https://www.cartechbooks.com/techtips/killerbigblockchevy

http://www.felpro.com/technical/tecblogs/head-gasket-coolant-holes.html

https://www.billmitchellproducts.com/world-cast-iron-26degree-269cc/

BIG-BLOCK CHEVY CYLINDER HEAD BASICS

by Molly Koecher

by Tom Dufur

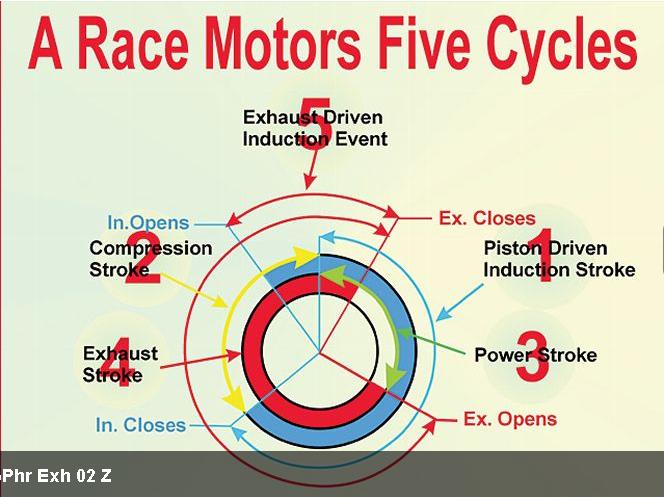

The big-block Chevy’s canted valve heads are largely responsible for the tremendous power capability of the Rat motor and its continued popularity. The original head design is often referred to as having a 26-degree valve angle, although this intake valve angle of inclination is only one of four angles needed to numerically describe the big-block’s valve angles. The exhaust is tilted 17 degrees relative to the deck surface, and both are inclined 4 degrees laterally. This compound arrangement of valve angles gives the big-block head its characteristic “valves pointing everywhere” appearance when the valve covers are removed and is responsible for the early “porcupine head” nickname when the big-block made its debut in the mid 1960s.

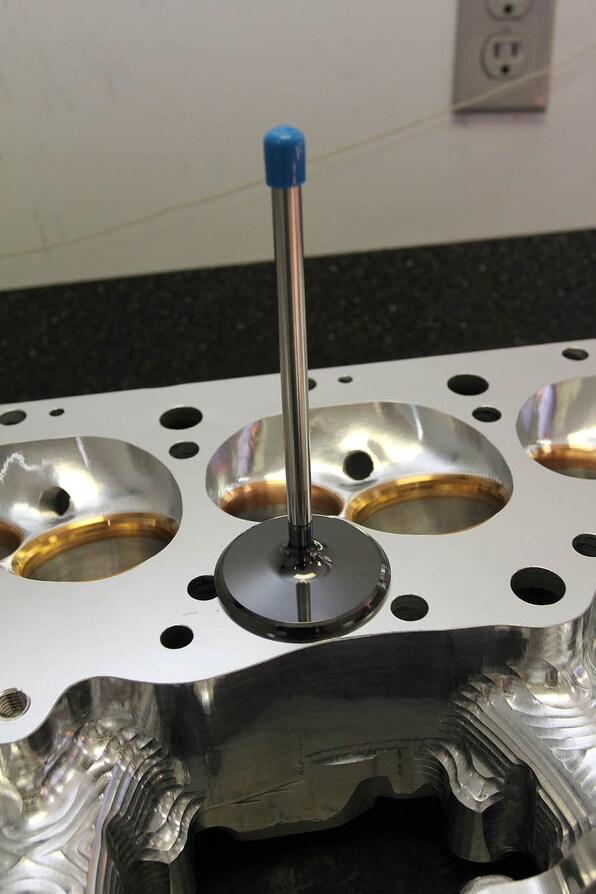

Aluminum aftermarket cylinder heads offer tremendous airflow potential to maximize power potential.

Big-block Chevy factory heads are offered in aluminum and cast iron, with either open or closed combustion chambers, and with oval or rectangular intake ports. In the aftermarket, most performance heads are aluminum rectangular port, open-chamber designs reminiscent of the original LS6 casting, although you can also buy aftermarket oval port and cast-iron heads.

Factory heads are classified as either high-performance (rectangular port) or standard passenger car (oval ports). Late-model trucks feature an even smaller oval intake port, frequently referred to as the “peanut” port, on heads that appear to be nearly round at the port entrance. Rat motor heads feature a unique combination of siamesed intake ports mated with symmetrical combustion chambers and equally spaced exhaust ports.

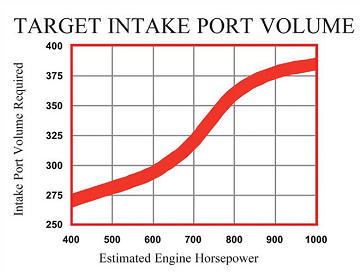

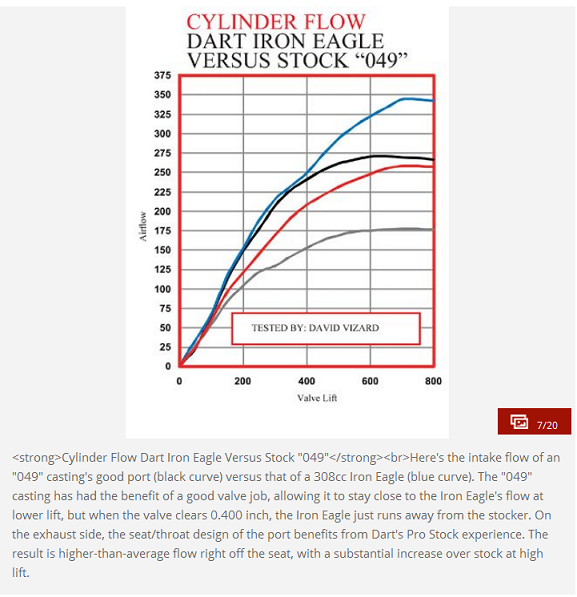

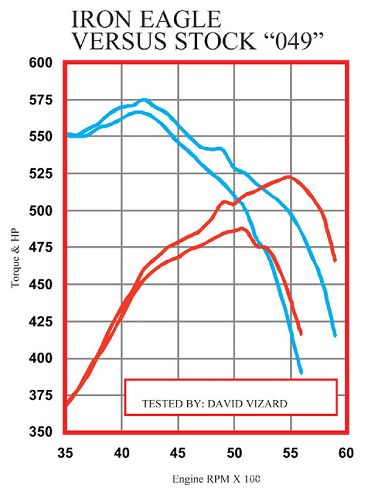

As a result of this arrangement, each siamesed pair of intake runners features non-symmetrical left-hand and right-hand ports. The port on the right side of each pair (as you face the intake flange surface) is longer and directs the inlet charge more to the center of the chamber, and is referred to as the “good” port; the one of the left, obviously referred to as the “bad” port, dumps the air/fuel mix toward the cylinder wall and usually doesn’t flow as well as the right port. This minor idiosyncrasy of the big-block’s design has never been a real problem in terms of limiting the engine’s power potential, until extremely high airflow levels are reached on large-displacement or very-high-RPM engines. On engines approaching or exceeding the 1,000-hp mark (normally aspirated), the use of race-only spread port or Big Chief–style heads serves to even out the port volume, shape, and airflow in all eight intake ports.

Why didn’t the Chevrolet engineers just make it a mirror-image design like the small-block V-8? Because the big-block has six head bolts around each bore (if you count the hidden bolt bosses on the bottom of two of the intake ports), and that dictates where the intake ports must be placed. Also, it’s possible that the resulting siamesed exhaust ports might run too hot for long-term reliability with the big-block’s higher power levels and resulting increased exhaust flow.

Oval or Rectangular Intake Ports

Much has been said about the differences between rectangular ports and oval ports, and the only fact that everyone agrees with is that each design has its own strengths and weaknesses. All factory high-performance engines featured the larger rectangular port heads, which have higher airflow rates than production oval port heads. However, the larger volume of the rectangular ports produces rather sluggish flow velocities at low speeds, and smaller oval port heads are often a better choice for a daily driver or street and strip car.

Stock iron oval ports from a “206” casting head. Note Stock iron rectangular ports from a “990” casting head. distance from the ports to the center bolt-hole above Note that the tops of the ports are almost even with the the pair of runners. bottom of the center bolt-hole.

When reworked by someone who really knows what to do, oval port heads are capable of providing very good performance up to 600 or more horsepower. However, most high-performance street and full-race big-blocks can still take advantage of larger rectangular port heads. When I refer to the port size as larger or smaller, I’d like to think in terms of port cross-sectional area, but that dimension changes constantly throughout the length of the port, so the most common way to measure port size is to determine the volume in cubic centimeters, just as with the combustion chamber.

Big-block head bolt torque pattern. Stock head bolts get torqued to 70 ft-lbs in three steps of 40, 55, and 70 ft-lbs. Use thread sealer on all bolts that go into the water jacket, which means all blocks except Bowtie and aftermarket. Aftermarket studs usually get torqued to 60 ft-lbs, but check with the fastener manufacturer for specific torque recommendations.

While intake port volumes are a valuable guide in cylinder head selection, remember that port volume is not necessarily proportional to port flow, and that just because one design has 340-cc runners and another has 320s, that doesn’t mean that the larger head flows more air or makes more power, although that is usually the case.

In fact, if two heads with different- size runners have the same flowbench numbers, you are generally better off with the smaller runner head, especially if low-RPM throttle response and drivability are important. Also, when comparing port volume of spread port cylinder heads, remember that because these heads have raised runner locations, they are longer than conventional cylinder head intake ports, and the port volume is greater due to the extra length. A 400-cc raised-runner intake port may actually be smaller in cross-sectional area than a 380-cc conventional intake port. Be careful when comparing apples to oranges.

There are aftermarket oval port heads with about 290-cc intake runners, and small rectangular port heads with around 300-cc ports. I’ll bet you a year’s supply of donuts that the power difference on the dyno is minimal, and you could never tell the difference from the driver’s seat.

The GMPP head (PN 12363400) with 300-cc rectangular intake ports (left) performs very similarly to the oval port head (PN 12363392) with 290-cc intake ports (right), if both have the same compression ratios. The oval port head has 110-cc chambers, and the rectangular port head comes with 118-cc chambers.

Open or Closed Combustion Chambers

Cast-iron late-1960s “206” head with bathtub-shaped Cast-iron high-performance rectangular port “990” head

98-cc closed combustion chambers with open 118-cc combustion chambers. Note the lazy-D

shape of the chambers.

Big-block heads all had closed combustion chambers, or bathtub-shaped chambers, when the engine was introduced in the mid 1960s. In 1969 the open combustion chamber was introduced and it offered better air/fuel flow and a better combustion burn in the chamber. The only drawback to the new chamber design was that it was large, around 118 cc compared to closed chamber heads, which had about 101 to 109 cc, so high-dome pistons were needed to achieve the same compression ratios as the closed chamber heads. Note that domed pistons designed for open chamber cylinder heads do not work with closed chamber heads due to insufficient clearance. While introduced on high-performance rectangular port heads, the open combustion chamber was soon being used in common oval port heads to lower the compression ratio for use with unleaded gasoline, and the reduced quench area was found to be helpful in reducing exhaust emissions.

Mark IV, Gen V and Gen VI Heads

All production big-block heads have similar characteristics, including 7/16-inch rocker studs (except Gen V and Gen VI) and the same seven-bolt valve cover pattern. Early cast-iron and all-aluminum heads used 3/4-inch-reach gasketed spark plugs, while most 1970-and-later iron heads switched to the smaller taper seat “peanut” plugs. Aluminum heads have two additional threaded bosses under the intake runners for additional clamping and better head gasket retention when used with engine blocks equipped with corresponding bosses in the lifter valley. The only OEM blocks with these bosses were the rare ZL1 aluminum blocks, but many modern aftermarket blocks have this added feature. Mark IV, Gen V and Gen VI heads all have the same head bolt pattern, but they are not interchangeable due to different water jacket cooling passages. Most aftermarket aluminum heads feature a universal water passage design allowing their use on Mark IV or Gen V/VI blocks, but you need to check with the manufacturer to verify this feature.

Gen V and Gen VI heads have different water jacket passages than Mark IV heads, and do not work on Mark IV blocks. (Photo Courtesy GMPP).

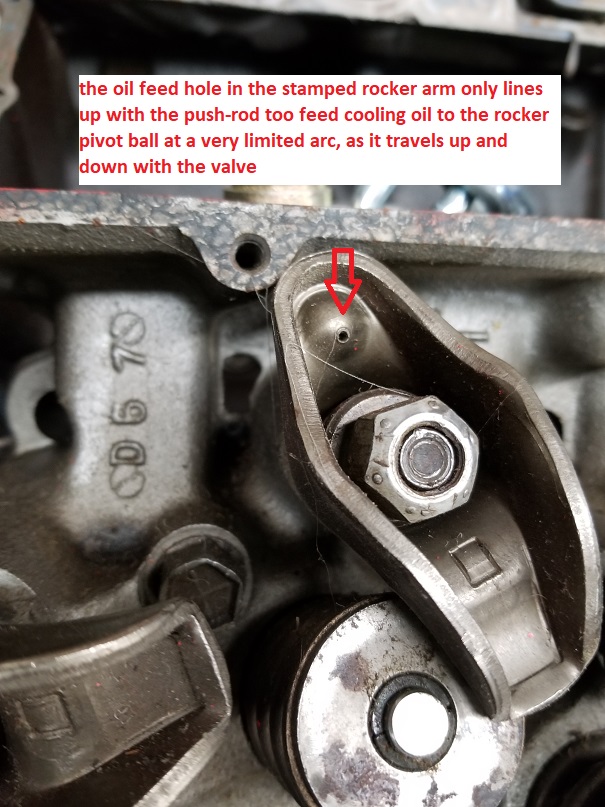

All production big-block heads have stamped steel pushrod guideplates under the rocker arm studs for either 5/16-, 3/8-, or 7/16-inch pushrods, but Gen V/VI heads switched to a non-adjustable valvetrain. Although Gen V/VI heads retained the original valve cover bolt pattern, their matching cast aluminum valve covers were equipped with a durable rubber O-ring in place of the traditional valve cover gasket. All production heads use the same intake and exhaust bolt patterns, which include a bolt-hole between each pair of intake ports. The boss required for this additional bolt-hole intrudes on the port entrance, so it is deleted on most aftermarket heads because it is not necessary for a good gasket seal.

All production big-block heads had an exhaust crossover passage between the two pairs of siamesed intake ports. The casting cavities above and below the center exhaust crossover are blind cavities that don’t connect to anything. Some aftermarket intake manifolds don’t cover the upper opening, which does not cause any problems.

All OEM big-block heads had an exhaust crossover passage for intake manifold heat and automatic choke operation, as well as supplying exhaust gas for EGR-equipped (exhaust gas recirculation) vehicles from the early 1970s on. High-performance engine builders try to keep the intake manifold as cool as possible for maximum intake charge density, so performance intake gasket sets usually include metal plates to block off this exhaust crossover passage, and most aftermarket heads delete the exhaust crossover provision entirely.

All OEM Rat motor heads were equipped with steel valves that have 3/8-inch diameter valvestems, and the overall length of the intake valves is 5.218 inches while the exhaust valves measure 5.350 inches. Aftermarket heads typically come with 11/32-inch-diameter valvestems, and frequently use longer than stock valve lengths that allow installation of taller valvesprings that are better suited for use with high-lift camshafts. The smaller-diameter stems not only lighten the valves for better high-RPM performance, but also offer a slight improvement in airflow. OEM intake valve head diameters were either 2.06 or 2.19 inches, and exhaust valve heads measured either 1.72, 1.84, or 1.88 inches. All production heads and most aftermarket heads come with traditional 45-degree valve seats; however, some high-end aftermarket heads are available with 55-degree seats, which offer improved high-lift flow at the expense of some low-lift flow.

Aftermarket Cylinder Heads

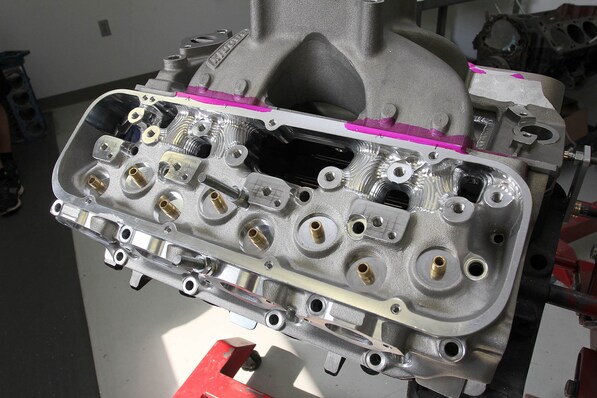

The vast majority of aftermarket heads are rectangular port aluminum with open combustion chambers, similar to the fabled LS6/LS7 production heads. However, they are much more than mere copies of the Chevy part, and many offer such advanced features as non-stock valve angles, larger valve head diameters for more flow, more robust valvesprings for high-RPM operation, and your choice of various intake port sizes to match your requirements. Some offer raised ports, usually by .100 inch on the intake ports and as much as 3/4 inch on the exhaust ports.

Many aftermarket heads, such as this Edelbrock Performer RPM 454-R, are rectangular port aluminum with open combustion chambers, similar to the fabled LS6/LS7 production heads. (Photo Courtesy Edelbrock)

Note that if you plan to use exhaust headers designed for stock heads in a stock engine compartment, you need to check for possible header interference with raised port heads, or have custom headers made. Typical material specs call for the use of either A355 or A356 aluminum alloy, usually hardened to T-6 specs, and most offer beefier construction with thicker-than-stock deck surfaces and port walls, allowing additional modifications by knowledgeable cylinder head specialists.

In addition to GMPP, there are an abundance of manufacturers offering high-performance heads for the big-block Chevy including Air Flow Research (AFR), Brodix, Carl Foltz Engineering (CFE), Dart, Edelbrock, Pro-Filer, Racing Head Service (RHS), Raptor (Reher-Morrison Racing Engines), Sonny’s Racing Engines (SRE), Trick Flow Specialties (TFS), World Products, and probably more by the time you read this. Contact the manufacturer of your choice for more specific information before making your final head selection.

Modern competition heads usually have heart-shaped combustion chambers to minimize chamber volume and increase the quench area.

Spread Port Heads

As good as the original Chevy head design was, things really started to heat up when GM engineers got involved in the Pro Stock wars in the 1980s. Because of the Corporate Engine policy, GM competitors were allowed to use any GM family engine in their race cars and the big-block Chevy was obviously better suited to all-out racing than any other GM big-block engine. Pontiac engineers took advantage of this break to create a head for the Rat motor with a superior port design, shallower valve angles, and smaller, more efficient combustion chambers.

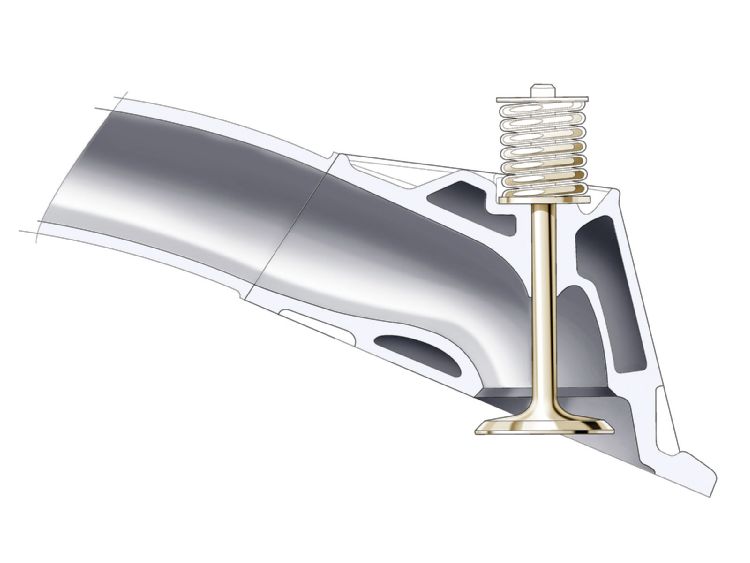

The quench or squish area of the cylinder head is the flat surface that hangs over the bore. As the piston comes to TDC the air/fuel mixture is rapidly expelled, creating turbulence in the chamber, which greatly increases combustion efficiency

The Pontiac Super Duty Pro Stock cylinder head (PN 10045427) featured intake ports that were spread apart to even out the flow differential inherent in the original Chevrolet siamesed port design, and the shallow valve angles required substantially raised intake ports to straighten the airflow path from the port entrance to the valve seat.

From there, Oldsmobile engineers took their shot at creating the best possible drag race head, and introduced the Oldsmobile Pro Stock head (PN 24502585). The Olds Pro Stock head evolved into the GM DRCE, the development of which was spearheaded by a young Warren Johnson, soon to be the dominant NHRA Pro Stock racer of the 1980s and 1990s.

D-shaped exhaust ports decrease the flow differential between the floor and the roof of the exhaust ports, and they help to combat reversion.

Not to be forgotten, Chevrolet engineers also developed a spread port head, the Chevy Symmetrical Port Head (PN 10051128), with similar design parameters: evenly spaced intake ports and shallow valve angles with miniscule combustion chambers.

Today, the latest version of the Olds DRCE is the spec cylinder head for all GM-powered vehicles in NHRA Pro Stock competition, while the Pontiac Pro Stock head has been widely copied by aftermarket manufacturers, resulting in the Dart Big Chief head (paying tribute to the Pontiac Indian tribe), the Brodix Big Duke head, and Edelbrock’s Big Victor head, with more development sure to follow. If you want to make 1,000 hp or more without power adders, “Big” heads are the way to go.

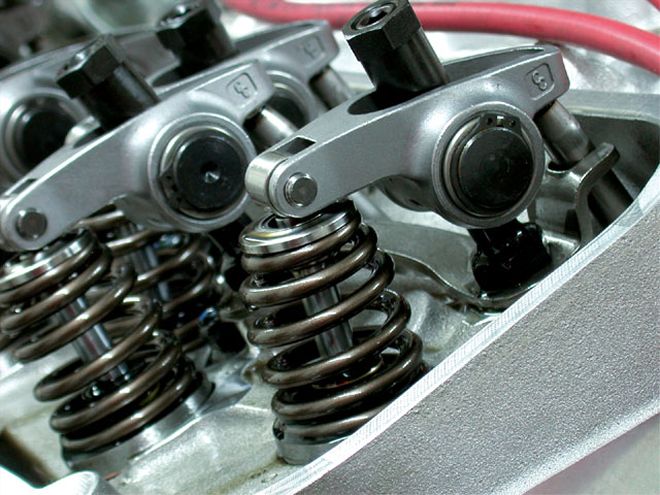

Even though these “Big” heads all share some common design parameters, they are not identical and most require specific matching components such as pistons, intake manifolds, and shaft rocker arm assemblies. All spread port big-block Chevy heads require shaft rocker arms because the pushrods must be relocated around the revised intake port location, and the large amount of rocker arm offset eliminates the use of traditional stud-mount rockers. Most accept the original Pontiac-designed eight-bolt valve covers, although the Edelbrock Big Victor head features a unique valve cover bolt pattern to relocate the bolt-hole bosses for improved rocker arm clearance and valvetrain geometry. This is one of the reasons that fabricated aluminum sheet-metal valve covers are so popular these days—they can be quickly produced one at a time or in relatively small batches to fit whatever bolt pattern you want. Besides, they look racy!

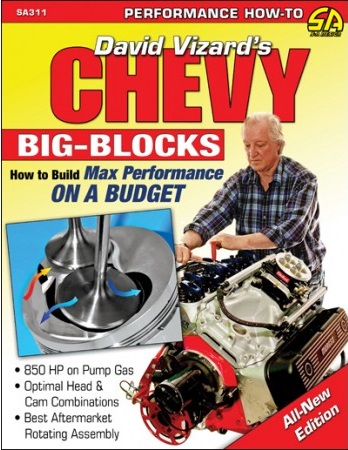

The big-block Chevy V-8 engine has been part of the automotive scene ever since it’s introduction in 1965. Its impact on the streets and race tracks of America were immediate and blatant. With time, the engine evolved and gained size, making it even better with age. Now, some four decades-plus later, there are a wide range of factory-based and aftermarket options for the legendary big-block Chevy engine. Which options are best for any specific purpose can be challenging to figure out, but this book makes it easier. In addition to identifying and reviewing all of the factory components, this book also takes a close look at all the major hard parts offered in the high-performance aftermarket.

The trick to building any high-performance engine is to properly team together the proper components, and How to Build Killer Big-Block Chevy Engines

shows readers exactly how to do so.

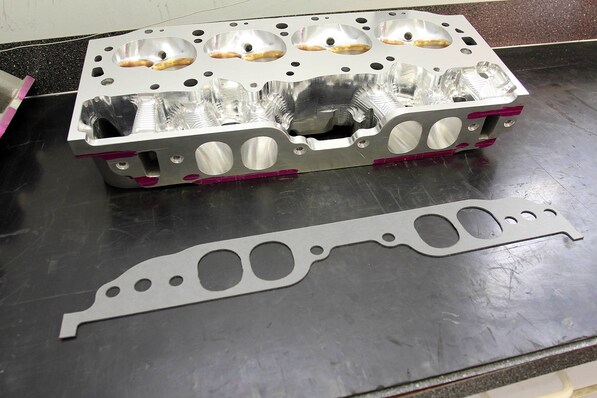

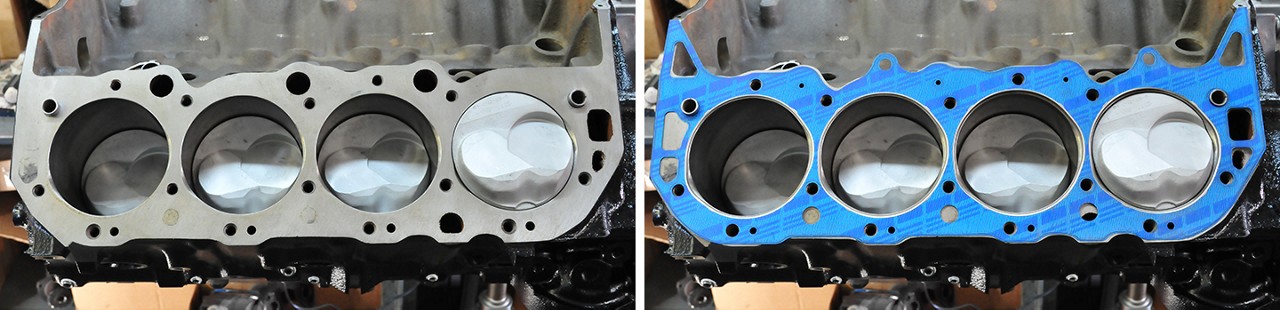

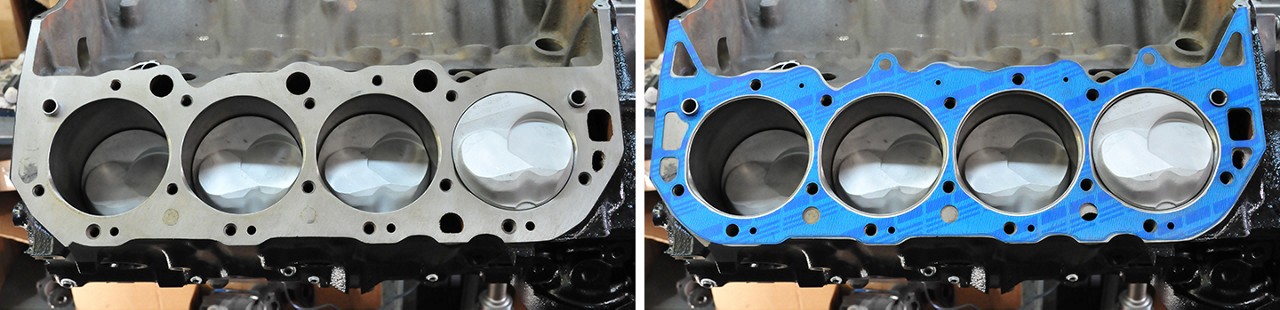

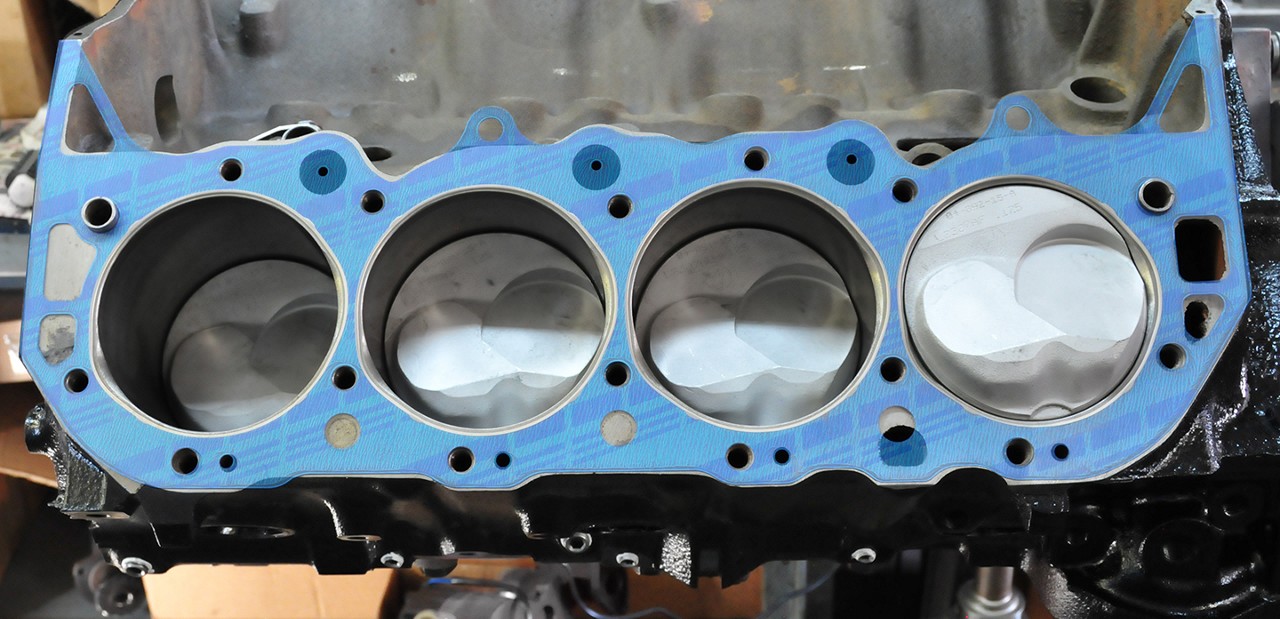

found this gasket over at summit..

using the correct head gasket too match the heads and cylinder heads your using on any big block chevy engine, is critical to prevent coolant loss, and maintain proper cooling

http://www.summitracing.com/parts/FE...2/?image=large

head gaskets are rarely completely round, nore are combustion chambers

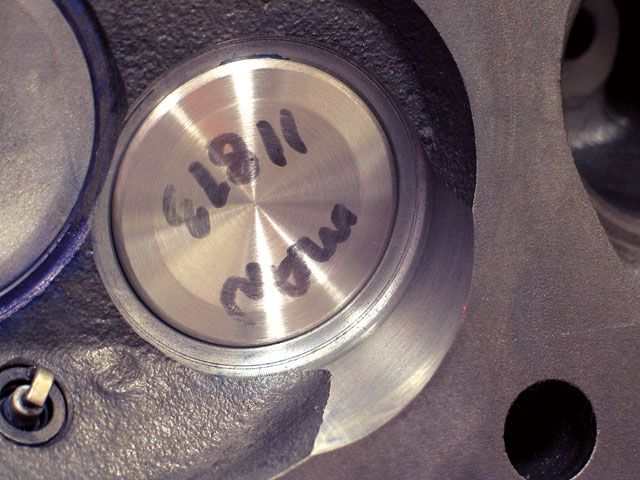

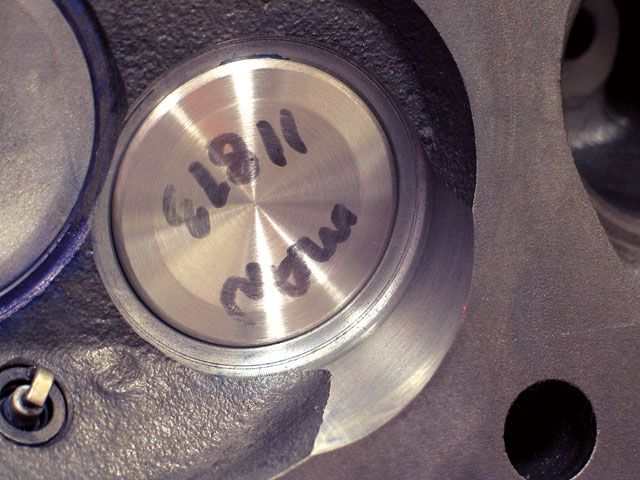

you,ll want to place a head gasket you,ll use on the heads and mark the area inside the opening as the only areas you can change,

(notice the gasket fire ring is NOT a perfect circle like many people assume)

ideally you,ll want to un-shroud the valves while opening up the combustion chamber volume,

but not extend the combustion chamber past the front edge of the gasket fire ring,

as that usually causes gasket failure

http://garage.grumpysperformance.com/index.php?threads/ccing-my-heads.14187/

http://garage.grumpysperformance.com/index.php?threads/iron-vs-aluminum-heads.389/#post-31684

http://garage.grumpysperformance.co...r-piston-dome-or-port-volume.2077/#post-60554

you might be amazed at how much material can be removed ,

too noticeably increase air-flow and un-shroud the valves,

and how little it might effectively change,

the combustion chamber volume and compression.

laying a head gasket on the head and use machinist blue dye to show the areas inside the gasket fire-ring

http://www.skygeek.com/dymon-8000-s...MI8vPS24jm1gIVBolpCh2pnAoWEAQYAiABEgL2ZPD_BwE

Brand Fel-Pro

Manufacturer's Part Number Q8180PT2

Part Type Head Gaskets

Product Line Fel-Pro Head Gaskets

Summit Racing Part Number FEL-8180PT-2

Bore (in) 4.370 in.

Bore (mm) 110.998mm

Gasket Material PermaTorqueMLS

Compressed Thickness (in) 0.039 in.

Compressed Volume (cc) 9.700cc

Lock Wire No

Quantity Sold individually.

According to summits apps page

The gasket your have fits

http://www.summitracing.com/parts/FP...ET&prefilter=1

Make CHEVROLET

Engine Type V8

Liter 6.5

CID 396

Engine Size 6.5L/396

Beginning Year 1966

Ending Year 1970

Engine Family Chevy big block Mark IV

Make CHEVROLET

Engine Type V8

Liter 6.6

CID 402

Engine Size 6.6L/402

Beginning Year 1970

Ending Year 1972

Engine Family Chevy big block Mark IV

Make CHEVROLET

Engine Type V8

Liter 7.4

CID 454

Engine Size 7.4L/454

Beginning Year 1970

Ending Year 1990

Engine Family Chevy big block Mark IV

http://www.superchevy.com/how-to/en...-big-block-casting-changes-through-the-years/

it may be the result of a crack in the head or block or just an intake or head gasket leaking, issue, as stated change oil and filter ,

and if the problem returns you darn sure better track down the source before repairs get exponentially more expensive

some cracks won,t leak until the engine heat of the engine thats been running for awhile expands the metal.

if its not up too operating temp, theres no leak.

its not un-common for intake gaskets to leak coolant,

into the lifter gallery if they were not correctly installed or damaged, or intake manifolds to leak coolant,

if the coolant passages are corroded or improperly machined,

or too find coolant leaks if the wrong head gaskets were used.

Quote:

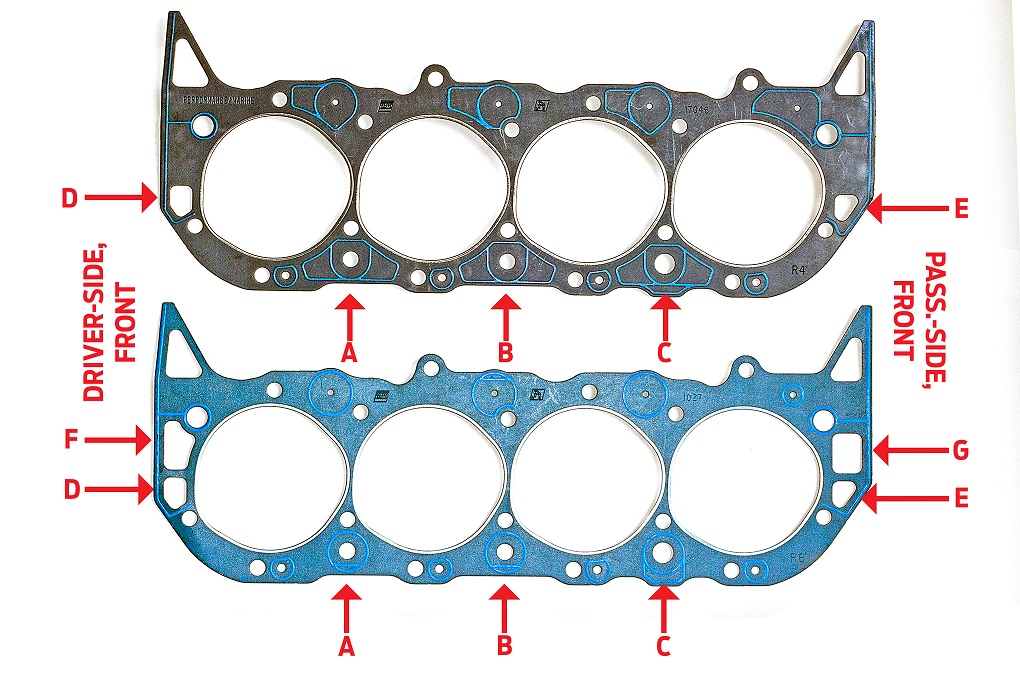

Coolant Routing Mk IV/Gen 5/Gen 6

There are two different ways that coolant can be routed through the engine: series flow and parallel flow. Both ways work just fine. There may be a slight preference for parallel flow, but it is not a big deal. Series flow has the water exiting the water pump, flowing through the block to the rear, it then transfers through the head gasket and into the cylinder head through two large passages on each cylinder bank at the rear of the block. The coolant then travels from the rear of the head, forward to the front of the head, into the intake manifold water passage and out past the thermostat and thermostat housing. The water cools the block first, then it cools the head. The coldest water (coming out of the water pump) is directly below the hottest water (having already picked up the heat of the block and the head) as the hot water transfers into the intake manifold. By contrast, parallel flow has the water exiting from the water pump into the block, where a portion "geysers" up into the head between the first and second cylinder, another portion "geysers" up to the head between the second and third cylinders, another portion geysers up to the head between the third and fourth cylinder, and the remainder transfers to the head at the rear of the block. The coolant temperature inside the engine is more even that way. The differences in coolant routing is having (or not having) the three additional coolant transfer holes in each block deck, and three matching holes in the head gasket. The heads have passages for either system, and are not different based on coolant flow.

Be aware that gaskets that DO have the three extra holes between the cylinders often have restricted coolant flow at the rear--instead of having two large coolant transfer holes at the rear, there is only one, and it's the smaller of the two holes that remains. This is important because if you use a parallel flow head gasket on a series flow block, you can have massive overheating and there's NOTHING that will cure the problem except to replace the head gaskets with ones that don't restrict flow at the rear of the block, or to drill the block decks to allow the coolant to flow into the head between the cylinders. Here's why they can overheat: A series-flow block doesn't have the openings between the cylinders, no coolant can flow up to the head there. The gasket may only have the single, smaller opening at the rear, so the amount of water that gets through that opening is greatly reduced from what the block designers intended. The result is that the coolant flow through the engine is only a fraction of what is needed.

Most, but NOT all Mk IV engines are Series Flow. ALL Gen 5 and Gen 6 engines are Parallel Flow. A series flow block can be converted to parallel flow by drilling 3 holes in each deck surface, and then use parallel flow head gaskets. You can use the parallel flow gaskets as templates for locating the additional holes. It's really easy: Put the parallel flow gaskets on the block, mark the location and size of the three extra holes. Remove the gasket. Grab a 1/2" drill and a drill bit of the correct size, and pop the extra holes in the block. There is NO modification needed on the head castings. Some blocks have one of the holes already, but it needs to be ground oblong to properly match the gasket. Again, very easy with a hand held die grinder and rotary file.

I'd assume the intake gaskets are the source until proven otherwise.

but be aware that miss matched head gaskets, to the heads and block combo in use, can cause several issues

don,t assume the worst, just logically and step by step track down and correct the issue using FACTS.

The Gen V was first installed in the 1991 year models.

The earliest casting I've decoded was a very late (Nov/Dec?) 1989 date.

The Gen VI was first installed in the 1996 year models.

The cams for the Mark IV and Gen V are interchangable for flat tappet lifters.

The Gen VI where the first equiped with Roller Lifters, but the main difference is the machined flats on the lifter bores of this block - you can still install an earlier cam without rollers.

The cam retainer plate holes are verticle on a Gen V~VI, rotated 90deg from the Mark IV's horizontal orientation.

The '91 on trucks with Gen V's had manual transmissions and use a bracket for the pivot, the later medium duty trucks have a hydraulic clutch.

The Gen blocks use longer main cap bolts than the Mark blocks.

The crank on the Gen engines uses one long key in the keyway slot for the cam drive gear and the damper - the Mark cranks have two short keyway slots and two seperate keys, one for the cam gear one for the damper.

As he stated, Gen cranks are one-piece seal, Mark are two-piece.

The Flex plates are interchangeable - but Flywheels, for truck and marine applications, are not interchangeable on Mark and Gen engines.

FAILING TO READ THE LINKS WOULD BE A BIG MISTAKE HERE!

http://www.chevydiy.com/gaskets-fasteners-guide-big-block-chevy-engines/

http://www.superchevy.com/how-to/4567-chevrolet-big-block-engine-generations/

http://hotrodenginetech.com/top-10-reasons-to-build-gen-vi-based-big-blocks/

http://garage.grumpysperformance.co...-brief-big-block-chevy-history.951/#post-5878