Here are some of the more common things I've seen with the 1984 CrossFire system.

if your 100% set on use of a stock x-fire

http://www.turbocity.com/product_info.p ... ucts_id=20

theres parts available

http://www.technovelocity.com/chevyhack ... olish.html

read this also

viewtopic.php?f=32&t=1148

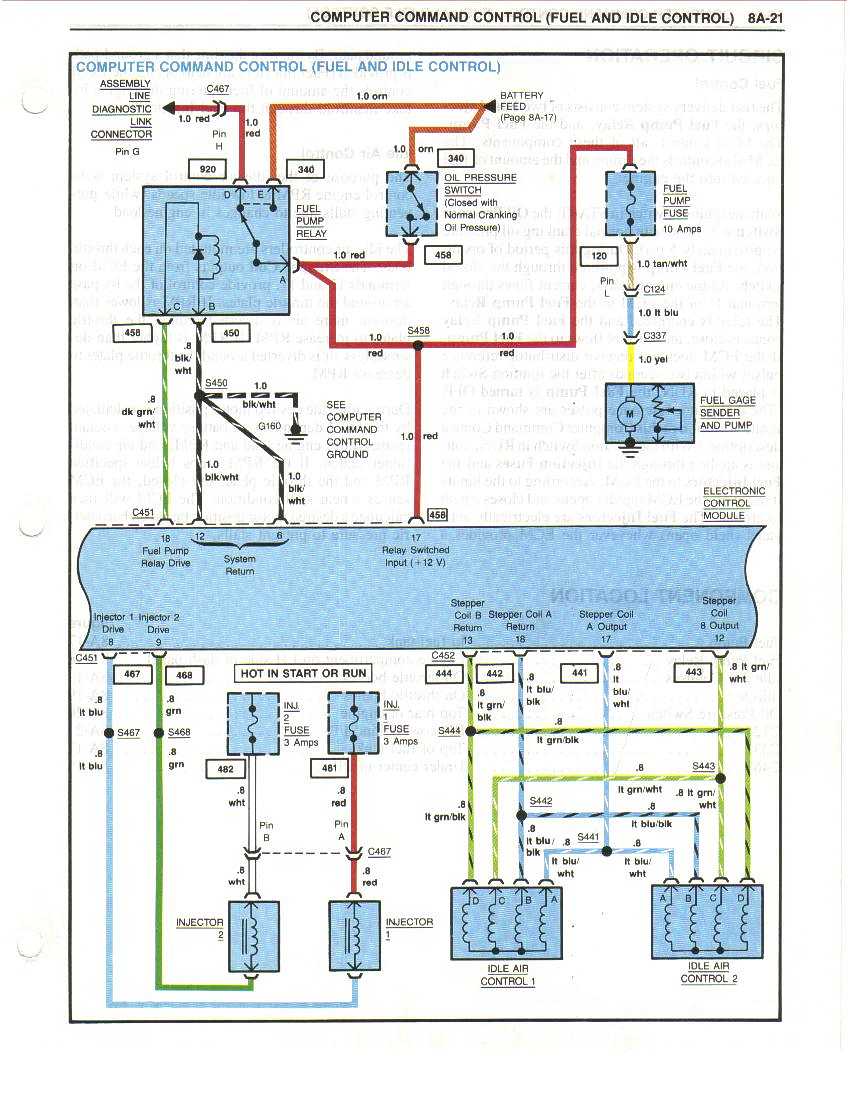

check out the flow chart

http://members.shaw.ca/corvette86/Fu...mDiagnosis.pdf

good info source

http://search.ebscohost.com/

code is library/library then put in the brand/year and model

http://www.thecubestudio.com/CrossfireT ... sIndex.htm

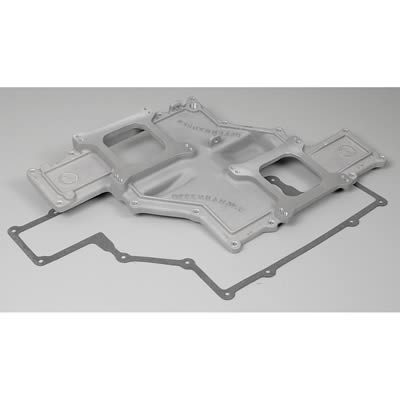

theres a new intake thats supposed to be available soon, heres

info

viewtopic.php?f=32&t=640

http://garage.grumpysperformance.com/index.php?threads/refresh-1982-crossfire-vette.14173/

http://garage.grumpysperformance.co...egade-intake-for-cross-fires.2796/#post-55208

http://garage.grumpysperformance.com/index.php?threads/got-a-cross-fire-corvette.640/

heres more good info

* Coolant Sensor is faulty - the gauge gives a false sense that it's doing okay, but the sensor that the ECM reads is totally separate from the one the gauge reads! Pinging on acceleration during warmer runs are noticed. If in doubt, just replace the thing. The one the ECM reads is in the FRONT of the manifold - has two wires (black and yellow) going to it.

* Throttle Position Sensor is faulty; can give strange results. Bad idle, great high-RPM power. Always good idea to check this thing out. Uses a +5v reference to send voltage to the ECM. Neat trick: setup the output (center wire) to where it switches to full +5v with the flip of a switch. Makes the ECM think you're at full-throttle when you're not. (Good for acceleration with an automatic tranny, which is all the crossfires ever came with that I know of.)

* MAP sensor - this thing reads in the amount of manifold vacuum and sends out a voltage to the ECM. If it's not getting the correct voltage, you can get pinging real bad on acceleration at any temperature. Pull the wires off. If the idle improves, you have a faulty one. Replace it.

* Bad O-rings or filters on injectors. Turn the key, but don't start the motor. Have the aircleaner assembly off and observe the injectors. If they leak, replace the o-rings and injector filters. If they still leak, replace the injectors!

* Bad O2 sensor. Runs rich sometimes. Won't pass emissions for sure! Is suggested to replace every 30k miles or so. They cost around $25 and are a snap to replace. Not a bad idea to replace if you're going to get under the car in the first place. You can run a wire inside your car and read the voltage with a DMM to see what your air/fuel ratio is.

* Spark Plugs fouling.. often this is due to bad valve seals. One of my tricks is to uncover the plug electrode by "side gapping" the plugs.

* Knock Sensor.. I think this is my problem right now. The "Computer Codes" book said it causes light pinging during acceleration on light loads.

ok the first step once you buy a corvette is ALWAYS buy the matching shop manual,and get a v.o.m. meter and use the shop manual, it will have detailed wiring diagrams and flow charts, and use the search feature on the site

as an example lets assume you buy a 1984 corvette

http://www.helminc.com/helm/Result.asp? ... LAKTTP9VS4

very good

http://www.haynes.com/products/productID/264

fair

http://performanceunlimited.com/documents/plugsidegapping.html

read these threads

viewtopic.php?f=50&t=609&p=3174#p3174

viewtopic.php?f=36&t=2619

viewtopic.php?f=70&t=2700

viewtopic.php?f=3&t=325&p=397&hilit=+meter#p397

viewtopic.php?f=44&t=469&p=7163&hilit=meter#p7163

viewtopic.php?f=62&t=987&p=2395&hilit=+meter#p2395

viewtopic.php?f=50&t=785&p=1337&hilit=+meter#p1337

viewtopic.php?f=32&t=2697

viewtopic.php?f=32&t=1773

viewtopic.php?f=32&t=596

if your 100% set on use of a stock x-fire

http://www.turbocity.com/product_info.p ... ucts_id=20

theres parts available

http://www.technovelocity.com/chevyhack ... olish.html

read this also

viewtopic.php?f=32&t=1148

check out the flow chart

http://members.shaw.ca/corvette86/Fu...mDiagnosis.pdf

good info source

http://search.ebscohost.com/

code is library/library then put in the brand/year and model

http://www.thecubestudio.com/CrossfireT ... sIndex.htm

theres a new intake thats supposed to be available soon, heres

info

viewtopic.php?f=32&t=640

http://garage.grumpysperformance.com/index.php?threads/refresh-1982-crossfire-vette.14173/

http://garage.grumpysperformance.co...egade-intake-for-cross-fires.2796/#post-55208

http://garage.grumpysperformance.com/index.php?threads/got-a-cross-fire-corvette.640/

heres more good info

* Coolant Sensor is faulty - the gauge gives a false sense that it's doing okay, but the sensor that the ECM reads is totally separate from the one the gauge reads! Pinging on acceleration during warmer runs are noticed. If in doubt, just replace the thing. The one the ECM reads is in the FRONT of the manifold - has two wires (black and yellow) going to it.

* Throttle Position Sensor is faulty; can give strange results. Bad idle, great high-RPM power. Always good idea to check this thing out. Uses a +5v reference to send voltage to the ECM. Neat trick: setup the output (center wire) to where it switches to full +5v with the flip of a switch. Makes the ECM think you're at full-throttle when you're not. (Good for acceleration with an automatic tranny, which is all the crossfires ever came with that I know of.)

* MAP sensor - this thing reads in the amount of manifold vacuum and sends out a voltage to the ECM. If it's not getting the correct voltage, you can get pinging real bad on acceleration at any temperature. Pull the wires off. If the idle improves, you have a faulty one. Replace it.

* Bad O-rings or filters on injectors. Turn the key, but don't start the motor. Have the aircleaner assembly off and observe the injectors. If they leak, replace the o-rings and injector filters. If they still leak, replace the injectors!

* Bad O2 sensor. Runs rich sometimes. Won't pass emissions for sure! Is suggested to replace every 30k miles or so. They cost around $25 and are a snap to replace. Not a bad idea to replace if you're going to get under the car in the first place. You can run a wire inside your car and read the voltage with a DMM to see what your air/fuel ratio is.

* Spark Plugs fouling.. often this is due to bad valve seals. One of my tricks is to uncover the plug electrode by "side gapping" the plugs.

* Knock Sensor.. I think this is my problem right now. The "Computer Codes" book said it causes light pinging during acceleration on light loads.

ok the first step once you buy a corvette is ALWAYS buy the matching shop manual,and get a v.o.m. meter and use the shop manual, it will have detailed wiring diagrams and flow charts, and use the search feature on the site

as an example lets assume you buy a 1984 corvette

http://www.helminc.com/helm/Result.asp? ... LAKTTP9VS4

very good

http://www.haynes.com/products/productID/264

fair

http://performanceunlimited.com/documents/plugsidegapping.html

read these threads

viewtopic.php?f=50&t=609&p=3174#p3174

viewtopic.php?f=36&t=2619

viewtopic.php?f=70&t=2700

viewtopic.php?f=3&t=325&p=397&hilit=+meter#p397

viewtopic.php?f=44&t=469&p=7163&hilit=meter#p7163

viewtopic.php?f=62&t=987&p=2395&hilit=+meter#p2395

viewtopic.php?f=50&t=785&p=1337&hilit=+meter#p1337

viewtopic.php?f=32&t=2697

viewtopic.php?f=32&t=1773

viewtopic.php?f=32&t=596

Last edited by a moderator: