one of my ELK hunting buddys calls me about a 383 he has that he just refreshed with new rings, bearings, and a valve job, it seems his old 383 had lost a noticeable bit of its previous power curve due to having about 60k miles and having lost a cam lobe, so knowing he would need to pull the engine and clean the blocks oil passages anyway , he ordered rings and bearings and gaskets, a new cam and lifters and put the heads into a know dependable local machine shop to have the heads rebuild before pulling the short block, he pulls the short block, disassemble,s the short block, used a high pressure spray gun to clean out the gunk and oil passages, did a quick break the glaze cylinder hone on the bores , so the new rings would seat , replaced the cam bearings and freeze plugs but never measured anything assuming that because he felt no bore wear ridge that the bore had stayed at .030 over size.

he had ordered new rings .030 over size and had cleaned the pistons, and gaped the rings and used plasti-gauge to verify bearing clearances.

he assembled the engine, fired it up and broke in the cam, and the engine smoked a bit, he assumed the rings just were a bit slow seating but the problem got slowly worse not better, at first he was convinced the guys that did the cylinder head rebuild had screwed up and the valve guides were clearanced wrong but there was zero indication of oil on the back of the valves looking into the ports with the intake off and once the heads were removed to inspect them the clearances on the valve guides proved to be within specs, it turned out that it was an installation error, thats fairly common with first time engine builders, 5 of his 8 pistons had one or more of the two top compression rings installed with the dot on the ring facing down toward the crank.

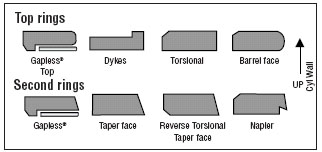

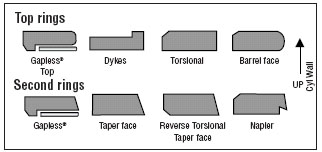

rings are designed so that cylinder pressure gets in behind the ring and forces it out into the cylinder wall, but if you install the rings upside down that doesn,t function correctly, rings normally have a dot on the upper surface to indicate that side faces up, but that's not universal so you need to look at rings carefully and ask questions if you have and doubts before installing the rings.

http://www.federalmogul.com/korihandboo ... ion_18.htm

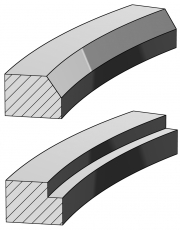

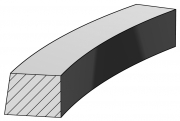

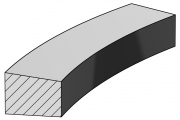

Rectangular Ring:

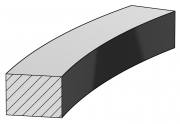

A piston ring with a rectangular cross section. This ring with its geometrically simple shape performs the necessary sealing functions under normal operating conditions. With a peripheral coating and appropriate barrel face the rectangular ring is today used mainly in the top groove in passenger car gasoline and diesel engines. Besides service in internal combustion engines, rectangular rings are commonly used as rotary shaft seals, e.g. transmission seals [1].

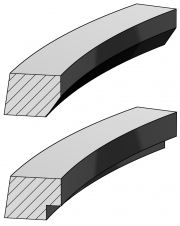

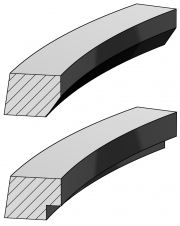

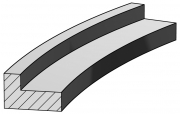

Taper Faced Ring:

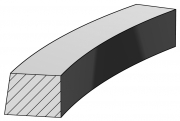

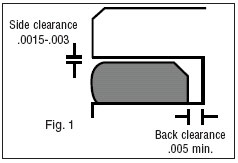

Owing to the tapered running face the ring contacts the cylinder bore with its bottom outer edge. This shortens running-in and improves oil scraping. The gas forces acting initially at the running face provide a degree of pressure relief (especially when used in the top groove). Taper faced rings are chiefly installed in the second groove in passenger car gasoline and passenger car and truck diesel engines. In passenger car gasoline engines they are also used in the top groove.

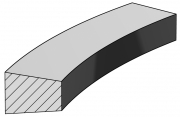

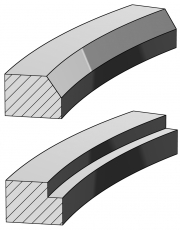

Internally Bevelled or Stepped Ring:

By providing an edge relief on the top side of rectangular and taper faced rings a twist effect is achieved which, in all operating phases without gas pressure loading, brings the ring into bore contact only with its bottom outer edge while the inner edge contacts the bottom groove side (positive twist). This helps to improve oil consumption control. Under operating conditions the gas pressure forces the ring flat against the piston groove, creating an additional dynamic behaviour of the ring. Rings of this kind are used in the top and second groove of passenger car gasoline and passenger car and truck diesel engines.

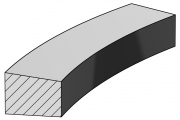

Taper Faced Ring with Inside Bottom Bevel or Step:

In the installed condition this edge relief causes a negative twist, i.e. in the opposite direction to a ring with the relief on the top side. The taper must be larger than on a taper faced ring without twist or with positive twist so that the top outer edge is prevented from contacting the cylinder wall.

The effect of the negative twist is to make the ring contact the groove and create a seal with its outer bottom side and its inner top side [8]. This type of ring is installed in the second groove in passenger car gasoline and passenger car and truck diesel engines.

Keystone Ring:

A compression ring with a wedge cross section. With its tapered sides, radial movement of the ring in engine operation will cause the axial clearance in the groove to increase and decrease. This greatly reduces ring sticking, as the ring continuously works its way free of the combustion residues. These rings are designed with an overall side angle of 6° bzw. 15°, the larger angle being more effective against the tendency to coking. The keystone ring is used in the top groove in passenger car and truck diesel engines where ring sticking must be expected.

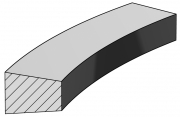

Half Keystone Ring:

A compression ring with only the top side tapered. Like on the keystone ring, the tapered side (keystone angle 7°) causes the axial clearance to vary as the ring moves radially, and thus reduces ring sticking. Owing to its asymmetrical cross section the ring has a positive twist when installed.

A half keystone ring is used in the top groove of passenger car and truck diesel engines when a rectangular ring is no longer adequate in regard to ring sticking but a keystone ring is not yet warranted. Another application is in 2-stroke gasoline engines, e.g. for snowmobiles and ultralight aircraft.

L-Shaped Compression Ring:

This ring is used mainly in small 2-stroke gasoline engines as a "head land" ring, the vertical arm of the L being flush with the top edge of the piston crown [9]. With gas pressure acting behind the vertical arm, this ring will also seal when in contact with the top side of the piston groove.

Besides being used in 2-stroke engines, in some cases it has been installed in automotive diesel engines in order to minimize crevice volume in the combustion chamber [10].

READING THIS related info, AND SUB LINKED INFO IN THOSE LINKS WILL SAVE YOU A GREAT DEAL OF TIME AND MONEY

viewtopic.php?f=53&t=2726

viewtopic.php?f=53&t=247

viewtopic.php?f=44&t=5886&p=17973#p17973

viewtopic.php?f=53&t=852

viewtopic.php?f=53&t=509

viewtopic.php?f=53&t=3449

viewtopic.php?f=53&t=1797

viewtopic.php?f=51&t=1479

viewtopic.php?f=51&t=2919

viewtopic.php?f=53&t=4294

he had ordered new rings .030 over size and had cleaned the pistons, and gaped the rings and used plasti-gauge to verify bearing clearances.

he assembled the engine, fired it up and broke in the cam, and the engine smoked a bit, he assumed the rings just were a bit slow seating but the problem got slowly worse not better, at first he was convinced the guys that did the cylinder head rebuild had screwed up and the valve guides were clearanced wrong but there was zero indication of oil on the back of the valves looking into the ports with the intake off and once the heads were removed to inspect them the clearances on the valve guides proved to be within specs, it turned out that it was an installation error, thats fairly common with first time engine builders, 5 of his 8 pistons had one or more of the two top compression rings installed with the dot on the ring facing down toward the crank.

rings are designed so that cylinder pressure gets in behind the ring and forces it out into the cylinder wall, but if you install the rings upside down that doesn,t function correctly, rings normally have a dot on the upper surface to indicate that side faces up, but that's not universal so you need to look at rings carefully and ask questions if you have and doubts before installing the rings.

http://www.federalmogul.com/korihandboo ... ion_18.htm

Rectangular Ring:

A piston ring with a rectangular cross section. This ring with its geometrically simple shape performs the necessary sealing functions under normal operating conditions. With a peripheral coating and appropriate barrel face the rectangular ring is today used mainly in the top groove in passenger car gasoline and diesel engines. Besides service in internal combustion engines, rectangular rings are commonly used as rotary shaft seals, e.g. transmission seals [1].

Taper Faced Ring:

Owing to the tapered running face the ring contacts the cylinder bore with its bottom outer edge. This shortens running-in and improves oil scraping. The gas forces acting initially at the running face provide a degree of pressure relief (especially when used in the top groove). Taper faced rings are chiefly installed in the second groove in passenger car gasoline and passenger car and truck diesel engines. In passenger car gasoline engines they are also used in the top groove.

Internally Bevelled or Stepped Ring:

By providing an edge relief on the top side of rectangular and taper faced rings a twist effect is achieved which, in all operating phases without gas pressure loading, brings the ring into bore contact only with its bottom outer edge while the inner edge contacts the bottom groove side (positive twist). This helps to improve oil consumption control. Under operating conditions the gas pressure forces the ring flat against the piston groove, creating an additional dynamic behaviour of the ring. Rings of this kind are used in the top and second groove of passenger car gasoline and passenger car and truck diesel engines.

Taper Faced Ring with Inside Bottom Bevel or Step:

In the installed condition this edge relief causes a negative twist, i.e. in the opposite direction to a ring with the relief on the top side. The taper must be larger than on a taper faced ring without twist or with positive twist so that the top outer edge is prevented from contacting the cylinder wall.

The effect of the negative twist is to make the ring contact the groove and create a seal with its outer bottom side and its inner top side [8]. This type of ring is installed in the second groove in passenger car gasoline and passenger car and truck diesel engines.

Keystone Ring:

A compression ring with a wedge cross section. With its tapered sides, radial movement of the ring in engine operation will cause the axial clearance in the groove to increase and decrease. This greatly reduces ring sticking, as the ring continuously works its way free of the combustion residues. These rings are designed with an overall side angle of 6° bzw. 15°, the larger angle being more effective against the tendency to coking. The keystone ring is used in the top groove in passenger car and truck diesel engines where ring sticking must be expected.

Half Keystone Ring:

A compression ring with only the top side tapered. Like on the keystone ring, the tapered side (keystone angle 7°) causes the axial clearance to vary as the ring moves radially, and thus reduces ring sticking. Owing to its asymmetrical cross section the ring has a positive twist when installed.

A half keystone ring is used in the top groove of passenger car and truck diesel engines when a rectangular ring is no longer adequate in regard to ring sticking but a keystone ring is not yet warranted. Another application is in 2-stroke gasoline engines, e.g. for snowmobiles and ultralight aircraft.

L-Shaped Compression Ring:

This ring is used mainly in small 2-stroke gasoline engines as a "head land" ring, the vertical arm of the L being flush with the top edge of the piston crown [9]. With gas pressure acting behind the vertical arm, this ring will also seal when in contact with the top side of the piston groove.

Besides being used in 2-stroke engines, in some cases it has been installed in automotive diesel engines in order to minimize crevice volume in the combustion chamber [10].

READING THIS related info, AND SUB LINKED INFO IN THOSE LINKS WILL SAVE YOU A GREAT DEAL OF TIME AND MONEY

viewtopic.php?f=53&t=2726

viewtopic.php?f=53&t=247

viewtopic.php?f=44&t=5886&p=17973#p17973

viewtopic.php?f=53&t=852

viewtopic.php?f=53&t=509

viewtopic.php?f=53&t=3449

viewtopic.php?f=53&t=1797

viewtopic.php?f=51&t=1479

viewtopic.php?f=51&t=2919

viewtopic.php?f=53&t=4294