chris wilson

Member

I was out for a drive the other week and shifting through the gears at 5500 when the motor seemed to lose compression on one cylinder and back fired and came to stop. I had just been working on carb prior to run as carb was flooding itself. There was a strong odor of fuel when i got under hood to see what was going on. Car refused to start.

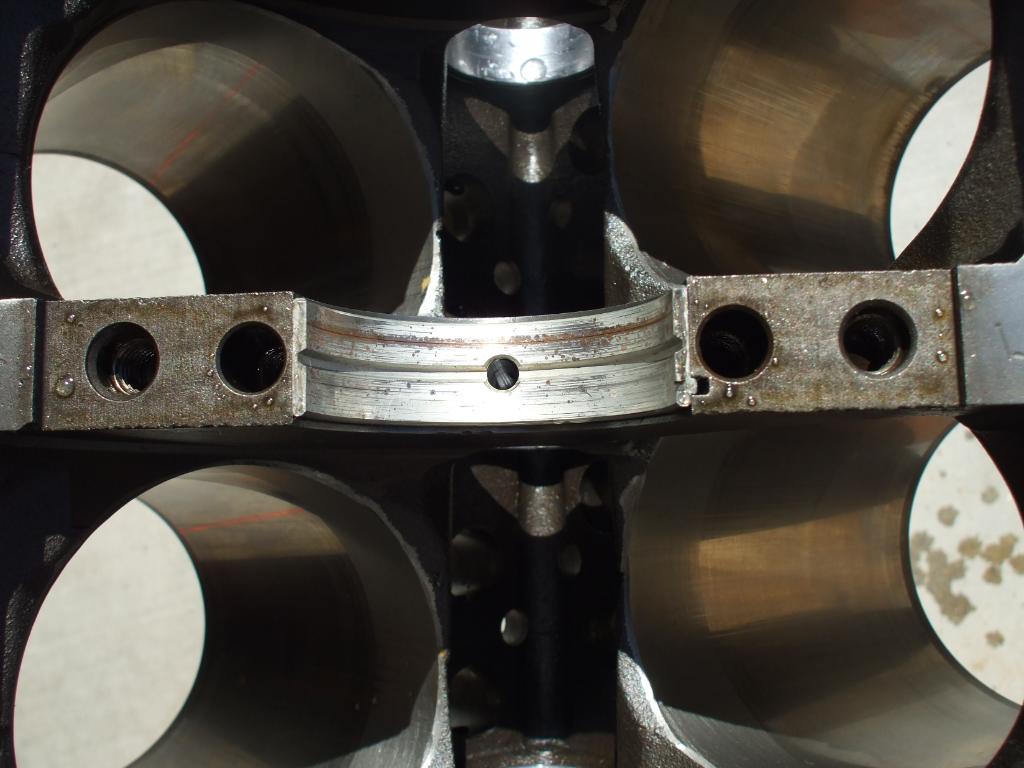

I was only a block from house so pushed car back. So i pulled the intake and checked lifters and pushrods and found one pushrod to be slightly bent and the rocker arm showing signs of heat. (Comp roller tip rockers). Concerned, i pulled the heads as this motor has less than 800 mi on it and found no issues with the cylinders. Cylinder #5 appears to be fine.

Drained oil and cut open filter but found nothing alarming.

I further pulled the AFR heads apart and found the valves to be straight although signs of overly rich conditions seemed to confirm my suspicions.

So ordered new replacement pushrods , lifters , and 7/16 full roller rockers ( Comp ultra Pro Magnum) and head gaskets and stick her back together thinking it was nothing more than a collapsed "Rhodes lifter" but thought having gone this far I should error on side of caution and pull the the cam and have a look. It all appears well visually ,still has lube from install a year ago on it. (Schneiders Cam)

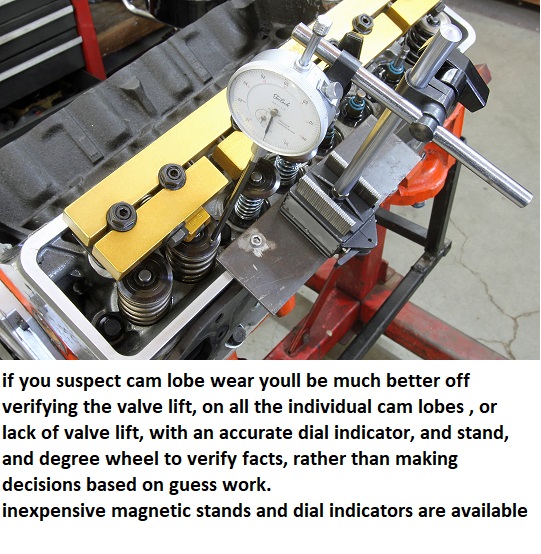

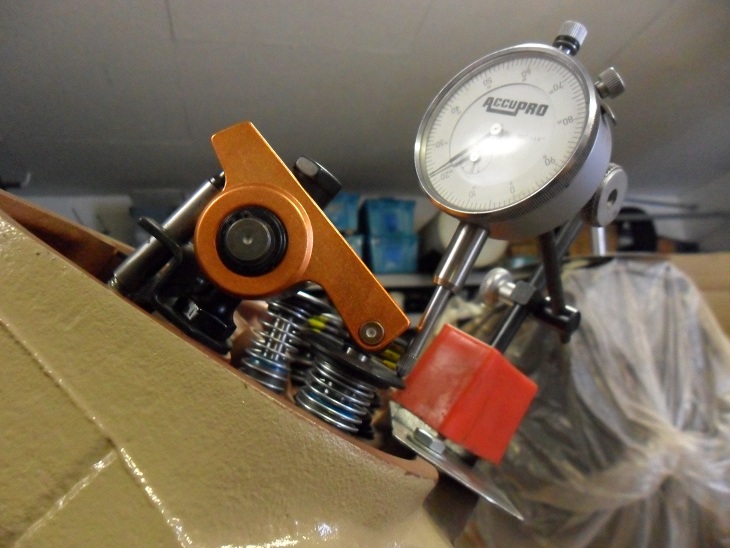

Was able to rig up a dial indicator on some metal steel "V" supports and took some readings. Highest were .320 on cyl # 8 intake/exh lobes and the lowest .313 the intake lobe on cyl #7 cylinder . My question is if this a concern or can i still run this cam or should i replace it? The funny thing is this was not the lobe with the bent bushrod or lifter that failed.

Your recommendations and or thoughts appreciated.

1).316

2).316

3).320

4).320

5).318

6).318

7).317

8).316

9).315

10).316

11).317

12).318

13).318

14).317

15).313

16).316

I was only a block from house so pushed car back. So i pulled the intake and checked lifters and pushrods and found one pushrod to be slightly bent and the rocker arm showing signs of heat. (Comp roller tip rockers). Concerned, i pulled the heads as this motor has less than 800 mi on it and found no issues with the cylinders. Cylinder #5 appears to be fine.

Drained oil and cut open filter but found nothing alarming.

I further pulled the AFR heads apart and found the valves to be straight although signs of overly rich conditions seemed to confirm my suspicions.

So ordered new replacement pushrods , lifters , and 7/16 full roller rockers ( Comp ultra Pro Magnum) and head gaskets and stick her back together thinking it was nothing more than a collapsed "Rhodes lifter" but thought having gone this far I should error on side of caution and pull the the cam and have a look. It all appears well visually ,still has lube from install a year ago on it. (Schneiders Cam)

Was able to rig up a dial indicator on some metal steel "V" supports and took some readings. Highest were .320 on cyl # 8 intake/exh lobes and the lowest .313 the intake lobe on cyl #7 cylinder . My question is if this a concern or can i still run this cam or should i replace it? The funny thing is this was not the lobe with the bent bushrod or lifter that failed.

Your recommendations and or thoughts appreciated.

1).316

2).316

3).320

4).320

5).318

6).318

7).317

8).316

9).315

10).316

11).317

12).318

13).318

14).317

15).313

16).316