I got asked a question about a similar clutch and just found this post which explains some of the design and function principals well.

there are other options available, ALL expensive, but prices generally range from $1200-$3700 for a QUALITY ADJUSTABLE ,multi disc slider clutch, so obviously doing so research on what your application needs and shopping carefully helps.

yes in most cases , if you select a multi disc or even a single disc adjustable clutch, youll need access to do the adjustments ,a two piece blow proof bell housing with a lower access plate that unbolts or youll need to carefully align and drill a couple access holes to adjust the clutch , for allen key or wrench access while its in the car

(which void the warranty)

http://www.summitracing.com/parts/cro-78813x6/overview/

http://www.advancedclutches.com/metalco ... #Sportsman

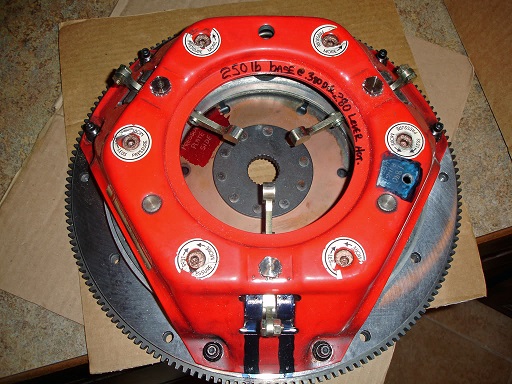

540Hotrod said:Thought I'd post a pic of the clutch assy I use in my car so folks could see what the Mcleod Soft Lok (and similar designs) look like and what you can do with them.

The Soft Lok is designed to slip a little on a hard launch to get you moving smoothly, keep RPM up with no bog and not break parts. When adjusted properly it will do all of that. The trick is the solid disc is made from a very aggressive sintered iron material. The hotter it gets..the harder it grabs. So when you launch..and it heats up a little during the slipping it just wants to hold tighter..vs an regular organic disc that starts to slip the hotter it gets. This pressure plate design is based on a *Long* design that Chevy never really used. You saw them in Fords usually. You can identify it from the "3 legged triangular shape" of the pressure plate. The Long design levers also do a better job of releasing at high RPM..so they are very popular in the racing world.

Take a look at the pressure plate. There are a total of 9 springs in the pressure plate and 6 of them have Allen head adjuster screws on each of them. You can see the white decals at each one of them. All clutches have springs..but they aren't adjustable. You turn the adjusters counterclockwise to increase pressure (sounds backwards,,but that's how they are threaded). This clutch starts with 250#'s of static *base*pressure on the disc if all the adjusters are backed out. If you turn all 6 adjusters 1 turn..you increase *base* pressure by 130#'s. You can turn them a total of 13 turns each..so you can add up to 1690#'s of additional pressure for a total of 1940#'s. This also allows you to compensate for disc wear through the life of the clutch. You always turn each adjuster the same amount..but it doesn't have to be in full turns. It can be 1/4..1/2 or whatever you want. Normal clutches continually have less pressure applied as they wear because the disc gets thinner and springs can't be adjusted.

Next...look at the 3 release fingers. On the outside edge of each one you can see a bolt and nut attached to them. This is how you add *centrifugal* assist. As RPM climbs, the weights on the arms makes them want to move outward which in turn applies more pressure to the clutch disc to keep it from slipping as RPM and load increases. You have an asst. of steel and aluminum bolts, nuts and spacers that all add up to various mix and match weight possibilities. You always add the same amount of weight to each finger.

You can also see the two blue stripes that indicate the balanced position of the assy. so it can be installed with no vibration issues.

The original disc was .280" thick. You can run them down to about .250" or so before they need replacing. I got 2-3 years out of the first disc in spite of going through the learning curve of adjustments and slipping it way too much the first couple of times out. This new disc starts out at .380" thick. That will give me a LOT longer life..especially without going through a learning curve again. To make the thicker disc work, you install thin spacer shims under each mounting bolt to space pressure plate away from flywheel. This is pretty common on high end clutches..the Mcleod Dual Disc Street Twin is the same way. You juggle the shims to arrive at the 1.890" plate height setting you see etched on the plate by the hole drilled into the cover. As the clutch wears, you remove shims to keep the plate height near that setting.

These clutch assemblies are designed to be rebuilt. The inner plate is actually aluminum with a carbon steel wear plate rived to it. During rebuilds you just put a new plate on it. Aluminum flywheels are the same way..you just change the plate when it's worn out. I use a steel flywheel..so they just turned it to be new again.

So anyway..if anyone is interested...we'll move into how to tune one for the street or strip....and then how to drive with one.

In fast stick shift cars....clutch management is EVERYTHING! Nothing like Top Fuel..but it's the same idea. Controlled slip so tires just barely spin and then add in centrifugal to hold at higher RPM.

First...SOMETHING has to give. Either the tires, the clutch...or the trans/rearend...but something has to give. Remember the old 3200LB clutches of the old days that broke your leg? No way they were going to slip...good thing tires weren't that great. Probably turned more people off to racing with a stick than anything. People broke lots of parts!

Dead hooking is BAD! You want to hit the tires hard enough to get a turn or so on the launch. That doesn't mean it won't still pull the wheels in the air....just that while it's doing it the clutch is also slipping a little saving parts! We'll talk more about how to drive it all later.

Launching at higher RPM is GOOD! You want to get it so you can launch 1000-1500 RPM above TQ peak if possible. That way you fall right back to the TQ peak on the launch recovery and are right in the middle of the serious HP climb.

You really have to look over your combo to get a good starting point. There are two schools of thought. The clutch guys will tell you to start with a lot of pressure and back off slightly until it slips..then add a little back in.

The trans folks...especially Jerico...will tell you to start out low and slipping a little and add some in until it doesn't slip. It all depends on who's trying to save who's parts!

I talked to everyone I could including mfgs and got a lot of great info. The problem is that it really is pretty specific to your car unless you are dead on copying everything else someone does...including driving style.

You have to take into account, weight, HP, RPM range, gearing, traction and how you're willing to drive it. Change any one of those and the *setup* changes. How much depends on how much or how many you changed.

For example...small block Stockers with lots of rules on motor combos have just so much power available. Often not enough..so they work on everything they can to make it 60' and pull to the 1/8th mile...and then just scream to the end. Usually lots of RPM and gearing makes it all work. In a deal like that, they will put static pressure down real low into the 400# range...and even lower..like 250#'s to allow motor to stay high in RPM when the clutch is sidestepped. Really acts like a converter and it slips a lot through low gear. They run enough centrifugal assist to keep it from slipping down track. Clutches don't last long...but that's how you when races.

I know another car well..it's an N/A LS-1 '99 Camaro that runs high 8's/low 9's with a Jerico. The Mcleod Soft Lok in it was run for years on the same disc and hit 1.28-1.29 60's on 10.5" tires. Mcleod always told him he needed to slip the clutch more since disc wasn't wearing much...but he preferred to hit it hard with just enough slip to get it moving smoothly. Now he did find that 12 bolt race rears didn't last long, aluminum spools don't last forever...nor do aluminum 9" center sections. A little more slip would have saved parts..but might have run a hundredth or two slower. This particular car used 800#'s static and no centrifugal assist. Weight was in the 3200 lb range with just under 900HP and LOTS of RPM...like in the high 8000-9000 rpm range.

Those bad boy Hemi 8 sec Cuda's you see run in the 600# range roughly. Again....mega RPM...low TQ and high HP.

So...little motors, low TQ, high RPM, light weight add up to lower pressure settings.

Big motors, high TQ, low RPM, heavy weight add up to higher pressure settings.

If you have a combo that needs a little of both...you add in some centrifugal to hold it at the end of the track.

OK...you've got the idea. Now let's talk about my goofy combo. It weighs 3650#'s at the starting line. Makes 700 ft lbs of TQ at moderate RPM...yet pulls well to the 7500 rpm range. I also use 3.07 rear gears and a 5 speed trans. I only use 4 gears through the 1/4 and 5th is for cruising. I first spec'd the trans for an early engine combo that didn't use as much RPM...but later I found it really like to rev. with a few changes. So I re-geared trans to allow more RPM. Right now I have a 3.49 first gear and the 3.07 rear. That's a total first gear of only 10.71..which is just slightly under what a 4.33 rear gear would be with a wide ratio Muncie. Serious stick racers use more first gear and often are in the 14-15 to 1 range. If they have a 5 speed they gear it to use all 5 gears in the 1/4 which can really help.

So my combo isn't terrible off the line..but definitely a compromise..but that's what you do with street cars. Roger rags on me all the time for *wasting* that good extra gear in my trans!

After listening to everyone, I took a stab at it and started with around 900#'s of static. That's 5 turns on the adjusters and the 250# base pressure. I added 5 grams of weight to each lever and headed to the track. Previously I had been using a McLeod Street Twin clutch with added pressure. It had 1600#'s with dual discs. It NEVER slipped no matter what I did....and it really planted tires into the ground..and you never knew where it would come down after the launch....and it broke a good Doug Nash 5 speed trans several times! The first time I launched with the Soft Lok was like heaven. The car just sat up...went straight and so smooth it was crazy. It ran about the same time right off the bat as the best the Street Twin had ever done and was super easy to drive. I had launched at about 3500 rpm to get a feel for it. Racing with the Street Twin had me usually launching about 2500 rpm to keep the violence down. This bogged the motor and made it hard to pull back up to RPM. What I learned from the initial runs that day was that you could raise RPM a LOT and it really did work better...and I needed more static pressure. The clutch was slipping a lot through low gear....but was fine on the shifts and at the end of the track. But also, by coming out at so low of an RPM...I was causing the slip to be worse.

Next time out I added 1 turn of adjustment to the static for a total of 1030#'s. About this time I also added some stiff sidewall slicks instead of the regular 28x10.5's I usually ran. The old slicks had to use about 12.5#'s of air to hook....but the pics looked like the rim was about to touch the ground on the launch with the Street Twin clutch. The new tires liked 16#'s and handled tons better! This time out it ran better....but it still slipped a lot in 1st gear. To give you an idea...I was slipping bad enough to slow to the mid 1.60's on 60's....from the normal low-mid 1.40's...yet the RPM was staying up so well on the launch that the end result was identical 1/4 mile times! Lose 2 tenths in 60's...and run same times..something wild is going on!

Next time out it all came together. I added 1 more turn to the base for a total of 1160#'s and used 6.5 grams of centrifugal assist. The idea was to bring it in quicker to get it to grab quicker at the top of first gear. I also started playing with launch RPM's. First run was launched at 4500 rpm and it ran a 9.94. Next pass I launched at 5000 rpm and it hit a 9.90. Next pass I tried 5500 rpm and it spun a little too much..that got me a 9.92. I think raising air pressure to 16.5 would've been a good move. It lifted the front tires pretty high on every pass and went nice and straight.

I've run that same combo for the last year or so and it's worked nice. I've now got it to the point where I can play with shock settings and stuff and come out even harder. With my lopsided ET/MPH results..there is a LOT more in it for the first 60' to 330'....but I doubt it will ever be ideal unless I completely change gearing combo.

I will probably add a little more static next time out and see how it does....but not much. It's working pretty decent right now. You can see how it takes a LOT more static pressure with my heavy, high TQ and poorly geared combo to get it to act just like a better/different combo. We end up with same results nearly..just it takes a different setting combo to do it.

For street use...the basic premise is to crank in the pressure. You can drive it with the low pressure settings..but you have to be careful not to burn it up. I found you have to be careful here. My Soft Lok has a total of 13 turns of adjustment. Normally on the street I run it with about 10 turns for a total of 1550#'s of pressure. That works well on street tires. Running that high pretty much eliminates any issues with low speed slippage...like goosing it at 2000 rpm. The part you have to be careful of is that when the disc is still in good shape and thick..that if you crank all 13 turns in it...it will *stack* solid and won't release. The ability to put in 13 turns allows you to still put enough pressure on it as the disc wears.

Other things you need to make sure of is that you have plenty of clutch freeplay. More is good. When all the centrifugal assist kicks in and the fingers move backtowards trans..you don't want then anywhere near the throwout bearing. It will just hold the fingers and allow it to slip. Even though the pedal pressure on this type of clutch is pretty darn low...you still want to make sure the linkage is in good shape. A little play here and there really eats up the travel. Make sure it's all good. When you get real serious you will install a clutch pedal stop to make sure you hit the same spot everytime you push the pedal. You also want to pay attention to the seat assy. Years ago Ronnie Sox liked seats with no padding so they wouldn't *give* when he pushed the pedal. That's no help for us...but the seat shouldn't flex or move any when you push pedal.

That's a lot for this *installment*. Next we'll get into actual driving the things after everyone has added in some more info to the discussion.

JIM

there are other options available, ALL expensive, but prices generally range from $1200-$3700 for a QUALITY ADJUSTABLE ,multi disc slider clutch, so obviously doing so research on what your application needs and shopping carefully helps.

yes in most cases , if you select a multi disc or even a single disc adjustable clutch, youll need access to do the adjustments ,a two piece blow proof bell housing with a lower access plate that unbolts or youll need to carefully align and drill a couple access holes to adjust the clutch , for allen key or wrench access while its in the car

(which void the warranty)

http://www.summitracing.com/parts/cro-78813x6/overview/

http://www.advancedclutches.com/metalco ... #Sportsman