rather interesting related linked info

http://www.superchevy.com/how-to/148-0505-engine-building-tools/

http://www.enginelabs.com/engine-tech/guide-to-proform-engine-building-tools/

http://www.wizardswarehouse.com/products/tools

Hey GRUMPY, I need a few basic tools to measure bearing clearances and tools for installing a cam, etc, and suggestions? (and yeah, I'm not swimming in cash, so please take that into account!) keep in mind there's a long list of more expensive tools, like mills, lathes, various types of...

garage.grumpysperformance.com

http://www.hotrod.com/how-to/engine/ccrp-9901-affordable-engine-building-tools/

THATS EASY! its the skill level and experience of the guy or gal IN that garage that determines the level of expertize,and the resulting finished work, hand tools a decent set of jack stands and knowing what your doing will ALWAYS produce better results than all the lifts, compressors,welders...

garage.grumpysperformance.com

http://www.powerhouseproducts.com/#

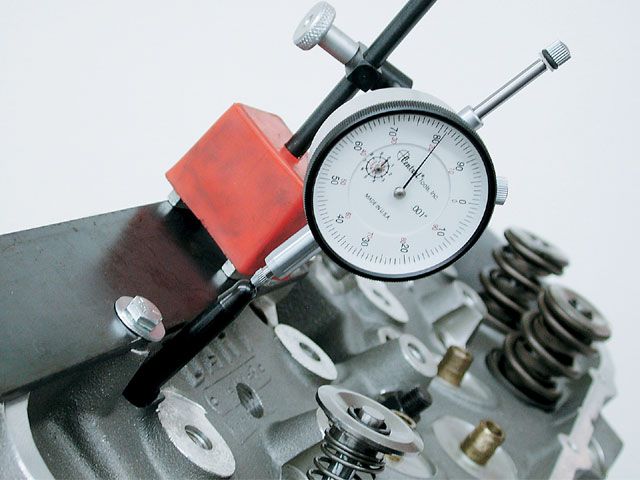

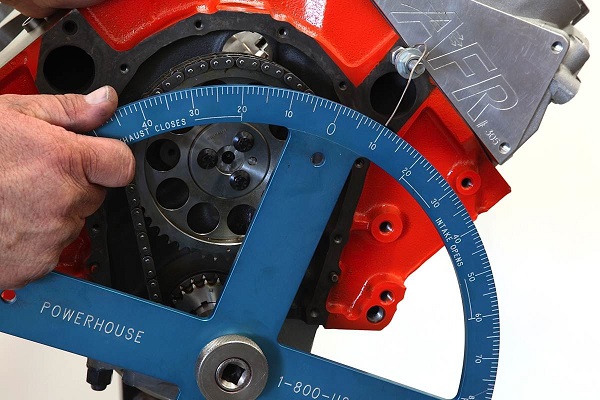

GrumpyVette I've bin reading alot about cam degreeing since i'll be attempting this in the next week or so, I'm pretty sure I can handle the process but wanted to know about the tools used I've read and also watch a video about degreeing a cam but have not found out is it better to use the...

garage.grumpysperformance.com

http://garage.grumpysperformance.co...me-repair-when-parts-are-not-available.11371/

http://www.moroso.com/eb/catalog/navigationPath/1::Moroso Performance Products/22000::Tools?resetOffset=true&entryId=catalog.productgroup.122000&expand=true&menuId=second.menu

http://garage.grumpysperformance.com/index.php?threads/under-car-safety.26/

http://www.sears.com/craftsman-311-...SellerId=Sears&prdNo=2&blockNo=2&blockType=G2

most of us find we accumulate tools on the basis of what we need at the time when we run into a job we can,t do with the tools we own.

http://garage.grumpysperformance.com/index.php?threads/starter-tool-set.6032/#post-18696

http://garage.grumpysperformance.com/index.php?threads/what-hand-tools-to-buy.4069/#post-10827

http://garage.grumpysperformance.com/index.php?threads/labeling-your-tool-chest-drawers.3283/

http://garage.grumpysperformance.co...ete-but-it-will-get-you-started.834/#post-125

http://garage.grumpysperformance.com/index.php?threads/tool-boxes-and-chests.10357/page-3#post-64730

http://garage.grumpysperformance.com/index.php?threads/bare-minimum-tools.11026/#post-51843

http://garage.grumpysperformance.com/index.php?threads/under-car-safety.26/

would suggest purchase of a semi-decent quality floor jack

https://www.harborfreight.com/3-ton-daytona-professional-steel-floor-jack-super-duty-63183.html

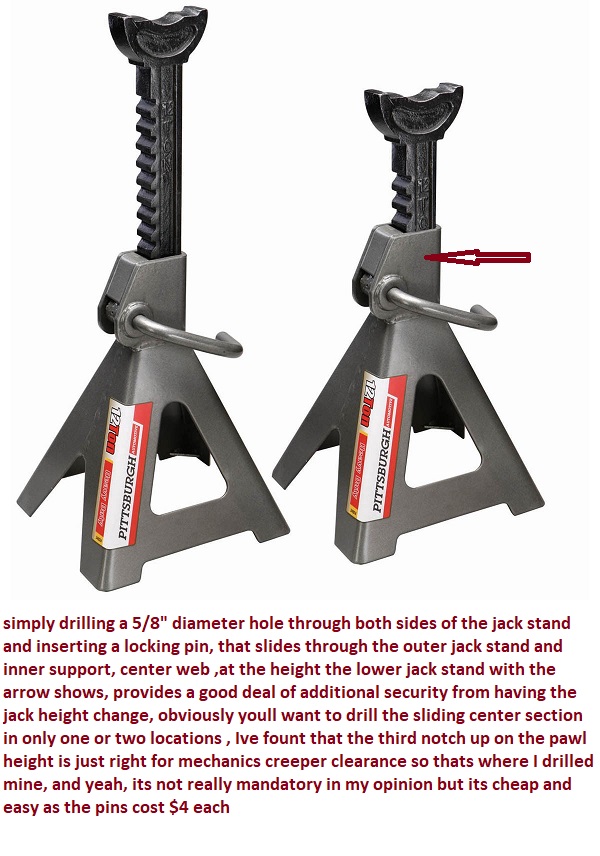

and 4 12 ton rated jack stands

https://www.harborfreight.com/12-ton-steel-jack-stands-61599.html

and a cheap mechanics creeper

https://www.harborfreight.com/40-in-300-lb-capacity-low-profile-creeper-69262.html

a couple work lamps

https://www.harborfreight.com/long-line-fluorescent-work-light-46890.html

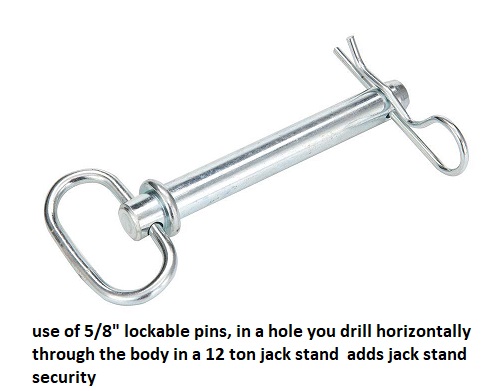

5/8 in. x 4-3/4 in. Clevis Pin available at home depot for $4 each

I've painted every third jack stands tooth yellow and the second tooth , the one below that red and the first tooth below that blue,

this makes matching the height on all 4 stand far faster too adjust , the third notch for the pawl,

is the preferred creeper height, under my corvettes,

for clutch and brake jobs

and where the pin slides through and locks,

with the pawl and pin engaged the stand height will not change accidentally

and suggest you try to only work on level concrete floors

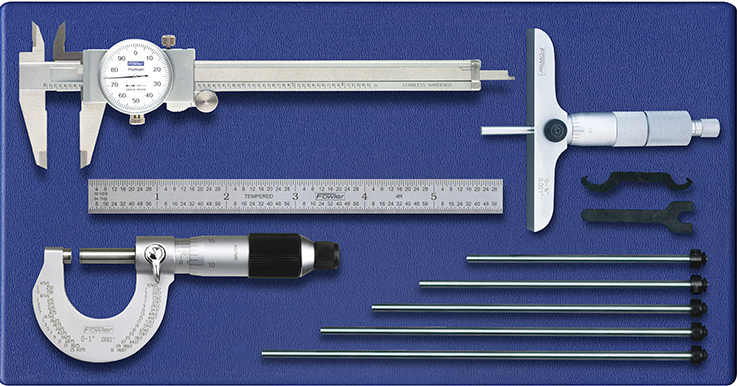

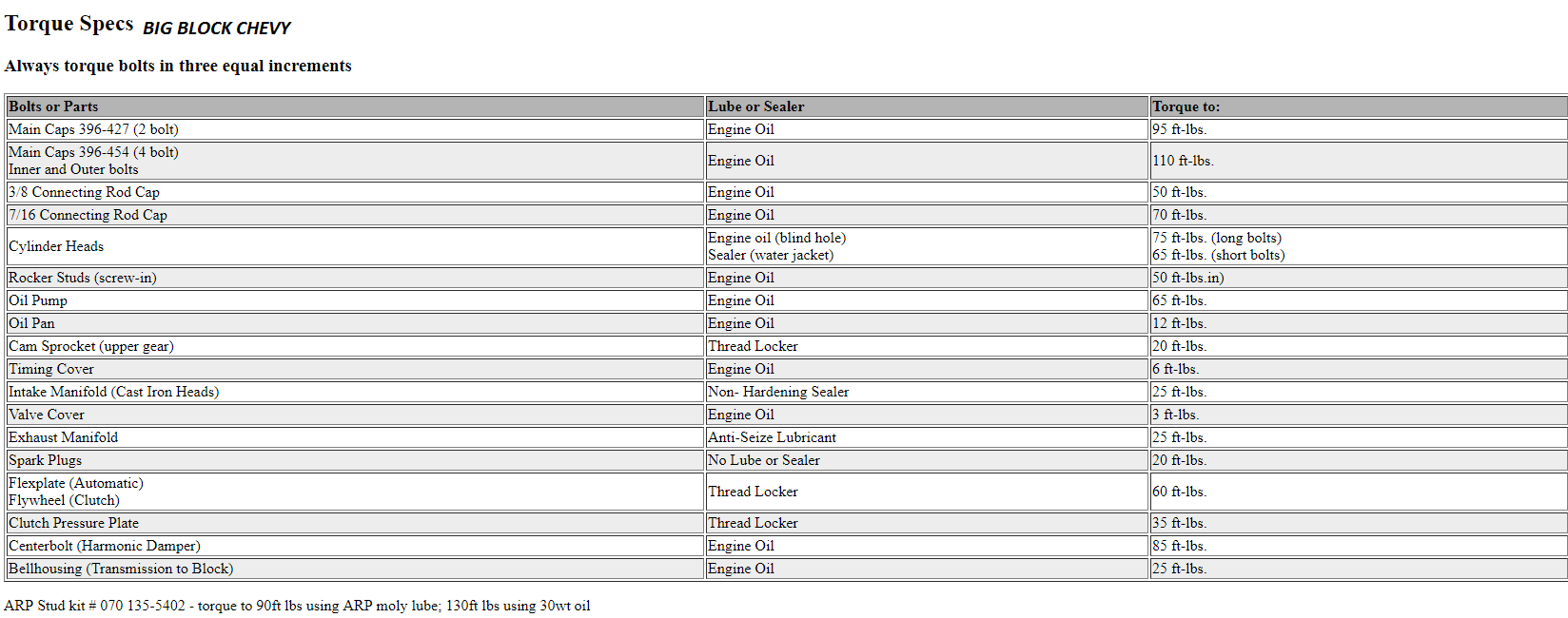

almost every mechanics tool box needs a few basic measuring tools and supplies, dealing in proven facts as to correct clearance sure beats guessing

https://www.amazon.com/Claytoon-Set...d=1466872286&sr=8-17&keywords=plastilina+clay

http://www.utrechtart.com/Plastalin...currency=USD&gclid=CN3G75zOw80CFQgaaQodKbgFjA

at times having an inspection tools handy when you can't get a good look at a problem any other way

if your going to buy a used short block or a bare block from an un-known private source or most salvage yards, obviously you'll need to do BOTH a close inspection, WITH some measuring tools

AND get some idea of the blocks physical condition

this is also a good inspection tool

http://www.thetoolwarehouse.net/p-6283- ... pv618.aspx

GOOGLE PV-618 and PV-636

High resolution lens provides a clear image of objects as close as 3/4 inch and over one foot away while providing a wide 40 degree field of view.

Powerful lamp illuminates dark crevices on-demand with the push of a button conveniently located on the handle.

Ergonomically designed handle is comfortable to hold and allows one-handed focusing and light activation.

Rugged and water resistant, ProVision is made of high impact ABS and flexible cable sheathing. (Note: Shaft is water resistant, not the handle.)

PV-618 and PV-636 models have .23†diameter, flexible, non-obedient cable. Durable carrying case included.

Accessories available to optimize ProVision for specialized applications.

Made in the USA

Specifications:

Cable Length: 18" (457.2mm)

Cable Diameter: .23"

Handle Length: 6" (152.4mm)

Handle Width: 1.43" (36.2mm)Overall Length: 24" (609.6mm)

Weight of Scope w/ Carrying Case: 1 lb. 5.7 oz (615 g)

Field of View: 40°

Optimal Viewing Distance: Min. .8" (20mm); Max. is dependent upon ambient lighting conditions.

Lamp Volts: 2.7 volts (Halogen)

Power Source: 2 AA batteries (not included)

Pressure Necessary to Operate Lamp: 2.9 avg. p/psi; 3.2 max. p/psi

heres a cheaper version that works with a lap top computer

GCA 5.5mm Diameter USB Waterproof 6 Led Endoscope Borescope Inspection Wire Camera (5m)

Price: $18.50 & FREE Shipping on orders over $49. Details

- Waterproof wire endoscope

- Diameter:5.5mm head, 5 meters long flexible tube

- High resolution 1.3MP with 1/12" VGA CMO

- 6 LED lighting adjustable, can be inspected the hard-to-see areas.

- Waterproof : IP67, 60°Viewable Angle. Can take photo & video and save in your computer

https://www.google.com/search?q=pro...=122&ie=UTF-8#q=proform+engine+tools&tbm=shop

http://www.goodson.com/

ENGINE BUILDING TOOL Shopping WISH LIST List

ENGINE STAND

Tapered Ring Compressor

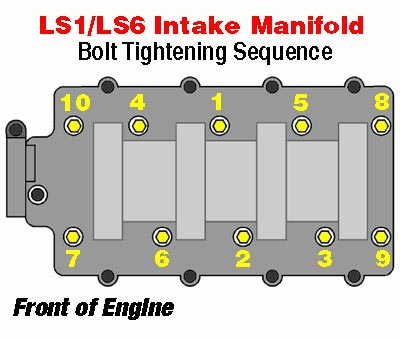

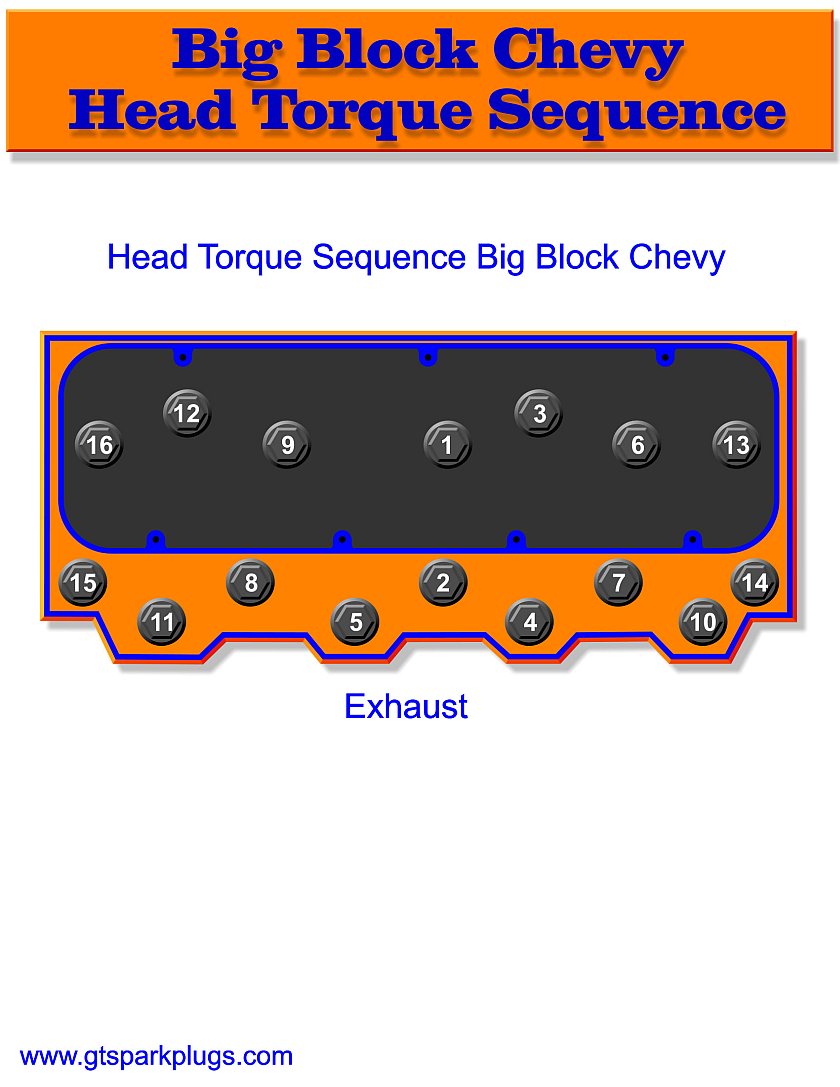

THIS BEAM STYLE TORQUE WRENCH IS THE TYPE TORQUE WRENCH YOU WANT TO CHECK ROTATIONAL RESISTANCE

BUT NOT WHAT YOULL USE TO TIGHTEN HEAD BOLTS

HUSKY $88 (worked rather well, over all I was pleased)

http://www.homedepot.com/p/Husky-1-2-in-Click-Torque-Wrench-H2DTW/202916180?N=5yc1vZc6ev

FOR HEAD BOLTS AND MAIN CAP STUDS ETC.

youll need a good quality torque wrench

the new ICON line looks decent

https://www.harborfreight.com/12-in-50-250-ft-lb-professional-torque-wrench-64064.html

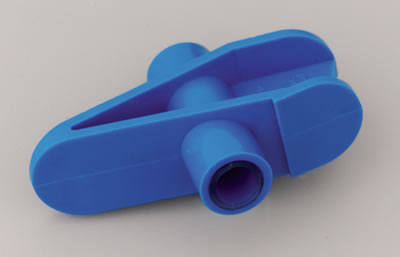

Piston Ring Squaring Tool

http://www.grumpysperformance.com/

ringsqtool.jpg

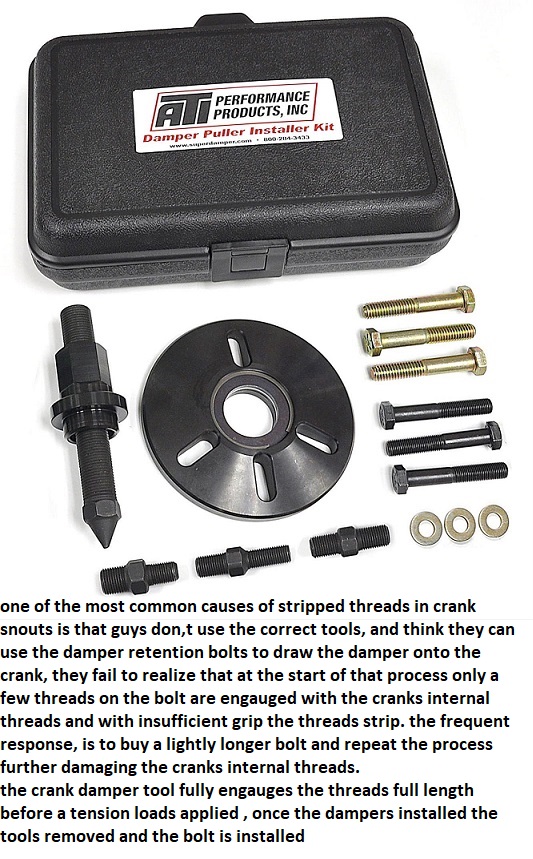

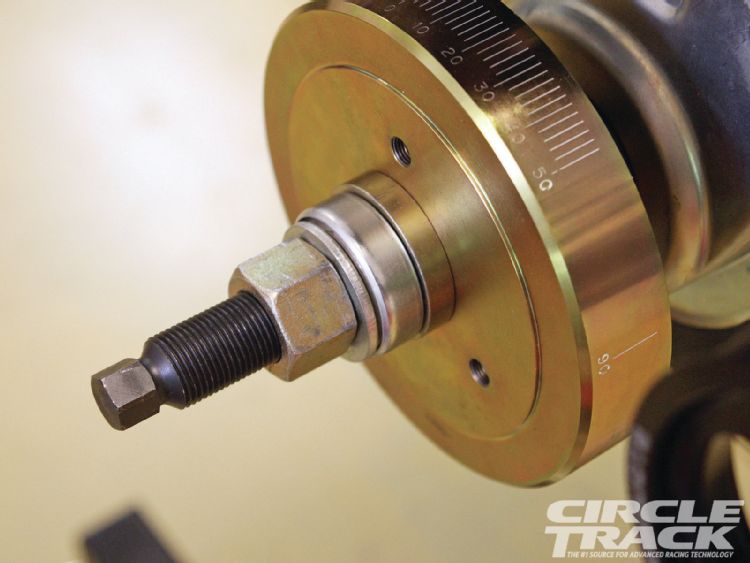

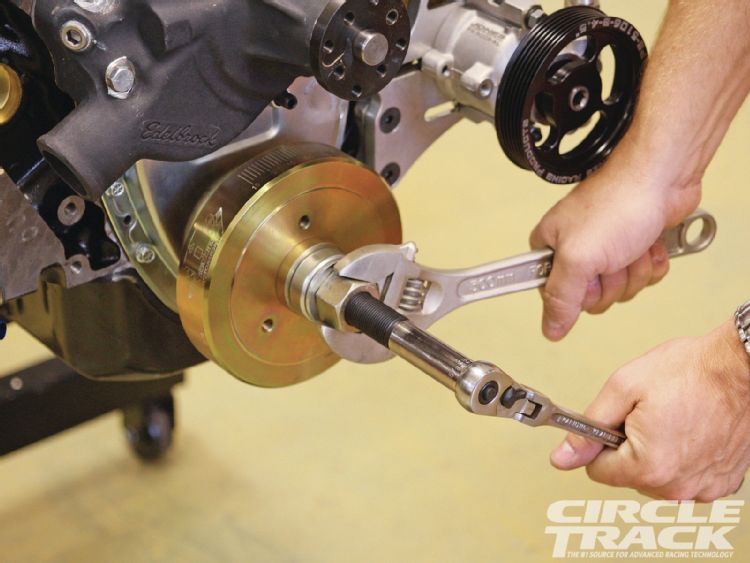

damper tool

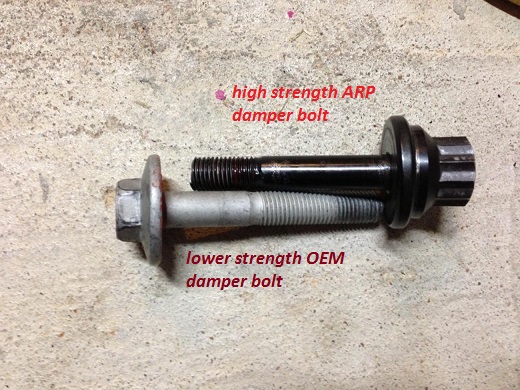

btw if youve ever tried to draw on a damper with a crank bolt from a local hard ware store this is frequently the result, that or stripped crank threads, ID strongly suggest use of the correct Damper tool, and use of ARP crank bolts once its properly installed

next time BUY AND USE AN ARP BRAND BOLT

I,ve generally found that if you've stripped the SBC crank snout threads the best answer is to drill and re-thread to the standard and larger BBC crank snout bolt threads size

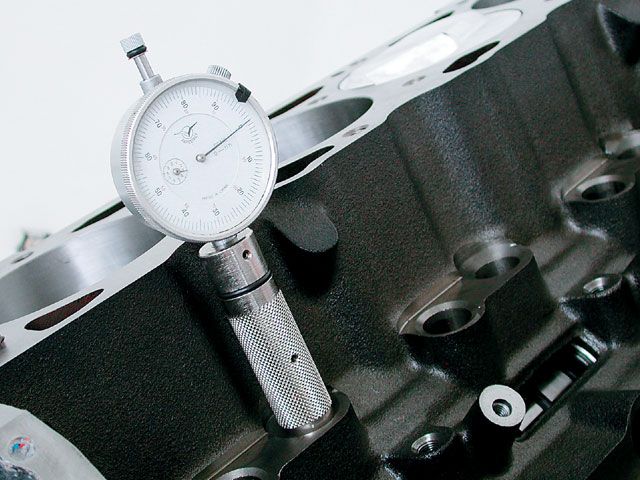

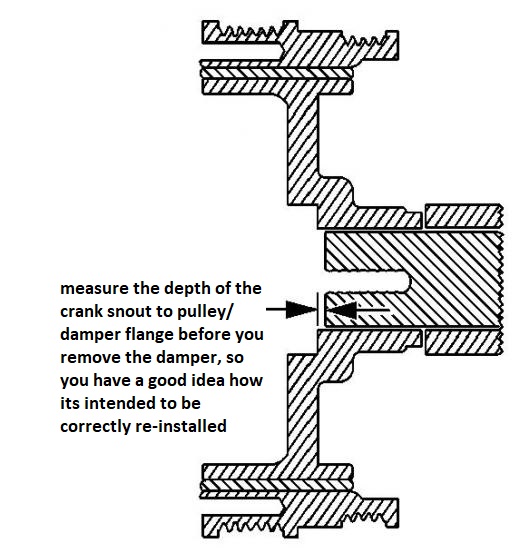

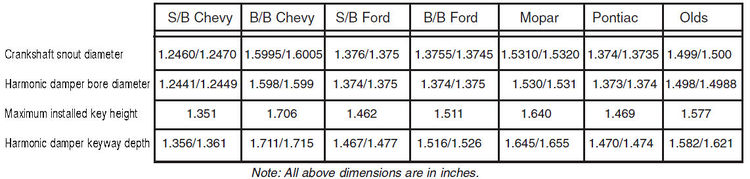

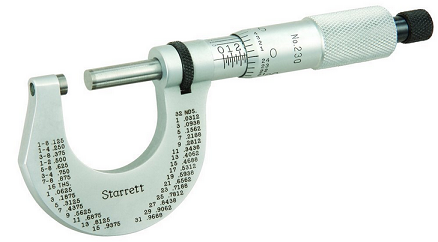

accurately measure the internal damper and the external crank snout diameter

Measure the crank-snout diameter with a micrometer (above left). Ours measured 1.600 inch, which is right on spec. Then use a dial-bore gauge to determine the inside diameter of the Fluidampr damper (below). Ours came in 1.599-inch, resulting in a .001-inch interference fit. This is the right amount of clearance to provide a good snug fit on the crankshaft, but still be able to install and remove without difficulty. Another method of measuring the damper hub ID of your is with a snap gauge (above right). After setting the gauge, the micrometer is used to to determine the final measurement. In this case, the same measurement as the dial bore gage was reached.

http://www.enginebuildermag.com/Article ... stons.aspx

http://www.arp-bolts.com/

http://www.summitracing.com/parts/ARP-134-2501/

http://www.summitracing.com/parts/ARP-234-2503/

if your current crank bolt is an ARP bolt, heres the dimensions,

keep in mind a bolt threaded in steel should have 1.5 times its diam. MINIMUM in the threads before the bolt starts to draw or tighten or clamp and TWICE its diam. in the threads is better as a minimum to prevent stripped threads, and remember the bolt should never be allowed to bottom out in the crank snout threads and tighten against the bottom of the drilled hole either[/B]

Summit Racing Part Number ARP-134-2501

Thread Size 7/16-20 RH in.

Underhead Length (in) 2.470 in.

Head Style 12-point

Washer Included Yes

Fastener Yield Strength (psi) 200,000 psi

Fastener Material Chromemoly

Fastener Finish Black oxide

Quantity Sold individually.

Notes Features 5/8 in. socket size.

One tough bolt.

As the crankshaft flexes, the damper absorbs incredible amounts of energy. These damper bolt kits from ARP will ensure that your balancer is locked into position. They feature a 1/4 in. thick wide-area washer and an extra tall 12-point head that accepts a deep socket to eliminate the fear of stripping the head.

http://www.summitracing.com/parts/ARP-134-2501/

now you can probably re-tap the current threads and use a longer bolt and get by for now, but drilling it with the correct larger drill diam. and re-threading for the big block Chevy bolt is the more common route taken once you strip crank threads

viewtopic.php?f=53&t=1480&p=6221&hilit=stripped+crank#p6221

viewtopic.php?f=53&t=1798&p=5680&hilit=stripped+crank#p5680

there is supposed to be about a .0001 -.0002 INTERFERENCE fit! so the damper has far less tendency to spin on the crank snout or work the woodriff key loose, you can generally polish the crank snout, and internal damper hole with a flap wheel and 400 grit sand paper enough to get a smoother surface, then, place the damper in boiling water to heat and expand it and oil its mating surface, use the correct damper installation tool, pick the damper up with oven mitts so you don,t get burned, use the tool to install it

http://www.summitracing.com/parts/otc-6505

I,ve generally found that if you've stripped the SBC crank snout threads the best answer is to drill and re-thread to the standard and larger BBC crank snout bolt threads size

https://www.nookandtranny.com/Info_LT1.html

these tools work well, fit most engines and if you do break off a thread adapter you can order a replacement without needing to pay for the whole new tool, and keep in mind the threads strip or adapters break if the dampers OVER TIGHTENED,ALL TOOLS WILL BREAK IF OVER STRESSED, this CAN generally be avoided with simply taking a few accurate measurements and use of some marvel mystery oil on the damper, crank and the installing tool threads

Yes I busted one thread adapter years back , but it was a P.I.T.A. waiting on a replacement and I learned not to over tighten the tool, and watch carefully on the measurements and have not had that happen for 30 plus years keeping the tool and damper and crank snout well lubed makes it slide on easier

measuring and checking the interference fits correct helps

read thru these threads, for info on seating a damper and re-threading a stripped crank

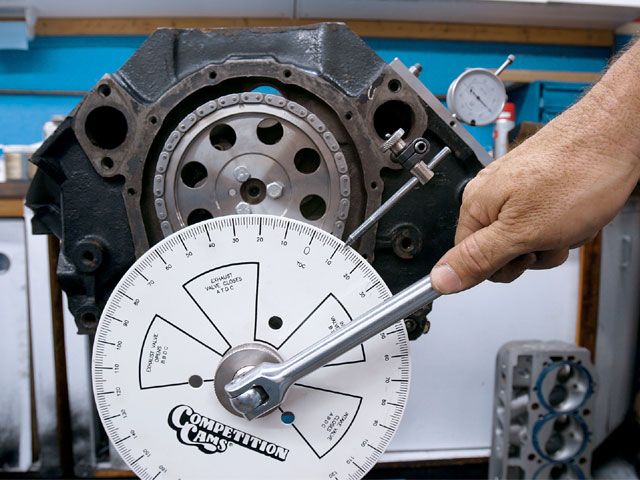

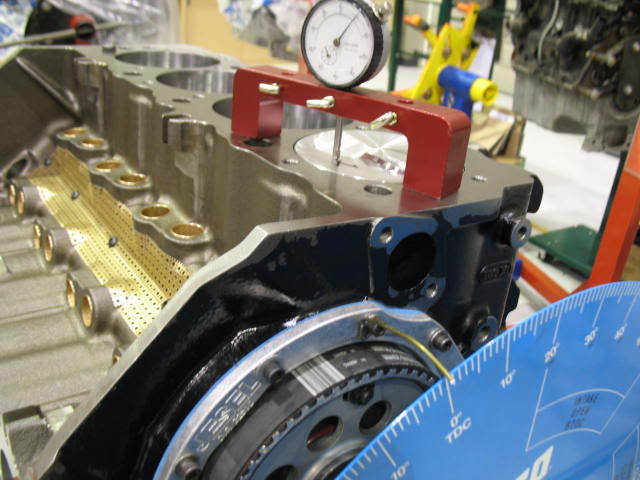

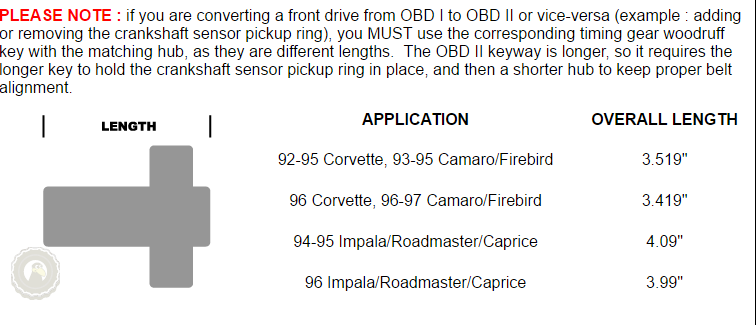

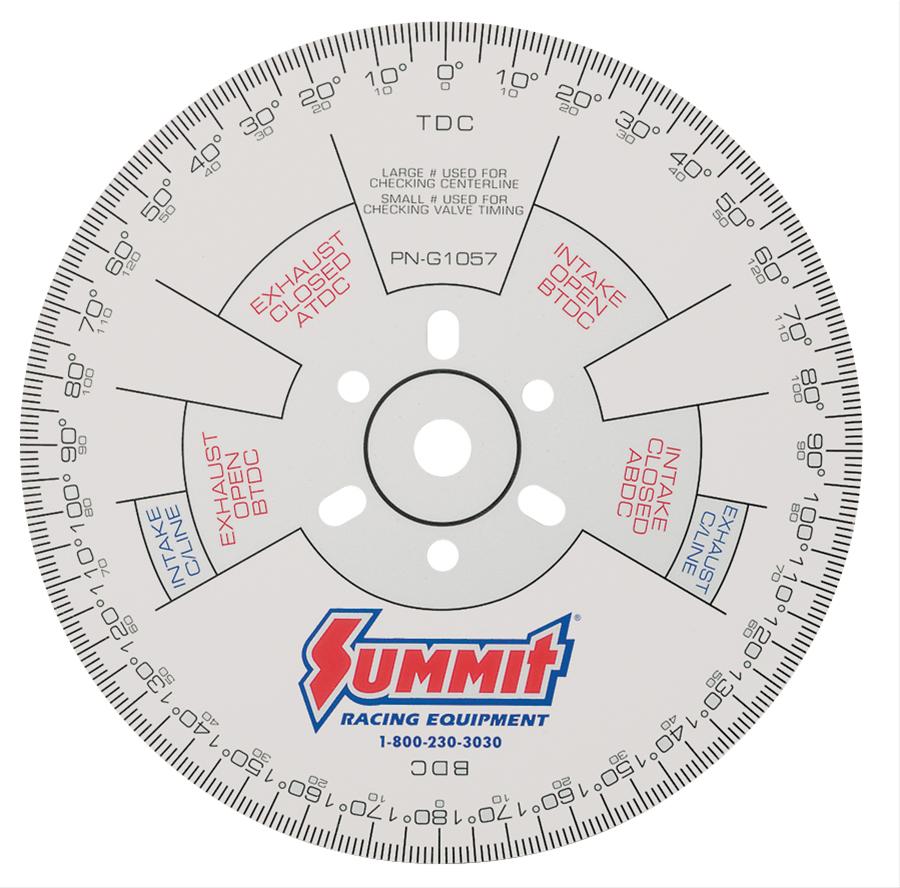

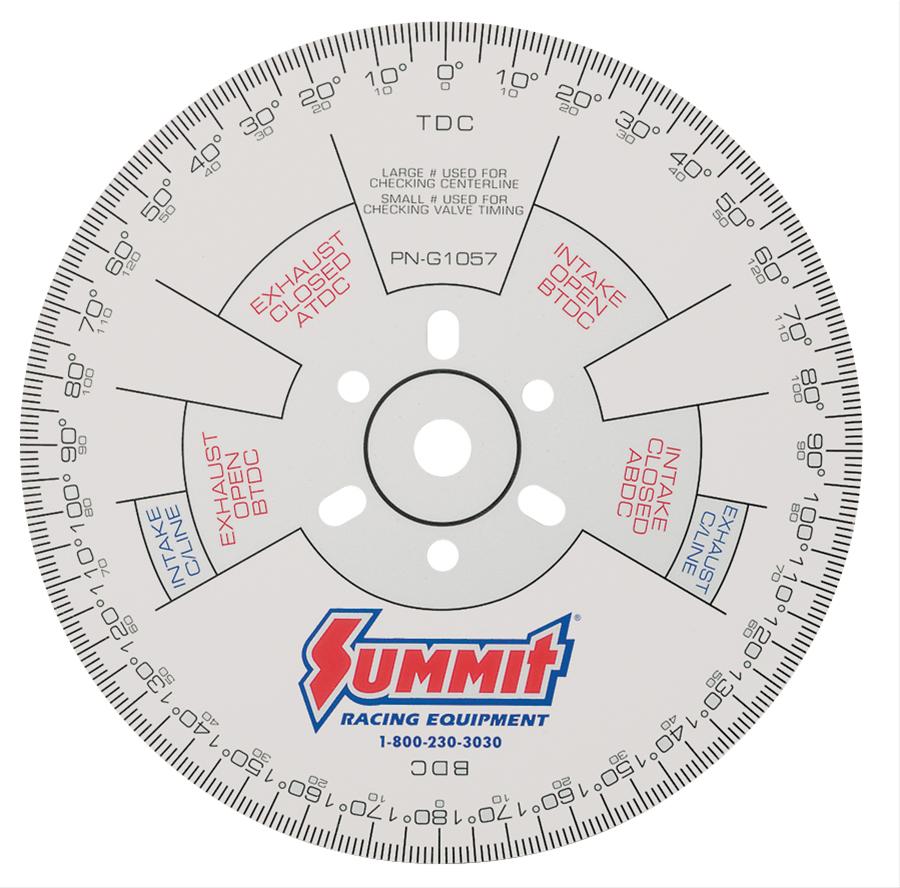

Degree Wheel

checking lifter

degree wheel

Dial Bore Gauge

Pushrod Length Checker

http://www.summitracing.com/search/...d-length-checkers?autoview=SKU&ibanner=SREPD5

Proform Pushrod Length Checkers 66789 SBC 3/8" rocker studs

Proform Pushrod Length Checkers 66790 SBC 7/16" rocker studs

Proform Pushrod Length Checkers 66806 BBC 7/16" rocker studs

Oil Pump Primer

http://www.harborfreight.com/36-piece-3 ... 60669.html

harbor freight has cheap and perfectly acceptable calipers

http://www.harborfreight.com/6-in-dial-caliper-62362.html

http://www.harborfreight.com/1-inch-travel-machinists-dial-indicator-623.html

http://www.harborfreight.com/multipositional-magnetic-base-with-fine-adjustment-5645.html

spring micrometers,

a crank snout, turning socket,

a dead blow mallet ,

a can of moly spray lube,

DECK BRIDGE

http://www.summitracing.com/parts/PRO-66797/

ring install pliers

piston ring filer,

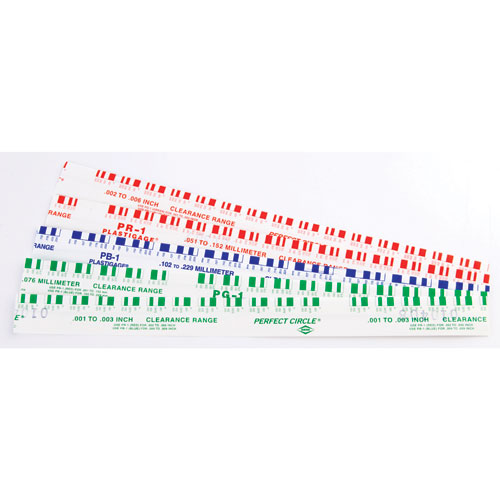

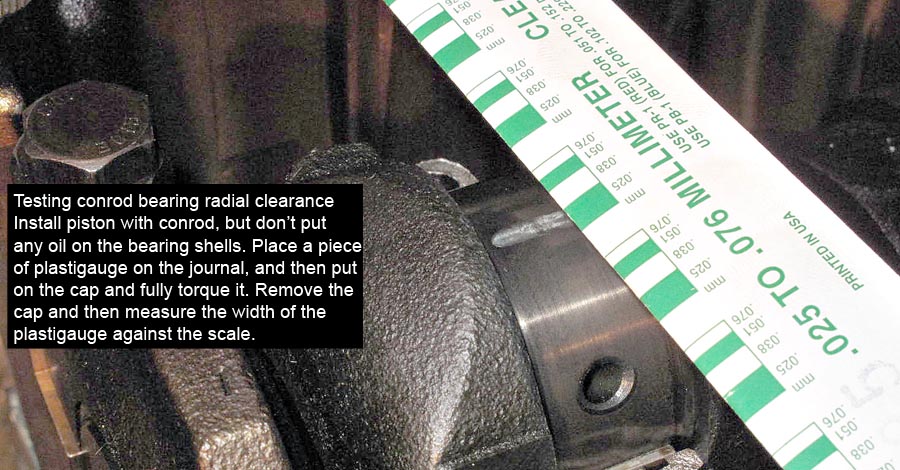

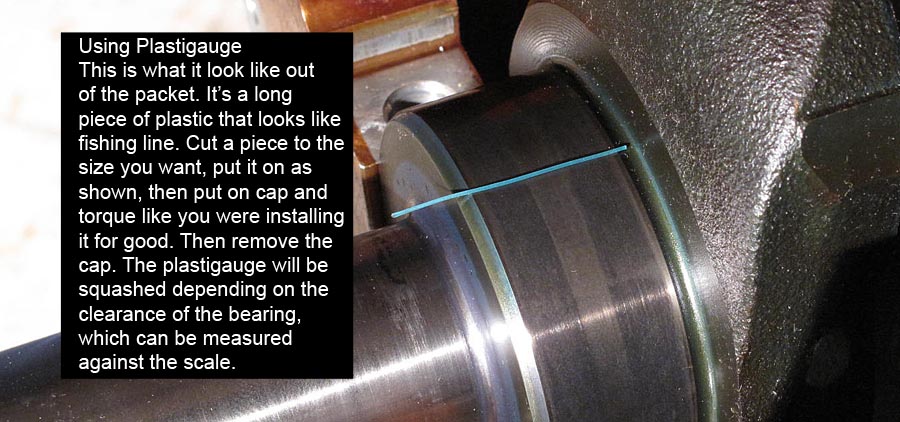

GEAR PULLERS

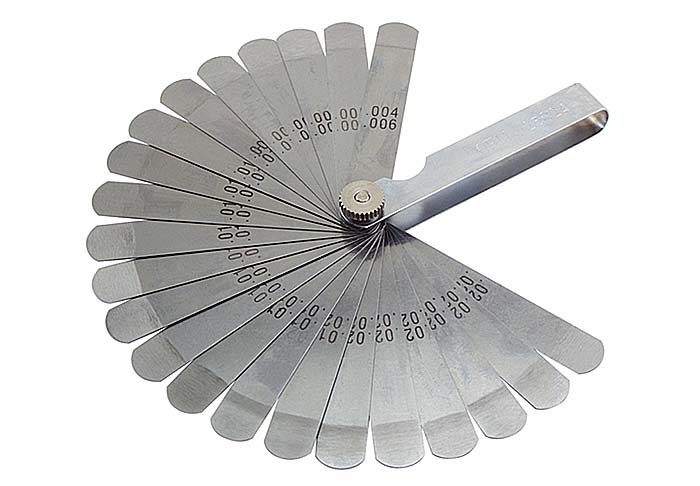

floridas hardly the ideal climate for keeping tools rust free so i generally take my set of micrometers out of the storage case and open and close them and spray them down with a light oil like WD 40 and place them back in the box then place the whole box in a 2 gallon zip lock bag in a shallow tupper ware type air tight storage box that is just the size to fit inside one of your tool chest drawers too protect the precision measuring tools , feeler gauges and plasti-gauge youll need to measure clearances correctly.when not in use along with the dial calipers.

http://garage.grumpysperformance.com/index.php?threads/bearing-clearances.2726/

the reason I bring this up is I recently was over at a friends house where I needed to accurately measure a u-joint bearing cap and asked if he had a micrometer or dial caliper, he responded he had a very expensive looking imported micrometer, he had acquired recently at an estate yard sale for $30,

when he opened the very impressive looking brass and mahogany box the micrometer, inside was a solid rusted mass, I soaked it in marvel mystery oil and acetone mix for 30 minutes then gradually worked it loose and polished it up with 1500 grit wet/dry sand paper figuring no loss at this point and was amazed that after about 30 minutes of constant cleaning it not only looked fairly decent it seemed to read accurately on a test gauge so I think it was mostly ugly surface rust, but it sure looked horrible, and to someone who appreciates good tools,that was depressing.

btw look around at yard sales and estate sales every so often youll find amazing bargains in used precision tools

yes it sure helps to have the correct tools and know where to measure parts

http://www.tooltopia.com/fowler-72-646-300.aspx

http://www.harborfreight.com/3-piece-micrometer-set-66512.html

http://www.hotrod.com/how-to/engine/ccrp-9901-affordable-engine-building-tools/

http://www.powerhouseproducts.com

https://www.proformtools.com/

http://www.bierbros.net/EngineBuildingAndPrecisionTools.html

http://www.superchevy.com/how-to/148-0505-engine-building-tools/

almost all starter tool kits are loaded with tools you seldom use to build up the tool numbers in the kits

yet many are still a good value, but remember you'll need a few auxiliary accessory kits for tools like screw drivers ratchet wrenches and a couple ,wire cutters drill bits, pliers,socket extensions and swivels,

frequently used tools like a decent 1/2" chuck electric drill, and vise grips, 12" dial caliper, multi meter,etc.

you can certainly use a couple of soft tool bags as they are far easier to carry , in your car or store than the cheap plastic or flimsy metal boxes that come with most starter tool kits

https://www.homedepot.com/p/Husky-2...d-16-large-total-pockets-HD60024-TH/312387489

https://www.acmetools.com/shop/tool...wTqPfS82YeLeAXpDNp-vuCv3uC7lV2d4aAtIvEALw_wcB

https://www.lowes.com/pd/Kobalt-138...c-Polished-Chrome-Mechanics-Tool-Set/50200791

https://www.lowes.com/pd/CRAFTSMAN-282-piece-Gunmetal-Chrome-Mechanic-s-Tool-Set/1002618996

https://www.walmart.com/ip/IRWIN-2078710-Vise-Grip-3-Pieces-GrooveLock-Pliers-Set/17238102

https://www.lowes.com/pd/Kobalt-10-Piece-Household-Tool-Set/50029436

https://www.lowes.com/pd/CRAFTSMAN-...Gunmetal-Chrome-Mechanics-Tool-Set/1000596571

https://www.lowes.com/pd/Kobalt-154...-Polished-Chrome-Mechanics-Tool-Set/999909119

https://www.lowes.com/collections/Kobalt-Mechanics-Collection/GR_609

https://www.lowes.com/pd/Kobalt-439-Piece-Mechanic-s-Tool-Set/1001448260

https://gemplers.com/products/dewal...3m7KE5XM0hXefj1ZDtgwWtbHqxTNiEx8aAteQEALw_wcB

https://www.harborfreight.com/5-in-1-digital-multimeter-98674.html

https://www.walmart.com/ip/12-Verni...82195?wmlspartner=wlpa&selectedSellerId=14201

https://www.amazon.com/INTOO-Indust...9Y2xpY2tSZWRpcmVjdCZkb05vdExvZ0NsaWNrPXRydWU=

https://www.amazon.com/Ridgid-Spade...ll+set&qid=1607798231&sr=8-51&tag=googhydr-20

Last edited: 2 minutes ago

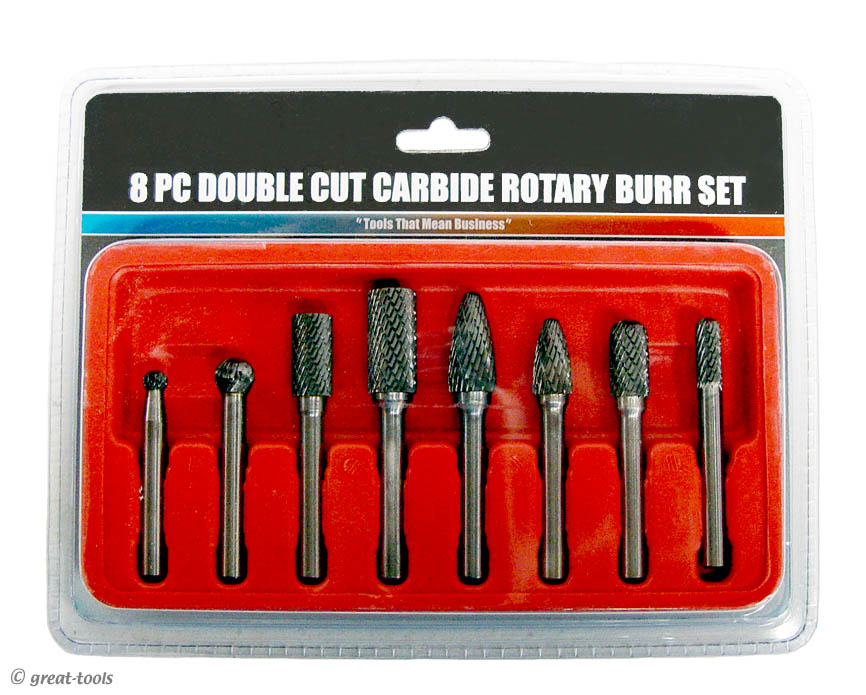

http://www.goodson.com/

dial indicator and magnetic stand

feeler gauges

torque wrench

gear puller

engine stand

engine crane

engine leveler

Valve Spring Height Micrometer

Engine Storage Cradle

btw, if you've ever had to stop a project because you could not locate the required matching bolt, or fastener, to install a bracket or accessory or engine component ,

you know how frustrating it will be to have to stop and locate the required fastener or go to a local hardware store and hope they have the required bolt.

and yes theres a great many sizes and types that are rather unique to automotive use and some specific to brands, and models.

now obviously you can spend a small fortune buying a vast assortment for your shops use.

or you can grab a 5 gallon bucket and a small assortment of ratchets wrenches and sockets ,

and visit your local salvage yard and grab some accessory or component you need and in the process,

you can remove and save, and throw several hands full of assorted fasteners in the bucket , on every trip to the salvage yard when your purchasing used re-buildable major components

to re-stock your shops bolt box.

most salvage yards don,t mind this approach

IF YOUR BUYING SEVERAL COMPONENTS in the process,

like all the parts and brackets off an engine , a set of cylinder heads, a power steering pump, or intake manifold for example or the disc brakes

most will NOT allow you to simply start pulling a large selection of fasteners , without a significant component purchase, or two too cover the cost of those fasteners.

http://garage.grumpysperformance.com/index.php?threads/fastener-storage-idea.3898/#post-10324

http://garage.grumpysperformance.co...spare-bolts-and-assorted-spare-parts-in.3557/