You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Another rings end gap question

- Thread starter PrefixAM

- Start date

https://www.summitracing.com/parts/sme-90a4000

https://www.summitracing.com/parts/sme-90a4120

https://www.summitracing.com/parts/sme-90a4250

https://www.summitracing.com/parts/tsr-rc4345-4455

https://www.summitracing.com/parts/tsr-rc4455-4575

having a decent set of piston ring compressors available in your tool box helps

make engine assembly far easier, using the type posted above makes the job rather easy

using the type below could make a preacher cuss up a blue streak

the #$%%^^& things are just prone to allowing rings too catch and potentially break, as they enter the bore, yeah they work at times but they are not nearly as easy or foolproof

https://www.summitracing.com/parts/lil-20500

these piston ring compressors don't cost much and are very versatile, but can be a P.I.T.A. to use compared to the rather limited range piston ring compressors like the upper picture

https://www.summitracing.com/parts/sme-90a4120

https://www.summitracing.com/parts/sme-90a4250

https://www.summitracing.com/parts/tsr-rc4345-4455

https://www.summitracing.com/parts/tsr-rc4455-4575

having a decent set of piston ring compressors available in your tool box helps

make engine assembly far easier, using the type posted above makes the job rather easy

using the type below could make a preacher cuss up a blue streak

the #$%%^^& things are just prone to allowing rings too catch and potentially break, as they enter the bore, yeah they work at times but they are not nearly as easy or foolproof

https://www.summitracing.com/parts/lil-20500

these piston ring compressors don't cost much and are very versatile, but can be a P.I.T.A. to use compared to the rather limited range piston ring compressors like the upper picture

Last edited:

https://www.totalseal.com/rings/gapless-rings

I was recently over at a buddies house/garage where he was pulling apart a recently rebuild engine that had a serious oil burning issue,

I originally expected to defective valve seals or worn valve guides but neither was the case

the indications strongly indicated ring seal failure, so we checked carefully,

the engine had brand new total seal rings installed,

and he swears he very carefully verified ring gaps.

before he had installed them on the pistons

what we found was that the rings may have been very correctly gapped but the pistons he had re-used in the build,

had about an 8 thousands clearance with the bore wall.

now to be fair this guy has very few tools and hes rather new to measuring and engine rebuilding.

he had simply removed the original pistons

honed the bore walls and installed new rings on the pistons, then reassembled and the rings never properly sealed.

one other reason I found that was a major factor was three of the top/upper rings were also installed with the wrong side facing up.

(yeah we all tend to learn the hard way at times)

always read, understand and follow the piston manufacturers guide for piston to bore clearance and how you measure that correctly

https://egge.com/info/piston_ring_installation/

links

https://enginetech.com/how-to-install-rings-blog/

http://blog.wiseco.com/how-to-file-fit-and-install-piston-rings

https://www.hastingspistonrings.com...n-ring-installation-piston-ring-assembly-tip/

https://auto.jepistons.com/je-auto-ring-installation-guide-4032-pistons

http://www.wiseco.com/PDFs/Manuals/RingEndGap.pdf

related threads

http://garage.grumpysperformance.co...ore-clearance-on-your-block.14251/#post-72471

http://garage.grumpysperformance.com/index.php?threads/piston-to-bore-clearance.4630/

http://garage.grumpysperformance.co...-safe-and-correct-bore-size.14797/#post-81619

http://garage.grumpysperformance.co...on-ring-info-youll-need.509/page-2#post-77508

http://garage.grumpysperformance.co...tion-of-crank-durring-short-blk-assembly.852/

http://garage.grumpysperformance.co...g-and-installing-connecting-rods-pistons.247/

http://garage.grumpysperformance.com/index.php?threads/another-rings-end-gap-question.14994/

http://garage.grumpysperformance.co...ng-and-basic-piston-ring-info-youll-need.509/

I was recently over at a buddies house/garage where he was pulling apart a recently rebuild engine that had a serious oil burning issue,

I originally expected to defective valve seals or worn valve guides but neither was the case

the indications strongly indicated ring seal failure, so we checked carefully,

the engine had brand new total seal rings installed,

and he swears he very carefully verified ring gaps.

before he had installed them on the pistons

what we found was that the rings may have been very correctly gapped but the pistons he had re-used in the build,

had about an 8 thousands clearance with the bore wall.

now to be fair this guy has very few tools and hes rather new to measuring and engine rebuilding.

he had simply removed the original pistons

honed the bore walls and installed new rings on the pistons, then reassembled and the rings never properly sealed.

one other reason I found that was a major factor was three of the top/upper rings were also installed with the wrong side facing up.

(yeah we all tend to learn the hard way at times)

always read, understand and follow the piston manufacturers guide for piston to bore clearance and how you measure that correctly

https://egge.com/info/piston_ring_installation/

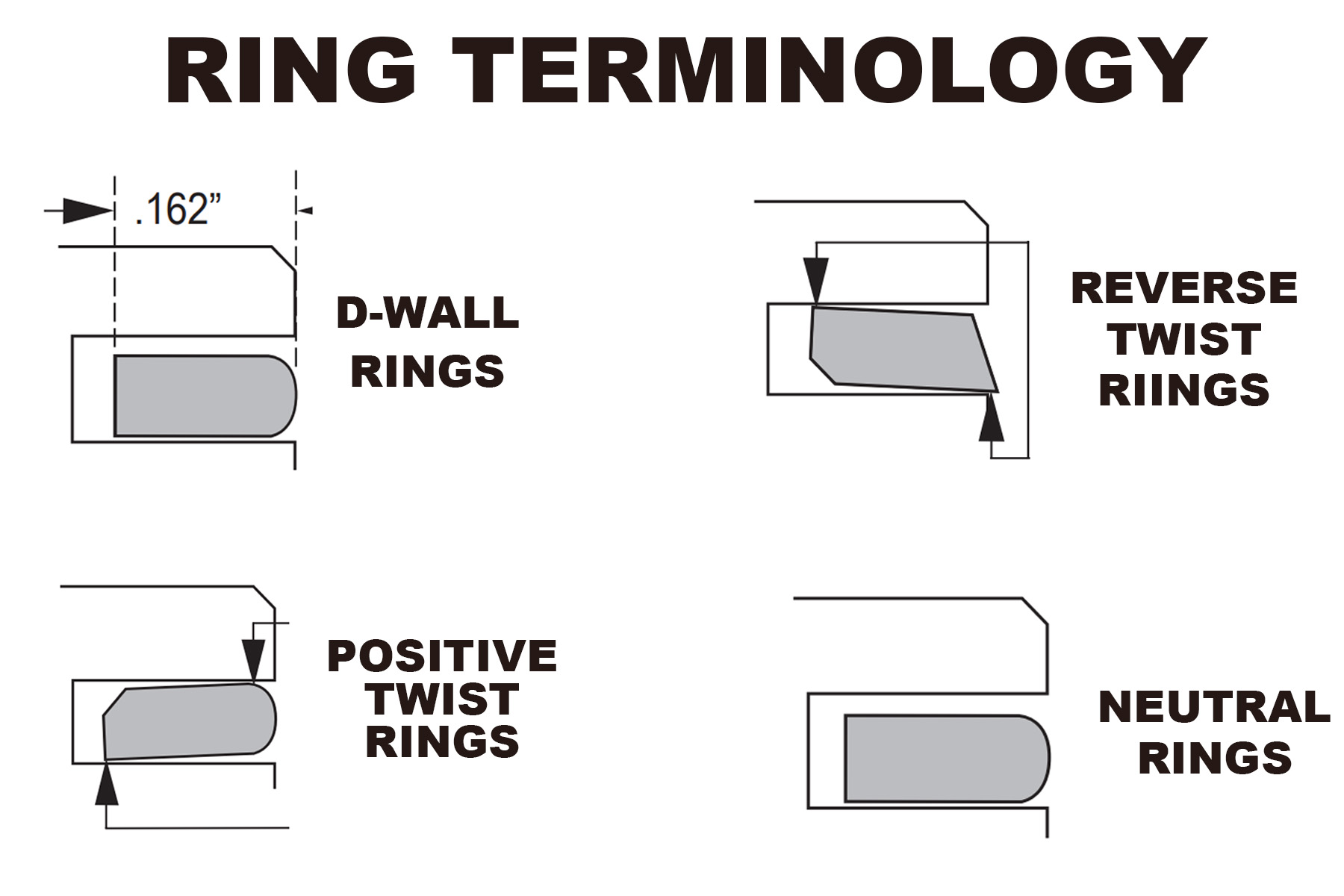

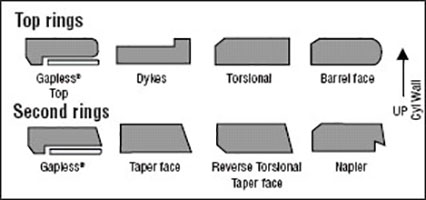

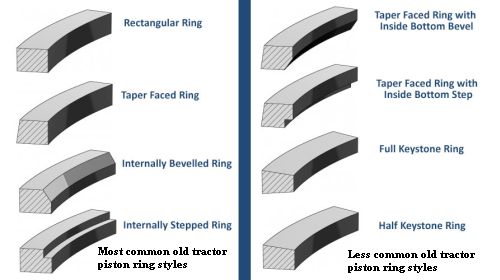

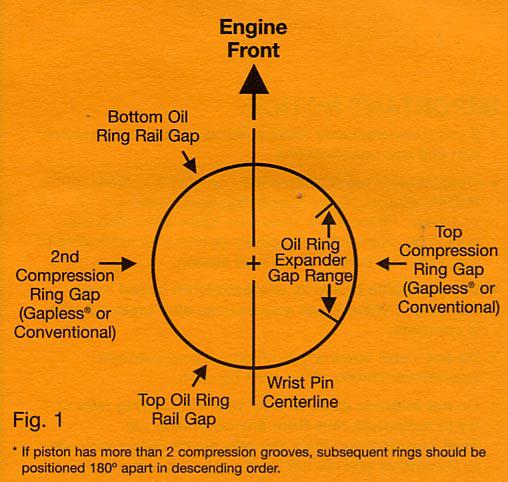

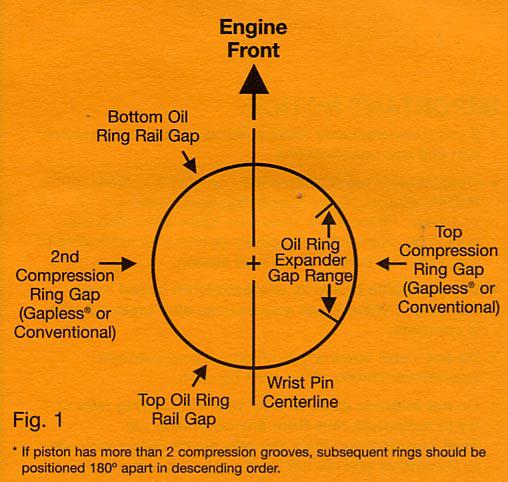

Correct Compression Ring Installation

Listed below are the general rules for the installation of various types of compression rings.

Rings having a "pip" mark or dot on the side of the ring must always be installed with the "pip" mark or dot towards the top of the piston.

Rings with a bevel on the inside diameter but no "pip" mark or dot must be installed with the bevel towards the top of the piston.

Rings with a groove or step in the outside diameter and no "pip" mark or dot must be installed with the groove toward the bottom of the piston.

It is a good idea after installing all rings on the pistons to recheck each ring on each piston for correct installation.

Rings having no dots, bevels, tapers, or grooves can be installed either way.

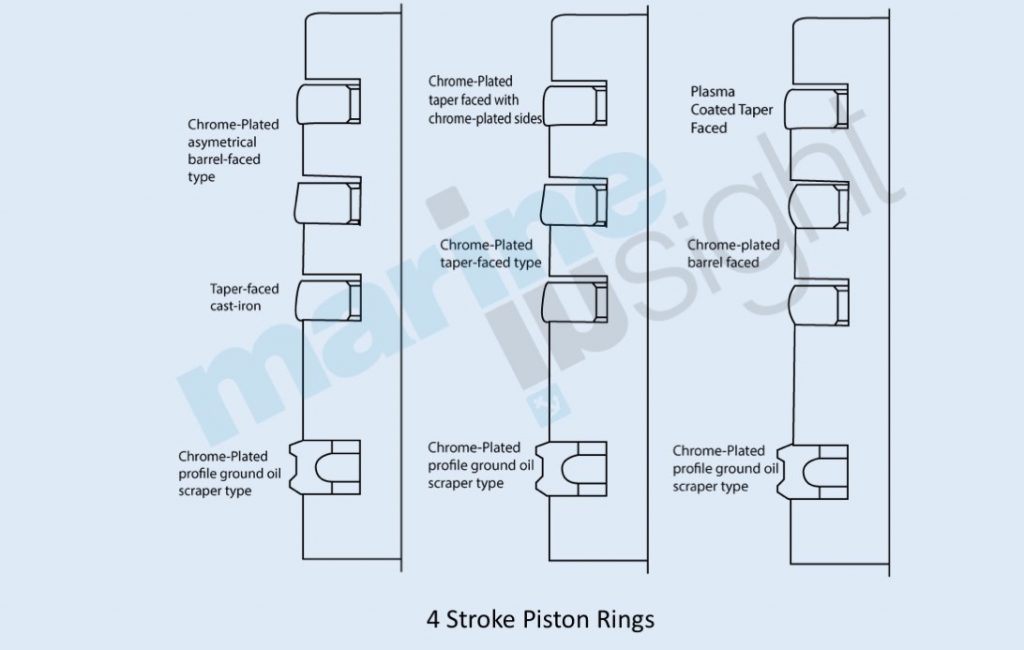

Typical Ring Types/Shapes

Top Compression Rings

2nd Compression & Oil Control Rings

Top of Page

Piston Ring Terminology

links

https://enginetech.com/how-to-install-rings-blog/

http://blog.wiseco.com/how-to-file-fit-and-install-piston-rings

https://www.hastingspistonrings.com...n-ring-installation-piston-ring-assembly-tip/

https://auto.jepistons.com/je-auto-ring-installation-guide-4032-pistons

http://www.wiseco.com/PDFs/Manuals/RingEndGap.pdf

related threads

http://garage.grumpysperformance.co...ore-clearance-on-your-block.14251/#post-72471

http://garage.grumpysperformance.com/index.php?threads/piston-to-bore-clearance.4630/

http://garage.grumpysperformance.co...-safe-and-correct-bore-size.14797/#post-81619

http://garage.grumpysperformance.co...on-ring-info-youll-need.509/page-2#post-77508

http://garage.grumpysperformance.co...tion-of-crank-durring-short-blk-assembly.852/

http://garage.grumpysperformance.co...g-and-installing-connecting-rods-pistons.247/

http://garage.grumpysperformance.com/index.php?threads/another-rings-end-gap-question.14994/

http://garage.grumpysperformance.co...ng-and-basic-piston-ring-info-youll-need.509/

Last edited:

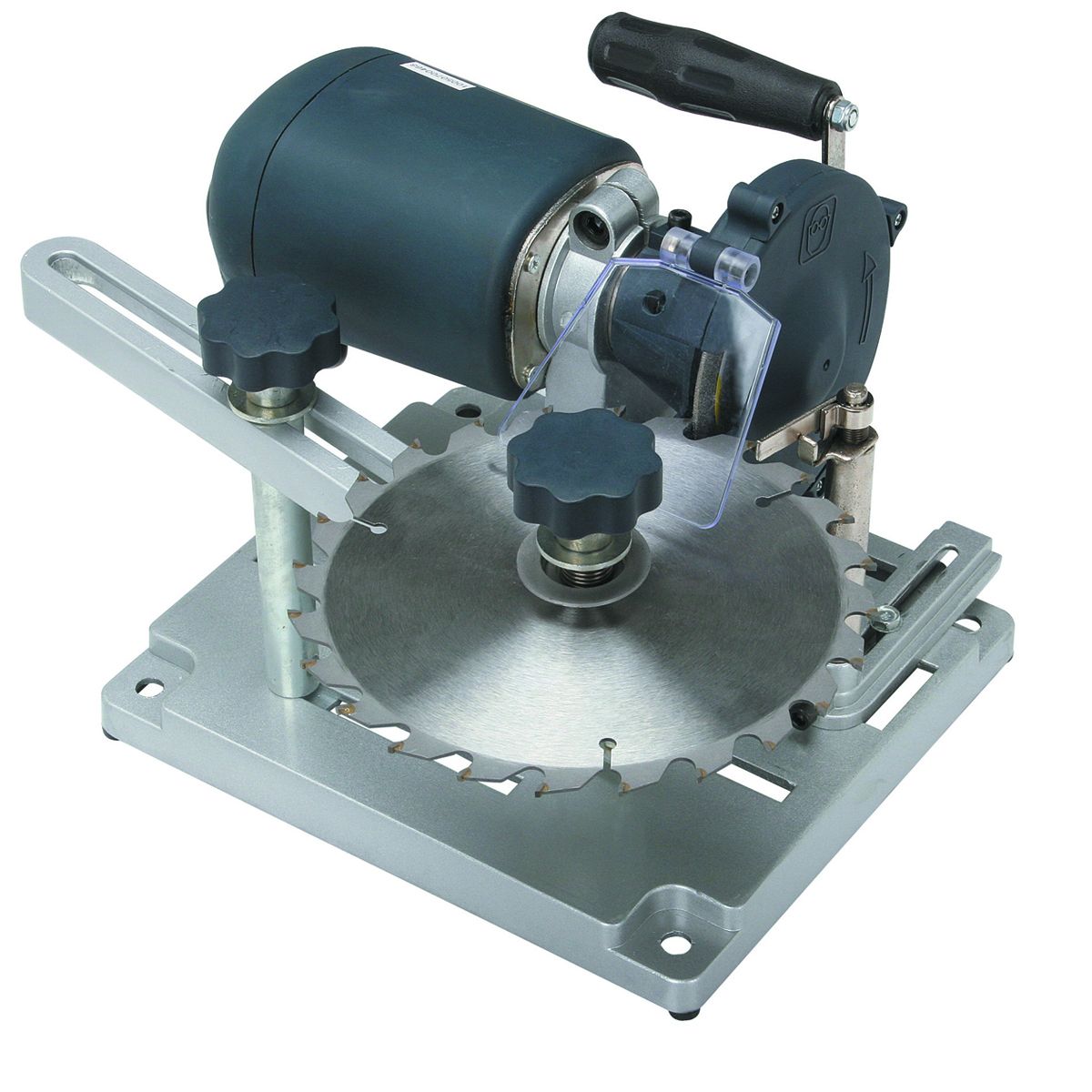

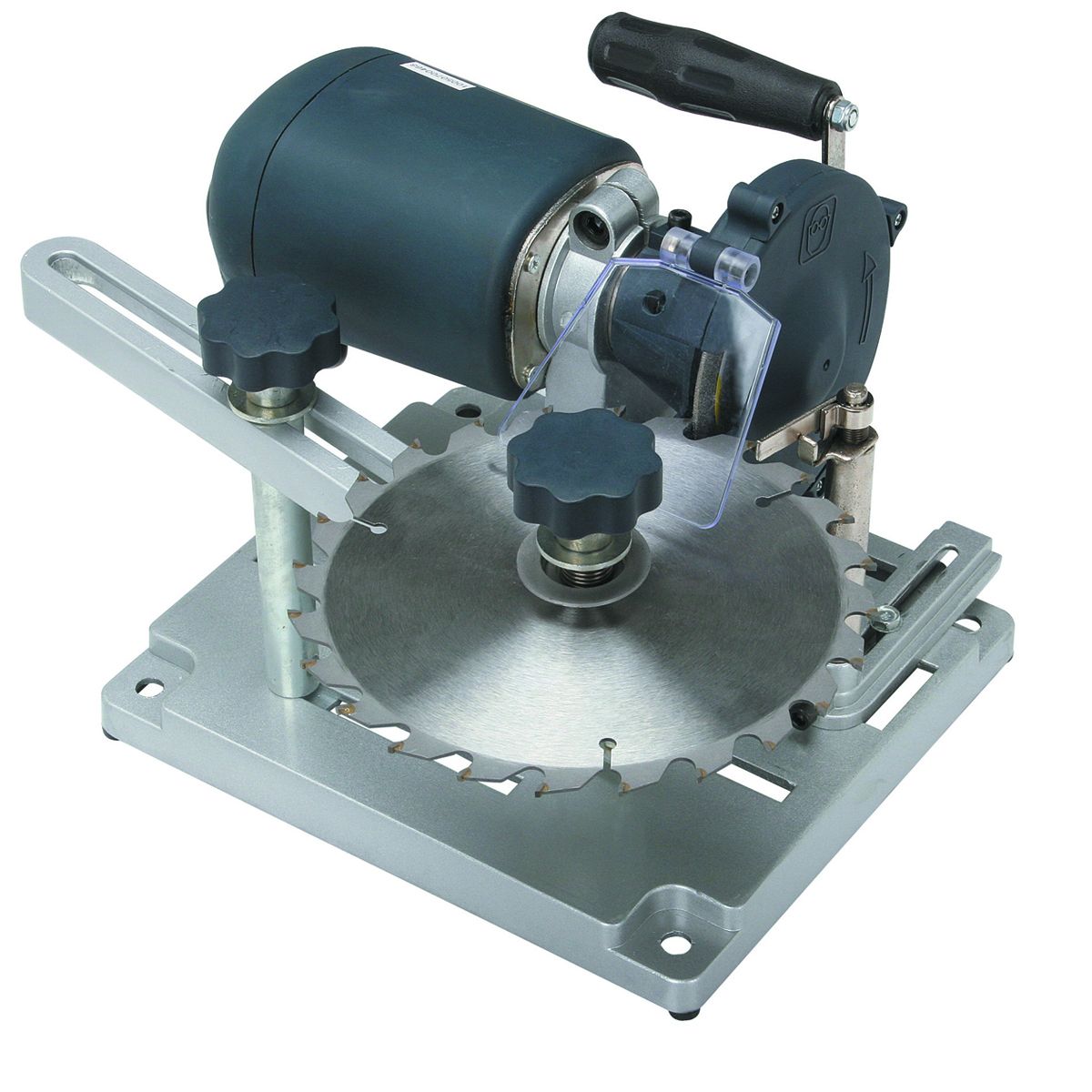

when I started building engines I purchased on of these hand crank, tools,

I rapidly found it had issues in keeping the ring end gaps parallel,

I found a carefully used DREMEL TOOL with cut off wheels and careful measuring to be a reliable route you can use

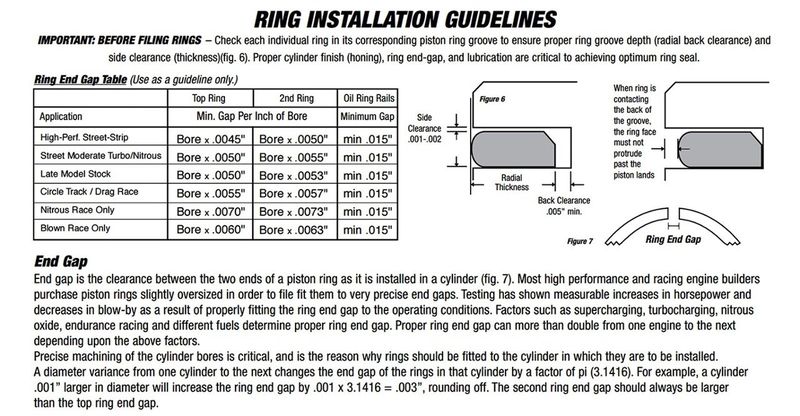

obviously measure very carefully and polish off LESS on the ring end gaps than you think , you need too,

and re-measure carefully and repeat, try to match the chart recommended end gaps

if your end gaps a tiny bit too large its no major issue ,but read and pay attention too the charts and work carefully

https://www.summitracing.com/parts/...MIpuDs0eDf9AIVGIiGCh3VKQvDEAQYAiABEgK8fPD_BwE

www.harborfreight.com

www.harborfreight.com

proform sells a power upgrade tool,

now I work mostly on BBC engines and I built a custom ring square tool , out of cheap and easy to find PVC plumbing pipe adapters, (look at the pictures, rick posted,)remember it does not need to be a perfect bore diam. match too square the rings , but of course it must fit down the bore, too use when gapping rings,and on the big block engines you can build and use a custom tool like this without reducing the diam., but Rick went the extra step and built a very similar tool for his SBC projects engine

ITS always nice to see the ideas, and designs that result, when you build custom built tools

used carefully, and with some experience,

a dremel tool cut-off wheel can do a decent job at cutting ring end gaps

read thru these related threads, posted below, youll find a good deal of info, on installing pistons and rings.

related threads with very useful info

I rapidly found it had issues in keeping the ring end gaps parallel,

I found a carefully used DREMEL TOOL with cut off wheels and careful measuring to be a reliable route you can use

obviously measure very carefully and polish off LESS on the ring end gaps than you think , you need too,

and re-measure carefully and repeat, try to match the chart recommended end gaps

if your end gaps a tiny bit too large its no major issue ,but read and pay attention too the charts and work carefully

https://www.summitracing.com/parts/...MIpuDs0eDf9AIVGIiGCh3VKQvDEAQYAiABEgK8fPD_BwE

9 Amp Circular Saw Blade Sharpener

Amazing deals on this 120Volt Circular Saw Blade Sharpener at Harbor Freight. Quality tools & low prices.

proform sells a power upgrade tool,

now I work mostly on BBC engines and I built a custom ring square tool , out of cheap and easy to find PVC plumbing pipe adapters, (look at the pictures, rick posted,)remember it does not need to be a perfect bore diam. match too square the rings , but of course it must fit down the bore, too use when gapping rings,and on the big block engines you can build and use a custom tool like this without reducing the diam., but Rick went the extra step and built a very similar tool for his SBC projects engine

ITS always nice to see the ideas, and designs that result, when you build custom built tools

used carefully, and with some experience,

a dremel tool cut-off wheel can do a decent job at cutting ring end gaps

read thru these related threads, posted below, youll find a good deal of info, on installing pistons and rings.

related threads with very useful info

assembling and installing connecting rods/pistons

look closely at the connecting rods one edge of the main bearing are is beveled noticeably more than the other that beveled side faces away from the rod its paired with because it matches the slight radiased bevel of the crank journal many builder class pistons are designed to go in, in either...

garage.grumpysperformance.com

assembling and installing connecting rods/pistons

look closely at the connecting rods one edge of the main bearing are is beveled noticeably more than the other that beveled side faces away from the rod its paired with because it matches the slight radiased bevel of the crank journal many builder class pistons are designed to go in, in either...

garage.grumpysperformance.com

Another rings end gap question

Hi, I'm rebuilding my 4.3L Vortec from 2003 Chevy Astro Cargo Van. When I bought it a year ago it had ~26.000 miles. The engine was knocking and I couldn't get rid of that annoying sound - tried to clean up lifters through the push roads and by "seafoaming". It didn't work out, so I just...

garage.grumpysperformance.com

resistance to rotation, of crank durring short blk assembly

Ok youve just installed your crankshaft in the engine block, with new main bearings and everything's well coated with assembly lube,and oil, and youve torqued down the main caps to spec. in at least three stages, and then gone back and rechecked the studs or bolts per the manufacturers...

garage.grumpysperformance.com

Made a mistake filing rings, still good?

First I want to thank Grumpy for his help on many forums and him maintaining this one. It's an absolute WEALTH of info. So.... I am assembling an essentially stock 350. For use in a daily driver 95 Tahoe with TBI. I'm using a .030 over eagle rotating kit and a hydraulic roller cam out of an...

garage.grumpysperformance.com

getting the correct piston to bore clearance, on your block

always think every step you take in any performance engine build through, logically and don't just jump off the dock head first, financially, without asking detailed questions , and documenting as much as you can in writing, and having a well thought through plan, parts list and time frame...

garage.grumpysperformance.com

maximizing piston to bore ring seal

From the February, 2009 issue of Circle Track By Jeff Huneycutt Piston Ring Prep It can be a hassle filing... read full caption Piston Ring Prep It can be a hassle filing three sets of rings per cylinder, but when done correctly the results can mean more power and less fall-off before the...

garage.grumpysperformance.com

installing rings in piston grooves

obviously if you've been around engine rebuilds, long enough, your aware that you'll eventually see guys installing rings in piston grooves by spiral twisting them into place, like the picture below depicts, AND YES YOU MIGHT NOT EVEN REALIZE THAT THE RING HAS BEEN SLIGHTLY DISTORTED...

garage.grumpysperformance.com

cleaning piston ring grooves, and related info

now if there's any job that's frequently ignored or avoided during an engine rebuild , its more than likely ,cleaning pistons and cleaning the grooves its high on the list! RELATED INFO (take advantage of millions of hours of previous engine builds, by skilled and experienced people, and the...

garage.grumpysperformance.com

crankshaft and connecting rod compatability

POSTED BY, navygunner08; "Does it matter what length rod you use with a particular crank? So if a crank is listed for use with 5.7" rods, can you use a 6" rod without modifications? And vise versa? " one factor to keep in mind is that rods typically have a side that rides against its matched...

garage.grumpysperformance.com

piston ring gaps

the general rule is that for normal use a pistons top ring should have a minimum of .004 thousandths end gap for each inch of bore diam. ie a 4" bore requires a minimum of a .016 end gap, to prevent the ring ends from bearing on each other after heat expansion,expanding them, so as to prevent...

garage.grumpysperformance.com

how piston ring groove depth & clearance effects ring seal

the job of the rings is to provide a high pressure gas tight seal preventing pressure in the combustion chamber during the compression, exhaust and power strokes above the piston from leaking past the rings and piston, the combination of slight inertial loads friction and pressure above the...

garage.grumpysperformance.com

piston rings & related info

step ONE if the bores not concentric, and bore walls parallel and the bore surface consistent in its surface Finish or if you had the bore honed without the use of torque plates simulating a cylinder heads bolted in place, the rings WILL NOT SEAL as effectively , as they would if you had...

garage.grumpysperformance.com

Last edited: