http://www.superchevy.com/how-to/en...206-oval-port-big-block-chevy-cylinder-heads/

Oval Port Big-Block Chevy Cylinder Heads - The Big O

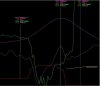

The best way to illustrate the power potential of performance cylinder heads is on the dyno.

Richard Holdener May 18, 2012

View Full Gallery

Ask a big-block enthusiast what they need to make 600 hp and chances are they will point to some sort of rectangular-port head. No one in their right mind would select an oval-port head to make that kind of power, let alone one with a diminutive 265cc intake port, right? Well, big-block fans, times have changed and so has that well-defined line between the pedestrian oval-port and rectangular-port performance heads.

Back in the day, all the factory high-performance Rat motors were sporting rectangular-port heads and the street/strip crowd followed suit. But that was then and this is now. The aftermarket has stepped up in a big way and produced oval-port heads that not only out-flow any factory rectangular-port version, but do so while dramatically reducing port volume. The combination of more flow and less port volume makes these oval-port heads a much better choice for your street/strip motor than their rectangular-port counterparts. For motors up to and even beyond 600 hp, especially small-displacement big-blocks (under 500 inches), the hot setup today is more than likely an aftermarket oval-port.

Top Searches

- Cars

- News

- 4L80e

- Lq4 Truck

- Best Cam Replacement For Ls2

- Shoestring Stroker

- Regter

With oval-port heads taking the street/strip market by storm, we decided it was a good idea to take a long hard look at them and thoroughly check out the performance potential. This meant gathering a number of different oval-port cylinder heads and putting them through their paces, both on the flow bench and the engine dyno.

First up, we needed a suitable test motor. We decided on a 0.060-over 454 equipped with a forged crank and forged rods from Procomp Electronics matched to a set of forged pistons from Probe Racing. The pistons feature an 18cc dome to help provide a streetable static compression over 10.0:1 with the 110cc chambers employed on a couple of the oval-port heads.

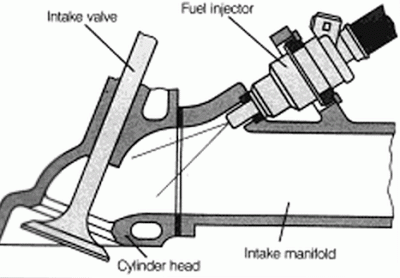

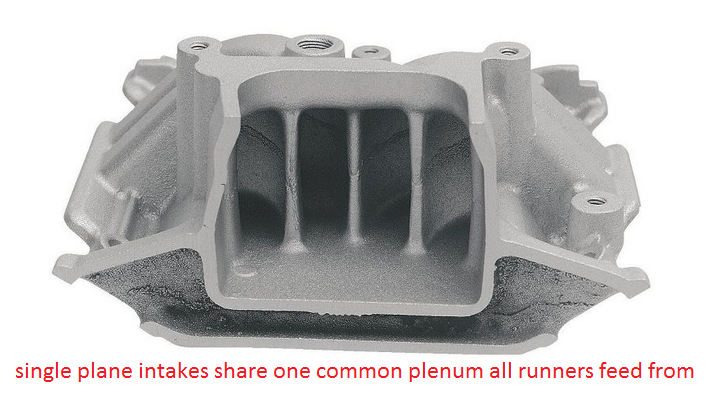

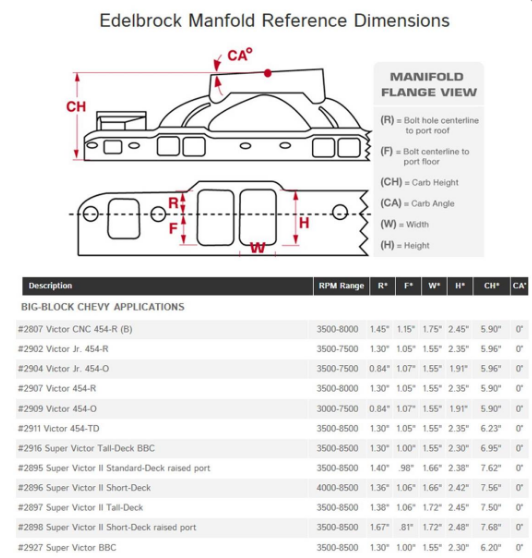

Many of these heads offered combustion chamber volumes below the 120cc range used on most rectangular-port heads. The smaller chamber (relative to factory rec-port heads) improved power by increasing the static compression--always a plus. The test motor also featured a healthy hydraulic roller cam in the form of an XR300HR from Comp Cams. It a 0.560/0.580 lift split, a 248/254 duration split, and a 110-degree LSA. All testing was run with an Edelbrock Victor Jr. intake fed by a Holley 950 HP carb.

Before being run on the engine dyno, each of the heads had to be mocked up to determine not only the appropriate pushrod length, but also the correct head bolt/stud combination. Our 2.25-inch dyno headers presented a problem for the heads equipped with stock port locations and required use of head bolts in the lower holes to provide adequate clearance. A few of the heads required different middle stud lengths, but ARP helped cure the situation. All we had to do was juggle the necessary bolts and studs to properly secure the heads. Thanks also goes out to Fel Pro for supplying the necessary head and intake gaskets for our test.

The test Rat was finished using a set of hydraulic roller lifters, timing chain, and a couple of different sets of pushrods from Comp Cams. Comp also supplied the aluminum roller rockers (1.7 ratio) for our head shootout.

The finishing touches included a Milodon oiling system, an electric water pump, and balancer from Procomp Electronics. Prior to their time on the test mill, each head was given the once over on the flow bench, then set up to measure port and chamber volumes.

The heads supplied for the test shared the oval-port configuration, but that doesn't mean they were all the same. We started with a factory oval-port head to establish a baseline, in this case the peanut-port variety. We hoped to include a traditional oval-port head as well, but it fell through at the last minute.

The heads from Dart and Procomp Electronics were as-cast with no additional machining of any kind. Heads supplied by Brodix and Trick Flow Specialties both featured port matching, but the Brodix head carried it one step further with CNC work on the combustion chamber. The AFR, Edelbrock, and 049 heads from Dr. Js all combined full porting and chamber work.

As expected, the level of work applied to the heads resulted in differences in flow and power. Take note that the combustion chamber volumes varied from 110 cc to 121 cc, resulting in a difference in static compression of 1 full point. This alone was worth 3-4 percent in power, so bear this in mind when reviewing the results.

The one upgrade we would like to see on many of the heads is more valve spring pressure. At the top of the power curve, some suffered slightly due to inadequate spring pressure.

Power and price usually go hand in hand, but check out the retail prices to determine how your favorite does in the all-important bang-for-the-buck category. Next month, we'll be testing some popular rectangular port heads on a larger-displacement Rat.

Test 1: Chevy Peanut-Port Heads

2/32

Our intention was to run a set of stock peanut-port heads and a set of stock oval-port heads, but our oval-port heads fell through. The stock peanut-port heads featured a 2.06/1.72 valve combination with 118cc combustion chambers. Closer inspection revealed that even our "stock" peanut-port heads had been milled sometime in their long life. The small valves, port volume, and flow numbers made them less than ideal with this healthy hydraulic roller cam, but they surprised us by exceeding 500 hp with peak numbers of 512 hp and 514 lb-ft of torque. Looking at the graphs, the peanut-port heads actually ran neck and neck with the aftermarket heads up to 4,500 rpm, which makes them ideal for intended low-speed truck applications. With a little porting, they make good heads for a mild street BBC, especially a small-displacement 396.

- Notes: Out-of-the box 360 castings

- Retail Price- N/A

- Intake Valve Size-2.06

- Exhaust Valve Size-1.72

- Intake port vol-253 cc

- Chamber Volume-117 cc [milled]

- Peak Power-512 @ 5,800 rpm

- Peak Torque-514 lb-ft @ 4,800 rpm

- Avg HP [3,500-6,300]-453.4 hp

- Avg TQ [3,000-6,500]-489.9 lb-ft

- Tq @ 4,000 RPM-508.5 lb-ft

Flow Data: CFM @ 28-ins

Lift In EX

.050 33 24

.100 57 51

.200 117 94

.300 185 128

.400 233 158

.500 247 179

.600 250 297

.700 250 211

3/32

Test 2: Airflow Research 265

4/32

The AFR 265 heads didnt produce the highest peak power and torque numbers of the test because of peak flow numbers. In fact, every aftermarket head we tested actually offered better flow number numbers at 0.700 lift (and many at 0.600 lift) than the AFRs. Even the ported 049 heads outflowed the AFRs at 0.700 lift, but our 0.580-lift cam never made it to 0.700 lift. Besides, power doesnt come from peak flow, it comes from maximizing flow in the usable lift range. Since the valve must open up to the maximum lift value, then close down, it spends twice as much time in the rest of the lift range as it does at the peak. Using the additional mid-lift flow offered by the AFR 265s, the 468 BBC produced 613 hp and 559 lb-ft of torque. The spring package provided by AFR allowed the hydraulic roller motor to rev cleanly to 6,500 rpm. In terms of average power production from 3,500 rpm to 6,300 rpm, the AFR 265s produced 501 hp and 536 lb-ft of torque, while knocking down 520 lb-ft at 4,000 rpm.

- Notes: Fully ported, chambers worked

- Retail Price- $2,238

- Intake Valve Size-2.19

- Exhaust Valve Size-1.88

- Intake port vol-266 cc

- Chamber Volume-112 cc

- Peak Power-612 hp @ 6,400 rpm

- Peak Torque-559 lb-ft @ 5,300 rpm

- Avg HP [3,500-6,500]-501 hp

- Avg TQ [3,500-6,500]-536 lb-ft

- Tq @ 4,000 RPM-520.3 lb-ft

Flow Data: CFM @ 28-ins

Lift In EX

.050 37 30

.100 73 63

.200 164 141

.300 241 196

.400 298 239

.500 332 260

.600 331 273

.700 316 280

5/32

Test 3: Brodix Race Rite Oval 270

6/32

The Brodix Race Rite oval-port heads featured 270cc intake ports that flowed just shy of 340 cfm--enough to support nearly 700 hp on the right application. Obviously, our mild combination could not take full advantage of what the Brodix heads had to offer, but they performed exceptionally well on the 468 nonetheless. Unlike the AFR or Edelbrock offerings, the Brodix Race Rite heads relied on CNC porting only in the combustion chamber. The intake ports received a minor gasket match, but the cutter was not allowed to do any serious work. The lack of CNC porting didnt seem to hurt the flow rates, as the intake and exhaust ports of the Brodix heads flowed 336 cfm and 270 cfm, respectively. This allowed the Brodix-headed 468 to produce 591 hp and 553 lb-ft of torque. The BBC averaged 492 hp and 528 lb-ft of torque while thumping out 512.8 lb-ft at 4,000 rpm.

- Notes: CNC'd comb. chambers, intake ports

- Retail Price- $2,796

- Intake Valve Size-2.25

- Exhaust Valve Size-1.88

- Intake port vol-269 cc

- Chamber Volume-111 cc

- Peak Power-591 hp @ 6,100 rpm

- Peak Torque-553 lb-ft @ 5,100 rpm

- Avg HP [3,500-6,500]-492.7 hp

- Avg TQ [3,500-6,500]-528 lb-ft

- Tq @ 4,000 RPM-512.8 lb-ft

Flow Data: CFM @ 28-ins

Lift In EX

.050 34 30

.100 69 64

.200 149 127

.300 220 163

.400 275 193

.500 315 225

.600 336 254

.700 333 270

7/32

Test 4: Dart Pro 1 270 Oval-Port

8/32

The Pro 1 name from Dart has always meant power and this new 270 oval port cast was no exception. The Pro 1 was one of only two full as-cast heads to be tested. All others featured some sort of CNC porting, chamber work, or port matching. Obviously the designers were earning their money, as despite the virgin aluminum, the as-cast Dart Pro 1 offered impressive flow numbers. It's always easier to improve the flow with porting, but getting the results from a casting takes real talent. With enough airflow to easily support our test motor, the Dart-headed BBC produced 593 hp and 554 lb-ft of torque. The 111cc combustion chamber makes the Dart Pro 1 a perfect candidate for head swapping on a 7.4L truck motor. Yank a wrecking yard mule, stuff in a cam, and ditch the peanut ports in favor of a set of Dart oval ports and you have one serious street motor. The smaller chambers on the Dart head (compared to a typical 119cc chamber on peanut-ports) add both flow and compression to further increase power. The Dart Pro 1s showed the power of oval ports by averaging 494 hp and 529 lb-ft of torque and offering 509 lb-ft of torque at 4,000 rpm.

- Notes: Totally unported, as-cast

- Retail Price- $2,995

- Intake Valve Size-2.25

- Exhaust Valve Size-1.88

- Intake port vol-274 cc

- Chamber Volume-111 cc

- Peak Power-593 hp @ 6,100 rpm

- Peak Torque-554 lb-ft @ 5,300 rpm

- Avg HP [3,500-6,500]-494.0 hp

- Avg TQ [3,500-6,500]-529.0 lb-ft

- Tq @ 4,000 RPM-509.8 lb-ft

Flow Data: CFM @ 28-ins

Lift In EX

.050 36 34

.100 71 69

.200 158 117

.300 235 159

.400 290 204

.500 323 234

.600 324 252

.700 325 267

9/32

Test 5: Dr. J's Ported 049 Oval

10/32

Popularity, availability, and cost all make a factory oval-port head appealing. Because so many enthusiasts not only have heads, but decided to massage them, we opted to include a set of ported 049s in this test. The factory 049 heads came from Dr. J's and were treated to their typical valve upgrade, full porting, and even a slight milling to get the chamber volume down to 118 cc. It is all but impossible to get the chamber size down to the 110cc range offered by the aftermarket heads, but the flow numbers were certainly right in the ballpark. The drop in compression caused by the larger chamber volume hurt power slightly through the entire rev range, but the ported 049s demonstrated why so many BBC owners insist on porting the stock stuff.

Equipped with the Dr. J heads, the 468 produced 576 hp and 538 lb-ft of torque. Torque production exceeded 515 lb-ft from 4,500 rpm to 5,800 rpm, while the BBC averaged 481 hp and 515.8 lb-ft of torque. Down at 4,000 rpm, the iron-headed big-block produced 504.7 lb-ft of torque. The one problem with iron heads is obviously the weight.

- Notes: Reworked factory heads

- Retail Price- $1,599 (porting customer-supplied castings)

- Intake Valve Size-2.25

- Exhaust Valve Size-1.88

- Intake port vol-267 cc

- Chamber Volume-118 cc

- Peak Power-576 hp @ 6,000 rpm

- Peak Torque-538 lb-ft @ 5,100 rpm

- Avg HP [3,500-6,500]-481.4 hp

- Avg TQ [3,500-6,500]-515.8 lb-ft

- Tq @ 4,000 RPM-504.7 lb-ft

Lift In EX

.050 33 34

.100 73 71

.200 152 120

.300 228 162

.400 282 188

.500 320 215

.600 336 238

.700 329 246

11/32

Test 6: Edelbrock RPM Xtreme

12/32

The name Edelbrock has been around since the dawn of hot rodding, but it still has a few tricks up its collective sleeve. Case in point: Its RPM Xtreme heads, which offered the highest peak airflow of any of the heads we tested. Unfortunately, our test Rat, or more specifically our cam choice, was not able to capitalize on the available airflow, as it occurred at 0.700 lift, though the RPM Xtreme heads flowed nearly as much at 0.600 lift. These heads featured CNC porting through the intake, exhaust, and combustion chamber, and the power numbers reflected the extra work. Only the Edelbrock and AFR heads allowed the 468 to exceed 600 hp, as the Edelbrock-headed BBC produced 601 hp and 552 lb-ft of torque. The average power numbers also reflected the port work, with average horsepower and torque checking in at 498.2 hp and 524.1 lb-ft, respectively. Down at 4,000 rpm, the Edelbrock heads managed 514.9 lb-ft of torque and averaged over 515 lb-ft from 4,100 rpm to 6,100 rpm.

- Notes: CNC porting throughout

- Retail Price- $2,597 (porting customer-supplied castings)

- Intake Valve Size-2.25

- Exhaust Valve Size-1.88

- Intake port vol-303 cc

- Chamber Volume-111 cc

- Peak Power-601 hp @ 6,200 rpm

- Peak Torque-552 lb-ft @ 5,300 rpm

- Avg HP [3,500-6,500]-498.2 hp

- Avg TQ [3,500-6,500]-524.1 lb-ft

- Tq @ 4,000 RPM-514.9 lb-ft

Flow Data: CFM @ 28-ins

Lift In EX

.050 35 29

.100 63 61

.200 133 125

.300 210 186

.400 280 225

.500 327 257

.600 351 277

.700 353 285

13/32

Test 7: Procomp Electronics

14/32

Procomp Electronics has made its name by providing affordable performance. Its BBC oval-port heads qualify on both counts, as the as-cast aluminum heads maximized airflow and minimized cost. The second of the true as-cast heads, the oval-ports from Procomp Electronics featured no porting or CNC chambers and instead relied on the as-cast port shape to maximize flow. With a peak flow number of 346 cfm, the Procomp Electronics casts had plenty of potential, but they were hampered by the largest combustion chamber of the group. The 121cc chambers dropped the static compression 1 full point compared to the other competitors. If each point is indeed worth an extra 3-4 percent in power, a comparable compression ratio would put these heads right in the hunt in terms of power. But equipped with the 121cc heads, the 468 produced 555 hp and 527 lb-ft of torque. Since compression hurts power everywhere, the average numbers dropped to 471.1 hp and 506.1 lb-ft of torque. Though down on power, Procomp Electronics should have no trouble selling these at a retail price of just over $1,000 a pair.

- Notes: As cast, no porting

- Retail Price- $1,095 (with spring upgrade)

- Intake Valve Size-2.25

- Exhaust Valve Size-1.88

- Intake port vol-311 cc

- Chamber Volume-121 cc

- Peak Power-555 hp @ 6,200 rpm

- Peak Torque-557 lb-ft @ 5,200 rpm

- Avg HP [3,000-6,500]-471.1 hp

- Avg TQ [3,000-6,500]-506.2 lb-ft

- Tq @ 4,000 RPM-507.6 lb-ft

Flow Data: CFM @ 28-ins

Lift In EX

.050 36 29

.100 77 61

.200 140 126

.300 214 174

.400 276 210

.500 314 241

.600 331 264

.700 346 284

15/32

Test 8: Trick Flow Specialities 280

16/32

When talk turns to performance cylinder heads, naturally Trick Flow Specialties has to be included. It stepped up for this test with a set of its PowerOval 280s. As indicated by the name, the PowerOvals combined 280cc intake ports with a 2.19/1.88 valve combination. Despite choosing the smaller intake valve (2.19 vs. 2.25), the PowerOval heads offered plenty of flow. Though the heads featured as-cast ports and chambers, the intake port did receive a minor port match. Even without the aide of CNC porting, the PowerOval heads offered flow numbers of 337 cfm on the intake and 261 cfm on the exhaust. These flow numbers translated into a peak power output of 576 hp and 544 lb-ft. The PowerOval heads offered a broad torque curve, bettering 515 lb-ft from 3,800 rpm to 5,700 rpm. In terms of average numbers, the TFS heads produced 485.7 hp and 521.7 lb-ft of torque and managed 517.8 lb-ft of torque at 4,000 rpm. The PowerOvals are affordably priced at under $2,000 assembled and ready to run.

- Notes: As cast no ports and chambers

- Retail Price- $1,849 (with spring upgrade)

- Intake Valve Size-2.19

- Exhaust Valve Size-1.88

- Intake port vol-279 cc

- Chamber Volume-113 cc

- Peak Power-576 hp @ 6,100 rpm

- Peak Torque-544 lb-ft @ 5,200 rpm

- Avg HP [3,500-6,500]-485.7 hp

- Avg TQ [3,500-6,500]-521.7 lb-ft

- Tq @ 4,000 RPM-517.8 lb-ft

Flow Data: CFM @ 28-ins

Lift In EX

.050 32 30

.100 67 62

.200 143 122

.300 212 160

.400 266 189

.500 302 221

.600 328 244

.700 337 261

17/32

Sources