Loves302Chevy

"One test is worth a thousand expert opinions."

Let's all get involved with this one, but please, explain why you made the choice you made.

(CRANE CAMS USED TO SUPPLY MANY G.M.PERFORMANCE CAMS,

Chevrolet Performance LT4 Hot Cam Hydraulic Roller Camshafts 24502586

this is no longer true and QUALITY has dropped off noticeably by who ever is currently supplying the cams)

This could prove interesting. The engine...... a .030 over rebuilt gutless wonder 1980 267 SB Chevy.

Background..... 25 years ago, a friend gave me this SBC that he thought was a 350. It had a 4 bbl intake on it and a Thermoquad 800 cfm carb. And he also gave me the home-made engine stand it was on that is now my engine test stand. I took the engine apart and measured it up and found it was a 267. It was also obvious that whoever did the machine work, and whoever put this thing together, were 2 different people. The machine work itself was decent (cylinder boring & honing & crankshaft grinding & polishing), except for the resizing of the connecting rods - the big ends were tapered, or conical. I don't know how someone could even manage to do this. The person who put the engine together didn't have a clue what he was doing. When I rolled the block over on the engine stand, it sounded like there were marbles within the water jackets. That was the old freeze plugs that they just knocked inside and left them there. But it did have new pistons & rings and bearings.

At the time I was working at an auto machine shop. So I cleaned the parts up and had the connecting rods properly resized. The heads needed work. I put new guides in and machined them for PC valve seals. With the 3.5" bore of this engine, the heads have tiny valves, I believe 1.72 IN & 1.5 EX. How to HotRod Small Block Chevys says, "the 1.72" intake and 1.38" exhaust valves were carried over from the ill-fated '75-'76 262 cid V8", but I swear mine are 1.5. I bought new intake valves and ground the exhausts. Then somewhere I got the bright idea of porting these heads to give this anemic little engine some help. But with valves that small, even gravel road rough ports could not be restrictive. I should have left well enough alone. Between the porting and trying to grind the seats, and then there was going to be resurfacing..... I threw them in the dumpster. But I got lucky. GM had 7 bare heads at dealers around the country just collecting dust that they were dying to get rid of. If I remember correctly, I got 1 head for about $100. and the other for about $150. This time, the grinders stayed in the toolbox, and I just put them together without the exhaust valve rotators (retainers & oil shedders only), and with new springs to match the new camshaft.

So I managed to get it all back together (properly assembled) with new bearings and gaskets, new steel chain & gears timing set, blueprinted the oil pump, and gave it a Weiand Action Plus #8004 intake manifold and a Carter #9504 500 cfm electric choke emissions calibrated carb. For a camshaft, I just wanted to give it something a little more than stock, so I went with a copy of an Edelbrock Performer bumpstick. So far, so good, right? Read on.

The 267 has the same stroke as a 350, but supposedly because of the smaller & much lighter pistons, the crank's counterweights are smaller. There are no part numbers that would identify it differently than a 350 crank. And I was not going to balance this engine. Either that was the correct crank, or the balance was going to be waaaay off.

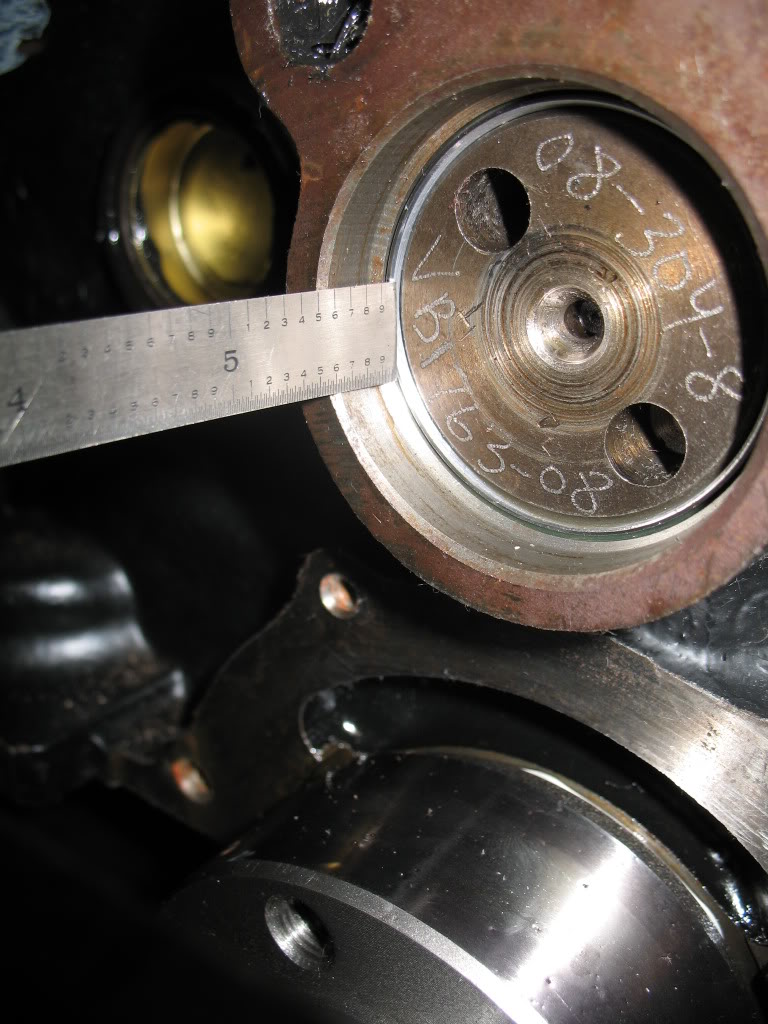

I wanted a way to test this engine when it was done to see if it was going to shake itself apart. That is when I began to modify the engine stand and turn it into an engine test stand, which I am still using today.

Skipping to the end, I fired it up and it ran..... really good. Even my father liked the way this engine ran. He has nothing good to say about anything. With just a flexplate on the back of the crank, it revs to 6400 rpm with good oil pressure and vacuum and a near stock smooth idle.

I still have this engine sitting in the basement. Years ago, I was going to put it into a Chevy Monza, but my car got rear-ended on the highway during my last semester of college - totalled. Too bad, because I already had everything I needed to do it as I had a 350 in there in the past. It was the first engine I built when I still didn't know anything. It was a home basement rebuild (stock) with an Edelbrock Torquer cam & lifters. What did I know? Torquer sounded smaller than Performer. NOT - big cams and low compression don't get along too well. After 7 months, I put the IronDuke Pontiac 151 (essentially a 302 SBC split down the middle with a HYD cam) back in. Then I thought about putting the 267 in a Jeep, but the cost of the conversion was out of my budget. So it still sits in the basement.

3.50 in bore family (1979-1982)

The 267 was introduced in 1979 for GM F-Body (Camaro), G-bodies (Chevrolet Monte Carlo, El Camino, and Malibu Classic) and also used on GM B-body cars (Impala and Caprice models). The 267 cu in (4.4 L) had the 350's crankshaft stroke of 3.48" and the smallest bore of any small-block, 3.500 in. The 3.500" bore was also used on the 200 cu in (3.3 L) V6, which was introduced a year earlier. (The 200 was a Chevrolet V6 engine based on the small block with the #3 and #6 cylinders removed). It was available with a Rochester Dualjet 210 - effectively a Rochester Quadrajet with no rear barrels. After 1980, electronic feedback carburetion was used on the 267. The 267 also saw use in 1980 to 1982 Checker Marathons.

While similar in displacement to the other 4.3-4.4 L V8 engines produced by General Motors (including the Oldsmobile 260 and Pontiac 265, the small bore 267 shared no parts with the other engines and was phased out after the 1982 model year due to inability to conform to emission standards. Chevrolet vehicles eventually used the 305 cu in (5 L) as its base V8 engine.

1979 - 125@3800 215@2400 8.5, 1980 - 120@3600 215@2000 8.3, 81-82 - 115@4000 200@2400 8.3

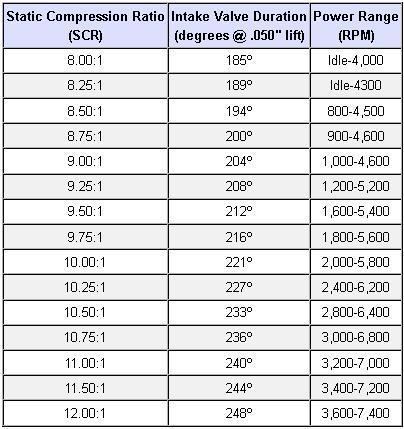

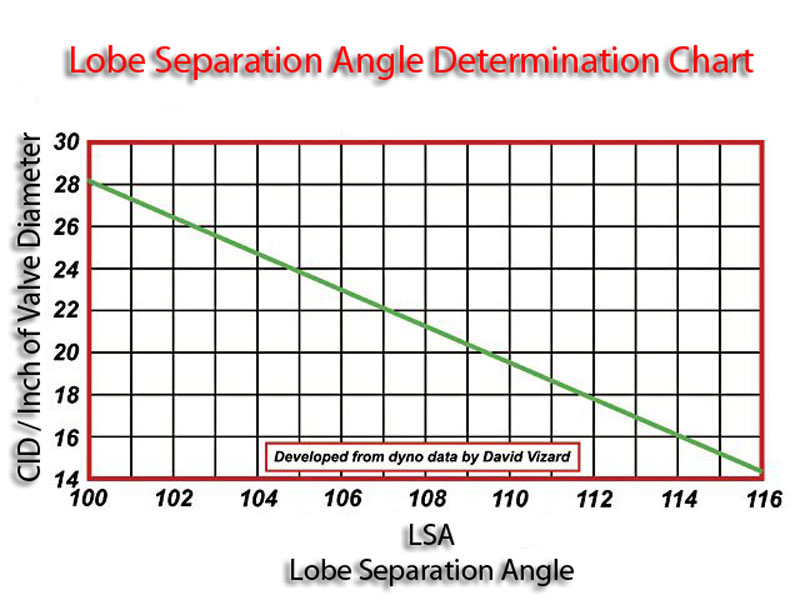

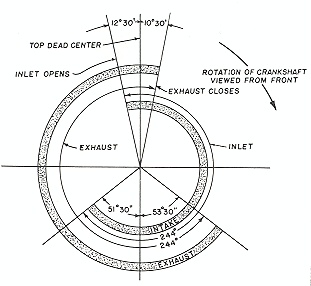

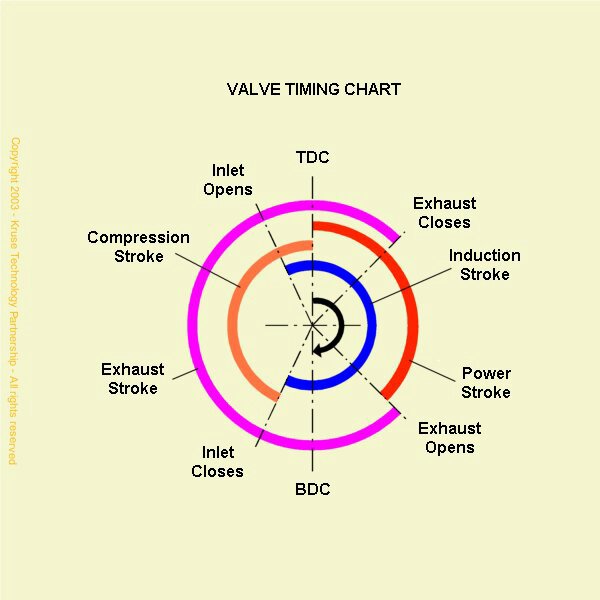

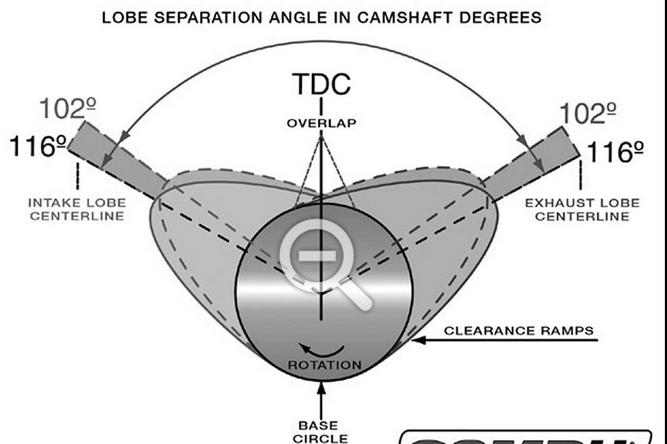

All of this happened before anyone knew anything about Dynamic Compression Ratio - DCR. Now for the fun part. Lately I have been looking back at my engine build records/notes and entering them into Rick's DCR calculator. After looking up the numbers for the camshaft I have in there (278/288 adv duration, .420/.442 lift(1.5), .448/.471(1.6), 204/214 duration at .050", 107 117 lobe centers 112 centerline, idle - 5500 rpm), the seat-to-seat numbers are these: Edelbrock 2102 1500-5500 0.420/0.442 Seat-To-Seat IVO 32.0 IVC 66.0 EVO 81.0 EVC 27.0 112 LSA 5 adv 59 OL 278/288 adv duration.

Rick's DCR calculator says 8.54 SCR, 6.80 DCR, and 131.87 Cranking Pressure. I'm worried about that LOW 6.80 DCR.

To get it up to around 7.5, the camshaft would have to have an IVC of about 50 degrees. I found a website that lists the old-school camshafts, with their specs: http://www.osorracing.com/cams/Chevy_Smallblock/ChevySB_279.htm

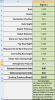

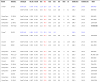

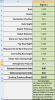

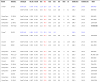

It took many hours, but I copied the HYD FT cams from the very smallest TOWING cam up to the Performer copy that is in there now and put them into a list. They are arranged by the IVC angle from smallest to largest. Use Wordpad to view, page setup to Landscape, and .25" margins.

OOPS, this site won't allow a .rtf file to be uploaded. So here are pictures instead:

Example: Crane 10003 21.0 59.0 61.0 19.0 >>> Wallace 25.0 55.0 65.0 15.0 IVC is 4 degrees less.

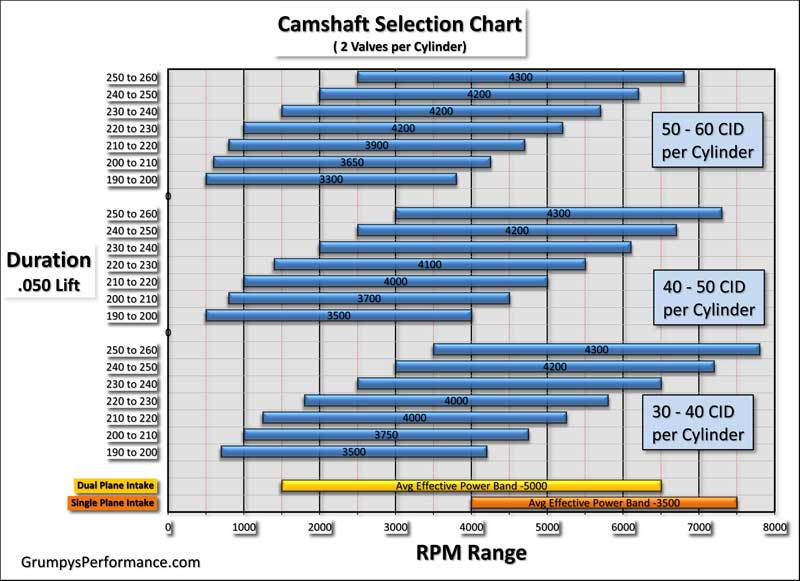

For those who want to participate, let's choose a new camshaft. We will assume an 80-82 Chevy Malibu, TH-350, 3.23 rear gears, & 26" tall tires.

Also assume that there is no restriction from the exhaust system. I'm thinking 1000-5000 rpm range.

There are a few Comp Cams that look pretty good to me, let's see what you come up with.

I know, Comp sucks, but I'm just looking at numbers right now.

Also, looking back at my build notes, I calculate that I'm dangerously close to coil bind, because I used 1.6 rockers, trying to compensate for the small valves with more lift. I will have to double-check that and my retainer-to-seal clearance, and I may have to switch to a little stiffer valve springs.

SSI #VS-380 valve springs, single with damper, 1.222 OD, .868 ID, 76.84# @ 1.700, 194# @ 1.25", and 1.15" coil bind.

I installed them at 1.700", oil shedders, pc type valve seals, stock retainers & locks, NO rotators used.

If I end up pulling the heads on this engine, I will put a 30 degree back cut on the intake valves, and do a little cleaning in the bowl areas, and just smooth out any rough stuff in the ports. NOTHING major.

Mike (Loves302Chevy)

(CRANE CAMS USED TO SUPPLY MANY G.M.PERFORMANCE CAMS,

Chevrolet Performance LT4 Hot Cam Hydraulic Roller Camshafts 24502586

this is no longer true and QUALITY has dropped off noticeably by who ever is currently supplying the cams)

This could prove interesting. The engine...... a .030 over rebuilt gutless wonder 1980 267 SB Chevy.

Background..... 25 years ago, a friend gave me this SBC that he thought was a 350. It had a 4 bbl intake on it and a Thermoquad 800 cfm carb. And he also gave me the home-made engine stand it was on that is now my engine test stand. I took the engine apart and measured it up and found it was a 267. It was also obvious that whoever did the machine work, and whoever put this thing together, were 2 different people. The machine work itself was decent (cylinder boring & honing & crankshaft grinding & polishing), except for the resizing of the connecting rods - the big ends were tapered, or conical. I don't know how someone could even manage to do this. The person who put the engine together didn't have a clue what he was doing. When I rolled the block over on the engine stand, it sounded like there were marbles within the water jackets. That was the old freeze plugs that they just knocked inside and left them there. But it did have new pistons & rings and bearings.

At the time I was working at an auto machine shop. So I cleaned the parts up and had the connecting rods properly resized. The heads needed work. I put new guides in and machined them for PC valve seals. With the 3.5" bore of this engine, the heads have tiny valves, I believe 1.72 IN & 1.5 EX. How to HotRod Small Block Chevys says, "the 1.72" intake and 1.38" exhaust valves were carried over from the ill-fated '75-'76 262 cid V8", but I swear mine are 1.5. I bought new intake valves and ground the exhausts. Then somewhere I got the bright idea of porting these heads to give this anemic little engine some help. But with valves that small, even gravel road rough ports could not be restrictive. I should have left well enough alone. Between the porting and trying to grind the seats, and then there was going to be resurfacing..... I threw them in the dumpster. But I got lucky. GM had 7 bare heads at dealers around the country just collecting dust that they were dying to get rid of. If I remember correctly, I got 1 head for about $100. and the other for about $150. This time, the grinders stayed in the toolbox, and I just put them together without the exhaust valve rotators (retainers & oil shedders only), and with new springs to match the new camshaft.

So I managed to get it all back together (properly assembled) with new bearings and gaskets, new steel chain & gears timing set, blueprinted the oil pump, and gave it a Weiand Action Plus #8004 intake manifold and a Carter #9504 500 cfm electric choke emissions calibrated carb. For a camshaft, I just wanted to give it something a little more than stock, so I went with a copy of an Edelbrock Performer bumpstick. So far, so good, right? Read on.

The 267 has the same stroke as a 350, but supposedly because of the smaller & much lighter pistons, the crank's counterweights are smaller. There are no part numbers that would identify it differently than a 350 crank. And I was not going to balance this engine. Either that was the correct crank, or the balance was going to be waaaay off.

I wanted a way to test this engine when it was done to see if it was going to shake itself apart. That is when I began to modify the engine stand and turn it into an engine test stand, which I am still using today.

Skipping to the end, I fired it up and it ran..... really good. Even my father liked the way this engine ran. He has nothing good to say about anything. With just a flexplate on the back of the crank, it revs to 6400 rpm with good oil pressure and vacuum and a near stock smooth idle.

I still have this engine sitting in the basement. Years ago, I was going to put it into a Chevy Monza, but my car got rear-ended on the highway during my last semester of college - totalled. Too bad, because I already had everything I needed to do it as I had a 350 in there in the past. It was the first engine I built when I still didn't know anything. It was a home basement rebuild (stock) with an Edelbrock Torquer cam & lifters. What did I know? Torquer sounded smaller than Performer. NOT - big cams and low compression don't get along too well. After 7 months, I put the IronDuke Pontiac 151 (essentially a 302 SBC split down the middle with a HYD cam) back in. Then I thought about putting the 267 in a Jeep, but the cost of the conversion was out of my budget. So it still sits in the basement.

3.50 in bore family (1979-1982)

The 267 was introduced in 1979 for GM F-Body (Camaro), G-bodies (Chevrolet Monte Carlo, El Camino, and Malibu Classic) and also used on GM B-body cars (Impala and Caprice models). The 267 cu in (4.4 L) had the 350's crankshaft stroke of 3.48" and the smallest bore of any small-block, 3.500 in. The 3.500" bore was also used on the 200 cu in (3.3 L) V6, which was introduced a year earlier. (The 200 was a Chevrolet V6 engine based on the small block with the #3 and #6 cylinders removed). It was available with a Rochester Dualjet 210 - effectively a Rochester Quadrajet with no rear barrels. After 1980, electronic feedback carburetion was used on the 267. The 267 also saw use in 1980 to 1982 Checker Marathons.

While similar in displacement to the other 4.3-4.4 L V8 engines produced by General Motors (including the Oldsmobile 260 and Pontiac 265, the small bore 267 shared no parts with the other engines and was phased out after the 1982 model year due to inability to conform to emission standards. Chevrolet vehicles eventually used the 305 cu in (5 L) as its base V8 engine.

1979 - 125@3800 215@2400 8.5, 1980 - 120@3600 215@2000 8.3, 81-82 - 115@4000 200@2400 8.3

All of this happened before anyone knew anything about Dynamic Compression Ratio - DCR. Now for the fun part. Lately I have been looking back at my engine build records/notes and entering them into Rick's DCR calculator. After looking up the numbers for the camshaft I have in there (278/288 adv duration, .420/.442 lift(1.5), .448/.471(1.6), 204/214 duration at .050", 107 117 lobe centers 112 centerline, idle - 5500 rpm), the seat-to-seat numbers are these: Edelbrock 2102 1500-5500 0.420/0.442 Seat-To-Seat IVO 32.0 IVC 66.0 EVO 81.0 EVC 27.0 112 LSA 5 adv 59 OL 278/288 adv duration.

Rick's DCR calculator says 8.54 SCR, 6.80 DCR, and 131.87 Cranking Pressure. I'm worried about that LOW 6.80 DCR.

To get it up to around 7.5, the camshaft would have to have an IVC of about 50 degrees. I found a website that lists the old-school camshafts, with their specs: http://www.osorracing.com/cams/Chevy_Smallblock/ChevySB_279.htm

It took many hours, but I copied the HYD FT cams from the very smallest TOWING cam up to the Performer copy that is in there now and put them into a list. They are arranged by the IVC angle from smallest to largest. Use Wordpad to view, page setup to Landscape, and .25" margins.

OOPS, this site won't allow a .rtf file to be uploaded. So here are pictures instead:

Example: Crane 10003 21.0 59.0 61.0 19.0 >>> Wallace 25.0 55.0 65.0 15.0 IVC is 4 degrees less.

For those who want to participate, let's choose a new camshaft. We will assume an 80-82 Chevy Malibu, TH-350, 3.23 rear gears, & 26" tall tires.

Also assume that there is no restriction from the exhaust system. I'm thinking 1000-5000 rpm range.

There are a few Comp Cams that look pretty good to me, let's see what you come up with.

I know, Comp sucks, but I'm just looking at numbers right now.

Also, looking back at my build notes, I calculate that I'm dangerously close to coil bind, because I used 1.6 rockers, trying to compensate for the small valves with more lift. I will have to double-check that and my retainer-to-seal clearance, and I may have to switch to a little stiffer valve springs.

SSI #VS-380 valve springs, single with damper, 1.222 OD, .868 ID, 76.84# @ 1.700, 194# @ 1.25", and 1.15" coil bind.

I installed them at 1.700", oil shedders, pc type valve seals, stock retainers & locks, NO rotators used.

If I end up pulling the heads on this engine, I will put a 30 degree back cut on the intake valves, and do a little cleaning in the bowl areas, and just smooth out any rough stuff in the ports. NOTHING major.

Mike (Loves302Chevy)

Attachments

Last edited by a moderator: