I get asked every few months about why I don,t use aluminum connecting rods in my nitrous engine builds like some guys do?

well lets look at it a bit!

why run aluminum connecting rods?

well The answer always given is that it makes the rotating assembly lighter weight so it can accelerate or gain rpms much faster

aluminum's lighter in weight but its not as strong and its got a far lower fatigue strength, or put a different way, a connecting rod made from aluminum must be made significantly larger to have equal strength, to a forged 4340 steel rod, so even though the materials lighter in weight your needing to use more material so theres not as great of a weight savings as you might at first suspect, and a larger rod requires a good deal more clearance work on the block and oil pan used.

youll generally find the aluminum rods REQUIRE use of aftermarket blocks and oil pans in many applications to get the required clearances if your building a 496-572 big block stroker

lets assume we want to build a 496 big block stroker, the 6.385" rods we use differ a great deal

aluminum rod generally should be replaced after 50 -60 hard runs, at the track, because stress is cumulative and aluminum will eventually fatigue and fail, steel rods can generally take 4-6 times that abuse if your running on thee ragged edge of the strength limitations of the steel connecting rods before replacement is a good idea, but if your running a 1500hp rated rod at lets say a 800hp-1000hp level they may last many years in most cases

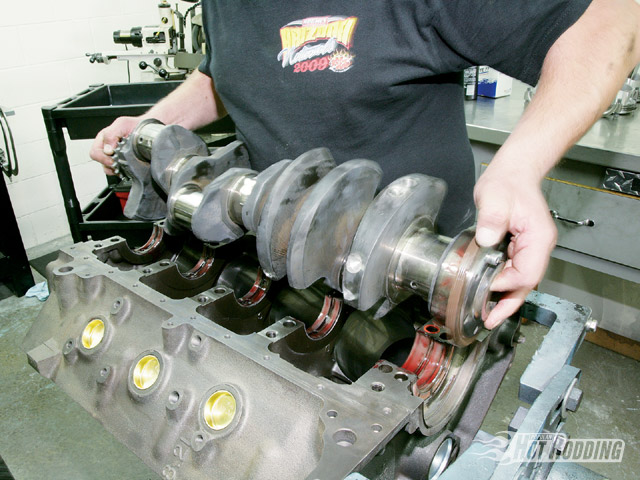

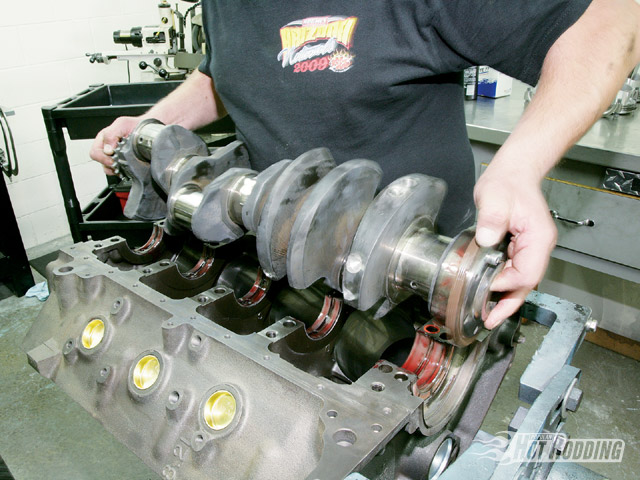

if you take the time youll find a decent big block stroker crank , weights between 57lbs and 63 lbs in many cases

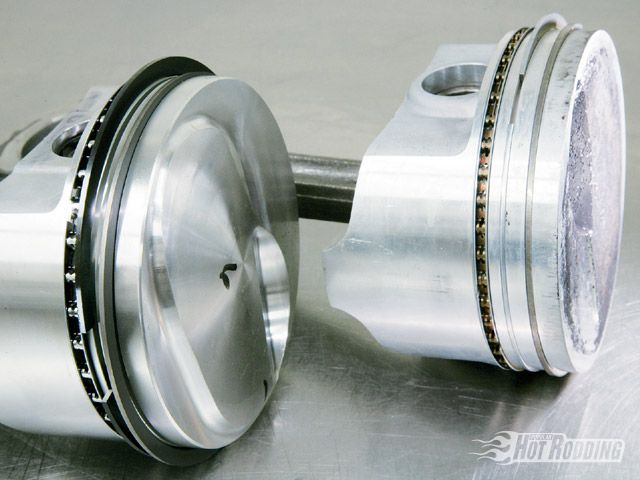

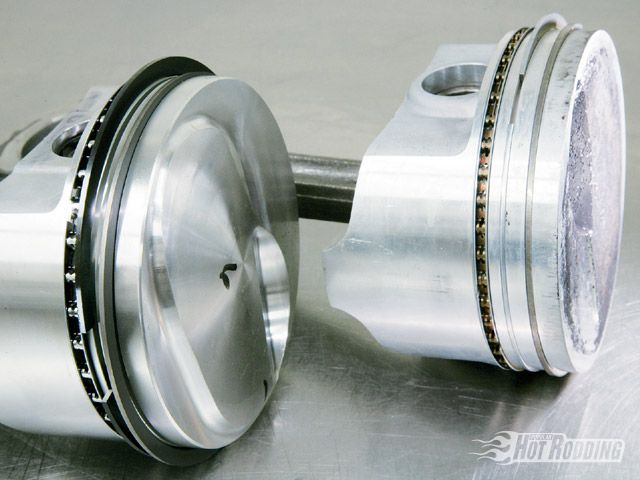

a light weight damper may weight 7-12 lbs, a flex plate 3-5 lbs a clutch and flywheel easily weight 40-50 lbs, piston and pin lets say 730 grams each or about 13 lbs per set

so lets say the average light stroker rotating assembly weights

http://www.cnc-motorsports.com/product. ... CtgID=7493

http://www.cnc-motorsports.com/product. ... 825&CtgID=

http://www.cnc-motorsports.com/product. ... tgID=33013

http://www.kb-silvolite.com/icon/icon.p ... s&P_id=622

a good 1500hp rated steel rod about 785 grams cost about $500-$800

or about 14 lbs per set with bearings

a semi comparable aluminum nitrous rod 676 grams cost $1100-$1500)

or about 12 lbs per set with bearings

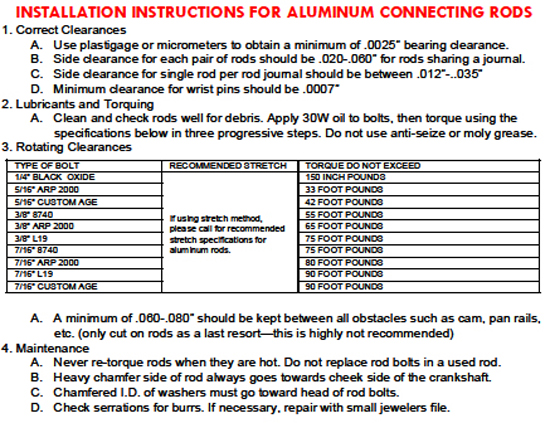

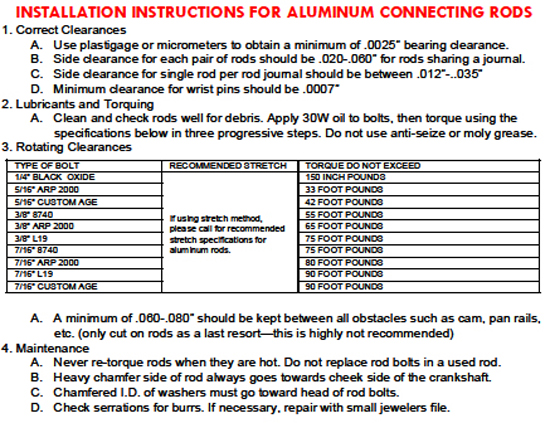

and aluminum rods stretch a good deal more under high rpms, while .044-.048 is generally a good quench distance on a steel rod BBC a aluminum rod will generally require a .080-.087 range due to iit getting longer at high rpms to prevent it contacting the heads

so swapping to aluminum rods reduced the rotating assembly by 2 lbs,

lets see thats

57lbs for the crank

13 lbs for pistons

12 lbs for rods

lets be kind and say 20 lbs for flex-plate, damper pulleys , or close to 100 lbs rotating in the block , you could add 20 more lbs minimum for a flywheel and clutch, so youve reduce the weight 2%-3%, but then remember the only time you can apply power your by definition spinning a total drive train weight and trying to accelerate the total car weight, the weight reduction is all but meaningless in anything over 3000 lbs

example

http://www.summitracing.com/parts/ESP-63853DL19/

READ THRU THE LINKED INFO

http://www.bmeltd.com/pdf_files/rod%20p ... 282%29.pdf

http://www.bmeltd.com/rods.htm

http://www.manleyperformance.com/dl/tec ... uminum.pdf

http://www.manleyperformance.com/pdfs/0 ... 03-134.pdf

well lets look at it a bit!

why run aluminum connecting rods?

well The answer always given is that it makes the rotating assembly lighter weight so it can accelerate or gain rpms much faster

aluminum's lighter in weight but its not as strong and its got a far lower fatigue strength, or put a different way, a connecting rod made from aluminum must be made significantly larger to have equal strength, to a forged 4340 steel rod, so even though the materials lighter in weight your needing to use more material so theres not as great of a weight savings as you might at first suspect, and a larger rod requires a good deal more clearance work on the block and oil pan used.

youll generally find the aluminum rods REQUIRE use of aftermarket blocks and oil pans in many applications to get the required clearances if your building a 496-572 big block stroker

lets assume we want to build a 496 big block stroker, the 6.385" rods we use differ a great deal

aluminum rod generally should be replaced after 50 -60 hard runs, at the track, because stress is cumulative and aluminum will eventually fatigue and fail, steel rods can generally take 4-6 times that abuse if your running on thee ragged edge of the strength limitations of the steel connecting rods before replacement is a good idea, but if your running a 1500hp rated rod at lets say a 800hp-1000hp level they may last many years in most cases

if you take the time youll find a decent big block stroker crank , weights between 57lbs and 63 lbs in many cases

a light weight damper may weight 7-12 lbs, a flex plate 3-5 lbs a clutch and flywheel easily weight 40-50 lbs, piston and pin lets say 730 grams each or about 13 lbs per set

so lets say the average light stroker rotating assembly weights

http://www.cnc-motorsports.com/product. ... CtgID=7493

http://www.cnc-motorsports.com/product. ... 825&CtgID=

http://www.cnc-motorsports.com/product. ... tgID=33013

http://www.kb-silvolite.com/icon/icon.p ... s&P_id=622

a good 1500hp rated steel rod about 785 grams cost about $500-$800

or about 14 lbs per set with bearings

a semi comparable aluminum nitrous rod 676 grams cost $1100-$1500)

or about 12 lbs per set with bearings

and aluminum rods stretch a good deal more under high rpms, while .044-.048 is generally a good quench distance on a steel rod BBC a aluminum rod will generally require a .080-.087 range due to iit getting longer at high rpms to prevent it contacting the heads

so swapping to aluminum rods reduced the rotating assembly by 2 lbs,

lets see thats

57lbs for the crank

13 lbs for pistons

12 lbs for rods

lets be kind and say 20 lbs for flex-plate, damper pulleys , or close to 100 lbs rotating in the block , you could add 20 more lbs minimum for a flywheel and clutch, so youve reduce the weight 2%-3%, but then remember the only time you can apply power your by definition spinning a total drive train weight and trying to accelerate the total car weight, the weight reduction is all but meaningless in anything over 3000 lbs

example

http://www.summitracing.com/parts/ESP-63853DL19/

READ THRU THE LINKED INFO

http://www.bmeltd.com/pdf_files/rod%20p ... 282%29.pdf

http://www.bmeltd.com/rods.htm

http://www.manleyperformance.com/dl/tec ... uminum.pdf

http://www.manleyperformance.com/pdfs/0 ... 03-134.pdf