ok here is MY two cents

OK ILL come right out and say it, for your street strip engine combos, its been my experiance that anytime you have an option, reguarding a bore and stroke combo, go for the larger displacement combo is everything else is about equal,

As long as the engines cylinder bore diameter, is larger than the engines stroke length or at least the same or equal to the bore diameter. You,ll rarely have problems with the engine power potential, DUE to the bore to stroke ratio, PROVIDED the ports and valves can effectively fill the cylinders a reasonable rpm ranges.Now the connecting rod length to stroke ratio should ideally be closer to 1.9:1 than 1.5:1, to lower the ring drag and allow the crank to rod angle at maximum cylinder pressure to effectively work at a mechanical advantage, and leave room for the cranks counter weights to pass under the piston skirts, but a few tenths of a degree won,t mean much to the power produced.

YES a shorter stroke and larger bore tends to work slightly better in a high rpm combo,due to slightly less valve shrouding, but the longer stroke and more square (IE bore and stroke about equal) tends to be very slightly less detonation prone if everything else is equal in both combos of equal displacement.

Effectively filling and emptying the cylinders at the upper rpms will be a bigger concern.

Years ago the SBC cylinder head flow rates available would barely feed a 327-331 spinning 7000 plus rpm, most guys were forced to work with ported factory castings.

BUT today the better cylinder 23 degree head designs on a first generation SBC can support a 427 displacement, or a bit more, but that was not true in the past.

That,s one reason why grumpy Jenkins used a sbc in a Vega to kick butt running in PRO STOCK.

Remember performance is the result of THE POWER TO WEIGHT RATIO, and the effective use of TRACTION in drag racing, and in many classes weight of the car is based on the engines displacement, so ideally you’ll want the lightest car with the most powerful engine for its size you can get, in the past you maxed out the head flow rates with a 327-331 displacement, that's a 3.25 stroke that’s about 0.8 of the 4â€bore size.

As tech. improved the 350 crank with its longer 3.48, stroke installed with spacers in the 400 block, 4.125 bore that resulted in the 377 sbc was found to be about the most effective combo. That's a 0.83 stroke to bore ratio.

Keep in mind the sbc bore limits you to about the 2.02" intake and 1.6"exhaust valve sizes. Also keep in mind that a 2.02 valve has to seat in the head and seal and the pocket/throat under the valve is almost never as large as 90% in diameter. or 1.82" in throat size. now a 1.82 hole has a cross sectional area of 2.6 sq inches, a 2.02 valve needs a lift of just over .420 to maximize that flow curtain, so a cam that keeps the valve above .420 for as long as possible maximizes the ports flow Potential. That curtain areas important because your entire cylinder sees is air/fuel mix fed thru that curtain area under a combination of positive outside air pressure and both a descending piston and exhaust inertia causing a negative pressure to draw in the intake charge.

The bore diameter matters because it can restrict flow where the cylinder wall runs tangent to the valve curtain. Smaller bores restrict a larger percentage of the curtain area flow from the valve.

Now lets look at the BBC engines, you.ve got a 2.2-2.3" intake valve,

Keep in mind the 2.3" intake and 1.9"exhaust valve sizes. Also keep in mind that a 2.3" valve has to seat in the head and seal and the pocket/throat under the valve is almost never as large as 90% in diameter. or 2.07" in throat size. now a 2.07" hole has a cross sectional area of 3.37 sq inches, a 2.3 valve needs a lift of just over .490 to maximize that flow curtain, so a cam that keeps the valve above .490 for as long as possible maximizes the ports flow Potential. That curtain areas important because your entire cylinder sees is air/fuel mix fed thru that curtain area under a combination of positive outside air pressure and both a descending piston and exhaust inertia causing a negative pressure to draw in the intake charge. The bore diameter. matters because it can restrict flow where the cylinder wall runs tangent to the valve curtain. Smaller bores restrict a larger percentage of the curtain area flow from the valve.

With a 4.25" bore in a 427 BBC that would be a 3.76" stroke to have a .88 stroke to bore ratio.

One interesting BBC combo is a 4.50, bore from a cleaned up 502 block with a 3.76, stroke, from a 427, resulting in a 478 displacement. Which makes for a very efficient combo in a light weight car like a T-bucket, style kit car?

Keep in mind that performance is the result of THE POWER TO WEIGHT RATIO, and the effective use of TRACTION and good handling is mostly the result of a well thought thru suspension and brakes and a low centered weight distribution.

IF your going to build a big block Chevy it usually helps to know your options and longer strokes and rods help.

Id also point out that doing the math before you purchase parts will save you a great deal of wasted cash,

and if that engine your contemplating is intended to exceed about 4200 feet per minute in piston speed or 6200rpm,

you might want too think seriously about 4340 forged steel crank, forged pistons, and rods with 7/16" ARP rod bolts

http://scatcrankshafts.com/

common BB CHEVY piston compression heights are

1.270"

1.395"

1.520"

1.645"

1.765"

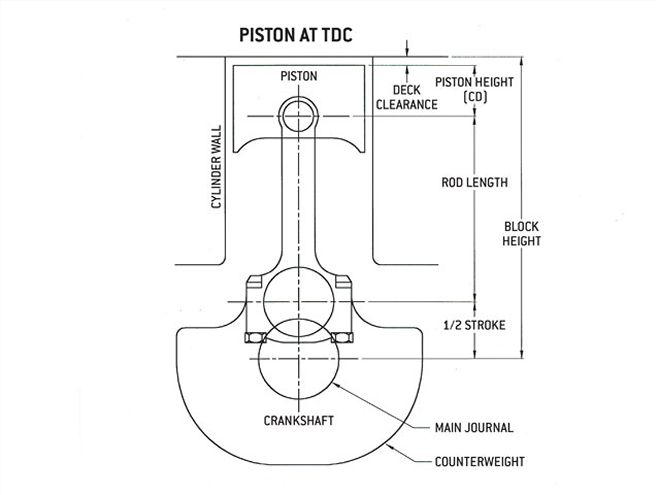

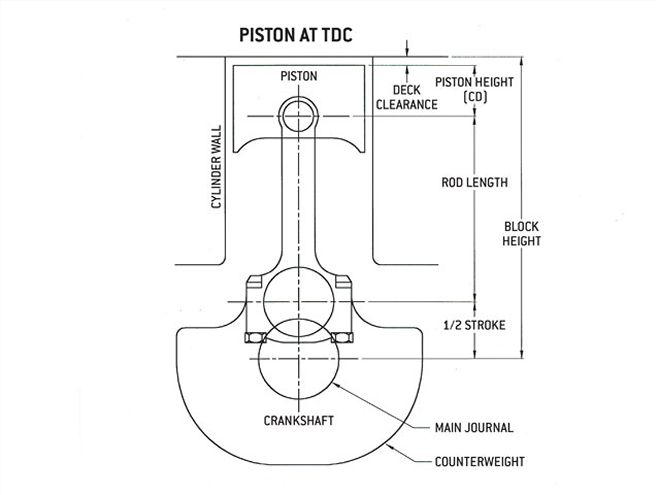

remember the blocks deck height, minus the piston pin height minus 1/2 the crank stroke will equal the required connecting rod length

OR

the blocks deck height, minus the connecting rod length, minus 1/2 the crank stroke. will equal the required piston pin height

yes its common for a combo to have the piston deck height located .010-.015 above or below the deck of the block so you'll need to select a head gasket thickness that compensates, too allow your engine to get a .038-.044 piston deck to cylinder head QUENCH DISTANCE.

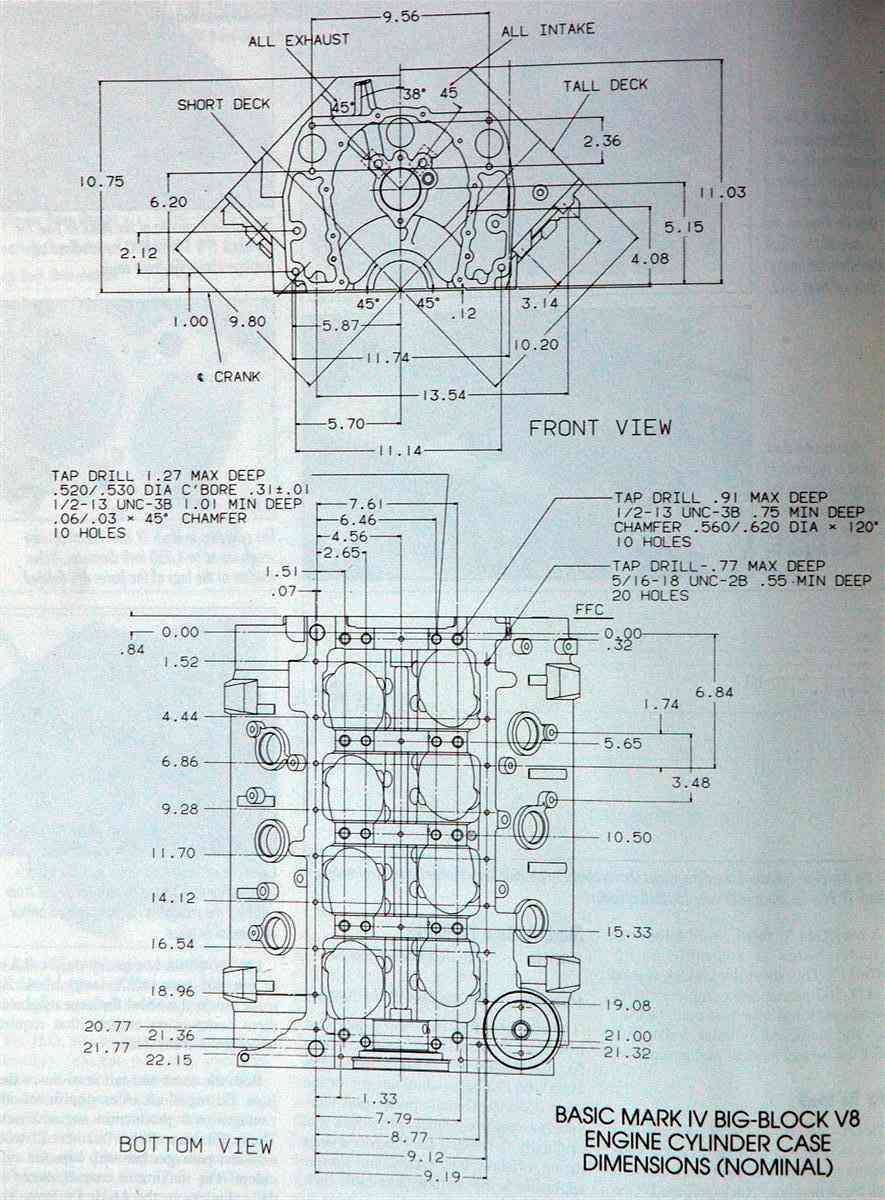

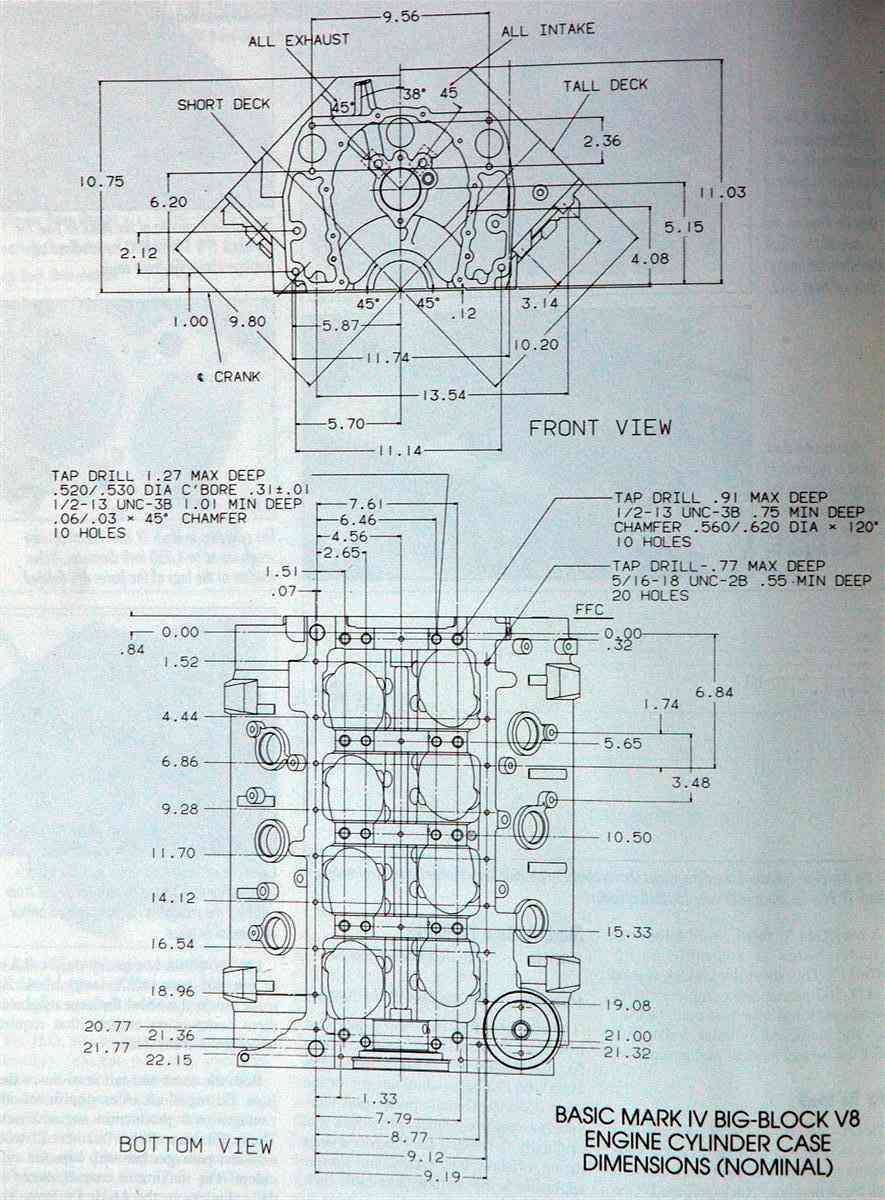

now you can have custom pistons fabricated in almost any configuration in that range and theres obviously a 9.8" standard and a 10.2" tall deck, and aftermarket blocks with deck heights to about 11" tall.

notice the pin height in the pistons pictured above allow a longer or shorter connecting rod length

heres a selection of commonly available big block chevy connecting rod lengths

viewtopic.php?f=53&t=510

THERES A TON OF INFO IF YOU LOOK OVER THIS SITE

INTERESTING INFO

http://phors.locost7.info/contents.htm

http://airflowresearch.com/articles/art ... /A3-P1.htm

viewtopic.php?f=52&t=322

http://victorylibrary.com/mopar/piston_position-c.htm

http://victorylibrary.com/mopar/rod-tech-c.htm

http://victorylibrary.com/mopar/cam-tech-c.htm

OK ILL come right out and say it, for your street strip engine combos, its been my experiance that anytime you have an option, reguarding a bore and stroke combo, go for the larger displacement combo is everything else is about equal,

As long as the engines cylinder bore diameter, is larger than the engines stroke length or at least the same or equal to the bore diameter. You,ll rarely have problems with the engine power potential, DUE to the bore to stroke ratio, PROVIDED the ports and valves can effectively fill the cylinders a reasonable rpm ranges.Now the connecting rod length to stroke ratio should ideally be closer to 1.9:1 than 1.5:1, to lower the ring drag and allow the crank to rod angle at maximum cylinder pressure to effectively work at a mechanical advantage, and leave room for the cranks counter weights to pass under the piston skirts, but a few tenths of a degree won,t mean much to the power produced.

YES a shorter stroke and larger bore tends to work slightly better in a high rpm combo,due to slightly less valve shrouding, but the longer stroke and more square (IE bore and stroke about equal) tends to be very slightly less detonation prone if everything else is equal in both combos of equal displacement.

Effectively filling and emptying the cylinders at the upper rpms will be a bigger concern.

Years ago the SBC cylinder head flow rates available would barely feed a 327-331 spinning 7000 plus rpm, most guys were forced to work with ported factory castings.

BUT today the better cylinder 23 degree head designs on a first generation SBC can support a 427 displacement, or a bit more, but that was not true in the past.

That,s one reason why grumpy Jenkins used a sbc in a Vega to kick butt running in PRO STOCK.

Remember performance is the result of THE POWER TO WEIGHT RATIO, and the effective use of TRACTION in drag racing, and in many classes weight of the car is based on the engines displacement, so ideally you’ll want the lightest car with the most powerful engine for its size you can get, in the past you maxed out the head flow rates with a 327-331 displacement, that's a 3.25 stroke that’s about 0.8 of the 4â€bore size.

As tech. improved the 350 crank with its longer 3.48, stroke installed with spacers in the 400 block, 4.125 bore that resulted in the 377 sbc was found to be about the most effective combo. That's a 0.83 stroke to bore ratio.

Keep in mind the sbc bore limits you to about the 2.02" intake and 1.6"exhaust valve sizes. Also keep in mind that a 2.02 valve has to seat in the head and seal and the pocket/throat under the valve is almost never as large as 90% in diameter. or 1.82" in throat size. now a 1.82 hole has a cross sectional area of 2.6 sq inches, a 2.02 valve needs a lift of just over .420 to maximize that flow curtain, so a cam that keeps the valve above .420 for as long as possible maximizes the ports flow Potential. That curtain areas important because your entire cylinder sees is air/fuel mix fed thru that curtain area under a combination of positive outside air pressure and both a descending piston and exhaust inertia causing a negative pressure to draw in the intake charge.

The bore diameter matters because it can restrict flow where the cylinder wall runs tangent to the valve curtain. Smaller bores restrict a larger percentage of the curtain area flow from the valve.

Now lets look at the BBC engines, you.ve got a 2.2-2.3" intake valve,

Keep in mind the 2.3" intake and 1.9"exhaust valve sizes. Also keep in mind that a 2.3" valve has to seat in the head and seal and the pocket/throat under the valve is almost never as large as 90% in diameter. or 2.07" in throat size. now a 2.07" hole has a cross sectional area of 3.37 sq inches, a 2.3 valve needs a lift of just over .490 to maximize that flow curtain, so a cam that keeps the valve above .490 for as long as possible maximizes the ports flow Potential. That curtain areas important because your entire cylinder sees is air/fuel mix fed thru that curtain area under a combination of positive outside air pressure and both a descending piston and exhaust inertia causing a negative pressure to draw in the intake charge. The bore diameter. matters because it can restrict flow where the cylinder wall runs tangent to the valve curtain. Smaller bores restrict a larger percentage of the curtain area flow from the valve.

With a 4.25" bore in a 427 BBC that would be a 3.76" stroke to have a .88 stroke to bore ratio.

One interesting BBC combo is a 4.50, bore from a cleaned up 502 block with a 3.76, stroke, from a 427, resulting in a 478 displacement. Which makes for a very efficient combo in a light weight car like a T-bucket, style kit car?

Keep in mind that performance is the result of THE POWER TO WEIGHT RATIO, and the effective use of TRACTION and good handling is mostly the result of a well thought thru suspension and brakes and a low centered weight distribution.

IF your going to build a big block Chevy it usually helps to know your options and longer strokes and rods help.

Id also point out that doing the math before you purchase parts will save you a great deal of wasted cash,

and if that engine your contemplating is intended to exceed about 4200 feet per minute in piston speed or 6200rpm,

you might want too think seriously about 4340 forged steel crank, forged pistons, and rods with 7/16" ARP rod bolts

http://scatcrankshafts.com/

common BB CHEVY piston compression heights are

1.270"

1.395"

1.520"

1.645"

1.765"

remember the blocks deck height, minus the piston pin height minus 1/2 the crank stroke will equal the required connecting rod length

OR

the blocks deck height, minus the connecting rod length, minus 1/2 the crank stroke. will equal the required piston pin height

yes its common for a combo to have the piston deck height located .010-.015 above or below the deck of the block so you'll need to select a head gasket thickness that compensates, too allow your engine to get a .038-.044 piston deck to cylinder head QUENCH DISTANCE.

now you can have custom pistons fabricated in almost any configuration in that range and theres obviously a 9.8" standard and a 10.2" tall deck, and aftermarket blocks with deck heights to about 11" tall.

notice the pin height in the pistons pictured above allow a longer or shorter connecting rod length

heres a selection of commonly available big block chevy connecting rod lengths

viewtopic.php?f=53&t=510

THERES A TON OF INFO IF YOU LOOK OVER THIS SITE

INTERESTING INFO

http://phors.locost7.info/contents.htm

http://airflowresearch.com/articles/art ... /A3-P1.htm

viewtopic.php?f=52&t=322

http://victorylibrary.com/mopar/piston_position-c.htm

http://victorylibrary.com/mopar/rod-tech-c.htm

http://victorylibrary.com/mopar/cam-tech-c.htm