this thread will contain several totally different engine builds with parts listed and when available the dyno results from the engines built,

it will be used as a guide to allow readers to compare the basic engine components , at least a bit too get a good idea as to the components selected and the expected results.

IGNORING THE LINKS AND SUB_LINKS CONTAINED IN THE THREAD,WOULD BE A HUGE MISTAKE

like with most performance parts and applications the critical part of the build,

is generally in selecting the correct components for that particular application,

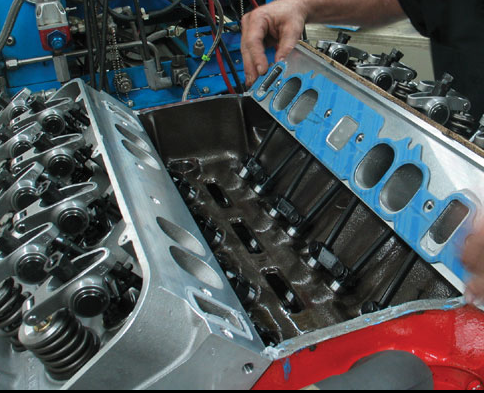

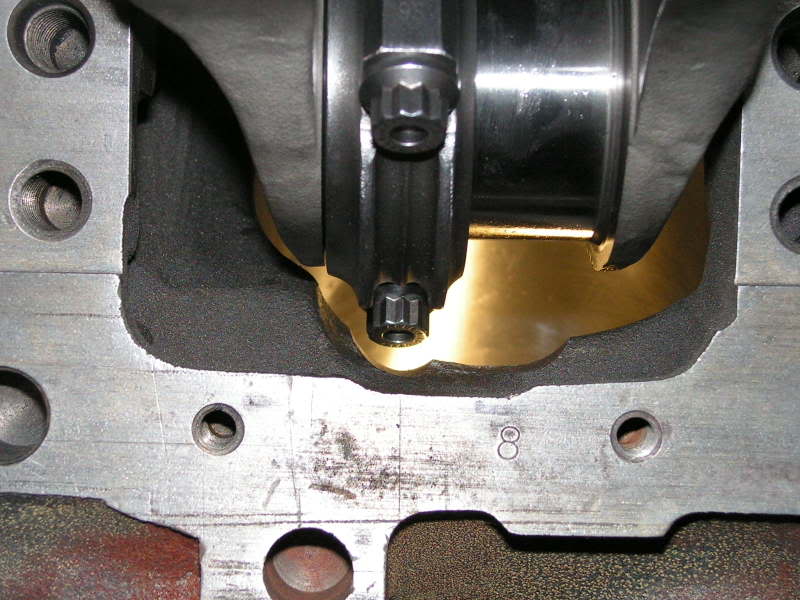

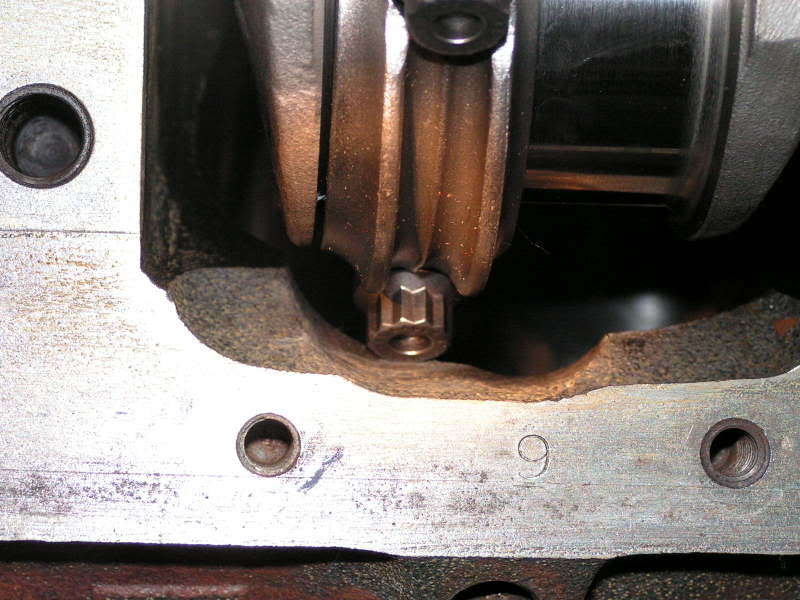

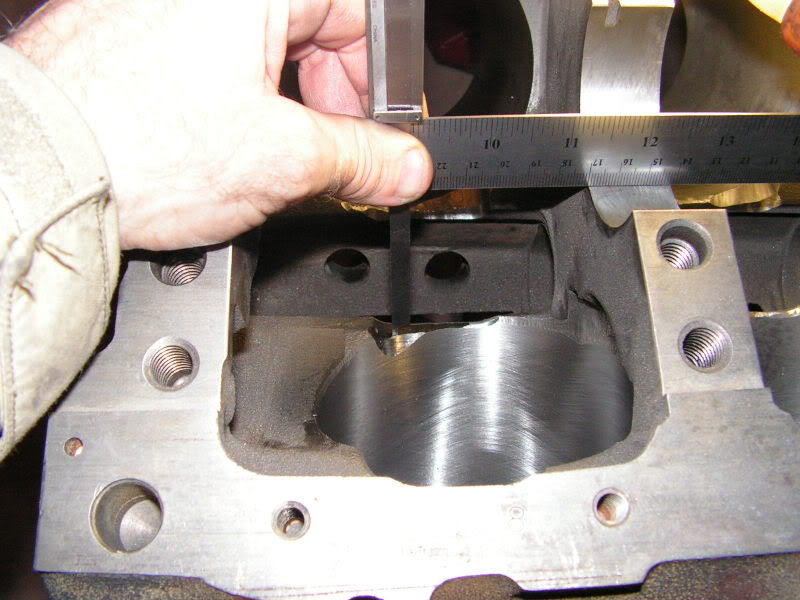

and in assembling those components correctly with the correct clearances.

its always a multi layered process,

you can't expect sub-par or weak parts to withstand the shock and torque and rpm/impact loads.

you can't also expect improperly installed or clearanced or insufficiently lubricated or cooled parts to last very long under loads.

obviously the process REQUIRES the person doing the work, or assembly to do some in depth research,

and have any tools or measuring devices that will be needed.

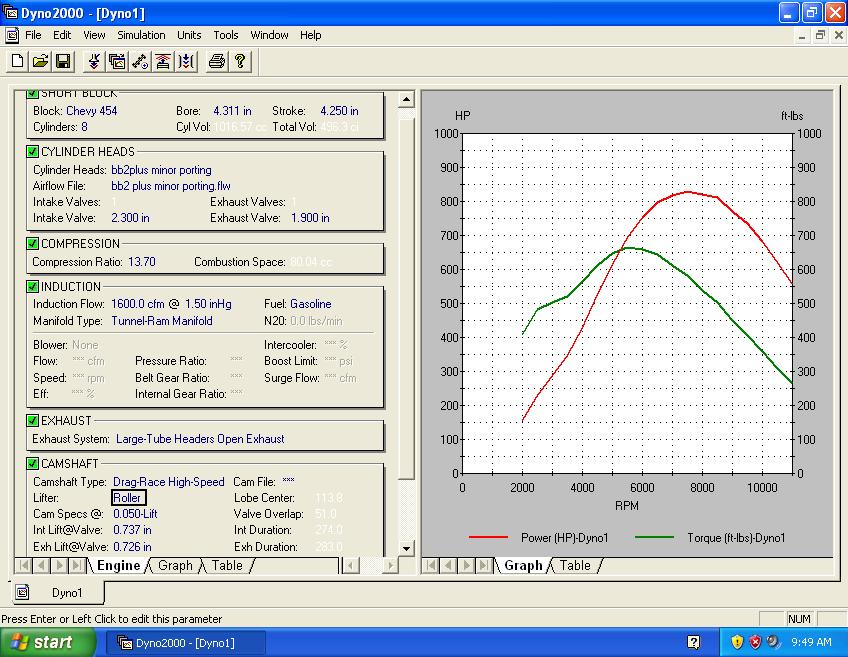

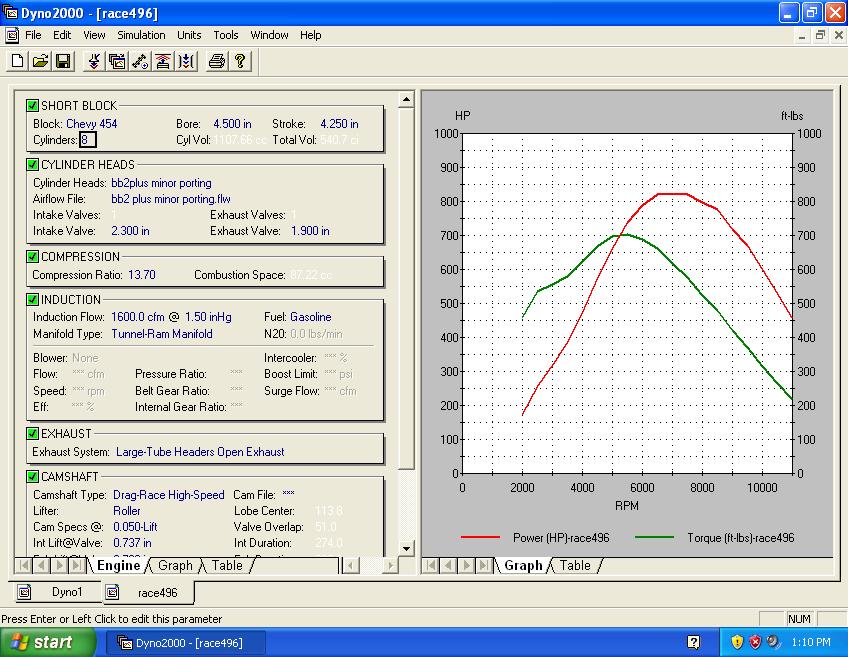

first thing Im forced to point out is theres several completely different 496 BBC engine build links, contained in this and linked related threads...

most are not designed as racing engine, those would have 12.5:1-13.7:1 compression, almost always a hydraulic or solid roller cam

and perhaps a tunnel ram intake or stack injection, maybe even super charged, etc.

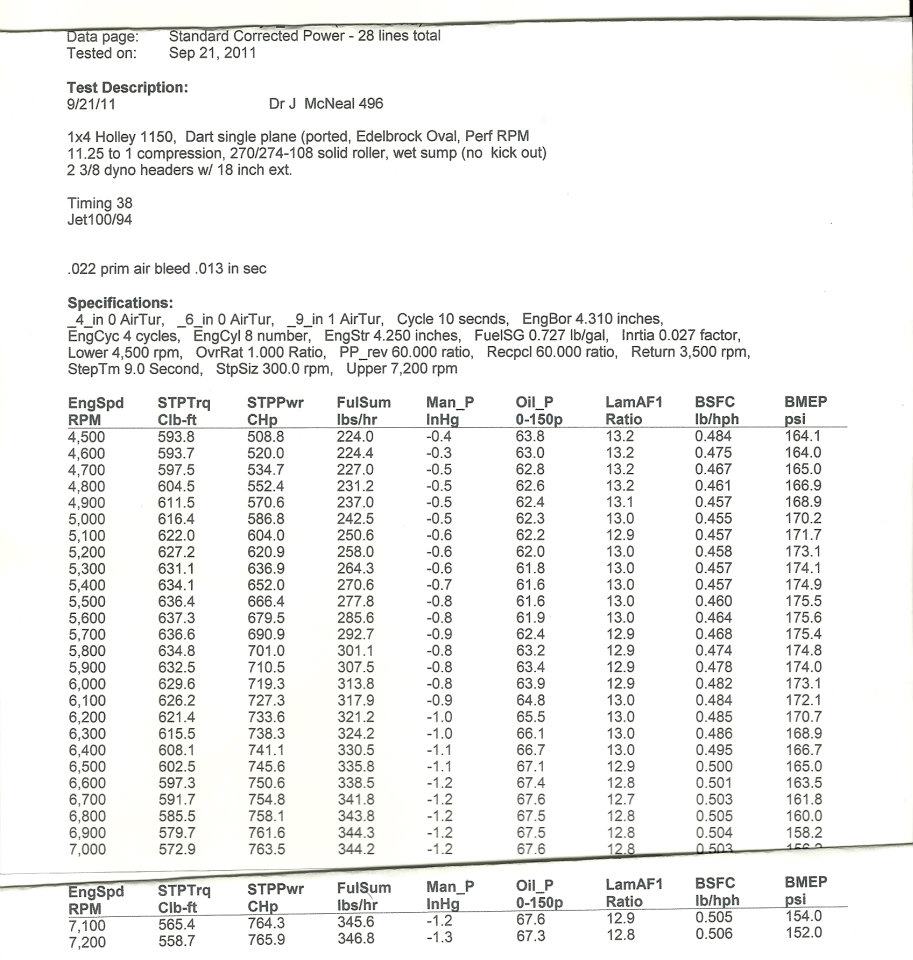

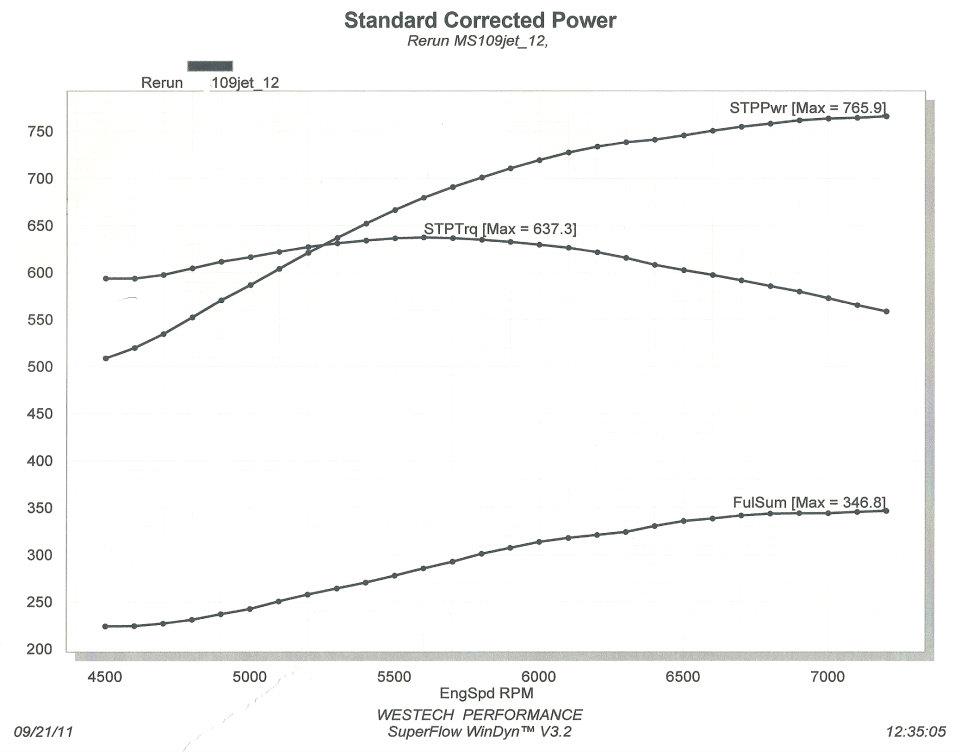

featuring parts lists and dyno results in this thread,

can be rather useful for comparing potential build ideas.

next the whole original concept was to point out the differences in the builds and results not to say any one particular build was a prime example of what to build.

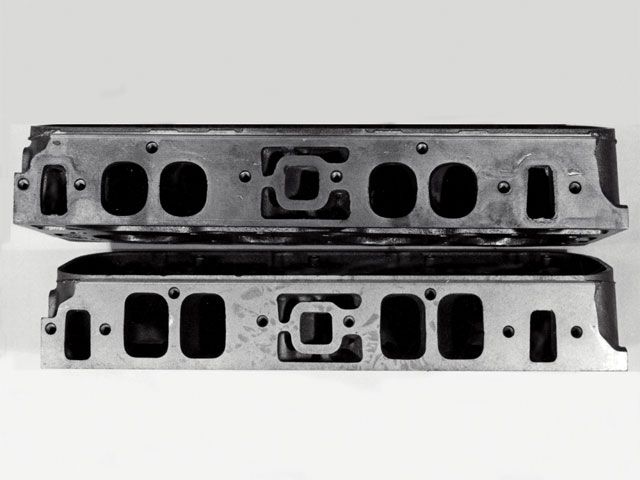

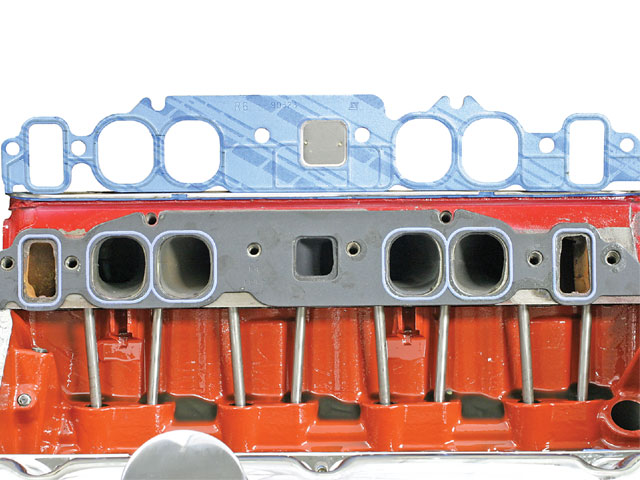

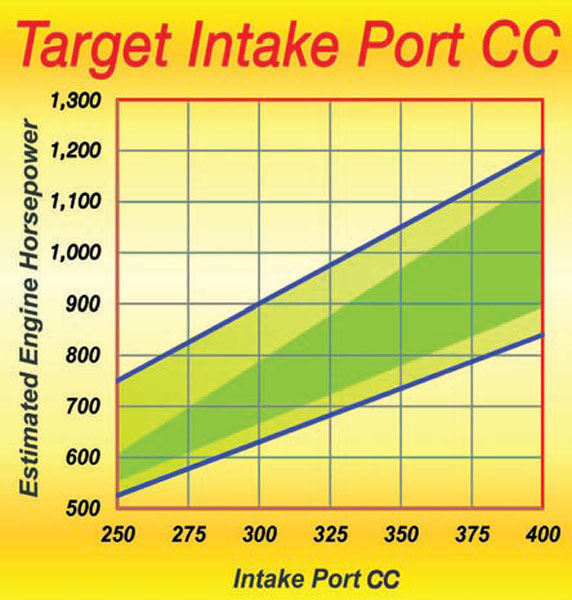

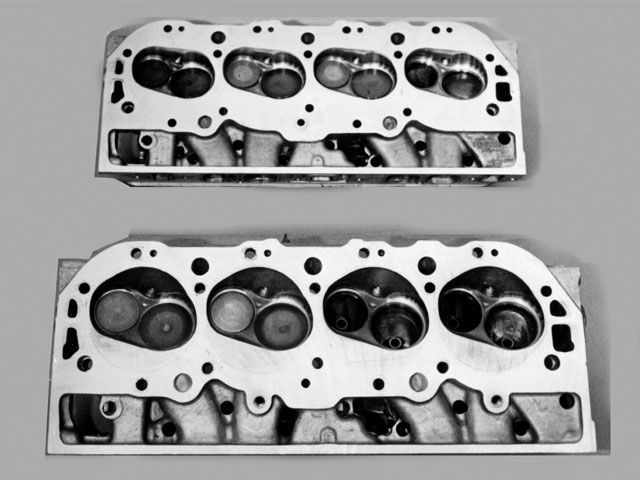

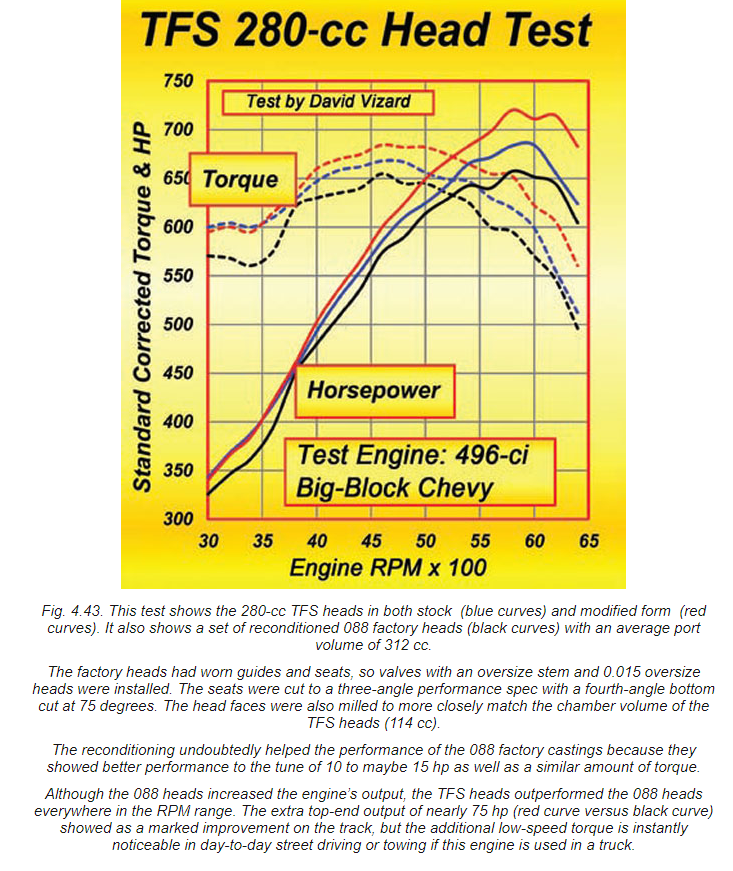

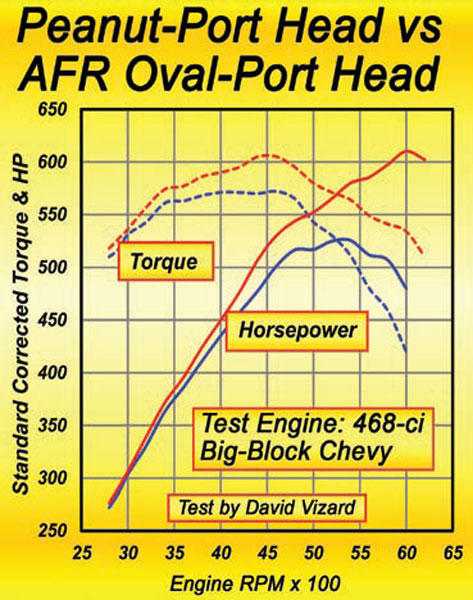

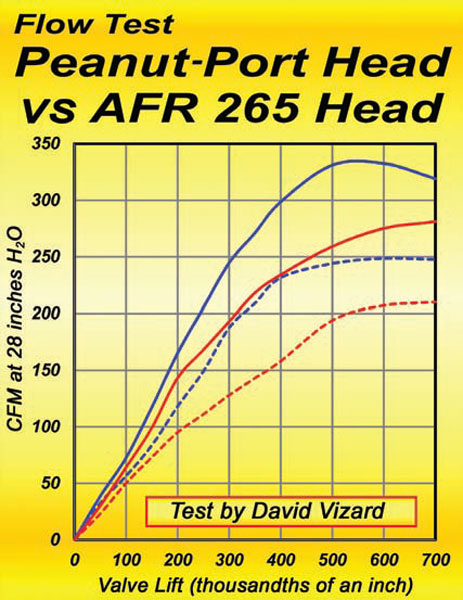

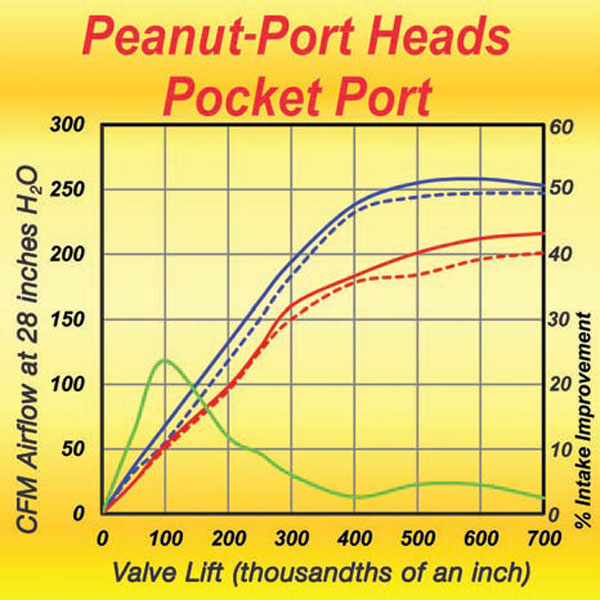

I started out with the build having the 265cc oval ports as a reasonable mid power range as a base line , not as the ideal build,

I also wanted you and anyone reading through the linked info to see how increases in port size compression and cam duration in similar displacement

(496 CID in most cases) engines tended to cause different power curves.

500hp-600 hp will be rather common,

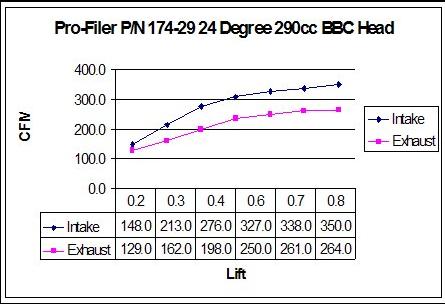

personally Ive found the 280cc-300cc oval port heads and the 305cc-315cc rectangle port heads on the BBC engines to be about ideal,

PROVIDED the compression and cam timing choices are carefully matched to maximize the head ports flow potential.

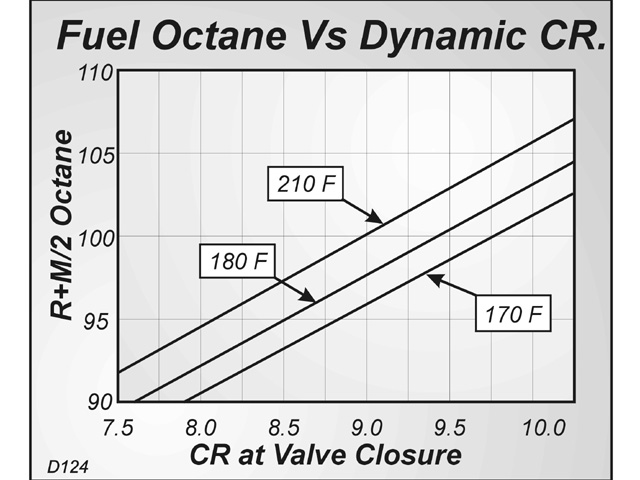

generally if your going to build a hotter street performance engine for a daily transportation used with commonly available pump octane gas,

perhaps an auto trans with a 2700 stall converter and 3.36-3.73:1 rear gears , and a decent dual plane intake,in what is basically fast daily transportation, in an older muscle car,

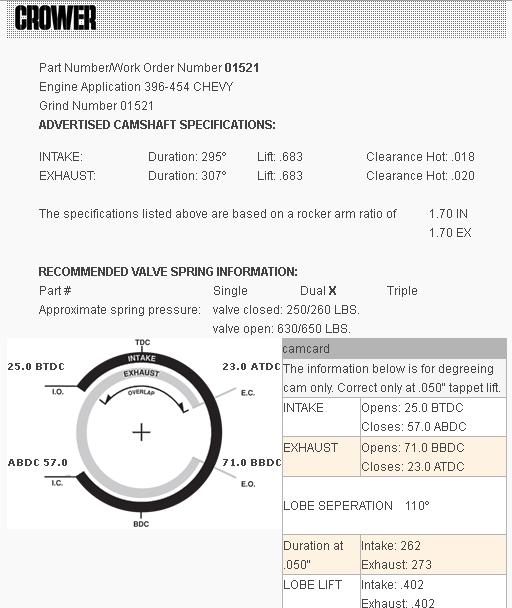

you want a 9:1-9.5:1 compression, a set of 280 cc-290 cc oval port heads and a cam duration in the 235-245 @.050 lift range and lift in the .580-.630 range flat tappet or hydraulic roller.

if you want increased performance and are willing to sacrifice some drive ability,

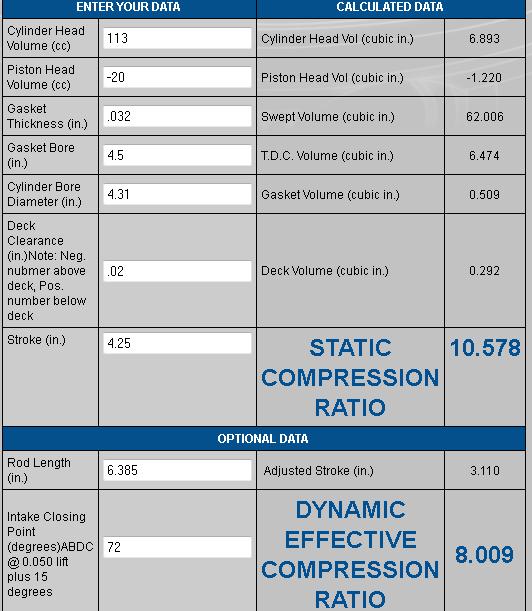

you might want to select a bit more compression, IE 10.0-10.5:1

the smaller rectangle port 300cc-315cc heads , a single plane intake , 3.73:1-4.11:1 rear gears

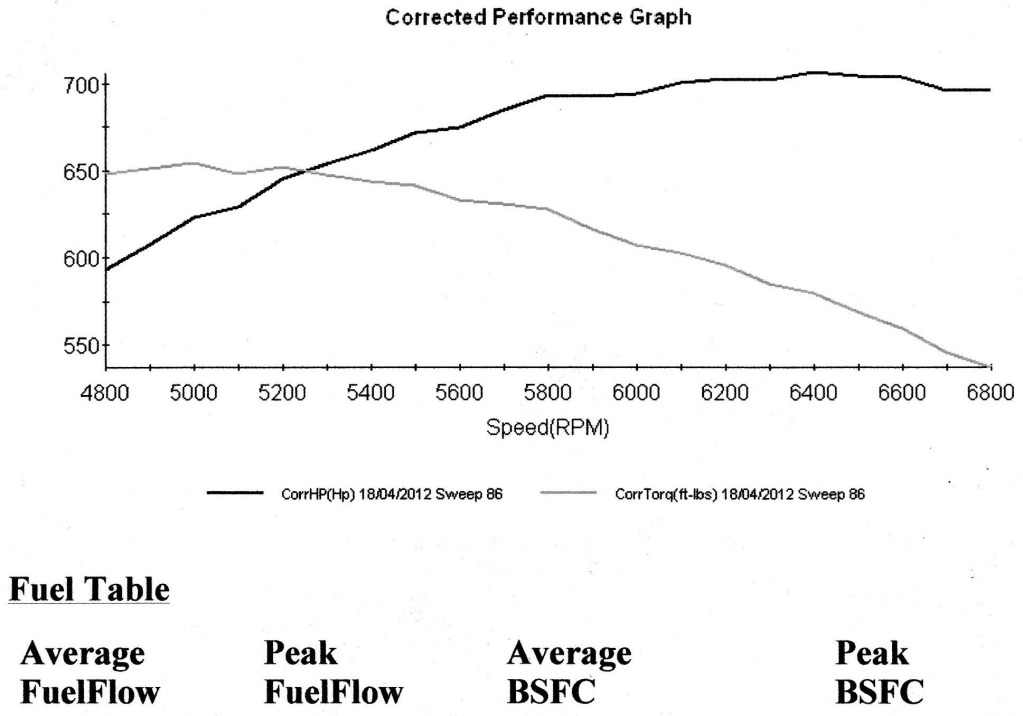

at least a 3000 rpm stall converter and a cam with about a 245-250 duration @.050 lift range, and lift in the .610-.715 range, almost always a hydraulic or solid roller, 600 hp-700 hp or a bit more is available.

assuming the proper headers exhaust and carb sizes are selected the difference in power could easily be 60-120 hp or more difference

between the two basic concepts and obviously a loss in easy street driveability in bumper to bumper traffic, you simply,

e make choices based on what your willing to put up with and what you want to trade off in drive-ability to gain performance.

before you buy components talk to both the vendors and your machine shop of choice , you damn sure don,t want mis-matched components and clearances.

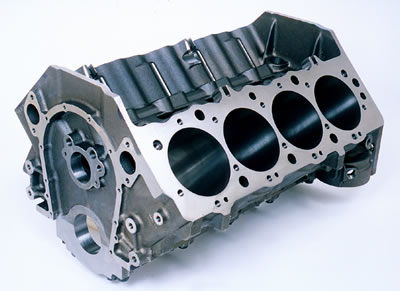

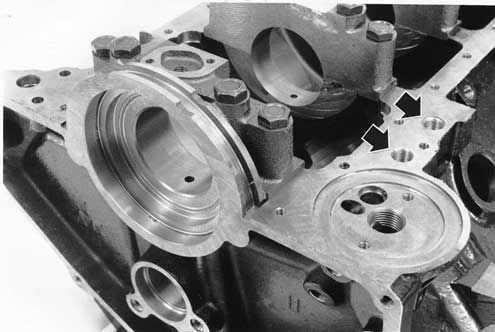

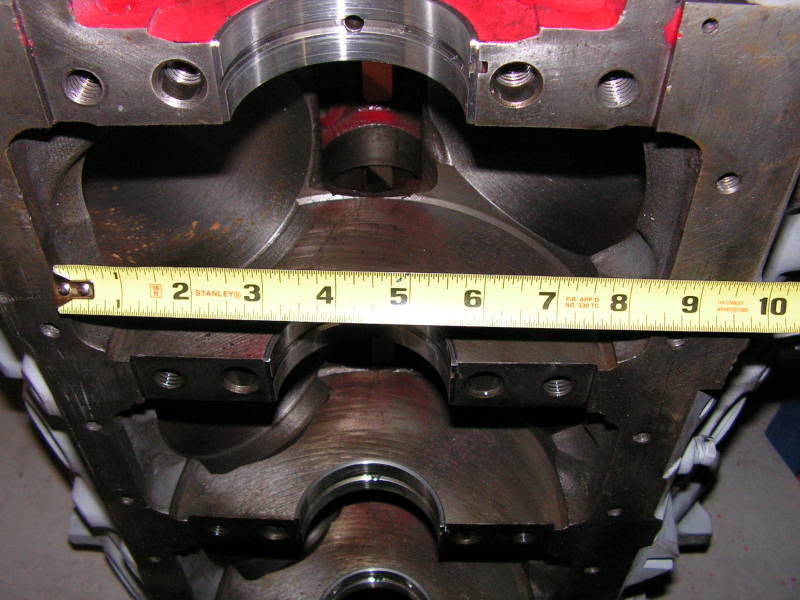

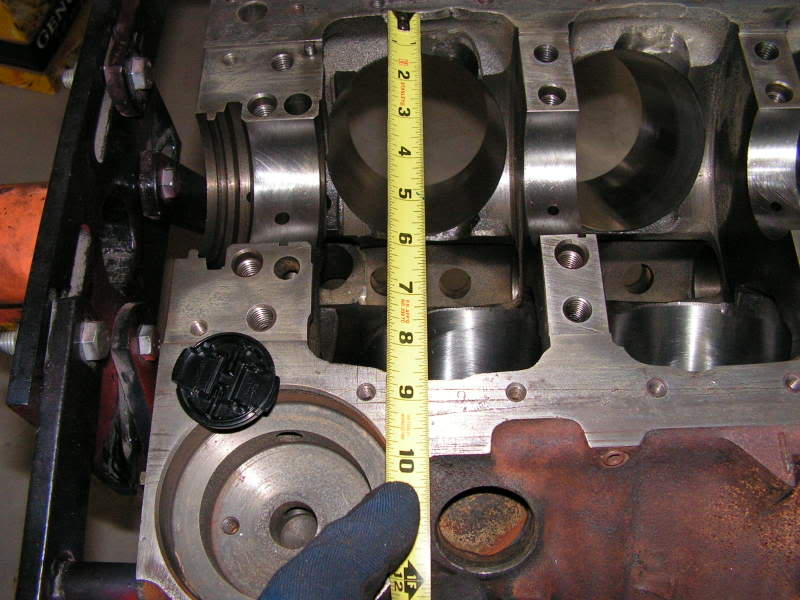

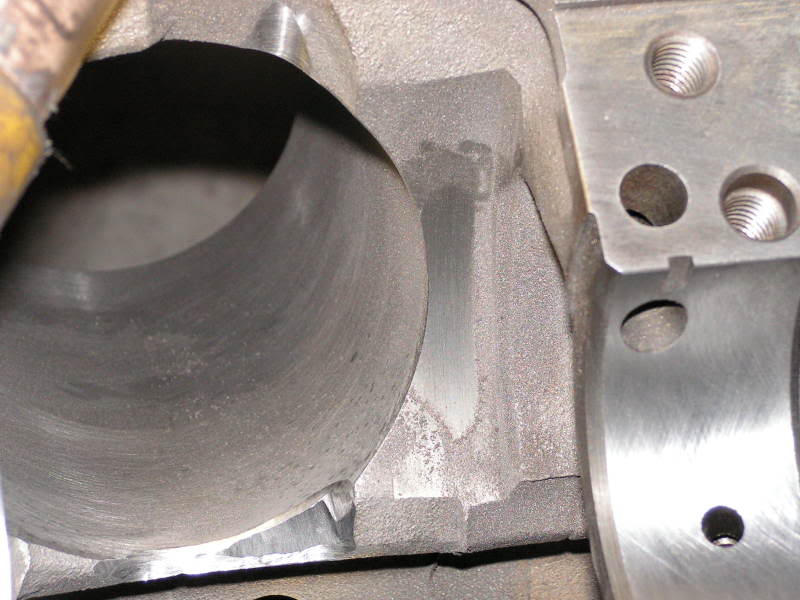

you need to measure accurately, know what your current block will function correctly with and pay attention to clearances and other details that make or break the engines potential durability and power potential.

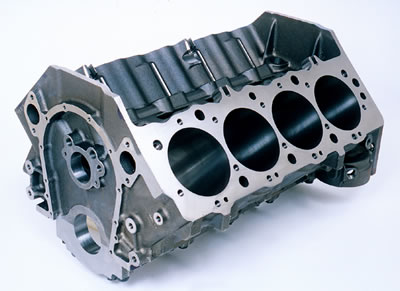

blueprint engine blocks

https://www.jegs.com/v/Blueprint-En...brand&storeId=10001&catalogId=10002&langId=-1

DART BLOCKS

http://dartheads.com/product-category/big-block-chevy/blocks/

world products blocks

https://www.billmitchellproducts.com/engine-blocks/

G.M. performance

https://www.gmperformancemotor.com/category/LS196.html

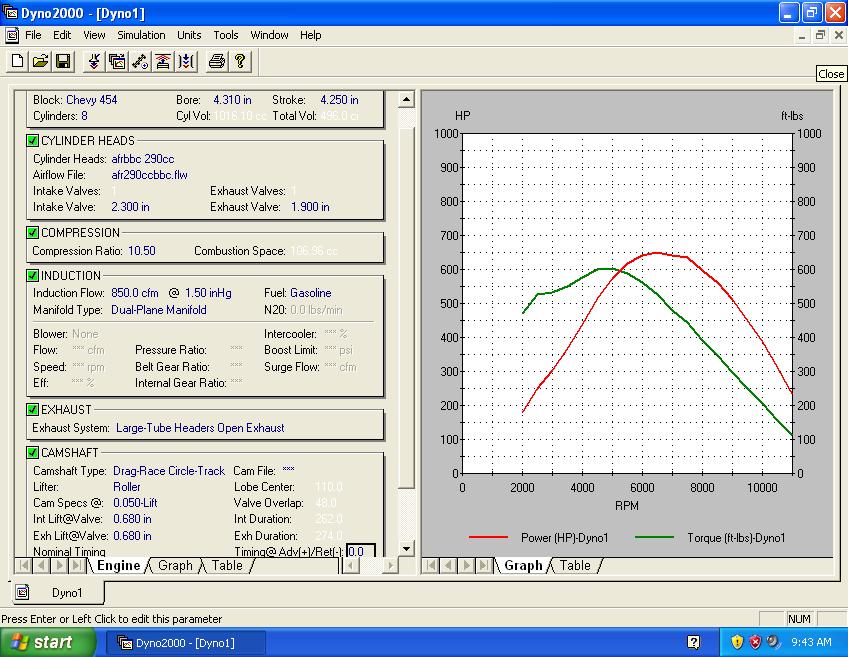

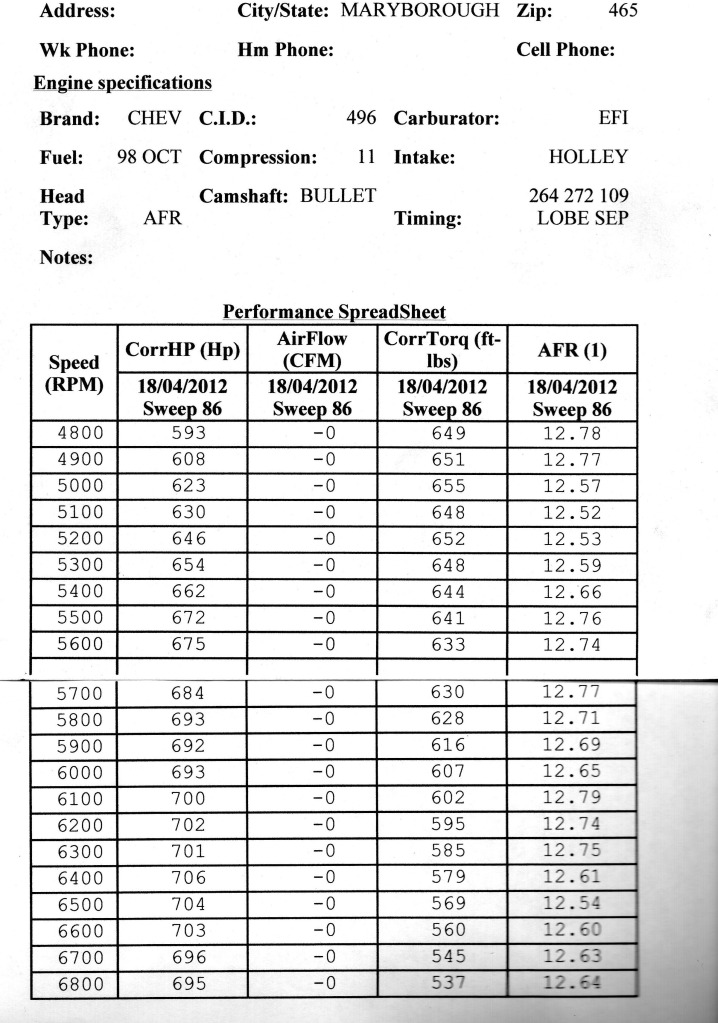

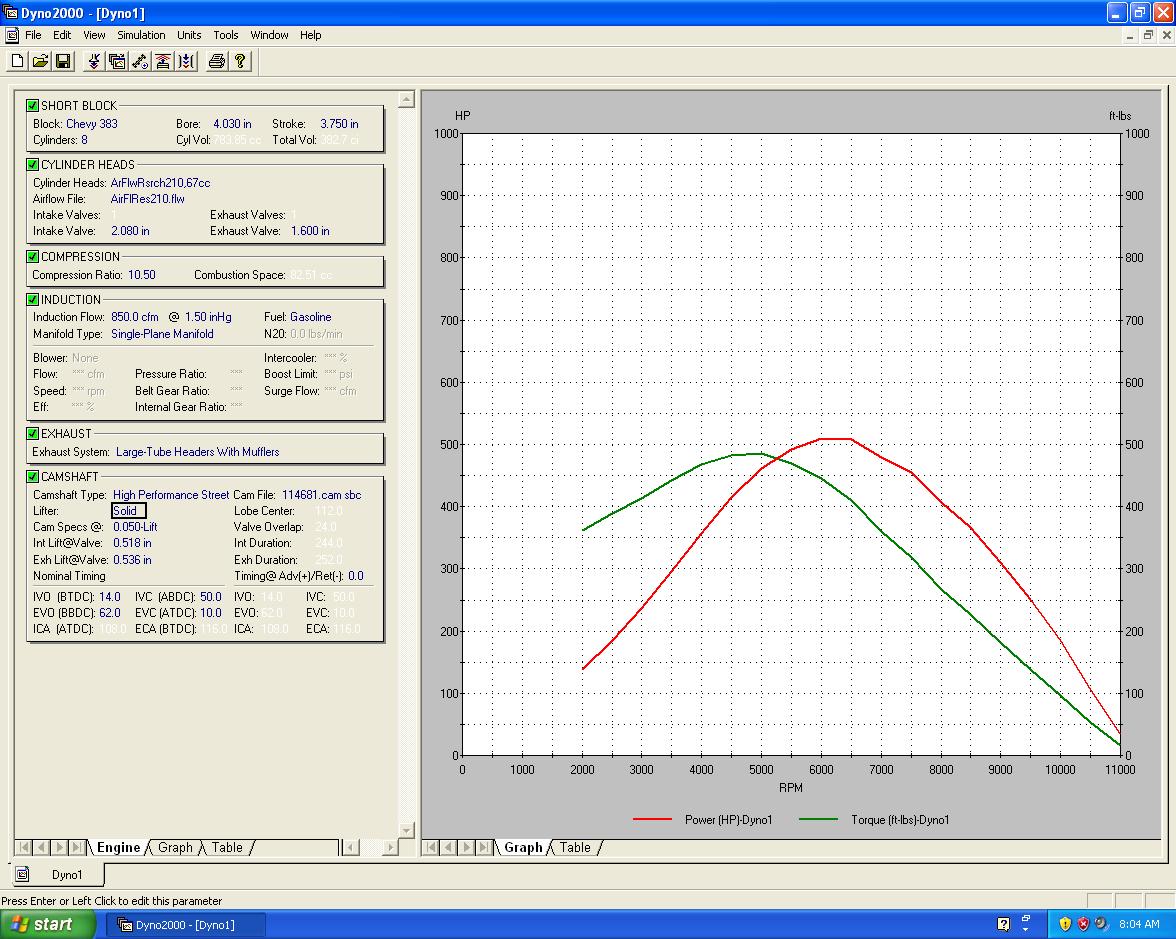

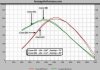

496 Gen V BBC

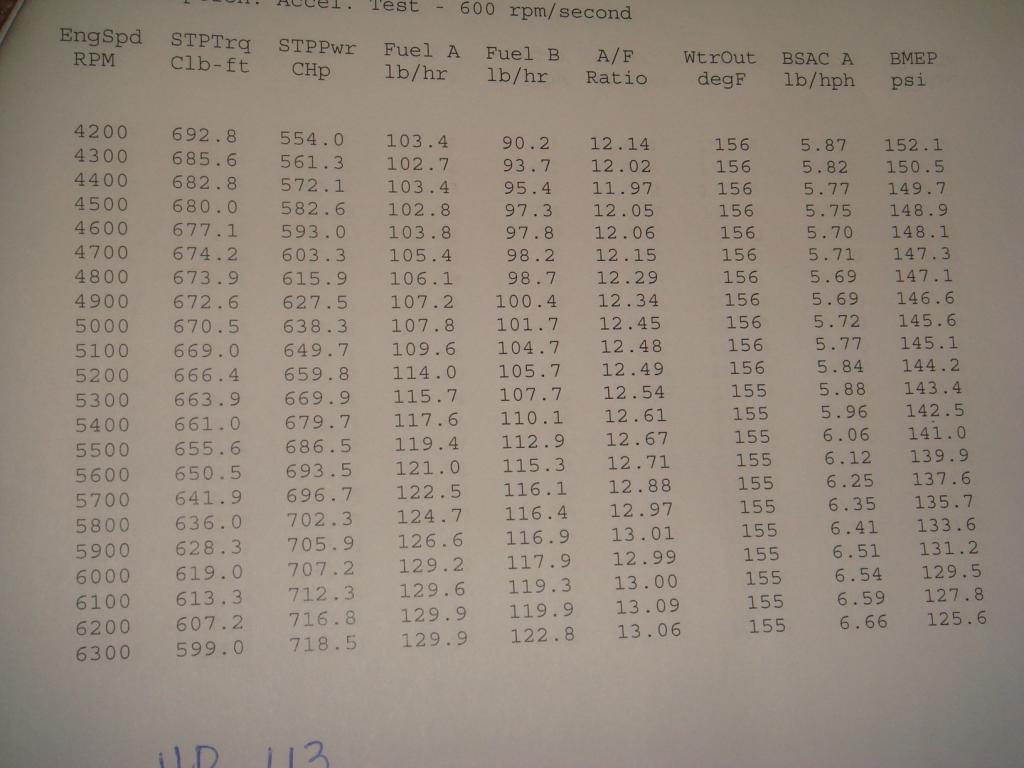

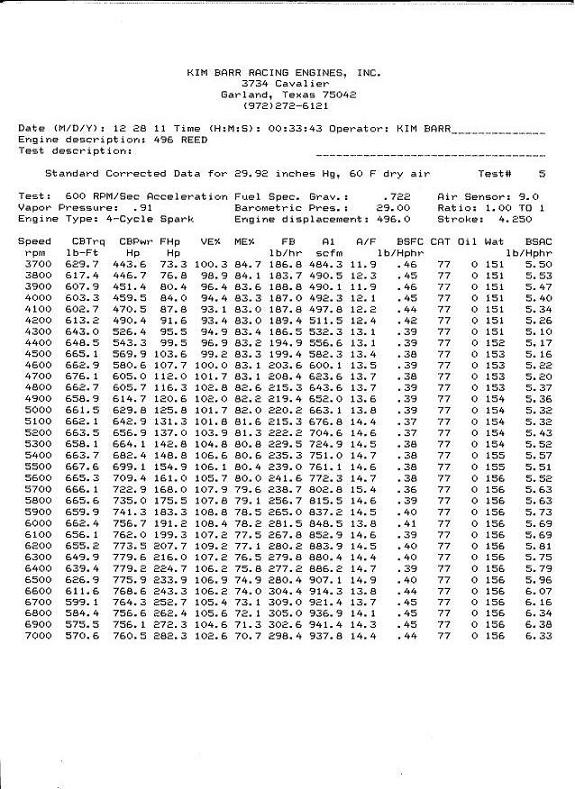

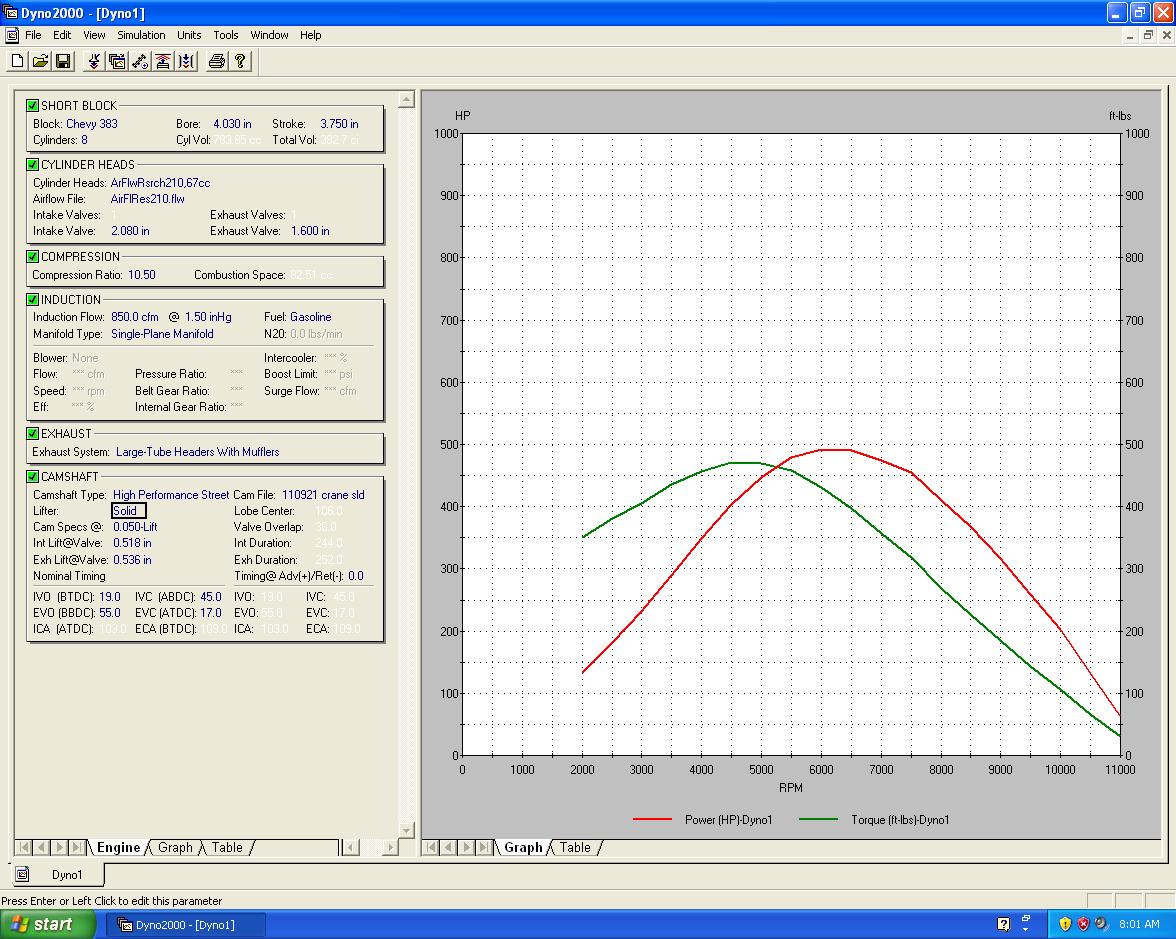

AFR 265cc Ovals CNC chambers

Eddy RPM AirGap w/ 1" spacer

850 AED HO carb (80 primaries / 88 secondaries)

10.7:1 compression

Morel hyd rollers

your cam...250/258@0.50...660/.612...108 LSA in at 103

http://www.dragzine.com/tech-stories/en ... ine-block/

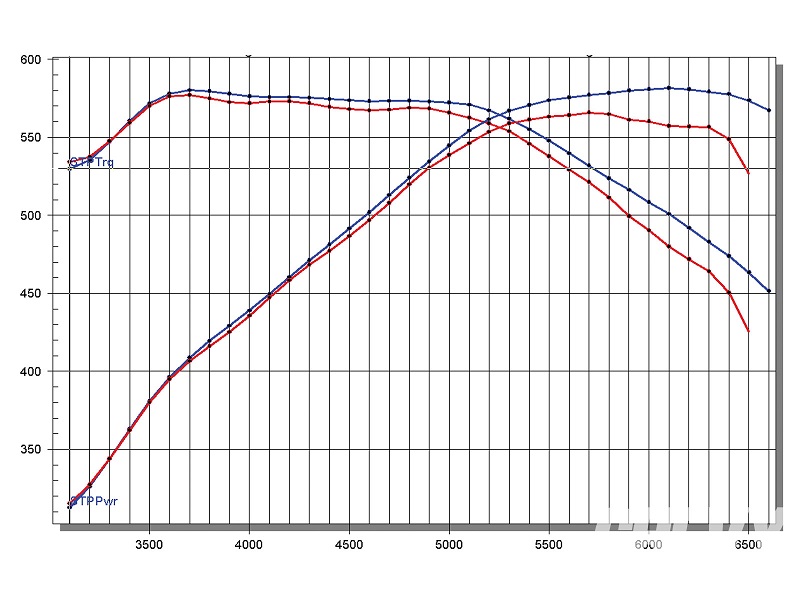

It put up 655hp @6300 and 639tq @4600

32 total on timing

3400 549.0 355.4

3500 562.5 374.8

3600 589.6 404.2

3700 595.4 419.5

3800 597.6 432.3

3900 600.8 446.2

4000 605.3 461.0

4100 611.1 477.0

4200 619.4 495.3

4300 628.5 514.6

4400 633.6 530.8

4500 636.2 545.1

4600 639.3 559.9

4700 636.5 569.6

4800 634.0 579.5

4900 631.3 589.0

5000 624.2 594.3

5100 622.6 604.6

5200 613.3 607.2

5300 614.0 619.6

5400 608.2 625.3

5500 599.6 627.9

5600 596.5 636.0

5700 593.5 644.1

5800 583.7 644.6

5900 574.7 645.6

6000 571.8 653.3

6100 559.4 649.7

6200 549.4 648.6

6300 546.3 655.3

6400 537.4 654.9

6500 526.1 651.1

6600 512.2 643.6

https://www.facebook.com/1768317223...831722380652/1269378959792584/?type=3&theater

http://garage.grumpysperformance.com/index.php?threads/can-t-find-matching-pistons.14206/

it will be used as a guide to allow readers to compare the basic engine components , at least a bit too get a good idea as to the components selected and the expected results.

IGNORING THE LINKS AND SUB_LINKS CONTAINED IN THE THREAD,WOULD BE A HUGE MISTAKE

like with most performance parts and applications the critical part of the build,

is generally in selecting the correct components for that particular application,

and in assembling those components correctly with the correct clearances.

its always a multi layered process,

you can't expect sub-par or weak parts to withstand the shock and torque and rpm/impact loads.

you can't also expect improperly installed or clearanced or insufficiently lubricated or cooled parts to last very long under loads.

obviously the process REQUIRES the person doing the work, or assembly to do some in depth research,

and have any tools or measuring devices that will be needed.

first thing Im forced to point out is theres several completely different 496 BBC engine build links, contained in this and linked related threads...

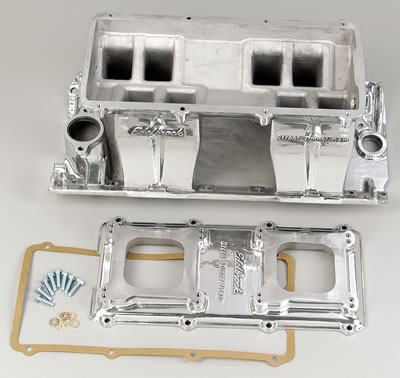

most are not designed as racing engine, those would have 12.5:1-13.7:1 compression, almost always a hydraulic or solid roller cam

and perhaps a tunnel ram intake or stack injection, maybe even super charged, etc.

featuring parts lists and dyno results in this thread,

can be rather useful for comparing potential build ideas.

next the whole original concept was to point out the differences in the builds and results not to say any one particular build was a prime example of what to build.

I started out with the build having the 265cc oval ports as a reasonable mid power range as a base line , not as the ideal build,

I also wanted you and anyone reading through the linked info to see how increases in port size compression and cam duration in similar displacement

(496 CID in most cases) engines tended to cause different power curves.

500hp-600 hp will be rather common,

personally Ive found the 280cc-300cc oval port heads and the 305cc-315cc rectangle port heads on the BBC engines to be about ideal,

PROVIDED the compression and cam timing choices are carefully matched to maximize the head ports flow potential.

generally if your going to build a hotter street performance engine for a daily transportation used with commonly available pump octane gas,

perhaps an auto trans with a 2700 stall converter and 3.36-3.73:1 rear gears , and a decent dual plane intake,in what is basically fast daily transportation, in an older muscle car,

you want a 9:1-9.5:1 compression, a set of 280 cc-290 cc oval port heads and a cam duration in the 235-245 @.050 lift range and lift in the .580-.630 range flat tappet or hydraulic roller.

if you want increased performance and are willing to sacrifice some drive ability,

you might want to select a bit more compression, IE 10.0-10.5:1

the smaller rectangle port 300cc-315cc heads , a single plane intake , 3.73:1-4.11:1 rear gears

at least a 3000 rpm stall converter and a cam with about a 245-250 duration @.050 lift range, and lift in the .610-.715 range, almost always a hydraulic or solid roller, 600 hp-700 hp or a bit more is available.

assuming the proper headers exhaust and carb sizes are selected the difference in power could easily be 60-120 hp or more difference

between the two basic concepts and obviously a loss in easy street driveability in bumper to bumper traffic, you simply,

e make choices based on what your willing to put up with and what you want to trade off in drive-ability to gain performance.

before you buy components talk to both the vendors and your machine shop of choice , you damn sure don,t want mis-matched components and clearances.

you need to measure accurately, know what your current block will function correctly with and pay attention to clearances and other details that make or break the engines potential durability and power potential.

blueprint engine blocks

https://www.jegs.com/v/Blueprint-En...brand&storeId=10001&catalogId=10002&langId=-1

DART BLOCKS

http://dartheads.com/product-category/big-block-chevy/blocks/

world products blocks

https://www.billmitchellproducts.com/engine-blocks/

G.M. performance

https://www.gmperformancemotor.com/category/LS196.html

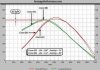

496 Gen V BBC

AFR 265cc Ovals CNC chambers

Eddy RPM AirGap w/ 1" spacer

850 AED HO carb (80 primaries / 88 secondaries)

10.7:1 compression

Morel hyd rollers

your cam...250/258@0.50...660/.612...108 LSA in at 103

http://www.dragzine.com/tech-stories/en ... ine-block/

It put up 655hp @6300 and 639tq @4600

32 total on timing

3400 549.0 355.4

3500 562.5 374.8

3600 589.6 404.2

3700 595.4 419.5

3800 597.6 432.3

3900 600.8 446.2

4000 605.3 461.0

4100 611.1 477.0

4200 619.4 495.3

4300 628.5 514.6

4400 633.6 530.8

4500 636.2 545.1

4600 639.3 559.9

4700 636.5 569.6

4800 634.0 579.5

4900 631.3 589.0

5000 624.2 594.3

5100 622.6 604.6

5200 613.3 607.2

5300 614.0 619.6

5400 608.2 625.3

5500 599.6 627.9

5600 596.5 636.0

5700 593.5 644.1

5800 583.7 644.6

5900 574.7 645.6

6000 571.8 653.3

6100 559.4 649.7

6200 549.4 648.6

6300 546.3 655.3

6400 537.4 654.9

6500 526.1 651.1

6600 512.2 643.6

https://www.facebook.com/1768317223...831722380652/1269378959792584/?type=3&theater

http://garage.grumpysperformance.com/index.php?threads/can-t-find-matching-pistons.14206/

Last edited by a moderator: