theres plenty of math, but clearance issues, and packaging limitations, are the factor that limits what CAN, be done in most cases

remember an internal combustion engine works by use of producing rapidly expanding gases over a piston to produce pressure that forces the piston to spin the crank, those gas pressures exceed 600 psi and over 1000F temps, a well designed exhaust system will have a low enough restriction to exhaust flow that the max positive pressure will remain below 2 psi at peak rpms, and ideally less

http://victorylibrary.com/mopar/header-tech-c.htm

http://victorylibrary.com/mopar/cam-tech-c.htm

http://www.corvettefever.com/techarticl ... index.html

viewtopic.php?f=56&t=91

http://www.corvetteactioncenter.com...xhaust-that-gains-28-hp-and-is-quiet-512.html

MOST OEM CORVETTE EXHAUST SYSTEMS, AND SOME AFTERMARKET, ARE HIGHLY RESTRICTIVE

http://www.corvettecentralexhaust.com/c4/stock/systems/

http://www.parts123.com/parts123/yb.dll ... 000050Q~~~

http://www.parts123.com/parts123/yb.dll ... 1~cadefibQ

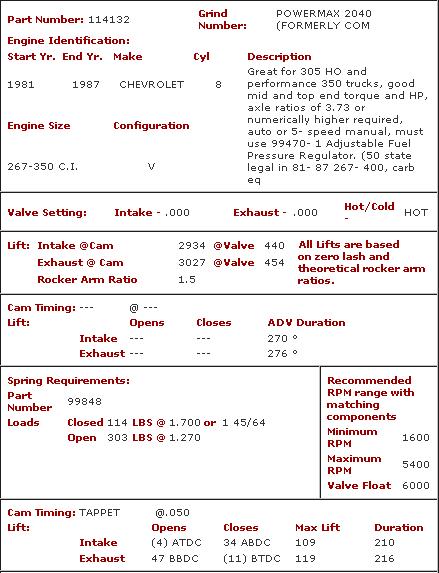

Id also point out that cam timing matched to the exhaust scavenging has a huge effect on potential intake flow rates

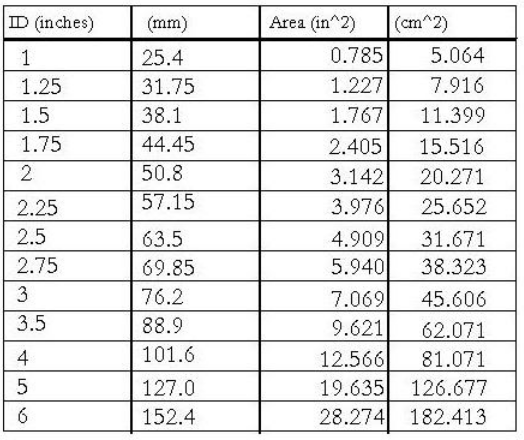

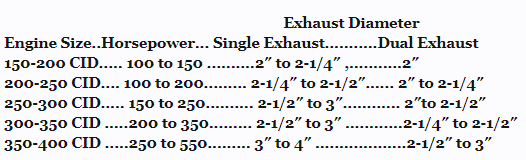

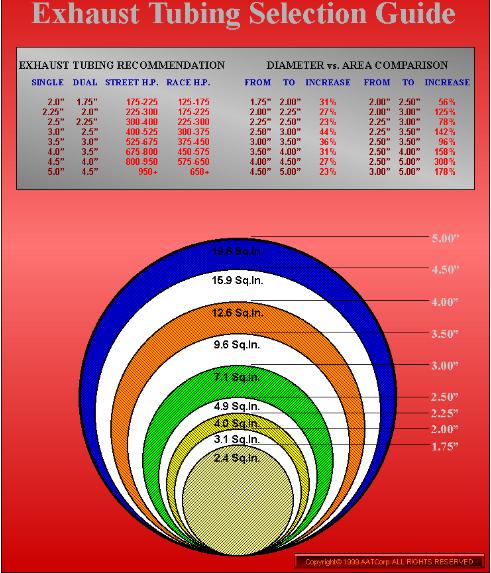

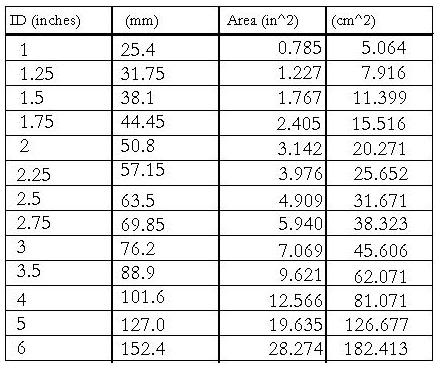

first ID advise STAINLESS as the material used in an exhaust and 2.5 minimum,pipe size 0r better yet 3" pipe size aft of the header collectors feeding into the (X) pipe, IDEALLY for size, on the pipes on a performance exhaust.especially with nitrous and ideally with

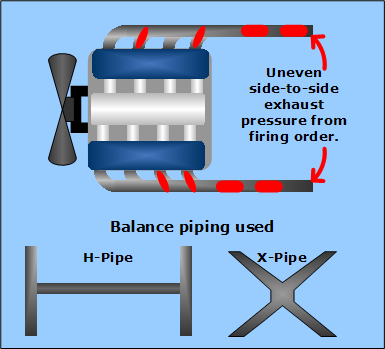

the (X) pipe located as close to the two header collectors as under the car clearances allow.(IDEALLY) if your forced to use an (H) pipe and ONLY if forced, by clearance issues, it ,should be as close to the header collectors as the available space/clearance allows, also, thats generally near the front u-joint due to the trans pan required clearances, the OPTIONAL second (H) to lower resonance, should be installed connecting the two exhaust pipes just in front of the muffler entrances

http://www.melroseheaders.com/products/smooth_flow_exhaust_systems/c-4.php

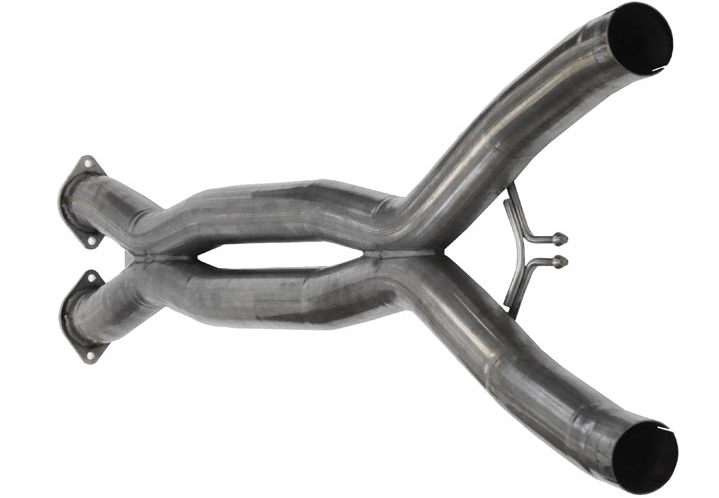

The melrose exhaust is a very well designed system, and keep in mind the exhaust gasses travel to the rear and pass through the (X) pipe they dissipate HEAT and loose some pressure and volume as a result, the (X) tends to mellow the growl slightly also, thus the two exhaust pipes past the (X) pipe share the split flow ,thats now sharing twice the original exhaust cross sectional area, at a reduced restriction, if I had the cash available thats the route ID suggest going , then you just need a decent quality, low flow restriction set of mufflers, added to the exhaust

Id buy this or duplicate this EXHAUST,and add an (H) where it connects to the mufflers, similar to this

the second (H) goes a long way to destroy resonance

http://store.summitracing.com/partdetail.asp?autofilter=1&part=SUM-642030&N=700+115&autoview=sku

viewtopic.php?f=56&t=10419

the idea is to minimize flow restriction and maximize cylinder scavaging in the rpm range youll operate in the majority of the time

remember an internal combustion engine works by use of producing rapidly expanding gases over a piston to produce pressure that forces the piston to spin the crank, those gas pressures exceed 600 psi and over 1000F temps, a well designed exhaust system will have a low enough restriction to exhaust flow that the max positive pressure will remain below 2 psi at peak rpms, and ideally less

http://victorylibrary.com/mopar/header-tech-c.htm

http://victorylibrary.com/mopar/cam-tech-c.htm

http://www.corvettefever.com/techarticl ... index.html

viewtopic.php?f=56&t=91

http://www.corvetteactioncenter.com...xhaust-that-gains-28-hp-and-is-quiet-512.html

MOST OEM CORVETTE EXHAUST SYSTEMS, AND SOME AFTERMARKET, ARE HIGHLY RESTRICTIVE

http://www.corvettecentralexhaust.com/c4/stock/systems/

http://www.parts123.com/parts123/yb.dll ... 000050Q~~~

http://www.parts123.com/parts123/yb.dll ... 1~cadefibQ

Id also point out that cam timing matched to the exhaust scavenging has a huge effect on potential intake flow rates

first ID advise STAINLESS as the material used in an exhaust and 2.5 minimum,pipe size 0r better yet 3" pipe size aft of the header collectors feeding into the (X) pipe, IDEALLY for size, on the pipes on a performance exhaust.especially with nitrous and ideally with

the (X) pipe located as close to the two header collectors as under the car clearances allow.(IDEALLY) if your forced to use an (H) pipe and ONLY if forced, by clearance issues, it ,should be as close to the header collectors as the available space/clearance allows, also, thats generally near the front u-joint due to the trans pan required clearances, the OPTIONAL second (H) to lower resonance, should be installed connecting the two exhaust pipes just in front of the muffler entrances

http://www.melroseheaders.com/products/smooth_flow_exhaust_systems/c-4.php

The melrose exhaust is a very well designed system, and keep in mind the exhaust gasses travel to the rear and pass through the (X) pipe they dissipate HEAT and loose some pressure and volume as a result, the (X) tends to mellow the growl slightly also, thus the two exhaust pipes past the (X) pipe share the split flow ,thats now sharing twice the original exhaust cross sectional area, at a reduced restriction, if I had the cash available thats the route ID suggest going , then you just need a decent quality, low flow restriction set of mufflers, added to the exhaust

Id buy this or duplicate this EXHAUST,and add an (H) where it connects to the mufflers, similar to this

the second (H) goes a long way to destroy resonance

http://store.summitracing.com/partdetail.asp?autofilter=1&part=SUM-642030&N=700+115&autoview=sku

viewtopic.php?f=56&t=10419

the idea is to minimize flow restriction and maximize cylinder scavaging in the rpm range youll operate in the majority of the time

Last edited by a moderator: