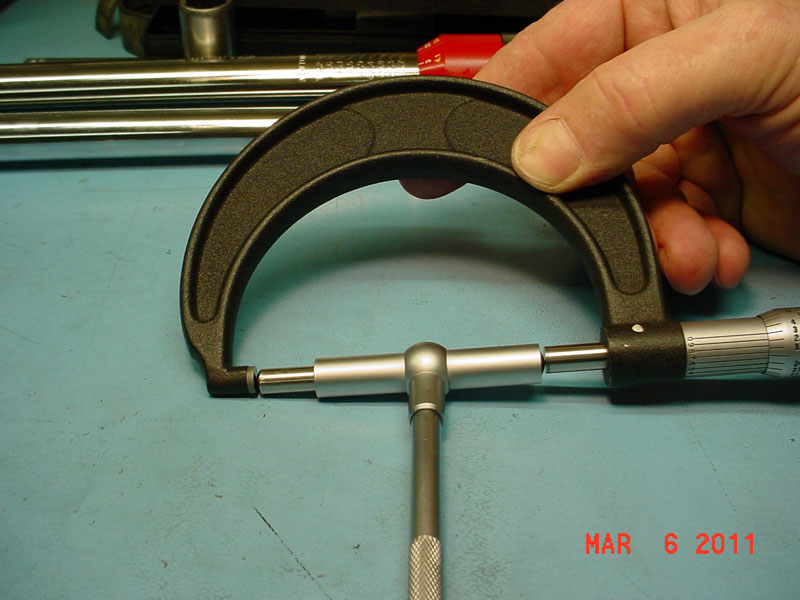

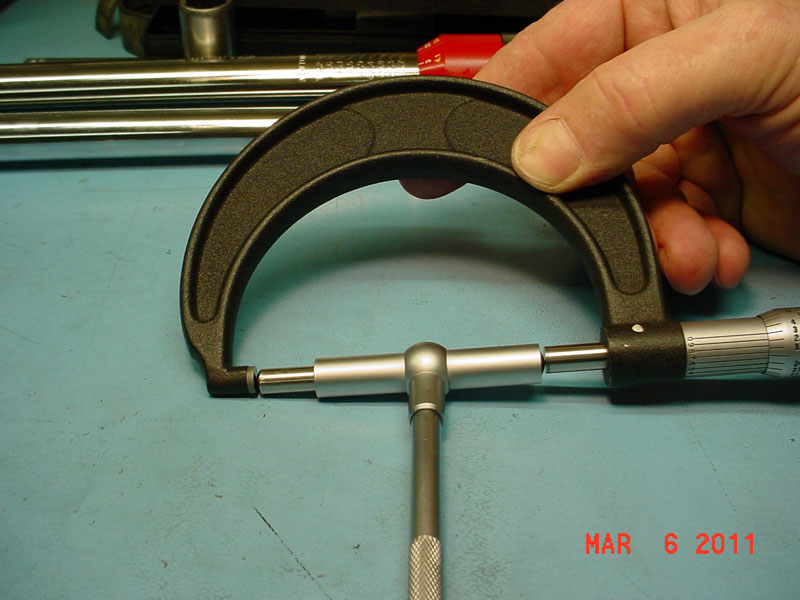

4. Dial Bore Gauge

Powerhouse Products

$99.99

PN POW205025

One of the most critical engine-building tools, the dial bore gauge is specifically designed to measure the inside diameter of an orifice whether it be a connecting rod journal, a crankshaft main journal, or a cylinder wall. Regardless, the engine-building process requires that there be enough space between moving parts for a thin film of oil to coat them. The thickness of this thin film is determined by measuring the orifice diameter and the actual rotating part diameter (with a micrometer) to ascertain a tolerance between the two objects. The kit displayed here is capable of measuring bore size diameters from 2 to 6 inches in 0.0005-inch increments.

148 0505 Tools 05 Z

5. Tap and Die Set

Powerhouse Products

$9.95 (die set)

$9.95 (tap set, course thread)

PN POW351685; PN POW351675

Misaligned bolt threads damage parts and waste time, which is why an inexpensive rethreading die-set kit should be in every tool box. This kit is capable of cleaning up bolt-thread sizes of 1/4, 5/16, 3/8, 7/16, and 1/2 inches. A thread-restoring tap set for galled-up bolt holes makes a good companion to a rethreading set. It cleans up the same-size holes as the rethreading die set, plus it has an additional 9/16-inch tap-restoring tool as well. This stuff is cheap insurance, folks.

148 0505 Tools 06 Z

6. Valve Checking Spring Kit

Powerhouse Products

$7.60

PN POW101325

Horsepower is directly correlated to engine airflow, which is why flow testing the cylinder heads is so important. In order to do the flow test, the valves must be held open at either 0.05- or 0.1-inch increments, and this requires low-tension valve checking springs that allow the valves to be opened slowly while cylinder-head airflow is measured. They assume the position of the actual engine valvesprings and are designed to work with most domestic lock and retainer hardware.

148 0505 Tools 07 Z

7. Pushrod Length Checking Tool

Powerhouse Products

$59 (complete set)

PN POW101240

Pushrod length-checking tools are another critical part used in an engine-assembly process. Pushrod length must be rechecked whenever an engine's factory specifications are altered in any way. A too short or too long of a pushrod will cause the rocker tips to roll over the edge of the valve stems and eventually wear the valve stem out. Powerhouse pushrod length-checking tools can be ordered in 1-inch increments under a specific part number or as an entire kit for the enthusiast who plans on building a variety of short- and tall-deck engines.

148 0505 Tools 08 Z

8. Sportsman Head CC Kit

Powerhouse Products

$29

PN POW351155

Computing the compression ratio is valuable because it helps determine the required octane rating an engine will use. While piston design, deck height, and head-gasket thickness all play a part in this equation, the cylinder-head combustion chamber size is what completes the formula. Aftermarket heads can often be misleading by a cc or two, as can porting, or what you find in a salvage yard, so it's a good idea to make sure that the stated combustion chamber size is exactly that.

148 0505 Tools 09 Z

9. Stud Removal Tool

Powerhouse Products

$22.95

PN POW351590

Head studs, main studs, carburetor studs, or any other stud can be problematic when it's time to remove them. Because this can be difficult, Powerhouse offers this tool designed to remove threaded studs or install the same from 1/4 to 3/4 inches. All that's required is a 1/2-inch drive ratchet.

148 0505 Tools 10 Z

10. Valve Lash Tool

Proform Products

$19.95

PN 66780

Correct camshaft lash and valvetrain movement ensure that the intake and exhaust valves open and close properly. Hydraulic tappet designs require the lifters to be set with zero lash before the engine is broken in; solid lifters require routine maintenance. In order to lash the valves, the rocker lock nuts must be loosened. Once the engine is turned over and the proper amount of lash is achieved, an internal lash nut must be tightened onto the rocker stud to keep the rocker nut tight during operation. Because valve adjustment requires three hands, Proform offers a two-in-one tool that allows the rocker nut to be held steady while the internal lash nut is set.

148 0505 Tools 11 Z

11. Stud Mount Valvespring Compressor Tool

Proform Products

$49.95

PN 66784

Valve control is an essential part of engine assembly and development. A proper amount of tension is required in order to keep the valves under control at high rpm. Over time, all valve springs lose their tension, which is why they sometimes float near the engine-redline rpm. In order to check valvespring tension on a regular basis, Proform offers its in-car stud mount valvespring compressor tool that allows the builder to attach the spring compressor to the rocker stud before its forks, slid around the valve retainer, and then compressed to free the valve locks. Once the locks are removed the retainer and valvespring will pop off the cylinder head. The valve springs will then need to be tested on a more costly tool. An engine shop should be equipped to take care of measuring actual valvespring tension. TIP: Unless you'd enjoy removing a cylinder head as well, don't forget to either fill the cylinder with air pressure or place the piston at its TDC position so the valve doesn't drop into the cylinder.

148 0505 Tools 12 Z

12. Cam Bearing Installation Tool

Proform Products

$69.95

PN 66794

Every engine builder should own one of these. While this tool is only used for a single assembly process, it's essential if the user is going to build more than one engine. Progressing from the front of the engine to the distributor, each camshaft-bearing orifice diameter is slightly larger than the previous one, which allows several bearings to be paced on one parallel axis inside the cylinder block. A special tool with specific sliders must be used to install each of the bearings. Each slider matches up to the individual bearing size and allows the engine builder to gently knock the camshaft bearings into place. This cam-bearing installation tool is a great choice for the garage enthusiast who plans on building a few engines a year and doesn't want to wait for the machine shop.

148 0505 Tools 13 Z

13. Rod Bolt Stretch Gauge

Proform Products

$59.95

PN 66788

When a bolt is tightened, its threads are pulled against the receiving threads to create a fastening effect as the material stretches a minute amount. Bolt torque is a measurement of thread resistance, while bolt stretch is the actual amount of the bolt clamping. In order to properly fasten a bolt, you can't strictly rely on a torque reading. If possible, each rod bolt should be stretched to the manufacturer's tolerance regardless of the torque rating. By torqueing each bolt, the engine builder may gain peace of mind knowing that the rod bolts will not loosen during operation. Proform Products offers this handheld rod bolt stretch gauge that uses a dial indicator to determine before and after (stretched) readings.

148 0505 Tools 14 Z

14. Rod Vise

Proform Products

$79.95

PN 66769

Engine building requires the measuring of bearing clearances, which means the connecting rod caps must be removed and torqued into place several times before the engine reaches final assembly. This connecting rod vise allows the engine builder to support the rod safely by making sure the rod does not experience torsional twist as the cap bolts are tightened or loosened.

148 0505 Tools 15 Z

15. Rod Splitting Fixture

Proform Products

$100.99

PN 66773

As mentioned in the previous rod vise section, removing connecting rod caps can be quite difficult. Instead of pulling and twisting something out of shape, it's a good idea to invest in a rod-splitting fixture. This simple tool places its expanding jaws inside the rod's big end before a leveraged arm expands its jaws. Once expanded, the cap is separated from the rod main body without any harm. Using the right tools for the job not only makes things easier, it can keep from damaging valuable engine parts as well.

148 0505 Tools 16 Z

16. Valve Height Micrometer

Proform Products

$49.95

PN 66902

Camshaft lobe lift, rocker arm ratio, and valvespring setup must all work together in order to make sure there is enough clearance for each of these valvetrain parts to operate properly. As the lift of the valve increases, valvespring height decreases, which makes it very important that the distance from the valvespring retainer to the cylinder head spring seat is predetermined before the engine runs. A valve height micrometer measures the total valvespring retainer travel before the engine is even turned over. Collapsed seals, binding springs, and worn metal pieces are all problems you can avoid ahead of time with a height micrometer.

148 0505 Tools 17 Z

17. Valvespring Compressor

Proform Products

$92.95

PN 66832

If you'll be doing cylinder head work in the garage, a heavy-duty Proform valvespring compressor is a must. Once the cylinder heads are off the engine, this tool is extremely useful in the removal of valves, locks, retainers, and springs. Its hand-operated design and the extendable arm allow it to be used on a variety of cylinder head designs. As long as the collapsed valvespring tension does not peak beyond the user's ability to compress the valvespring by hand, this tool will work well for the average garage enthusiast.

148 0505 Tools 18 Z

18. Leak Down Gauge

Proform Products

$69.99

PN 66839

Cylinder pressure can be lost due to improper ring seating, broken rings, worn valve seats/guides, a burned piston, or a blown head gasket. All of these problems snuff power and in some cases they will lower engine vacuum. In order to diagnose them, you must perform a cylinder leak-down test. Proform offers its dual leak-down cylinder pressure tester that requires an adapter fitting in a spark-plug hole. Once compressed air fills a cylinder, the gauge is calibrated to a manufacturer's pre-set position before providing the percentage of leakage. While Proform recommends using its pre-calibrated set position as the starting point, the industry leak-down incoming air standard usually allows 80 psi in the cylinder before the test is preformed.

148 0505 Tools 19 Z

19. Cranking Compression Gauge

Craftsman

$49.95

PN 47089

In order to make considerable horsepower, four major ingredients are required: air, fuel, spark, and compression. While the first three variables can be diagnosed as external factors, the process of compression is mainly an internal function. This requires a cranking compression tester that uses an adapter fitting threaded into a spark-plug hole that connects the gauge to the cylinder. Once connected to the cylinder, the engine is turned over using the starter motor. After a few crankshaft revolutions, the gauge will display the amount of compression inside the cylinder. Street and strip engines running a 9:1 compression ratio and a healthy but streetable camshaft sporting less than 235 degrees of duration at 0.05 inches should read somewhere between 165 psi and 200 psi, depending on the application.

148 0505 Tools 20 Z

20. Torque Wrench 1/2-inch Drive

Craftsman

$69.99

PN 44595

All bolts require a recommended torque specification (a measurement of resistance) that should be considered when fastening threads (see "Rod Bolt Stretch Gauge" in this section). Some bolts cannot be accessed from the bottom side to measure stretch, which leaves the engine builder with only one option. Our Craftsman torque wrench is designed to fasten bolt threads to a predetermined torsional load. When using a torque wrench, be sure to lubricate the bolt threads and face to ensure as little resistance as possible. TIP: After using this tool, remove all tension from the internal torque regulating spring by placing the torque setting at zero. This will ensure that the torque wrench reads accurately the next time it is used.

148 0505 Tools 21 Z

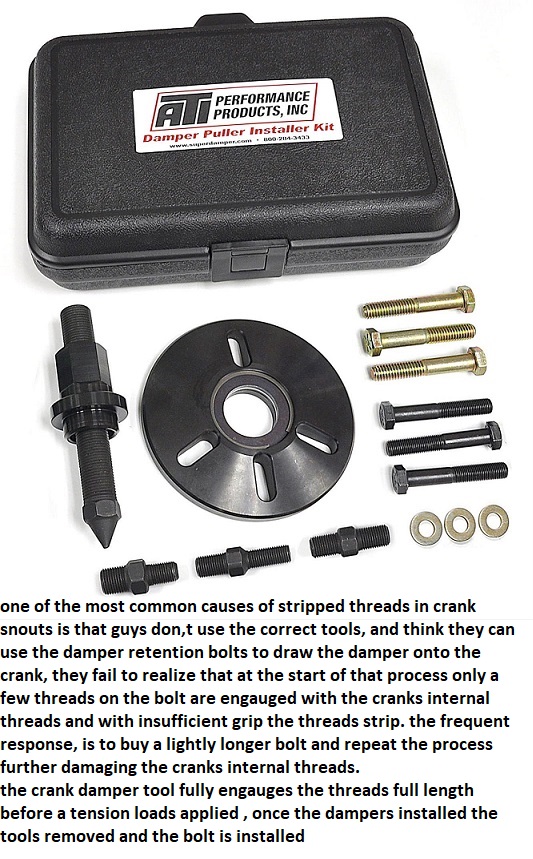

21. Dampener Puller

Matco Tools

$99.99

PN MST6501

In order to remove the timing cover (special covers excluded), the harmonic dampener must come off first. Due to the press-fit design, it can only be removed using a specifically designed pulling tool. This Matco Tools harmonic dampening puller kit allows the removal of just about any dampener imaginable. Course threads, fine threads, and thick and thin dampeners will all come off with a breeze. Even though the kit is designed to remove dampeners, it will also pull a few other pressed-on items as well. For a complete professional kit for less than a $100, this Matco item is top-notch piece.

http://www.summitracing.com/parts/pro-66514

or

http://www.summitracing.com/parts/shc-947626

http://www.harborfreight.com/2000-lb-fo ... 67015.html

http://www.northerntool.com/shop/tools/ ... _200442439

yes I find it amazing that theres guys in this hobby without snap gauges and dial indicator calipers, so many problems are avoided by actually knowing the accurate measurements

http://www.harborfreight.com/6-inch-dia ... 66541.html

GrumpyThe Grumpy Grease MonkeyStaff Member

http://www.homedepot.com/p/Powerbuilt-23-Piece-Ball-Joint-U-Joint-Service-Kit-648617/203120548?cm_mmc=Shopping|THD|G|0|G-BASE-PLA-D25T-Garage-Automotive|&gclid=CM7-rI-e-tQCFUa4wAodcnEHfg&gclsrc=aw.ds

http://www.harborfreight.com/36-piece-3 ... 60669.html

harbor freight has cheap and perfectly acceptable calipers

http://www.harborfreight.com/6-in-dial-caliper-62362.html

http://www.harborfreight.com/1-inch-travel-machinists-dial-indicator-623.html

https://www.summitracing.com/parts/ATI-918999/?image=large

https://www.summitracing.com/parts/arp-100-9942/overview/

one factor I find rather annoying is that every time I price out tools, I purchased years ago , or need to replace worn out tools,

, the price has increased a great deal, Ive purchased dozens of tools over the decades,

and yeah, occasionally lent those out and its seems like a great many never get returned or get returned with broken or missing parts.

yeah I'm well aware of inflation, but its still a bit of a shock when a tool you purchased a decade ago now lists for 2-3 times what you originally paid.

a few tool related threads with sub links

http://garage.grumpysperformance.com/index.php?threads/what-hand-tools-to-buy.4069/#post-10827

http://garage.grumpysperformance.com/index.php?threads/what-tools-are-important.39/#post-47

http://garage.grumpysperformance.com/index.php?threads/precision-measuring-tools.1390/#post-52469

http://garage.grumpysperformance.com/index.php?threads/finding-a-machine-shop.321/#post-55314

http://garage.grumpysperformance.com/index.php?threads/bare-minimum-tools.11026/#post-51823

http://garage.grumpysperformance.com/index.php?threads/cam-degreeing.9010/#post-35474

http://garage.grumpysperformance.co...all-tools-install-info.1479/page-2#post-35245

http://garage.grumpysperformance.co...et-it-to-last-cam-install-info.90/#post-57942

http://garage.grumpysperformance.com/index.php?threads/porting-can-help.462/

21 Engine-Building Tools for Under $100

From the February, 2009 issue of Chevy High Performance

By Scott Crouse

Photography by Scott Crouse

http://www.chevyhiperformance.com/techa ... ewall.html

|

|http://www.wizardswarehouse.com/products/tools

http://garage.grumpysperformance.com/index.php?threads/starter-tool-set.6032/

148 0505 Tools 22 Z

Torque it, stretch it, compress it--these are just a few of the exercises that engine builders encounter when assembling a high-performance engine. The process of building a bullet requires the skills to set up internal engine clearances and demands a legion of tools that can be costly to average enthusiasts. While engine building and the skilled steps involved are a story of their own, this month's chronicle takes a look at some of the tools needed to assemble a Chevrolet powerplant. Every month, CHP delivers attainable and affordable stout engine combinations, but that pile of parts is only as good as the person assembling them. In order to construct a home-built bullet on a budget, we chose 21 reasonably priced items for less than $100. If high-performance garage tinkering gets your heart pumping, then make room in the toolbox. This year's wish list could be a long one.

148 0505 Tools 01 Z

1. Deck Bridge

Powerhouse Products

$19

PN POW101310

The internal timing of the crankshaft, camshaft, and piston location all play vital roles in determining the characteristics of the engine's power curve. In order to put each of these parts into the proper timing sequence, the number 1 piston must be measured at its top dead center (TDC) point with a dial indicator that is connected to a deck bridge. The piston location allows the engine builder to determine when the engine's firing sequence will occur. In order to use the dial indicator/deck bridge tool correctly, the dial indicator reading tip must be placed on the center of the piston to experience as little piston rock as possible. While turning the engine over by hand, the dial indicator will reveal the piston's TDC point, which will allow the builder to set the internal timing of the engine by installing the timing chain at a desired location.

148 0505 Tools 02 Z

2. Magnetic Base Dial Indicator

Powerhouse Products

$39.95 (magnetic base stand)

$29.95 (dial indicator only)

PN POW151140; PN POW151100

Accurately measuring lifter rise, piston movement, or any other oscillating part can be tough without the help of a dial indicator. Powerhouse Products offers a dial indicator by itself, as well as a magnetic base designed to hold the indicator in innumerable positions. Whether it's degreeing internal timing, lining up bellhousings, or simply checking rocker roll, a magnetic-base dial indicator is a must-have tool when it comes to engine assembly.

148 0505 Tools 03 Z

3. Crankshaft Turning Socket

Powerhouse Products

$14.95 SBC

$29.95 BBC

PN POW102050; PN POW103055

Whether it's connecting the rods to the crankshaft or adjusting the valves, a rotating assembly is constantly being turned over. Using the balancer bolt to turn over a rotating assembly will eventually become a problem, which is why Powerhouse Products offers its crankshaft turning socket. The small-block piece is cast aluminum and works well with a 2- to 3-inch extension; the big-block Pro crankshaft turning socket is constructed of hardened steel in order to turn over the biggest engines. When engine maintenance and assembly lay ahead, a crankshaft turning socket is the only way to go. TIP: When turning an engine over by hand, it's easier to do so once the spark plugs have been removed. This allows compressed air to escape from each cylinder and drastically reduce rotating resistance.

148 0505 Tools 04 Z

4. Dial Bore Gauge

Powerhouse Products

$99.99

PN POW205025

One of the most critical engine-building tools, the dial bore gauge is specifically designed to measure the inside diameter of an orifice whether it be a connecting rod journal, a crankshaft main journal, or a cylinder wall. Regardless, the engine-building process requires that there be enough space between moving parts for a thin film of oil to coat them. The thickness of this thin film is determined by measuring the orifice diameter and the actual rotating part diameter (with a micrometer) to ascertain a tolerance between the two objects. The kit displayed here is capable of measuring bore size diameters from 2 to 6 inches in 0.0005-inch increments.

148 0505 Tools 05 Z

5. Tap and Die Set

Powerhouse Products

$9.95 (die set)

$9.95 (tap set, course thread)

PN POW351685; PN POW351675

Misaligned bolt threads damage parts and waste time, which is why an inexpensive rethreading die-set kit should be in every tool box. This kit is capable of cleaning up bolt-thread sizes of 1/4, 5/16, 3/8, 7/16, and 1/2 inches. A thread-restoring tap set for galled-up bolt holes makes a good companion to a rethreading set. It cleans up the same-size holes as the rethreading die set, plus it has an additional 9/16-inch tap-restoring tool as well. This stuff is cheap insurance, folks.

148 0505 Tools 06 Z

6. Valve Checking Spring Kit

Powerhouse Products

$7.60

PN POW101325

Horsepower is directly correlated to engine airflow, which is why flow testing the cylinder heads is so important. In order to do the flow test, the valves must be held open at either 0.05- or 0.1-inch increments, and this requires low-tension valve checking springs that allow the valves to be opened slowly while cylinder-head airflow is measured. They assume the position of the actual engine valvesprings and are designed to work with most domestic lock and retainer hardware.

148 0505 Tools 07 Z

7. Pushrod Length Checking Tool

Powerhouse Products

$59 (complete set)

PN POW101240

Pushrod length-checking tools are another critical part used in an engine-assembly process. Pushrod length must be rechecked whenever an engine's factory specifications are altered in any way. A too short or too long of a pushrod will cause the rocker tips to roll over the edge of the valve stems and eventually wear the valve stem out. Powerhouse pushrod length-checking tools can be ordered in 1-inch increments under a specific part number or as an entire kit for the enthusiast who plans on building a variety of short- and tall-deck engines.

148 0505 Tools 08 Z

8. Sportsman Head CC Kit

Powerhouse Products

$29

PN POW351155

Computing the compression ratio is valuable because it helps determine the required octane rating an engine will use. While piston design, deck height, and head-gasket thickness all play a part in this equation, the cylinder-head combustion chamber size is what completes the formula. Aftermarket heads can often be misleading by a cc or two, as can porting, or what you find in a salvage yard, so it's a good idea to make sure that the stated combustion chamber size is exactly that.

148 0505 Tools 09 Z

9. Stud Removal Tool

Powerhouse Products

$22.95

PN POW351590

Head studs, main studs, carburetor studs, or any other stud can be problematic when it's time to remove them. Because this can be difficult, Powerhouse offers this tool designed to remove threaded studs or install the same from 1/4 to 3/4 inches. All that's required is a 1/2-inch drive ratchet.

148 0505 Tools 10 Z

10. Valve Lash Tool

Proform Products

$19.95

PN 66780

Correct camshaft lash and valvetrain movement ensure that the intake and exhaust valves open and close properly. Hydraulic tappet designs require the lifters to be set with zero lash before the engine is broken in; solid lifters require routine maintenance. In order to lash the valves, the rocker lock nuts must be loosened. Once the engine is turned over and the proper amount of lash is achieved, an internal lash nut must be tightened onto the rocker stud to keep the rocker nut tight during operation. Because valve adjustment requires three hands, Proform offers a two-in-one tool that allows the rocker nut to be held steady while the internal lash nut is set.

148 0505 Tools 11 Z

11. Stud Mount Valvespring Compressor Tool

Proform Products

$49.95

PN 66784

Valve control is an essential part of engine assembly and development. A proper amount of tension is required in order to keep the valves under control at high rpm. Over time, all valve springs lose their tension, which is why they sometimes float near the engine-redline rpm. In order to check valvespring tension on a regular basis, Proform offers its in-car stud mount valvespring compressor tool that allows the builder to attach the spring compressor to the rocker stud before its forks, slid around the valve retainer, and then compressed to free the valve locks. Once the locks are removed the retainer and valvespring will pop off the cylinder head. The valve springs will then need to be tested on a more costly tool. An engine shop should be equipped to take care of measuring actual valvespring tension. TIP: Unless you'd enjoy removing a cylinder head as well, don't forget to either fill the cylinder with air pressure or place the piston at its TDC position so the valve doesn't drop into the cylinder.

148 0505 Tools 12 Z

12. Cam Bearing Installation Tool

Proform Products

$69.95

PN 66794

Every engine builder should own one of these. While this tool is only used for a single assembly process, it's essential if the user is going to build more than one engine. Progressing from the front of the engine to the distributor, each camshaft-bearing orifice diameter is slightly larger than the previous one, which allows several bearings to be paced on one parallel axis inside the cylinder block. A special tool with specific sliders must be used to install each of the bearings. Each slider matches up to the individual bearing size and allows the engine builder to gently knock the camshaft bearings into place. This cam-bearing installation tool is a great choice for the garage enthusiast who plans on building a few engines a year and doesn't want to wait for the machine shop.

148 0505 Tools 13 Z

13. Rod Bolt Stretch Gauge

Proform Products

$59.95

PN 66788

When a bolt is tightened, its threads are pulled against the receiving threads to create a fastening effect as the material stretches a minute amount. Bolt torque is a measurement of thread resistance, while bolt stretch is the actual amount of the bolt clamping. In order to properly fasten a bolt, you can't strictly rely on a torque reading. If possible, each rod bolt should be stretched to the manufacturer's tolerance regardless of the torque rating. By torqueing each bolt, the engine builder may gain peace of mind knowing that the rod bolts will not loosen during operation. Proform Products offers this handheld rod bolt stretch gauge that uses a dial indicator to determine before and after (stretched) readings.

148 0505 Tools 14 Z

14. Rod Vise

Proform Products

$79.95

PN 66769

Engine building requires the measuring of bearing clearances, which means the connecting rod caps must be removed and torqued into place several times before the engine reaches final assembly. This connecting rod vise allows the engine builder to support the rod safely by making sure the rod does not experience torsional twist as the cap bolts are tightened or loosened.

148 0505 Tools 15 Z

15. Rod Splitting Fixture

Proform Products

$100.99

PN 66773

As mentioned in the previous rod vise section, removing connecting rod caps can be quite difficult. Instead of pulling and twisting something out of shape, it's a good idea to invest in a rod-splitting fixture. This simple tool places its expanding jaws inside the rod's big end before a leveraged arm expands its jaws. Once expanded, the cap is separated from the rod main body without any harm. Using the right tools for the job not only makes things easier, it can keep from damaging valuable engine parts as well.

148 0505 Tools 16 Z

16. Valve Height Micrometer

Proform Products

$49.95

PN 66902

Camshaft lobe lift, rocker arm ratio, and valvespring setup must all work together in order to make sure there is enough clearance for each of these valvetrain parts to operate properly. As the lift of the valve increases, valvespring height decreases, which makes it very important that the distance from the valvespring retainer to the cylinder head spring seat is predetermined before the engine runs. A valve height micrometer measures the total valvespring retainer travel before the engine is even turned over. Collapsed seals, binding springs, and worn metal pieces are all problems you can avoid ahead of time with a height micrometer.

148 0505 Tools 17 Z

17. Valvespring Compressor

Proform Products

$92.95

PN 66832

If you'll be doing cylinder head work in the garage, a heavy-duty Proform valvespring compressor is a must. Once the cylinder heads are off the engine, this tool is extremely useful in the removal of valves, locks, retainers, and springs. Its hand-operated design and the extendable arm allow it to be used on a variety of cylinder head designs. As long as the collapsed valvespring tension does not peak beyond the user's ability to compress the valvespring by hand, this tool will work well for the average garage enthusiast.

148 0505 Tools 18 Z

18. Leak Down Gauge

Proform Products

$69.99

PN 66839

Cylinder pressure can be lost due to improper ring seating, broken rings, worn valve seats/guides, a burned piston, or a blown head gasket. All of these problems snuff power and in some cases they will lower engine vacuum. In order to diagnose them, you must perform a cylinder leak-down test. Proform offers its dual leak-down cylinder pressure tester that requires an adapter fitting in a spark-plug hole. Once compressed air fills a cylinder, the gauge is calibrated to a manufacturer's pre-set position before providing the percentage of leakage. While Proform recommends using its pre-calibrated set position as the starting point, the industry leak-down incoming air standard usually allows 80 psi in the cylinder before the test is preformed.

148 0505 Tools 19 Z

19. Cranking Compression Gauge

Craftsman

$49.95

PN 47089

In order to make considerable horsepower, four major ingredients are required: air, fuel, spark, and compression. While the first three variables can be diagnosed as external factors, the process of compression is mainly an internal function. This requires a cranking compression tester that uses an adapter fitting threaded into a spark-plug hole that connects the gauge to the cylinder. Once connected to the cylinder, the engine is turned over using the starter motor. After a few crankshaft revolutions, the gauge will display the amount of compression inside the cylinder. Street and strip engines running a 9:1 compression ratio and a healthy but streetable camshaft sporting less than 235 degrees of duration at 0.05 inches should read somewhere between 165 psi and 200 psi, depending on the application.

148 0505 Tools 20 Z

20. Torque Wrench 1/2-inch Drive

Craftsman

$69.99

PN 44595

All bolts require a recommended torque specification (a measurement of resistance) that should be considered when fastening threads (see "Rod Bolt Stretch Gauge" in this section). Some bolts cannot be accessed from the bottom side to measure stretch, which leaves the engine builder with only one option. Our Craftsman torque wrench is designed to fasten bolt threads to a predetermined torsional load. When using a torque wrench, be sure to lubricate the bolt threads and face to ensure as little resistance as possible. TIP: After using this tool, remove all tension from the internal torque regulating spring by placing the torque setting at zero. This will ensure that the torque wrench reads accurately the next time it is used.

148 0505 Tools 21 Z

21. Dampener Puller

Matco Tools

$99.99

PN MST6501

In order to remove the timing cover (special covers excluded), the harmonic dampener must come off first. Due to the press-fit design, it can only be removed using a specifically designed pulling tool. This Matco Tools harmonic dampening puller kit allows the removal of just about any dampener imaginable. Course threads, fine threads, and thick and thin dampeners will all come off with a breeze. Even though the kit is designed to remove dampeners, it will also pull a few other pressed-on items as well. For a complete professional kit for less than a $100, this Matco item is top-notch piece.

http://www.summitracing.com/parts/pro-66514

or

http://www.summitracing.com/parts/shc-947626

http://www.harborfreight.com/2000-lb-fo ... 67015.html

http://www.northerntool.com/shop/tools/ ... _200442439

yes I find it amazing that theres guys in this hobby without snap gauges and dial indicator calipers, so many problems are avoided by actually knowing the accurate measurements

http://www.harborfreight.com/6-inch-dia ... 66541.html

GrumpyThe Grumpy Grease MonkeyStaff Member

http://www.homedepot.com/p/Powerbuilt-23-Piece-Ball-Joint-U-Joint-Service-Kit-648617/203120548?cm_mmc=Shopping|THD|G|0|G-BASE-PLA-D25T-Garage-Automotive|&gclid=CM7-rI-e-tQCFUa4wAodcnEHfg&gclsrc=aw.ds

http://www.harborfreight.com/36-piece-3 ... 60669.html

harbor freight has cheap and perfectly acceptable calipers

http://www.harborfreight.com/6-in-dial-caliper-62362.html

http://www.harborfreight.com/1-inch-travel-machinists-dial-indicator-623.html

https://www.summitracing.com/parts/ATI-918999/?image=large

https://www.summitracing.com/parts/arp-100-9942/overview/

one factor I find rather annoying is that every time I price out tools, I purchased years ago , or need to replace worn out tools,

, the price has increased a great deal, Ive purchased dozens of tools over the decades,

and yeah, occasionally lent those out and its seems like a great many never get returned or get returned with broken or missing parts.

yeah I'm well aware of inflation, but its still a bit of a shock when a tool you purchased a decade ago now lists for 2-3 times what you originally paid.

a few tool related threads with sub links

http://garage.grumpysperformance.com/index.php?threads/what-hand-tools-to-buy.4069/#post-10827

http://garage.grumpysperformance.com/index.php?threads/what-tools-are-important.39/#post-47

http://garage.grumpysperformance.com/index.php?threads/precision-measuring-tools.1390/#post-52469

http://garage.grumpysperformance.com/index.php?threads/finding-a-machine-shop.321/#post-55314

http://garage.grumpysperformance.com/index.php?threads/bare-minimum-tools.11026/#post-51823

http://garage.grumpysperformance.com/index.php?threads/cam-degreeing.9010/#post-35474

http://garage.grumpysperformance.co...all-tools-install-info.1479/page-2#post-35245

http://garage.grumpysperformance.co...et-it-to-last-cam-install-info.90/#post-57942

http://garage.grumpysperformance.com/index.php?threads/porting-can-help.462/

Last edited by a moderator: