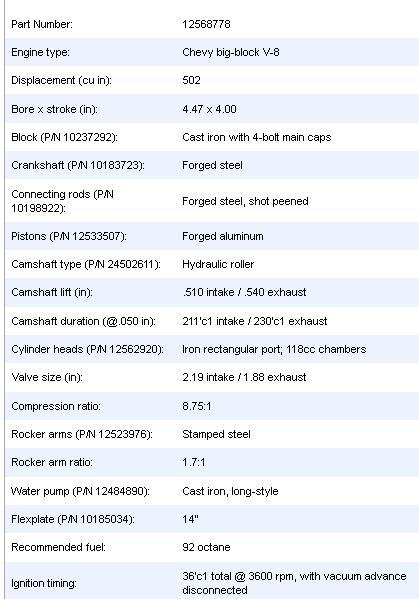

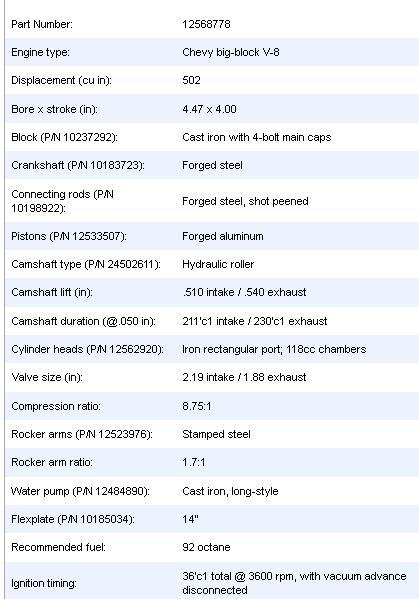

I recently got a call from a high school buddy that purchased a 502 crate engine and that crate engine had factory big rectangular port heads but the non-adjustable rockers and a mild factory cam, heres the specs from the engine he purchased

http://gmhorsepower.com/502-HO.php

http://paceperformance.com/i-6255352-12 ... ngine.html

502 HO - Maximum displacement with maximum value!

This is what all big-block crate engines should be: maximum power with a maximum return on your money invested. GM performance Parts started with the 454 Chevy crate engine that everyone loves and pumped it up to a 502 cubic inch powerhouse that delivers gobs of low-end torque and top-end horsepower.

Even though the 502 is a great value, don’t think for a minute that we skimped on parts or validation of those parts to the highest standard in the industry. The 502 HO bottom end consists of a cast iron four-bolt block, forged steel crankshaft, forged steel connecting rods that have been shot-peened for durability, and forged pistons. A high-lift roller camshaft controls the airflow through our legendary rectangular-port cast iron cylinder heads—more than enough air to fill those hungry 502 cubes! One other key engineering feature is that the final compression ratio comes in at 8.75:1, so that when outfitted with our 502 HO, your performance GM car will make tremendous power from just pump gas.

GM Performance Parts has completed this amazing crate engine with an aluminum dual-plane intake manifold, cast iron water pump, 6-quart oil pan (with windage tray), damper, and a 14" flexplate. Pick the carburetor, starter, and ignition system—all available from GM Performance Parts—and you are on your way to big-block bliss!

Possible Applications

A hot Chevy that deserves a stroked Rat

Low 11-second bracket car

Heavy metal hot rod that needs heavy metal power

*Applications have not been validated. They are merely suggestions of how you might enjoy your GM Performance Parts crate engine. Some applications may affect engine warranty. See specific warranty information. Some applications may not be emission legal; check state and local ordinances.

Installation Notes

NOTE: Distributor with melonized steel gear MUST be used with long blocks and partial engines with steel camshafts, or engine damage will occur. GMPP distributor P/N 93440806 is recommended.

Requires addition of carburetor, fuel pump, starter, distributor and ignition system.

Clutch linkage boss is cast into block, but must be drilled and tapped. When using cast iron exhaust manifolds, lower head bolts may need to be replaced with bolts with shorter heads, for clearance.

Requires electric fuel pump because the Gen VI block has no mechanical fuel pump boss.

Comes with a 14" automatic transmission flexplate; use flywheel P/N 14096987 and 11" clutch assembly for manual transmission.

Intended for pre-1977 street vehicles or all off-road vehicles.

Not intended for marine applications.

now this is a decent replacement muscle car STREET engine but its a MISS MATCH of parts in its original condition, as the cam is far to small in DURATION AND LIFT to maximize the cylinder heads port cross sectional area, and the COMPRESSION RATIO IS FAR TO LOW TO MAXIMIZE THE ENGINES TRUE POWER POTENTIAL, plus the heads have non-adjustable rockers.... this can of course be rectified with careful parts upgrades to take full use of the engine potential.

those big port heads are designed to operate efficiently, in the 5000rpm-7500rpm power band and that cam is obviously well past its power potential at under 4000rpm in that engine displacement.

There are also much better flowing heads available, to be matched with a better cam.

heads like these

http://www.profilerperformance.com/raci ... c-24-heads

http://www.summitracing.com/parts/tfs-4 ... /chevrolet

http://www.airflowresearch.com/index.php?cPath=68_74

http://www.brodix.com/heads/raceritebb.php

a cam similar to these

http://www.cranecams.com/product/cart.p ... il&p=24241

http://www.crower.com/index.php/cam...hydraulic-roller-cam-253hr260-late-model.html

and a set of pistons that boost compression up into the 11.7:1-12:1 RANGE WOULD MAKE A HUGE DIFFERENCE IN A CAR WITH THE CORRECT DRIVE TRAIN AND GEARING TO KEEP THE ENGINE OPERATING INN THE 3500RPM-6500RPM RANGE

viewtopic.php?f=52&t=4564

viewtopic.php?f=69&t=5123

viewtopic.php?f=52&t=8460

viewtopic.php?f=52&t=333

viewtopic.php?f=52&t=399

viewtopic.php?f=52&t=181

viewtopic.php?f=52&t=319

viewtopic.php?f=50&t=11064

viewtopic.php?f=52&t=6414

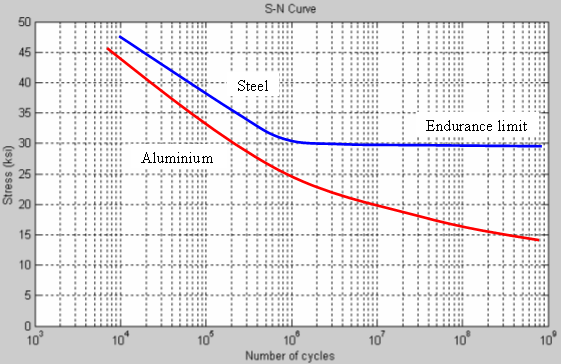

the crower steel roller rockers or similar rocker units will have a longer fatigue life, than aluminum rockers, and the bearing trunions are replaceable so they can be rebuilt after 60K-80K

,Fatigue limit, endurance limit, and fatigue strength are all expressions used to describe a property of materials: the amplitude (or range) of cyclic stress that can be applied to the material without causing fatigue failure.[1] Ferrous alloys and titanium alloys[2] have a distinct limit, an amplitude below which there appears to be no number of cycles that will cause failure. Other structural metals such as aluminium and copper, do not have a distinct limit and will eventually fail even from small stress amplitudes. In these cases, a number of cycles (usually 107) is chosen to represent the fatigue life of the material.

[color:red]READ THE LINKS[/color]

http://garage.grumpysperformance.co...train-clearances-and-problems.528/#post-57678

http://garage.grumpysperformance.co...train-clearances-and-problems.528/#post-66870

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

http://garage.grumpysperformance.co...fit-under-stock-valve-covers.6641/#post-21035

http://garage.grumpysperformance.com/index.php?threads/rocker-push-rod-wear-issues.9815/#post-54232

http://garage.grumpysperformance.co...g-block-pushrod-guide-plates.4596/#post-52034

http://gmhorsepower.com/502-HO.php

http://paceperformance.com/i-6255352-12 ... ngine.html

502 HO - Maximum displacement with maximum value!

This is what all big-block crate engines should be: maximum power with a maximum return on your money invested. GM performance Parts started with the 454 Chevy crate engine that everyone loves and pumped it up to a 502 cubic inch powerhouse that delivers gobs of low-end torque and top-end horsepower.

Even though the 502 is a great value, don’t think for a minute that we skimped on parts or validation of those parts to the highest standard in the industry. The 502 HO bottom end consists of a cast iron four-bolt block, forged steel crankshaft, forged steel connecting rods that have been shot-peened for durability, and forged pistons. A high-lift roller camshaft controls the airflow through our legendary rectangular-port cast iron cylinder heads—more than enough air to fill those hungry 502 cubes! One other key engineering feature is that the final compression ratio comes in at 8.75:1, so that when outfitted with our 502 HO, your performance GM car will make tremendous power from just pump gas.

GM Performance Parts has completed this amazing crate engine with an aluminum dual-plane intake manifold, cast iron water pump, 6-quart oil pan (with windage tray), damper, and a 14" flexplate. Pick the carburetor, starter, and ignition system—all available from GM Performance Parts—and you are on your way to big-block bliss!

Possible Applications

A hot Chevy that deserves a stroked Rat

Low 11-second bracket car

Heavy metal hot rod that needs heavy metal power

*Applications have not been validated. They are merely suggestions of how you might enjoy your GM Performance Parts crate engine. Some applications may affect engine warranty. See specific warranty information. Some applications may not be emission legal; check state and local ordinances.

Installation Notes

NOTE: Distributor with melonized steel gear MUST be used with long blocks and partial engines with steel camshafts, or engine damage will occur. GMPP distributor P/N 93440806 is recommended.

Requires addition of carburetor, fuel pump, starter, distributor and ignition system.

Clutch linkage boss is cast into block, but must be drilled and tapped. When using cast iron exhaust manifolds, lower head bolts may need to be replaced with bolts with shorter heads, for clearance.

Requires electric fuel pump because the Gen VI block has no mechanical fuel pump boss.

Comes with a 14" automatic transmission flexplate; use flywheel P/N 14096987 and 11" clutch assembly for manual transmission.

Intended for pre-1977 street vehicles or all off-road vehicles.

Not intended for marine applications.

now this is a decent replacement muscle car STREET engine but its a MISS MATCH of parts in its original condition, as the cam is far to small in DURATION AND LIFT to maximize the cylinder heads port cross sectional area, and the COMPRESSION RATIO IS FAR TO LOW TO MAXIMIZE THE ENGINES TRUE POWER POTENTIAL, plus the heads have non-adjustable rockers.... this can of course be rectified with careful parts upgrades to take full use of the engine potential.

those big port heads are designed to operate efficiently, in the 5000rpm-7500rpm power band and that cam is obviously well past its power potential at under 4000rpm in that engine displacement.

There are also much better flowing heads available, to be matched with a better cam.

heads like these

http://www.profilerperformance.com/raci ... c-24-heads

http://www.summitracing.com/parts/tfs-4 ... /chevrolet

http://www.airflowresearch.com/index.php?cPath=68_74

http://www.brodix.com/heads/raceritebb.php

a cam similar to these

http://www.cranecams.com/product/cart.p ... il&p=24241

http://www.crower.com/index.php/cam...hydraulic-roller-cam-253hr260-late-model.html

and a set of pistons that boost compression up into the 11.7:1-12:1 RANGE WOULD MAKE A HUGE DIFFERENCE IN A CAR WITH THE CORRECT DRIVE TRAIN AND GEARING TO KEEP THE ENGINE OPERATING INN THE 3500RPM-6500RPM RANGE

viewtopic.php?f=52&t=4564

viewtopic.php?f=69&t=5123

viewtopic.php?f=52&t=8460

viewtopic.php?f=52&t=333

viewtopic.php?f=52&t=399

viewtopic.php?f=52&t=181

viewtopic.php?f=52&t=319

viewtopic.php?f=50&t=11064

viewtopic.php?f=52&t=6414

the crower steel roller rockers or similar rocker units will have a longer fatigue life, than aluminum rockers, and the bearing trunions are replaceable so they can be rebuilt after 60K-80K

,Fatigue limit, endurance limit, and fatigue strength are all expressions used to describe a property of materials: the amplitude (or range) of cyclic stress that can be applied to the material without causing fatigue failure.[1] Ferrous alloys and titanium alloys[2] have a distinct limit, an amplitude below which there appears to be no number of cycles that will cause failure. Other structural metals such as aluminium and copper, do not have a distinct limit and will eventually fail even from small stress amplitudes. In these cases, a number of cycles (usually 107) is chosen to represent the fatigue life of the material.

[color:red]READ THE LINKS[/color]

http://garage.grumpysperformance.co...train-clearances-and-problems.528/#post-57678

http://garage.grumpysperformance.co...train-clearances-and-problems.528/#post-66870

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

http://garage.grumpysperformance.co...fit-under-stock-valve-covers.6641/#post-21035

http://garage.grumpysperformance.com/index.php?threads/rocker-push-rod-wear-issues.9815/#post-54232

http://garage.grumpysperformance.co...g-block-pushrod-guide-plates.4596/#post-52034

Last edited by a moderator: