most of us want to save money and theres almost always some guy selling used " C4 ALUMINUM CORVETTE HEADS" at a good price so I get asked if thats a good performance upgrade, as they are usually far less expensive than new aftermarket heads,those used aluminum corvette heads can usually be found for well under $400 a set, making them appear to be a bargain.

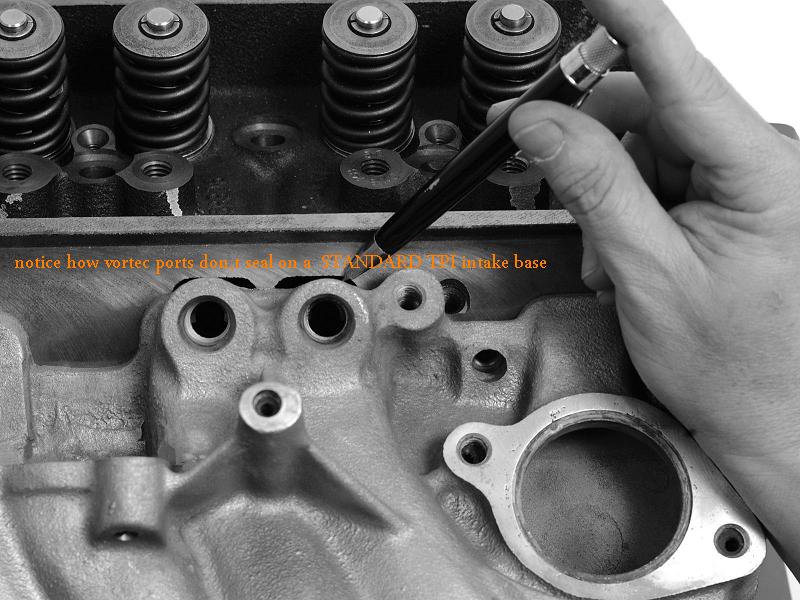

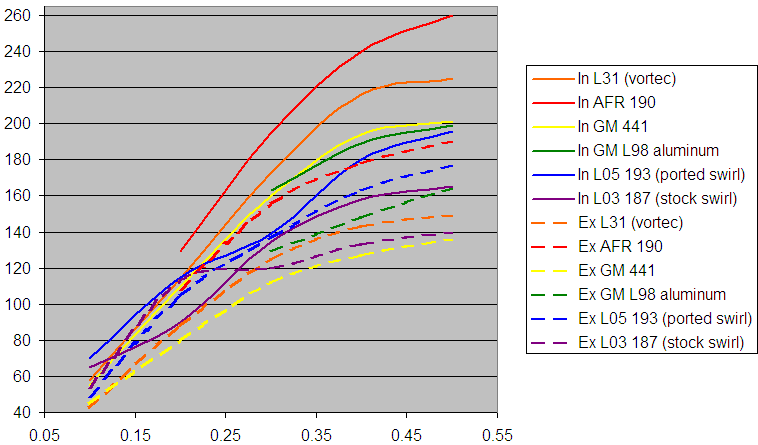

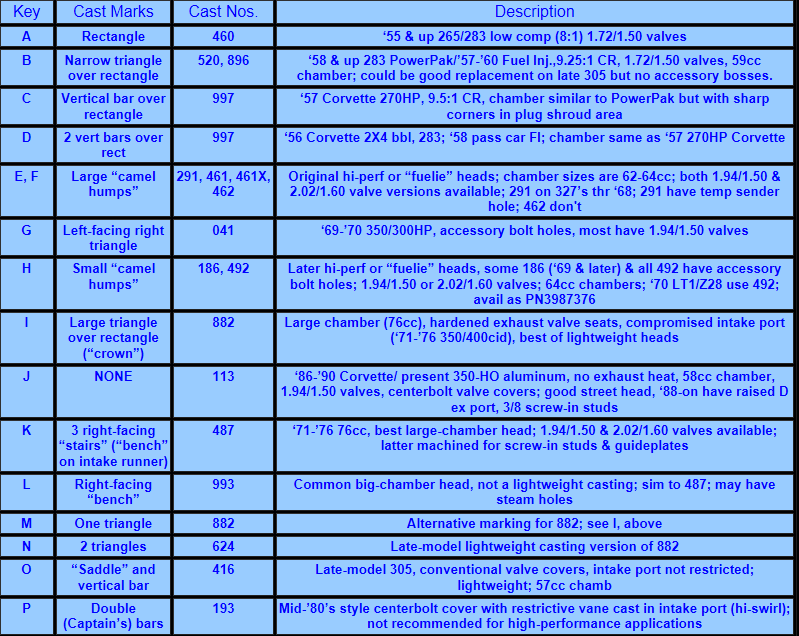

short answer? the stock, un-ported aluminum L98 heads flow about 200cfm and even stock iron VORTEC HEADS easily out perform them,as the stock 170cc production versions flow about 228cfm un touched

If you have them they save about 50 LBS on the front of the car, thats good and aluminum heads are easier to repair if damaged , but they do not provide a significant air flow advantage or power increase over the iron heads they replaced,

the basic bottom line here is that the stock L98 aluminum heads flow about 200cfm while even vortec heads flow about 230cfm and thats a significant difference, yet even vortec head are restrictive if your looking to exceed about 430hp, good aftermarket aluminum heads with 215cc or larger ports from AFR,BRODIX,TRICKFLOW,DART can easily flow 270-300cfm, making the corvette heads a lost cause in an all out horse power race.

buying out dated fuelie heads with todays increased tech aftermarket heads available if max performance is your goal is a bad joke, as you can easily put $1200 into machine work and porting and not come close to some of the better current aluminum aftermarket head flow levels

www.profilerperformance.com

these were great heads back in the 1960s but current design and testing technology has far surpassed that flow and power level nearly 60 years after they were originally used.

www.profilerperformance.com

these were great heads back in the 1960s but current design and testing technology has far surpassed that flow and power level nearly 60 years after they were originally used.

https://www.summitracing.com/parts/pro-66485

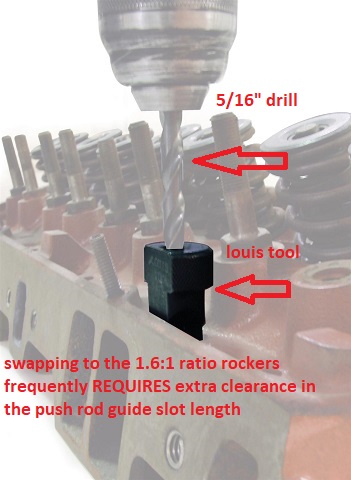

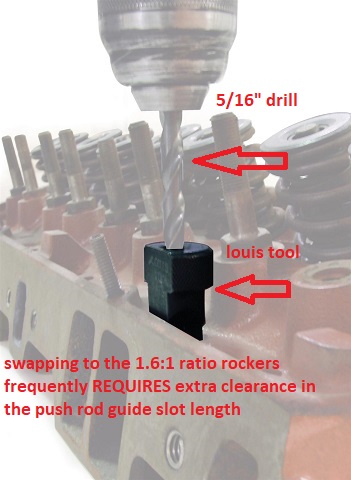

These Proform pushrod slotting tools are designed to elongate the pushrod slot in the cylinder head. They will make room for higher ratio rocker arms. Use these tools with a drill and a 5/16 in. drill bit to elongate the pushrod slot.

http://sallee-chevrolet.com/Cylinder_Heads/Vortec.html

read these threads and sub links

if you spend some time reading links and threads youll find theres far better options than the stock aluminum l98 corvette cylinder heads

http://garage.grumpysperformance.co...ding-sbc-crate-engine-heads.13041/#post-69348

http://garage.grumpysperformance.com/index.php?threads/port-speeds-and-area.333/

http://garage.grumpysperformance.co...llecting-cylinder-heads.796/page-2#post-57173

http://garage.grumpysperformance.co...ed-up-fuelie-heads-for-cheap.2099/#post-50526

http://garage.grumpysperformance.co...ose-first-sbc-heads-you-buy.10910/#post-47875

http://garage.grumpysperformance.com/index.php?threads/the-new-215cc-vortec-heads.266/#post-35948

http://garage.grumpysperformance.com/index.php?threads/port-and-runner-math.148/#post-13755

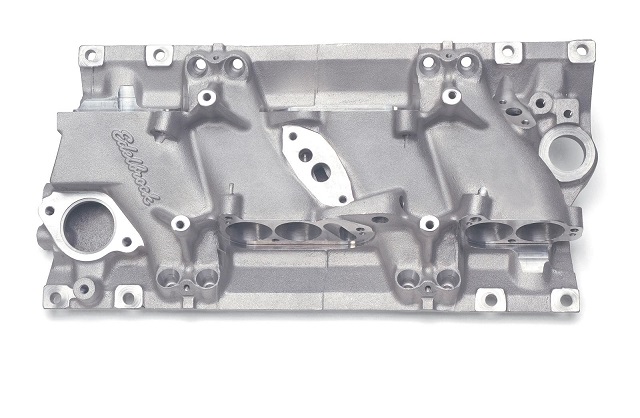

http://garage.grumpysperformance.com/index.php?threads/porting-the-edelbrock-pro-flow-xt-7137.14248/

http://garage.grumpysperformance.com/index.php?threads/c4-larger-intake-runners-l98-tpi.13785/

http://garage.grumpysperformance.com/index.php?threads/porting-can-help.462/

http://www.carcraft.com/techarticles/cc ... ewall.html

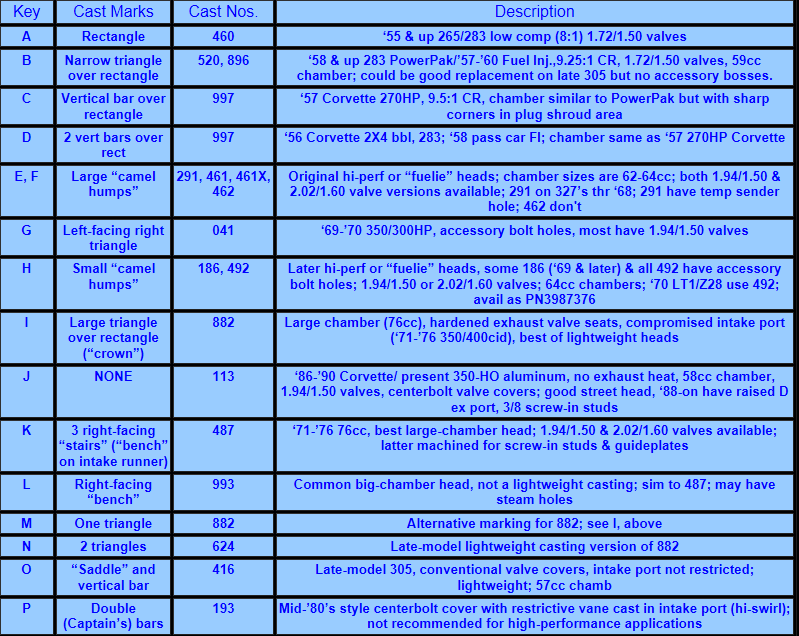

HERES SOME INFO

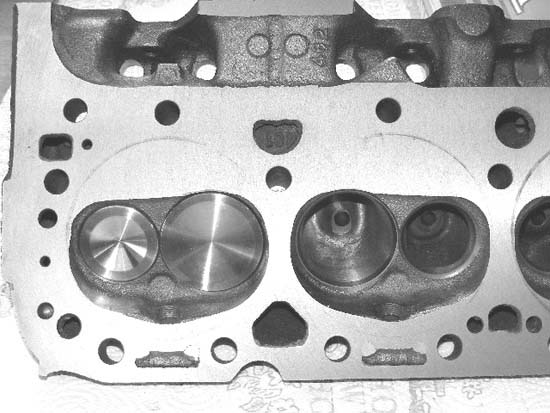

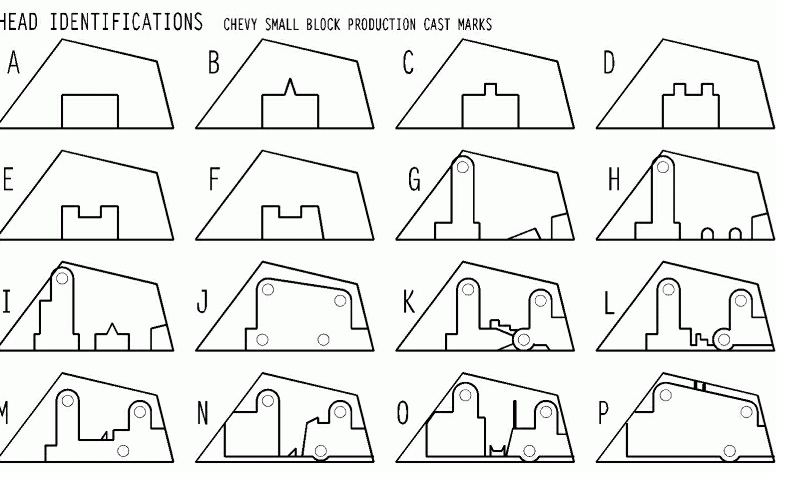

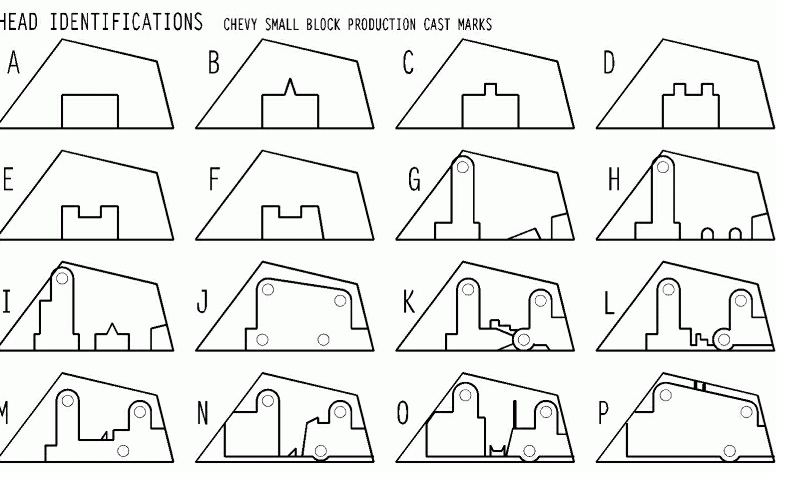

In mid-1986, GM converted the corvette over to aluminum heads, casting '128. (Saving about 40lbs off the front end compared to the old '624 Iron heads.)This continued throughout the 1987 model year. In '88, they revised the exhaust port design, raising it 0.100" and it was shaped into a "D", thus they are called D-ports. There are other differences in the two heads also, in that the 128 heads were fitted with an exhaust valve rotator. To accomodate this, the valve spring seat was lowered approximately 0.125" or so. Therefore to delete the heavy exhaust valve rotator on the 128's, you need to shim the spring accordingly to achieve the correct spring installed height.

Usually when you see "L98 vette" heads listed on some site, this '113 head is what they are talking about. ZZ4 and H.O. 350 heads are the same, but with different springs.

Note: I have 'heard' that the last 250 units of the 87 model year came with the '113 head, from the factory.

'128s should be good for 300-325ish, whereas the '113s should support up to 350.

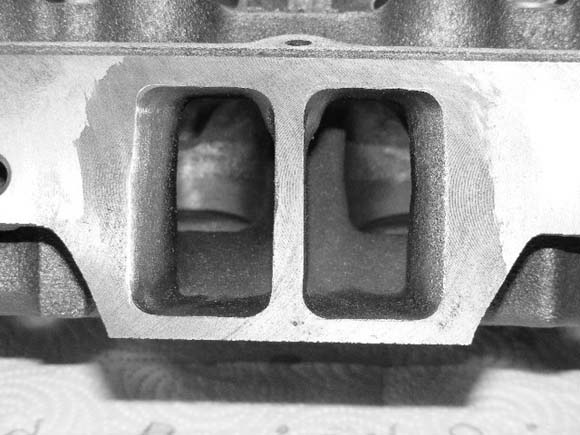

Intake runner-163cc

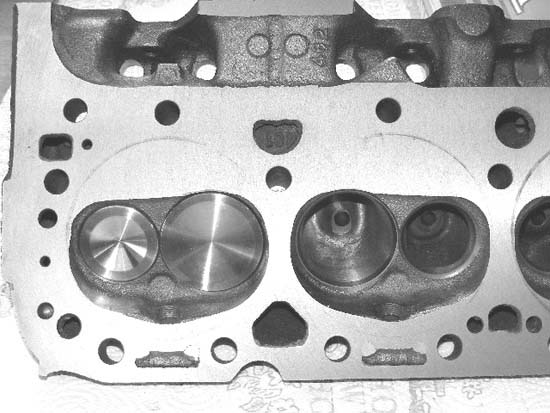

Combustion Chamber size for '113-58cc

Valves-1.94/1.5

Plug-L98 angle, this is a GM angle, not every angled-plug head offered in aftermarket is this angle. You must check on what is being sold, as not all headers fit different angled plug heads.

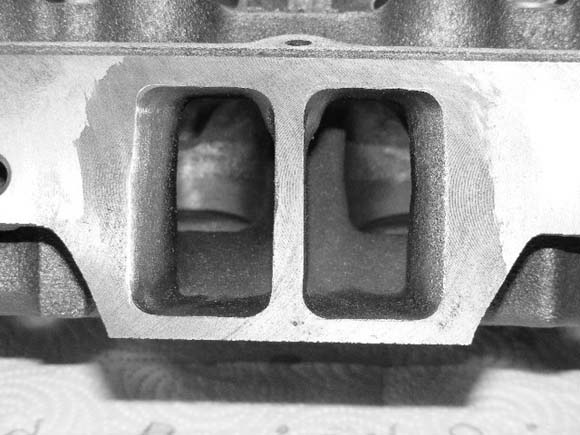

Stock exhaust port dimension for '113 D-ports:

1.55" horizontal dimension (flat part of the D)

1.475" vertical dimension (total port height)

0.775" radius along the upper port surface

5.38" perimeter length (requires 1.75" header pipe without stretching)

Here are some intake flow numbers for #113 heads from TPIS "Insider Hints":

Lift......Stock......Ported

.100"......62...........68

.200".....116.........149

.300".....161.........193

.400".....185.........211

.500".....195.........211

.600".....198.........211

Note that the "Ported" numbers were with 1.940" intake valves.

These flow #'s are from fully ported '113 heads:

The flow numbers are with 2.02/1.57 valves and the figures are from the one doing the work.

I have not had them verified by any other source:

.1000 86.9

.2000 144.1

.3000 179.3

.4000 215.2

.5000 231.0

.5500 232.3

.6000 242.3

.6500 243.0

The only data I have on '128 flow was posted on the forum years ago:

Intake - 199 cfm @ 0.500" @ 28" H2O

Exhaust - 110 cfm @ 0.500" @ 28" H2O

You may also find data on the Cylinder Heads links on my main page.

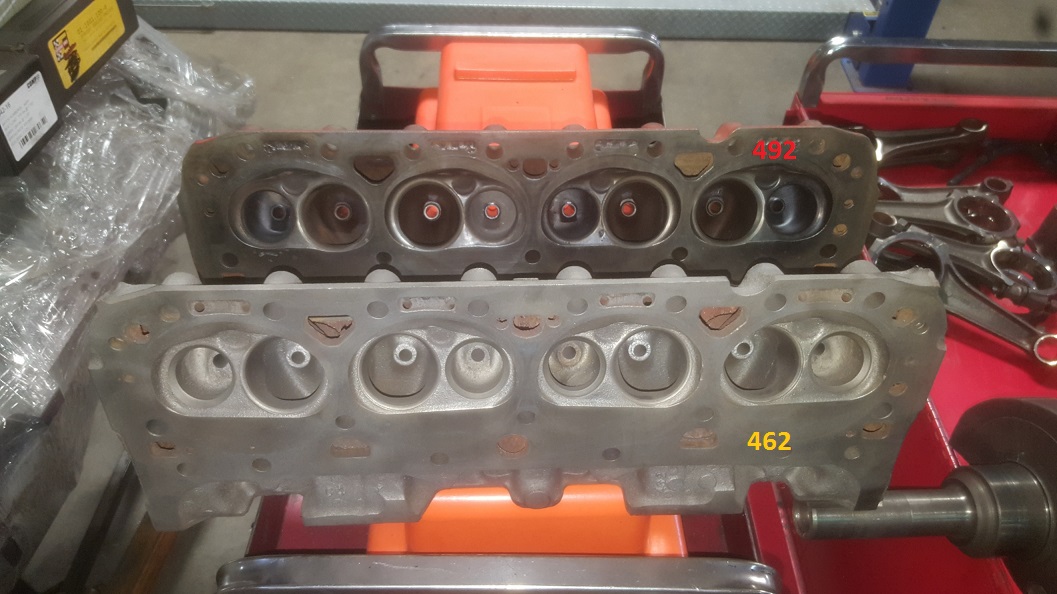

The 84-86E head is casting #462624 (PN #464045)

161/62 int/exh port in cc

2.02/1.6 valves

76cc combustion chamber

Plug-straight

It is an identical casting to the '492 head, except that the '492 has a smaller chamber. '492 is itself a replacement for 461, 462, and 186.

They both have a heat-riser passage for fast warm-ups.

keep in mind swapping heads gives you the option to increase or decrease the compression ratio of the combo, and once the compression ratios increased you can use a longer duration cam timing without sacrificing a great deal of low rpm torque, that you would loose with the lower compression ratio if the same cam were installed in the lower compression ratio combo

"(assume on a stock 350 small block)

Speaking in generalities and assuming no other changes, what's the relation between cylinder head combustion chamber size and overall engine compression?

Does just changing heads from a stock 76cc head, to a head with a smaller chamber make that much overall difference on engine c/ratio? Such as a 64cc or 58cc chamber. How about changes on necessary octane requirement?

Just curious to see what can be expected. I've read plenty on what performance gains can be had and what would work best for 350 TPI, but curious to see the other factors may play out.

Thanks"

Ok lets look at it a bit, theres two types of compression ratio, static and dynamic, keep in mind its MOSTLY dynamic compression ratio, that effects your results.

youll gain about 3% in hp increasing the effective static compression ratio one full point, so swapping from a 9:1 to a 10:1 cpr boost torque about 3%

swapping from a 76cc head to a 58cc head is a 1.84:1 cpr change so you can reasonably expect a 1.84 x 3% or a 5.52% boost in torque from that change alone.

if your current engine made 330hp that would jump to about 5.52% higher if the tq curve remained consistant, so youll see about 350 hp.

one of the the main functions of compression is to pack the fuel/air mix into a tight area for both fast effective ignition and to provide a mechanical advantage for the piston & rod assembly to push against the crank throw,as that mass in the combustion chamber burns and rapidly expands.

lets look at your question, given identical 350 displacement engines with flat top pistons and a common .032 thick head gasket, a .023 deck and 5cc valve notches, heres what your going to see in STATIC COMPRESSION,as a result of combustion chamber changes

58cc=10.61/1

60cc=10.36/1

62cc=10.12/1

64cc=9.89/1

68cc=9.47/1

72cc=9.09/1

74cc=8.91/1

76cc=8.75/1

keep in mind you want to stay at about 8:1-8.5:1 in DYNAMIC compression

to run common pump gas without getting into detonation

that depends on the fuel octane, cylinder head temp. and several other variables but generally 8.0-8.5:1 dynamic works out well if your going to run mid grade pump gas

calculators

http://kb-silvolite.com/calc.php?action=comp

http://www.csgnetwork.com/compcalc.html

http://www.bgsoflex.com/cr.html

threads/info

viewtopic.php?f=52&t=266&p=40004&hilit=215cc+vortec#p40004

http://victorylibrary.com/mopar/chamber-tech-c.htm

http://victorylibrary.com/mopar/piston_position-c.htm

http://victorylibrary.com/mopar/cam-tech-c.htm

http://forum.grumpysperformance.com/viewtopic.php?f=52&t=727

http://forum.grumpysperformance.com/viewtopic.php?f=50&t=499

short answer? the stock, un-ported aluminum L98 heads flow about 200cfm and even stock iron VORTEC HEADS easily out perform them,as the stock 170cc production versions flow about 228cfm un touched

If you have them they save about 50 LBS on the front of the car, thats good and aluminum heads are easier to repair if damaged , but they do not provide a significant air flow advantage or power increase over the iron heads they replaced,

the basic bottom line here is that the stock L98 aluminum heads flow about 200cfm while even vortec heads flow about 230cfm and thats a significant difference, yet even vortec head are restrictive if your looking to exceed about 430hp, good aftermarket aluminum heads with 215cc or larger ports from AFR,BRODIX,TRICKFLOW,DART can easily flow 270-300cfm, making the corvette heads a lost cause in an all out horse power race.

buying out dated fuelie heads with todays increased tech aftermarket heads available if max performance is your goal is a bad joke, as you can easily put $1200 into machine work and porting and not come close to some of the better current aluminum aftermarket head flow levels

210cc All American Aluminum 23° SBC Racing Heads, Assembled, Straight

Producer and Seller of aluminum aftermarket cylinder heads, intake manifolds and engine accessories. Specializing in big block chevy ,small block chevy, big block ford and small block ford.

https://www.summitracing.com/parts/pro-66485

These Proform pushrod slotting tools are designed to elongate the pushrod slot in the cylinder head. They will make room for higher ratio rocker arms. Use these tools with a drill and a 5/16 in. drill bit to elongate the pushrod slot.

http://sallee-chevrolet.com/Cylinder_Heads/Vortec.html

read these threads and sub links

if you spend some time reading links and threads youll find theres far better options than the stock aluminum l98 corvette cylinder heads

http://garage.grumpysperformance.co...ding-sbc-crate-engine-heads.13041/#post-69348

http://garage.grumpysperformance.com/index.php?threads/port-speeds-and-area.333/

http://garage.grumpysperformance.co...llecting-cylinder-heads.796/page-2#post-57173

http://garage.grumpysperformance.co...ed-up-fuelie-heads-for-cheap.2099/#post-50526

http://garage.grumpysperformance.co...ose-first-sbc-heads-you-buy.10910/#post-47875

http://garage.grumpysperformance.com/index.php?threads/the-new-215cc-vortec-heads.266/#post-35948

http://garage.grumpysperformance.com/index.php?threads/port-and-runner-math.148/#post-13755

http://garage.grumpysperformance.com/index.php?threads/porting-the-edelbrock-pro-flow-xt-7137.14248/

http://garage.grumpysperformance.com/index.php?threads/c4-larger-intake-runners-l98-tpi.13785/

http://garage.grumpysperformance.com/index.php?threads/porting-can-help.462/

http://www.carcraft.com/techarticles/cc ... ewall.html

HERES SOME INFO

In mid-1986, GM converted the corvette over to aluminum heads, casting '128. (Saving about 40lbs off the front end compared to the old '624 Iron heads.)This continued throughout the 1987 model year. In '88, they revised the exhaust port design, raising it 0.100" and it was shaped into a "D", thus they are called D-ports. There are other differences in the two heads also, in that the 128 heads were fitted with an exhaust valve rotator. To accomodate this, the valve spring seat was lowered approximately 0.125" or so. Therefore to delete the heavy exhaust valve rotator on the 128's, you need to shim the spring accordingly to achieve the correct spring installed height.

Usually when you see "L98 vette" heads listed on some site, this '113 head is what they are talking about. ZZ4 and H.O. 350 heads are the same, but with different springs.

Note: I have 'heard' that the last 250 units of the 87 model year came with the '113 head, from the factory.

'128s should be good for 300-325ish, whereas the '113s should support up to 350.

Intake runner-163cc

Combustion Chamber size for '113-58cc

Valves-1.94/1.5

Plug-L98 angle, this is a GM angle, not every angled-plug head offered in aftermarket is this angle. You must check on what is being sold, as not all headers fit different angled plug heads.

Stock exhaust port dimension for '113 D-ports:

1.55" horizontal dimension (flat part of the D)

1.475" vertical dimension (total port height)

0.775" radius along the upper port surface

5.38" perimeter length (requires 1.75" header pipe without stretching)

Here are some intake flow numbers for #113 heads from TPIS "Insider Hints":

Lift......Stock......Ported

.100"......62...........68

.200".....116.........149

.300".....161.........193

.400".....185.........211

.500".....195.........211

.600".....198.........211

Note that the "Ported" numbers were with 1.940" intake valves.

These flow #'s are from fully ported '113 heads:

The flow numbers are with 2.02/1.57 valves and the figures are from the one doing the work.

I have not had them verified by any other source:

.1000 86.9

.2000 144.1

.3000 179.3

.4000 215.2

.5000 231.0

.5500 232.3

.6000 242.3

.6500 243.0

The only data I have on '128 flow was posted on the forum years ago:

Intake - 199 cfm @ 0.500" @ 28" H2O

Exhaust - 110 cfm @ 0.500" @ 28" H2O

You may also find data on the Cylinder Heads links on my main page.

The 84-86E head is casting #462624 (PN #464045)

161/62 int/exh port in cc

2.02/1.6 valves

76cc combustion chamber

Plug-straight

It is an identical casting to the '492 head, except that the '492 has a smaller chamber. '492 is itself a replacement for 461, 462, and 186.

They both have a heat-riser passage for fast warm-ups.

keep in mind swapping heads gives you the option to increase or decrease the compression ratio of the combo, and once the compression ratios increased you can use a longer duration cam timing without sacrificing a great deal of low rpm torque, that you would loose with the lower compression ratio if the same cam were installed in the lower compression ratio combo

"(assume on a stock 350 small block)

Speaking in generalities and assuming no other changes, what's the relation between cylinder head combustion chamber size and overall engine compression?

Does just changing heads from a stock 76cc head, to a head with a smaller chamber make that much overall difference on engine c/ratio? Such as a 64cc or 58cc chamber. How about changes on necessary octane requirement?

Just curious to see what can be expected. I've read plenty on what performance gains can be had and what would work best for 350 TPI, but curious to see the other factors may play out.

Thanks"

Ok lets look at it a bit, theres two types of compression ratio, static and dynamic, keep in mind its MOSTLY dynamic compression ratio, that effects your results.

youll gain about 3% in hp increasing the effective static compression ratio one full point, so swapping from a 9:1 to a 10:1 cpr boost torque about 3%

swapping from a 76cc head to a 58cc head is a 1.84:1 cpr change so you can reasonably expect a 1.84 x 3% or a 5.52% boost in torque from that change alone.

if your current engine made 330hp that would jump to about 5.52% higher if the tq curve remained consistant, so youll see about 350 hp.

one of the the main functions of compression is to pack the fuel/air mix into a tight area for both fast effective ignition and to provide a mechanical advantage for the piston & rod assembly to push against the crank throw,as that mass in the combustion chamber burns and rapidly expands.

lets look at your question, given identical 350 displacement engines with flat top pistons and a common .032 thick head gasket, a .023 deck and 5cc valve notches, heres what your going to see in STATIC COMPRESSION,as a result of combustion chamber changes

58cc=10.61/1

60cc=10.36/1

62cc=10.12/1

64cc=9.89/1

68cc=9.47/1

72cc=9.09/1

74cc=8.91/1

76cc=8.75/1

keep in mind you want to stay at about 8:1-8.5:1 in DYNAMIC compression

to run common pump gas without getting into detonation

that depends on the fuel octane, cylinder head temp. and several other variables but generally 8.0-8.5:1 dynamic works out well if your going to run mid grade pump gas

calculators

http://kb-silvolite.com/calc.php?action=comp

http://www.csgnetwork.com/compcalc.html

http://www.bgsoflex.com/cr.html

threads/info

viewtopic.php?f=52&t=266&p=40004&hilit=215cc+vortec#p40004

http://victorylibrary.com/mopar/chamber-tech-c.htm

http://victorylibrary.com/mopar/piston_position-c.htm

http://victorylibrary.com/mopar/cam-tech-c.htm

http://forum.grumpysperformance.com/viewtopic.php?f=52&t=727

http://forum.grumpysperformance.com/viewtopic.php?f=50&t=499

Last edited by a moderator: