http://store.summitracing.com/partdetai ... toview=sku

its basically a heavy duty can opener , or an oil filter cutter designed to make it easy to internally inspect oil filters, by allowing you to remove the filter element , from inside the surrounding (CAN) for close visual inspection.

If you don,t have one, and have not used one, your unlikely to see, or appreciate the benefits,close inspection can and does frequently give you prior evidence of impending or at least gradually occurring wear and with practice you can make an excellent guess as to the parts and condition of those components.

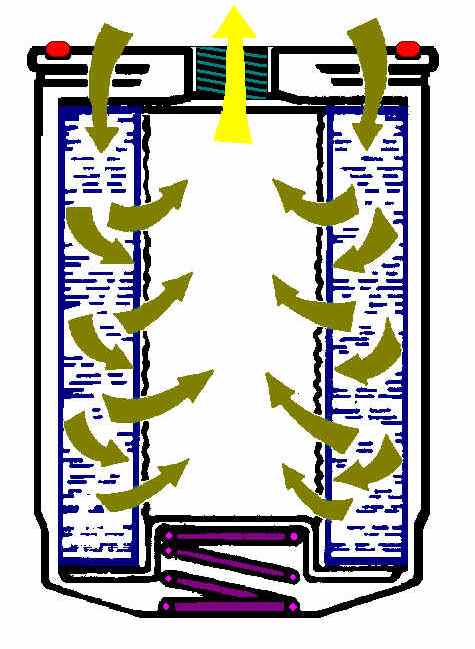

IT also helps to trap crud if you install a couple high temp magnets on the filter and in the oil pan.

Regular oil changes can drastically reduce the amount of sludge buildup in the oil.

Basic filter cutting & inspection procedures

you would be amazed at the sludge build up in some engines

· Visually check the filter and or filter canister for cracks and leaks.

· Inspect the filter`s bypass valve to ensure it is operating correctly.

· Drain the filter of its contents (dispose of this liquid in the correct manner in accordance with local environmental guidelines).

· Firmly hold the filter in an upright position (head on top) taking care not to crush or damage the housing.

· Using a specially designed filter cutting tool (for example, Komatsu part number 3310587S )

heres a helpful diagnostic tool,

carefully cut off the top of the filter.

· Remove the element from the filter housing and pour the contents of the housing onto some clean absorbent paper.

· Inspect the absorbent paper for traces of foreign particles.

· Inspect the filter medium for signs of damage and blockages. Blockages force the bypass valve into operation, allowing unfiltered fluid to travel to and enter major components.

· Remove the filter medium from the filter by cutting between 2030 mm (about one inch) from the end plate and cut the medium into small pieces.

· Carefully inspect the filter medium for traces of metal contaminants.

Most engine trouble involves the lube system, and cutting waste filters apart often reveals warning signs that will help avert major damage. As a disposable element of the system, the filter sometimes acts as a fuse, calling attention to problems by failing before engine components are damaged. Problems associated with wear in the combustion chamber inevitably show up in the oil, and the filter collects clues. Field maintenance operations that take time to read the signs will have another tool for anticipating failures and reducing repair costs.

http://www.machinerylubrication.com/Rea ... inspection

http://www.tomorrowstechnician.com/Arti ... lters.aspx

http://www.tomorrowstechnician.com/Arti ... lures.aspx

http://www.summitracing.com/parts/SUM-9 ... toview=sku

http://www.circletrack.com/techarticles ... index.html

related info

viewtopic.php?f=51&t=2919

viewtopic.php?f=44&t=799&p=1161&hilit=+filter+select#p1161

viewtopic.php?f=54&t=3834&p=10199&hilit=+filter+oil#p10199

viewtopic.php?f=54&t=117

viewtopic.php?f=54&t=3519&p=9289&hilit=+filter+oil#p9289

viewtopic.php?f=54&t=2080&p=5568&hilit=+filter+oil#p5568

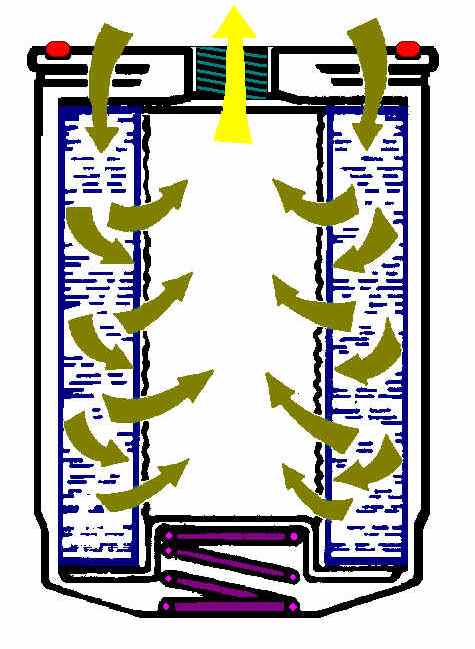

btw, add a few magnets to the oil pan and drain back area in your engine, the trap and hold metalic dust that comes from wear and increase engine life span by preventing that crap embedding in the bearings

http://www.kjmagnetics.com/proddetai...d=D66SH&cat=13

http://www.kjmagnetics.com/proddetail.asp?prod=D66SH

http://www.kjmagnetics.com/proddetail.asp?prod=D82SH

these are even more tollerant of temp swings and retain strength at even higher engine oil temps plus they are smaller and easier to use

The SH material in the D66SH magnets, means that the magnets can be heated to 300° F without any loss of magnetic strength, unlike standard neodymium magnets that begin to lose strength at 175° F. Suitable for many high temperature applications.

http://www.centuryperformance.com/tunin ... g-148.html

http://www.secondchancegarage.com/public/186.cfm

http://www.corvette-101.com/

(info on left border)

http://www.summitracing.com/search/?key ... kers&dds=1

there ARE reduced ratio roller rockers designed to significantly lower the lifter to lobe pressures during the cam break-in process, and its a whole lot easier to swap rockers during the break-in process than swap to lower pressure springs or remove inner springs from dual spring valve trains during the break in process

heres a couple darn good links you need to read thru, lets have some additional info or comments and questions??

its basically a heavy duty can opener , or an oil filter cutter designed to make it easy to internally inspect oil filters, by allowing you to remove the filter element , from inside the surrounding (CAN) for close visual inspection.

If you don,t have one, and have not used one, your unlikely to see, or appreciate the benefits,close inspection can and does frequently give you prior evidence of impending or at least gradually occurring wear and with practice you can make an excellent guess as to the parts and condition of those components.

IT also helps to trap crud if you install a couple high temp magnets on the filter and in the oil pan.

Regular oil changes can drastically reduce the amount of sludge buildup in the oil.

Basic filter cutting & inspection procedures

you would be amazed at the sludge build up in some engines

· Visually check the filter and or filter canister for cracks and leaks.

· Inspect the filter`s bypass valve to ensure it is operating correctly.

· Drain the filter of its contents (dispose of this liquid in the correct manner in accordance with local environmental guidelines).

· Firmly hold the filter in an upright position (head on top) taking care not to crush or damage the housing.

· Using a specially designed filter cutting tool (for example, Komatsu part number 3310587S )

heres a helpful diagnostic tool,

carefully cut off the top of the filter.

· Remove the element from the filter housing and pour the contents of the housing onto some clean absorbent paper.

· Inspect the absorbent paper for traces of foreign particles.

· Inspect the filter medium for signs of damage and blockages. Blockages force the bypass valve into operation, allowing unfiltered fluid to travel to and enter major components.

· Remove the filter medium from the filter by cutting between 2030 mm (about one inch) from the end plate and cut the medium into small pieces.

· Carefully inspect the filter medium for traces of metal contaminants.

Most engine trouble involves the lube system, and cutting waste filters apart often reveals warning signs that will help avert major damage. As a disposable element of the system, the filter sometimes acts as a fuse, calling attention to problems by failing before engine components are damaged. Problems associated with wear in the combustion chamber inevitably show up in the oil, and the filter collects clues. Field maintenance operations that take time to read the signs will have another tool for anticipating failures and reducing repair costs.

http://www.machinerylubrication.com/Rea ... inspection

http://www.tomorrowstechnician.com/Arti ... lters.aspx

http://www.tomorrowstechnician.com/Arti ... lures.aspx

http://www.summitracing.com/parts/SUM-9 ... toview=sku

http://www.circletrack.com/techarticles ... index.html

related info

viewtopic.php?f=51&t=2919

viewtopic.php?f=44&t=799&p=1161&hilit=+filter+select#p1161

viewtopic.php?f=54&t=3834&p=10199&hilit=+filter+oil#p10199

viewtopic.php?f=54&t=117

viewtopic.php?f=54&t=3519&p=9289&hilit=+filter+oil#p9289

viewtopic.php?f=54&t=2080&p=5568&hilit=+filter+oil#p5568

btw, add a few magnets to the oil pan and drain back area in your engine, the trap and hold metalic dust that comes from wear and increase engine life span by preventing that crap embedding in the bearings

http://www.kjmagnetics.com/proddetai...d=D66SH&cat=13

http://www.kjmagnetics.com/proddetail.asp?prod=D66SH

http://www.kjmagnetics.com/proddetail.asp?prod=D82SH

these are even more tollerant of temp swings and retain strength at even higher engine oil temps plus they are smaller and easier to use

The SH material in the D66SH magnets, means that the magnets can be heated to 300° F without any loss of magnetic strength, unlike standard neodymium magnets that begin to lose strength at 175° F. Suitable for many high temperature applications.

http://www.centuryperformance.com/tunin ... g-148.html

http://www.secondchancegarage.com/public/186.cfm

http://www.corvette-101.com/

(info on left border)

http://www.summitracing.com/search/?key ... kers&dds=1

there ARE reduced ratio roller rockers designed to significantly lower the lifter to lobe pressures during the cam break-in process, and its a whole lot easier to swap rockers during the break-in process than swap to lower pressure springs or remove inner springs from dual spring valve trains during the break in process

heres a couple darn good links you need to read thru, lets have some additional info or comments and questions??