You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Another 383 build...

- Thread starter DorianL

- Start date

busterrm

solid fixture here in the forum

Just seems to work better for me! With those plugs I'd use one size of the square in the plug, if you drill the hole the right size you can drive the shaft of the easeout into the square and have better hold on the plug, and use leverage of a cresent wrench. Push and release pressure, repeat over and over till breaks loose, don't push all out, every now and then tap it with a hammer, also tap the block.

Last edited:

Loves302Chevy

"One test is worth a thousand expert opinions."

Well i tried heating with propane and spaying WD40 but I chickened out with my 1/4-inch drive. I know SnapOn has a tool for this. Like a 1/4-inch drive but heavy duty.

I'll see if I can locate one this weekend

You are trying to do as much as you can so you are not paying the machine shop.

They have all the tools and tricks for getting those stuck plugs out.

Don't invest a lot of your time and money into them - they will take care of it.

If you can't find the rear main cap, then the block will have to be align-bored. More $$$.

A wire wheel in a drill motor works fine for removing the rust. Wear a dust mask.

If they have the block cleaner that heats the block and blasts it with abrasive, then you

don't have to do anything. It will come out like brand new.

The old style Jet Cleaner is basically a dishwasher for engine parts.

They used to use Oakite for a cleaner - no more. Needless to say, they don't do as

good of a job as they used to.

You really want oxy-acetylene to rapidly heat the area around the plug (not the plug itself).

That way the surrounding area expands while the plug remains cooler.

The special square impact socket + impact gun usually gets those out alone.

Only the really stubborn ones need the extra heat.

Last edited:

busterrm

solid fixture here in the forum

If that's the case I'd buy a full set of main caps. Here's something to think about, with all the maching costs adding up, Summit sells a already prepped roller block already bored and clearanced with 1 pc rms for 700 bux. Shipping to you in Belgium, cheapest 345 bux, all machine work done for about 1050 bux.If you can't find the rear main cap, then the block will have to be align-bored. More $$$.

https://www.summitracing.com/parts/sum-150100-30/overview/

If that's the case I'd buy a full set of main caps. Here's something to think about, with all the maching costs adding up, Summit sells a already prepped roller block already bored and clearanced with 1 pc rms for 700 bux. Shipping to you in Belgium, cheapest 345 bux, all machine work done for about 1050 bux.

https://www.summitracing.com/parts/sum-150100-30/overview/

Now this is interesting... This might actually save me $$$.

So it is already over-bored 030... does it need to be honed for a perfect clearance with the over-sized 030 pistons?

It's ready to take on factory style roller cam... but how is this a saving?

With my old block, the machine shop would have to clean, align bore, deck and over-bore, yank plugs and drive out the cam bearings... somewhere along the way, I'd still need to check the block for cracks before most of the machining... haul the block around...

Hm, as romantic as it is rebuilding a block that I have had for years... I suspect that I may be way ahead getting this

busterrm

solid fixture here in the forum

what will rear main cap, core plugs, oil galley plugs, and cam bearings cost? just an idea, look at the ad, that stuff is done.Now this is interesting... This might actually save me $$$.

So it is already over-bored 030... does it need to be honed for a perfect clearance with the over-sized 030 pistons?

It's ready to take on factory style roller cam... but how is this a saving?

With my old block, the machine shop would have to clean, align bore, deck and over-bore, yank plugs and drive out the cam bearings... somewhere along the way, I'd still need to check the block for cracks before most of the machining... haul the block around...

Hm, as romantic as it is rebuilding a block that I have had for years... I suspect that I may be way ahead getting this

just check all specs on the block, we do it anyway.

busterrm

solid fixture here in the forum

Thats not really, just added bonus!It's ready to take on factory style roller cam... but how is this a saving?

Request that the block be "re-inspected" prior to shipping. You don't want a rusty block. It's honed

Request that the block be "re-inspected" prior to shipping. You don't want a rusty block. It's honed

Ah! Thanks!

http://garage.grumpysperformance.co...plate-honing-makes-a-differance.588/#post-869

http://garage.grumpysperformance.com/index.php?threads/piston-to-bore-clearance.4630/#post-48955

http://garage.grumpysperformance.com/index.php?threads/flex-hone.9538/#post-35100

http://garage.grumpysperformance.co...ing-piston-to-bore-ring-seal.3897/#post-26602

http://garage.grumpysperformance.co...block-cylinder-wall-thickness.976/#post-22976

http://garage.grumpysperformance.co...c-piston-ring-info-youll-need.509/#post-11324

http://garage.grumpysperformance.co...ring-grooves-and-related-info.1797/#post-4586

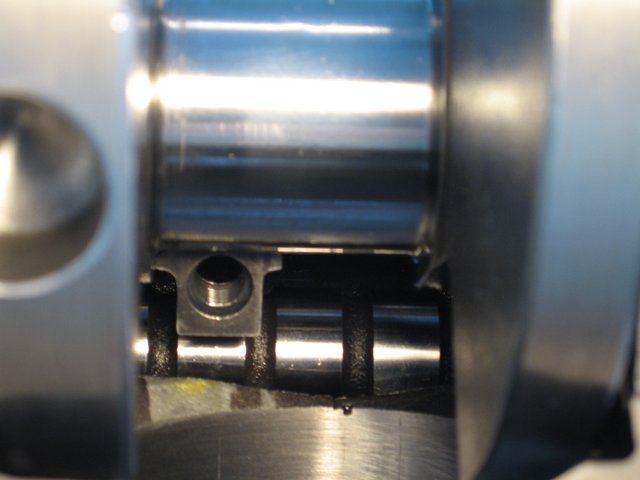

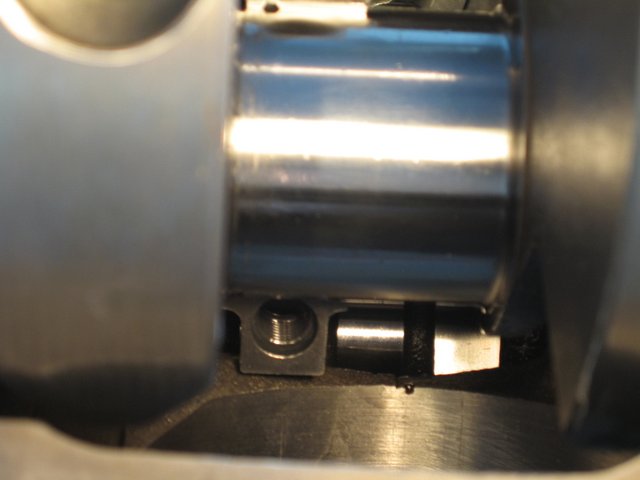

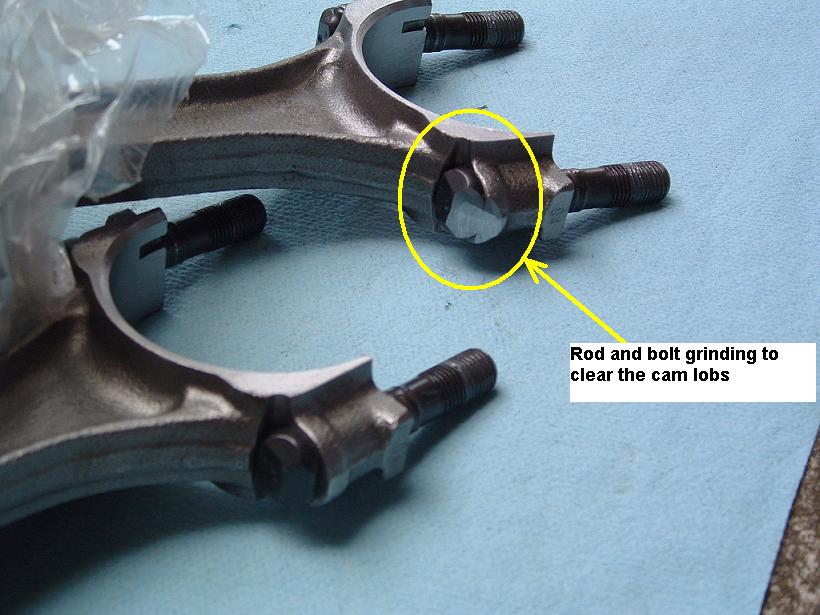

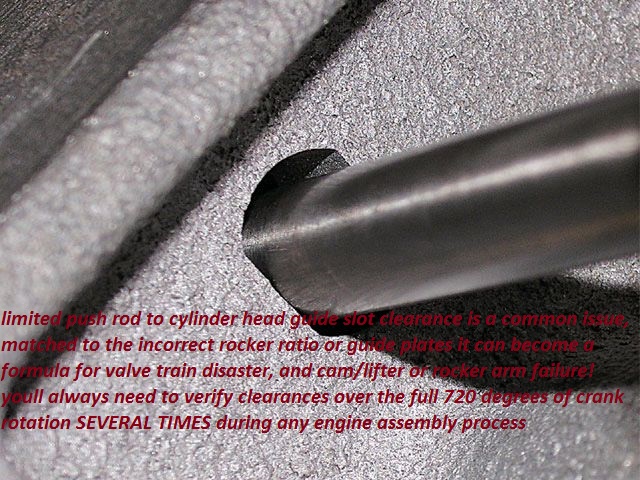

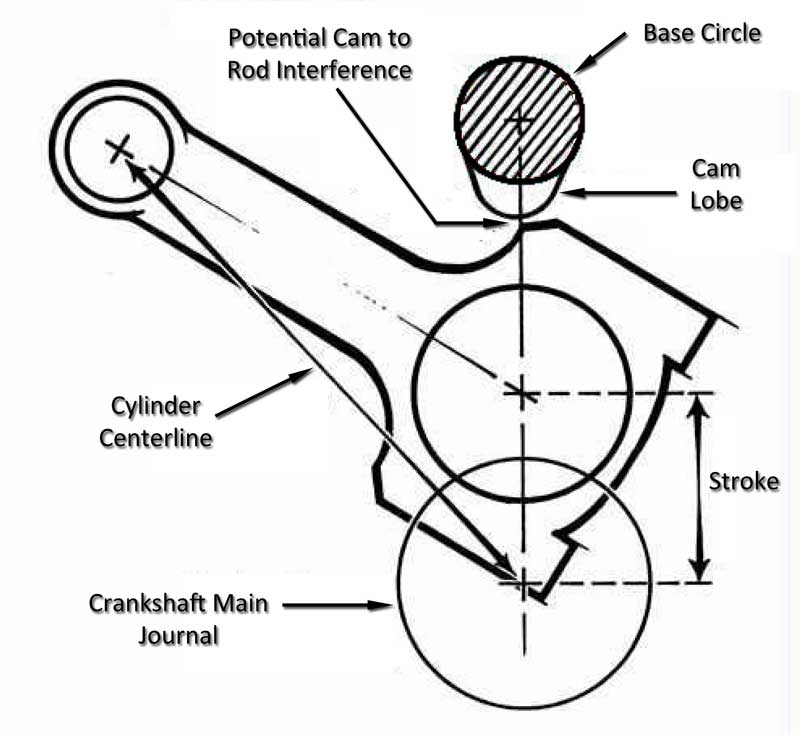

notice how the rod bolts come close to the cam bearings and cam lobes, as the pistons reach top dead canter in the bores, this clearance must be individually checked and should be no less than about .060 (generally you cam use a LARGE plastic tie-wrap, you must install the timing set and index the cam correctly to get a valid clearance , as the cam lobes rotate and at some point they can be incorrectly indexed too hit the rods, while they would not if correctly timed.

https://www.amazon.com/BuyCableTies...D=41U9CtmwOuL&preST=_SY300_QL70_&dpSrc=detail

placed between the cam lobe and connecting rod bolts or connecting rod shoulder areas to check clearances as the soft tie-wrap will not damage the cam lobe while you verify clearances)

why you need to verify the cam to rod bolt clearance

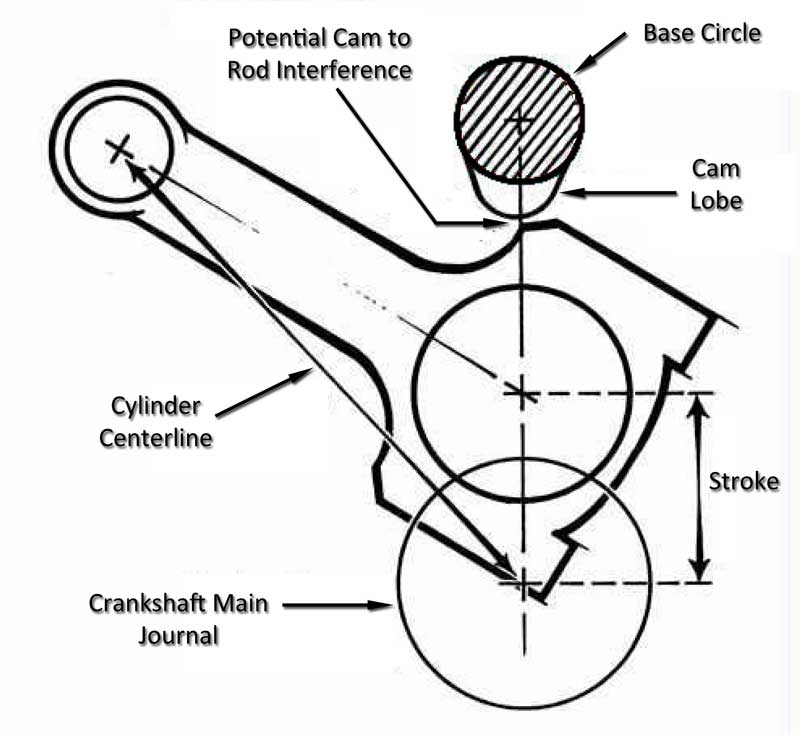

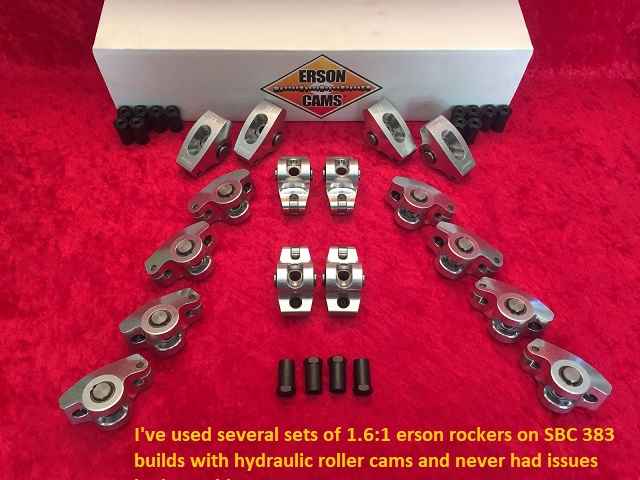

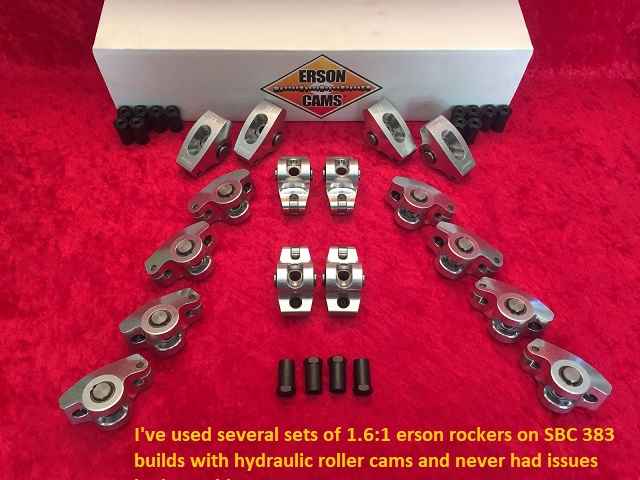

Id also use 1.6:1 roller rockers on a mild 383 SBC build in most cases

http://www.pbm-erson.com/Catalog/Erson/Camshafts/Retro_Fit Hydraulic Roller_E/ERSE119815

https://www.ebay.com/itm/Erson-Cams-803-16-SB-Chevy-Extreme-Duty-1-6-Aluminum-Roller-Rockers-7-16-Stud/173036288915?_trkparms=aid=222007&algo=SIM.MBE&ao=1&asc=20160908110712&meid=dd2ef46908f84d1994db01594e3da770&pid=100677&rk=4&rkt=8&sd=173036285468&_trksid=p2385738.c100677.m4598

rods that use bolts with nuts like pictured below will be weakened if excessively clearance ground

stroker profile rods offer more clearance to cam lobes, and yes the stroker clearanced profile rods are available in both (h) and (I ) beam designs

on some stroker applications SOME rods need to have the bolts ground for cam lobe clearance

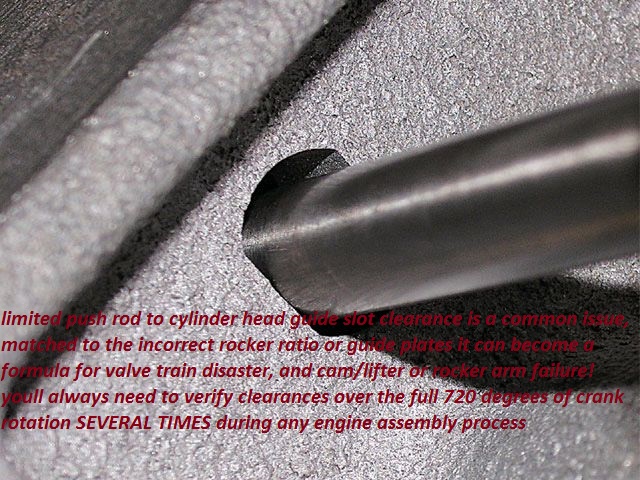

Verifying your engines clearances, and rocker geometry, and use of A rocker stud girdle and high quality roller rockers go a long way towards maintaining valve train durability

first CHEVK CLEARANCES AND GEOMETRY

the higher rocker ratio increases the effective acceleration rate of the cams lobe ramp, being transmitted to the valve so the higher ratio tends to cause valve control issues at a lower rpm level UNLESS the valve spring load rates increased to compensate. this allows a greater area of lift or open port area so the engine will tend to run better in the mid rpm range, generally making it well worth while as the mile duration cam can use the extra lift and duration at the valve.

these links contain a great deal of related & useful info

yeah I know, its a huge amount of info in the links,

and sub-links that may take you days to wade through,

but in the long run it will save you lots of time,

and prevent a ton of wasted cash.

http://garage.grumpysperformance.co...g-block-for-stroker-assembly.2855/#post-77609

http://garage.grumpysperformance.com/index.php?threads/small-base-circle-cams.3810/#post-72554

http://garage.grumpysperformance.co...ing-parts-and-a-logical-plan.7722/#post-71181

http://garage.grumpysperformance.com/index.php?threads/another-383-build.12786/page-2#post-66126

http://garage.grumpysperformance.com/index.php?threads/bits-of-383-info.38/page-2#post-61958

http://garage.grumpysperformance.co...-for-new-383-sbc-cam-instal.13109/#post-68326

http://garage.grumpysperformance.com/index.php?threads/bits-of-383-info.38/page-2#post-61958

http://garage.grumpysperformance.co...tion-of-crank-durring-short-blk-assembly.852/

http://garage.grumpysperformance.com/index.php?threads/another-rings-end-gap-question.14994/

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/

http://garage.grumpysperformance.com/index.php?threads/valve-train-clearances-and-problems.528/

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

http://garage.grumpysperformance.com/index.php?threads/piston-to-bore-clearance.4630/#post-48955

http://garage.grumpysperformance.com/index.php?threads/flex-hone.9538/#post-35100

http://garage.grumpysperformance.co...ing-piston-to-bore-ring-seal.3897/#post-26602

http://garage.grumpysperformance.co...block-cylinder-wall-thickness.976/#post-22976

http://garage.grumpysperformance.co...c-piston-ring-info-youll-need.509/#post-11324

http://garage.grumpysperformance.co...ring-grooves-and-related-info.1797/#post-4586

notice how the rod bolts come close to the cam bearings and cam lobes, as the pistons reach top dead canter in the bores, this clearance must be individually checked and should be no less than about .060 (generally you cam use a LARGE plastic tie-wrap, you must install the timing set and index the cam correctly to get a valid clearance , as the cam lobes rotate and at some point they can be incorrectly indexed too hit the rods, while they would not if correctly timed.

https://www.amazon.com/BuyCableTies...D=41U9CtmwOuL&preST=_SY300_QL70_&dpSrc=detail

placed between the cam lobe and connecting rod bolts or connecting rod shoulder areas to check clearances as the soft tie-wrap will not damage the cam lobe while you verify clearances)

why you need to verify the cam to rod bolt clearance

Id also use 1.6:1 roller rockers on a mild 383 SBC build in most cases

http://www.pbm-erson.com/Catalog/Erson/Camshafts/Retro_Fit Hydraulic Roller_E/ERSE119815

https://www.ebay.com/itm/Erson-Cams-803-16-SB-Chevy-Extreme-Duty-1-6-Aluminum-Roller-Rockers-7-16-Stud/173036288915?_trkparms=aid=222007&algo=SIM.MBE&ao=1&asc=20160908110712&meid=dd2ef46908f84d1994db01594e3da770&pid=100677&rk=4&rkt=8&sd=173036285468&_trksid=p2385738.c100677.m4598

rods that use bolts with nuts like pictured below will be weakened if excessively clearance ground

stroker profile rods offer more clearance to cam lobes, and yes the stroker clearanced profile rods are available in both (h) and (I ) beam designs

on some stroker applications SOME rods need to have the bolts ground for cam lobe clearance

Verifying your engines clearances, and rocker geometry, and use of A rocker stud girdle and high quality roller rockers go a long way towards maintaining valve train durability

first CHEVK CLEARANCES AND GEOMETRY

the higher rocker ratio increases the effective acceleration rate of the cams lobe ramp, being transmitted to the valve so the higher ratio tends to cause valve control issues at a lower rpm level UNLESS the valve spring load rates increased to compensate. this allows a greater area of lift or open port area so the engine will tend to run better in the mid rpm range, generally making it well worth while as the mile duration cam can use the extra lift and duration at the valve.

these links contain a great deal of related & useful info

yeah I know, its a huge amount of info in the links,

and sub-links that may take you days to wade through,

but in the long run it will save you lots of time,

and prevent a ton of wasted cash.

http://garage.grumpysperformance.co...g-block-for-stroker-assembly.2855/#post-77609

http://garage.grumpysperformance.com/index.php?threads/small-base-circle-cams.3810/#post-72554

http://garage.grumpysperformance.co...ing-parts-and-a-logical-plan.7722/#post-71181

http://garage.grumpysperformance.com/index.php?threads/another-383-build.12786/page-2#post-66126

http://garage.grumpysperformance.com/index.php?threads/bits-of-383-info.38/page-2#post-61958

http://garage.grumpysperformance.co...-for-new-383-sbc-cam-instal.13109/#post-68326

http://garage.grumpysperformance.com/index.php?threads/bits-of-383-info.38/page-2#post-61958

http://garage.grumpysperformance.co...tion-of-crank-durring-short-blk-assembly.852/

http://garage.grumpysperformance.com/index.php?threads/another-rings-end-gap-question.14994/

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/

http://garage.grumpysperformance.com/index.php?threads/valve-train-clearances-and-problems.528/

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

Last edited:

Loves302Chevy

"One test is worth a thousand expert opinions."

So it is already over-bored 030... does it need to be honed for a perfect clearance with the over-sized 030 pistons?

No, it is already honed. And it will work fine with .030 over pistons (you still have to measure).

Machinists usually measure each piston and finish hone the bores to each individually. Others don't.

But everything should fall within a perfectly acceptable range.

If you like the block idea, then you could also order an assembled shortblock, or a kit if you want to

put all the pieces and parts together yourself. Or you can order a longblock or even a complete engine.

It's ready to take on factory style roller cam... but how is this a saving?

The conversion to run a roller cam in a non-roller block will cost about $1000. The retro-fit lifters are expensive.

A factory roller block will save you $$$.

Busterrm is correct about having it inspected before it ships. I've seen more than a few complaints about receiving rusty blocks.

But I would not use a dingle ball hone. You can easily screw up the professional honing job if you don't know what you are doing.

Check Competition Products Broom Sheet regularly for some great deals.

http://www.competitionproducts.com/Rotating-Assemblies/products/681/

busterrm

solid fixture here in the forum

Chromebumpers suggested the inspection. I would hand hone if there is any flash rust is what I meant to say.Busterrm is correct about having it inspected before it ships. I've seen more than a few complaints about receiving rusty blocks.

But I would not use a dingle ball hone. You can easily screw up the professional honing job if you don't know what you are doing.

Loves302Chevy

"One test is worth a thousand expert opinions."

All 3 of you guys have red cars for your avatar...... and I'm getting older and easily confused. You know what I meanChromebumpers suggested the inspection. I would hand hone if there is any flash rust is what I meant to say.