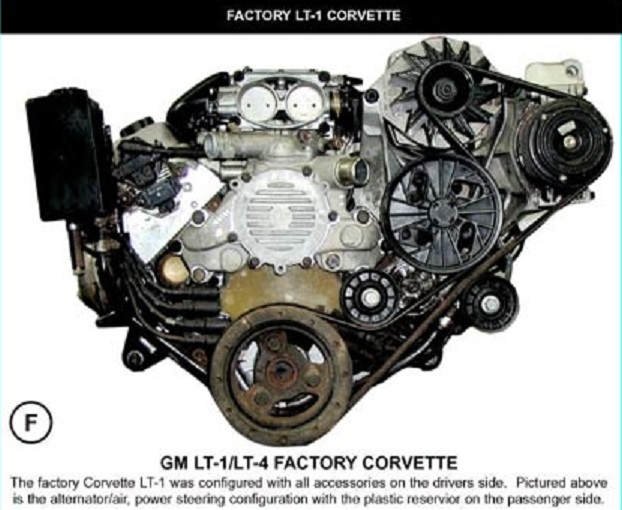

put in a pulley that replaces the air pump. less drag against the engines output,gain a few usable hp

http://www.zip-corvette.com/Zip/dept.asp?dept_id=526

http://www.tpis.com/index.php?module=2_23_08

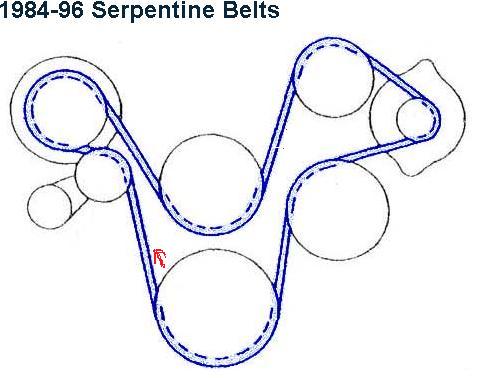

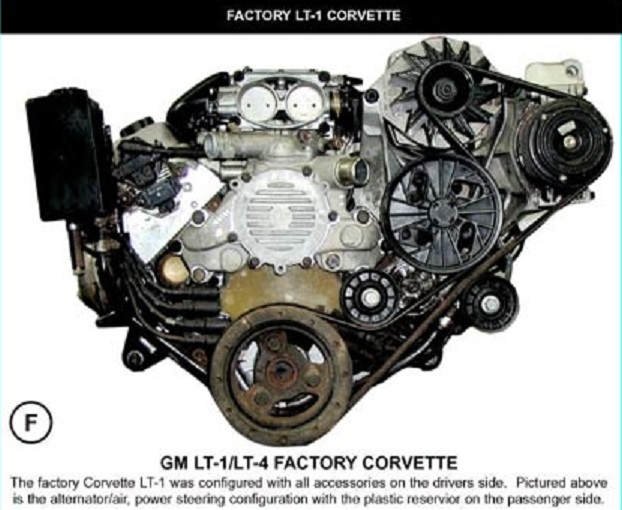

looks like this:

They're $150

http://www.mamotorworks.com/corvette?frame=3.842

you can buy one and thats a valid option,

but you can purchase the idler pulley that's used to replace the air pump in the belt routing for about $20,

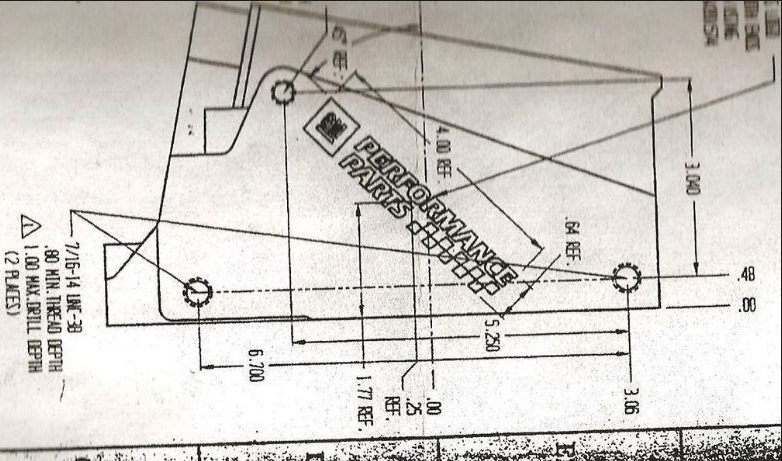

or get one from a salvage yard for UNDER $10 , take a few careful measurements and use the WELDER YOU SHOULD HAVE IN YOUR SHOP to fabricate a very effective clone for well under $30

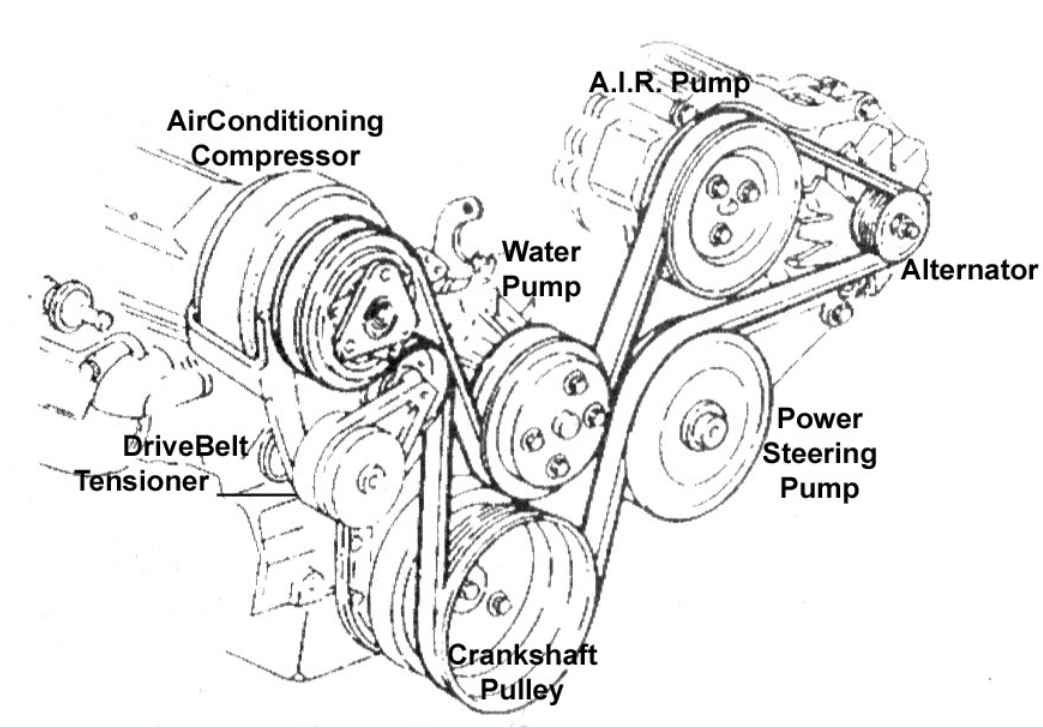

I MEAN ,COME ON GUYS!!! LOW TECH! easy project you can build with a welder and hand tools in under a couple hours , the secret to fabricating one is mocking up the, measurements , belt tension and belt alignment BEFORE you start welding, USE THE STANDARD BELT WHILE MOCKING IT UP TO INSURE YOU'LL HAVE ZERO PROBLEMS FINDING THE CORRECT LENGTH BELT, I used several different components, in building several of these over the years, the only tools you really need are a drill press,and a decent welder and a pipe cutter while not mandatory is handy , some careful planing and measuring helps and yes it helps to have an adjustable length brace to the alternator, to vary the belt tension as a secondary tension device

WELDERS AND THINKING things thru carefully ARE ALMOST MANDATORY in a shop

it does not take long for a DECENT welder too MORE than recover its up front costs in savings in a shop!

you'll save $100 plus on this one project, I can,t tell you how handy a decent welder in the shop is! :mrgreen:

GOOD for most jobs in the shop

http://www.welders-direct.com/merchant2 ... ode=907312

SLIGHTLY BETTER

http://www.welders-direct.com/merchant2 ... ode=907324

PROBABLY OVERKILL, BUT I LOVE MINE

http://www.welders-direct.com/merchant2 ... ode=907321

just as a point of interest, its not all that difficult to fabricate an adjustable belt tension arm on the air pump eliminator and a coaster wheel bracket for serpentine belt drives, or to get one from a salvage yard

that can be modified to fit and work correctly, keep in mind you can work in steel cheaper and easier than aluminum, but either will work and once its built and tested you can powder coat the brackets to give that custom look

BTW obviously having a lathe and milling machine would make this a total no brainer but I built several with only a drill press and oxy-acetolene torch, and a hack saw, and a belt sander so its not a high tech deal...............don,t forget powder coating it does give it that custom look, if the brackets all match the car colors

viewtopic.php?f=62&t=1519&p=3482&hilit=+powder#p3482

these can come in handy at times

http://www.vxb.com/page/bearings/PROD/HR/Kit214

https://shop.advanceautoparts.com/p...VnLjACh0SZwr3EAQYAiABEgLuaPD_BwE&gclsrc=aw.ds

https://www.summitracing.com/parts/...MI2NXypK-54gIVGrjACh3BUAwiEAYYAyABEgI3gvD_BwE

http://www.zip-corvette.com/Zip/dept.asp?dept_id=526

http://www.tpis.com/index.php?module=2_23_08

looks like this:

They're $150

http://www.mamotorworks.com/corvette?frame=3.842

you can buy one and thats a valid option,

but you can purchase the idler pulley that's used to replace the air pump in the belt routing for about $20,

or get one from a salvage yard for UNDER $10 , take a few careful measurements and use the WELDER YOU SHOULD HAVE IN YOUR SHOP to fabricate a very effective clone for well under $30

I MEAN ,COME ON GUYS!!! LOW TECH! easy project you can build with a welder and hand tools in under a couple hours , the secret to fabricating one is mocking up the, measurements , belt tension and belt alignment BEFORE you start welding, USE THE STANDARD BELT WHILE MOCKING IT UP TO INSURE YOU'LL HAVE ZERO PROBLEMS FINDING THE CORRECT LENGTH BELT, I used several different components, in building several of these over the years, the only tools you really need are a drill press,and a decent welder and a pipe cutter while not mandatory is handy , some careful planing and measuring helps and yes it helps to have an adjustable length brace to the alternator, to vary the belt tension as a secondary tension device

WELDERS AND THINKING things thru carefully ARE ALMOST MANDATORY in a shop

it does not take long for a DECENT welder too MORE than recover its up front costs in savings in a shop!

you'll save $100 plus on this one project, I can,t tell you how handy a decent welder in the shop is! :mrgreen:

GOOD for most jobs in the shop

http://www.welders-direct.com/merchant2 ... ode=907312

SLIGHTLY BETTER

http://www.welders-direct.com/merchant2 ... ode=907324

PROBABLY OVERKILL, BUT I LOVE MINE

http://www.welders-direct.com/merchant2 ... ode=907321

just as a point of interest, its not all that difficult to fabricate an adjustable belt tension arm on the air pump eliminator and a coaster wheel bracket for serpentine belt drives, or to get one from a salvage yard

that can be modified to fit and work correctly, keep in mind you can work in steel cheaper and easier than aluminum, but either will work and once its built and tested you can powder coat the brackets to give that custom look

BTW obviously having a lathe and milling machine would make this a total no brainer but I built several with only a drill press and oxy-acetolene torch, and a hack saw, and a belt sander so its not a high tech deal...............don,t forget powder coating it does give it that custom look, if the brackets all match the car colors

viewtopic.php?f=62&t=1519&p=3482&hilit=+powder#p3482

these can come in handy at times

http://www.vxb.com/page/bearings/PROD/HR/Kit214

https://shop.advanceautoparts.com/p...VnLjACh0SZwr3EAQYAiABEgLuaPD_BwE&gclsrc=aw.ds

https://www.summitracing.com/parts/...MI2NXypK-54gIVGrjACh3BUAwiEAYYAyABEgI3gvD_BwE

Last edited by a moderator: