my brother in law wanted to replace the bearings in an electric motor that was no longer made or for sale, hes looked for a few months now.

the bearings are seated in a blind hole and he had no way to remove them easily from a recess in the housing,

that motor housing is likely to be damaged if subjected to much abuse,

parts like alternators, starters, power steering pumps, and super chargers have these bearings

I suggested he purchase a small recessed bearing puller tool, as that's the ideal tool.

as the cost of the tool and bearing would be far lower than the motor replacement ..if he could even find one.

I offered to pay 1/2 the cost of that 689/2b tool set,

or some similar quality tool set,

https://uniorusa.com/collections/bearing-tools/products/bearing-puller

if I keep the tool after he used it...as he's very unlikely to ever need it again anyway

and yes it way overpriced and less expensive tools are available

and less expensive tools are available

READ THIS THREAD ALSO

http://garage.grumpysperformance.com/index.php?threads/pilot-bushing-installation.2596/#post-95633

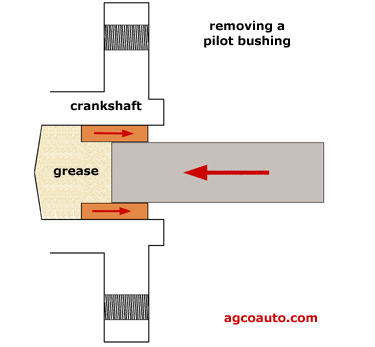

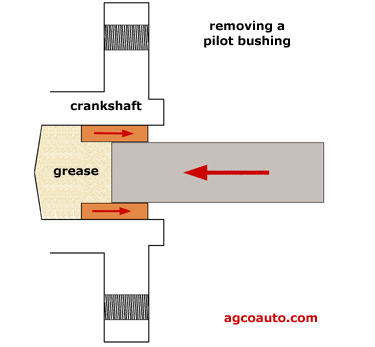

and yeah a bolt wrapped with tape and grease can be used,

in some applications like crank pilot bearing removal

yes there are other options

I've seen guys simply TIG weld a 10" long bolt,

a 10" long bolt,

inside the worn recessed bearing,

and use it as a handle to pull the defective bearing out,

but that's not always an option due to heat or bearing access issues

https://orionmotortech.com/products..._content=sag_organic&utm_campaign=sag_organic

https://www.amazon.com/DASBET-Beari...coding=UTF8&psc=1&refRID=9NM69BV8CHKJ6JSP2XZ9

the bearings are seated in a blind hole and he had no way to remove them easily from a recess in the housing,

that motor housing is likely to be damaged if subjected to much abuse,

parts like alternators, starters, power steering pumps, and super chargers have these bearings

I suggested he purchase a small recessed bearing puller tool, as that's the ideal tool.

as the cost of the tool and bearing would be far lower than the motor replacement ..if he could even find one.

I offered to pay 1/2 the cost of that 689/2b tool set,

or some similar quality tool set,

https://uniorusa.com/collections/bearing-tools/products/bearing-puller

if I keep the tool after he used it...as he's very unlikely to ever need it again anyway

and yes it way overpriced

READ THIS THREAD ALSO

http://garage.grumpysperformance.com/index.php?threads/pilot-bushing-installation.2596/#post-95633

and yeah a bolt wrapped with tape and grease can be used,

in some applications like crank pilot bearing removal

yes there are other options

I've seen guys simply TIG weld

inside the worn recessed bearing,

and use it as a handle to pull the defective bearing out,

but that's not always an option due to heat or bearing access issues

https://orionmotortech.com/products..._content=sag_organic&utm_campaign=sag_organic

https://www.amazon.com/DASBET-Beari...coding=UTF8&psc=1&refRID=9NM69BV8CHKJ6JSP2XZ9

Last edited: