brad.arcova

Member

Is an air gap manifold a good choice for a street driven cruiser?

Read through A LOT of the threads and links on this topic. Generally, all the publications love the air gap manifolds. On one of the other sites though, there's a lot of bad mouthing of air gap main for street use. Not sure what to believe. None of the magazines want to offend their advertisers so I don't completely trust them. On the other hand, I suspect some the loud voices on the forums are actually no smarter than I am so I don't trust them completely either.

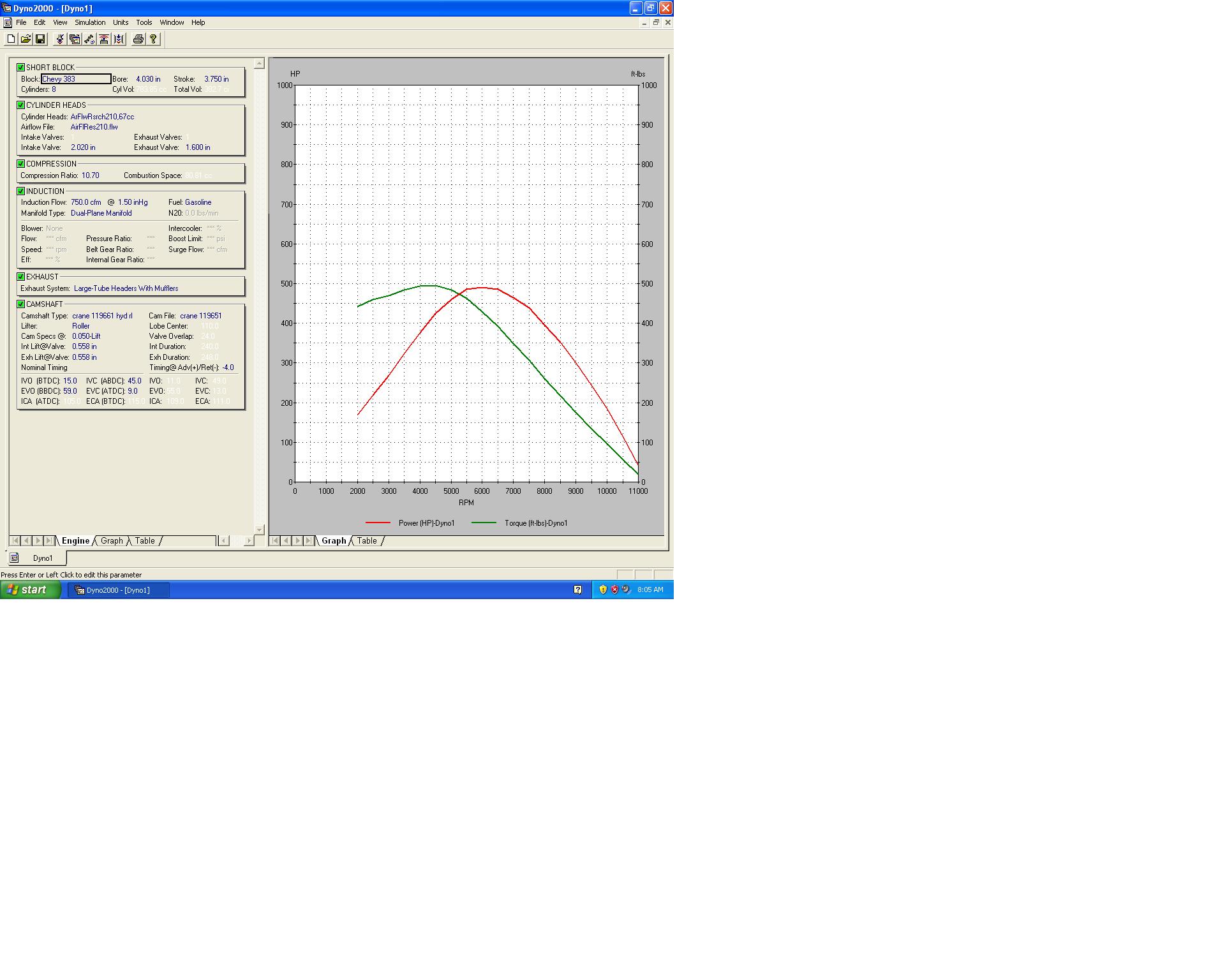

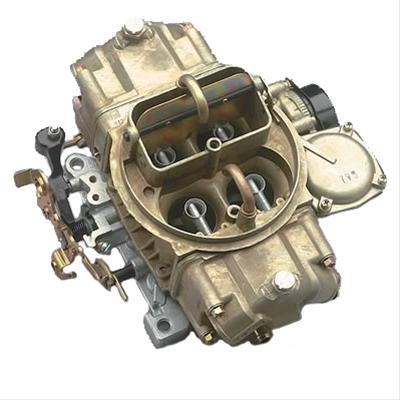

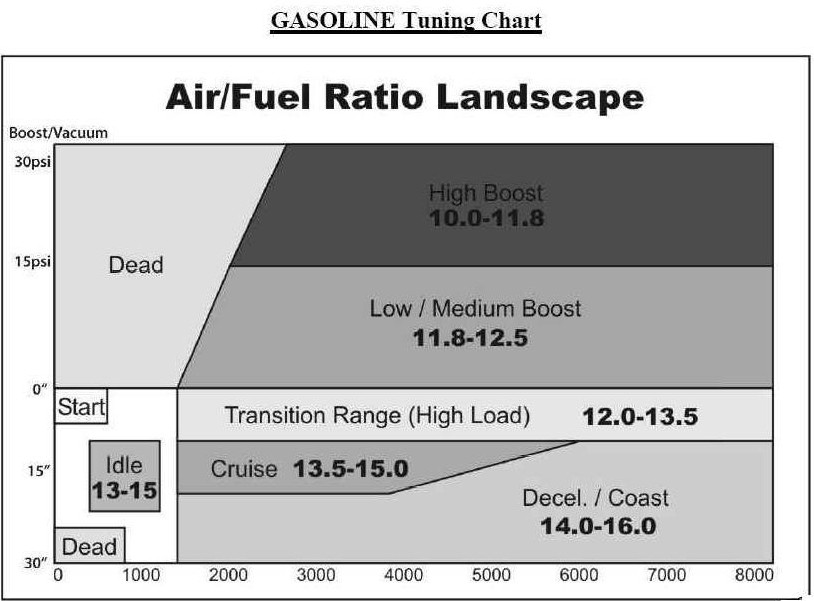

This seems like a nice quiet place with smart people, so, is an air gap manifold a good choice for a street driven cruiser? Naturally I'm concerned about my own vehicle, a 3500 lb car with a 383, an air gap, a 234/244 cam, a 670 Holley street avenger, a manual trans and a 3.36 rear end. It's a little undercarbed for maximum performance but I really don't care about peak horsepower; I just love that torque from 2000 -4000 rpm. Struggling to get it set up, it seems to be running lean, based on plugs, even after going up 4 jet sizes, but I have a couple of things to check on before considering that the air gap manifold is a problem.

Thanks,

Brad

Read through A LOT of the threads and links on this topic. Generally, all the publications love the air gap manifolds. On one of the other sites though, there's a lot of bad mouthing of air gap main for street use. Not sure what to believe. None of the magazines want to offend their advertisers so I don't completely trust them. On the other hand, I suspect some the loud voices on the forums are actually no smarter than I am so I don't trust them completely either.

This seems like a nice quiet place with smart people, so, is an air gap manifold a good choice for a street driven cruiser? Naturally I'm concerned about my own vehicle, a 3500 lb car with a 383, an air gap, a 234/244 cam, a 670 Holley street avenger, a manual trans and a 3.36 rear end. It's a little undercarbed for maximum performance but I really don't care about peak horsepower; I just love that torque from 2000 -4000 rpm. Struggling to get it set up, it seems to be running lean, based on plugs, even after going up 4 jet sizes, but I have a couple of things to check on before considering that the air gap manifold is a problem.

Thanks,

Brad