(1) list all components and verify you have ALL of them currently available including bolts, sealants and gaskets and assembly lube

viewtopic.php?f=51&t=7697&p=26187#p26187

head assembly,

valve cover & bolts

rockers,

rocker studs

stud girdle,

guide plates

valves,

springs,

retainers

keepers,

shims,

head bolts

etc.

block ,

viewtopic.php?f=51&t=7697&p=26187#p26187

with all machine work and clearance work and honing done and well cleaned

main caps and mount studs & nuts

freeze plugs

oil gallery plugs

timing cover and bolts

shrapnel screens

magnets

oil filter mount adapter and bolts

j&b weld epoxy

rotating assembly,

crank

connecting rods,

pistons,

pins,

snap rings or true locs

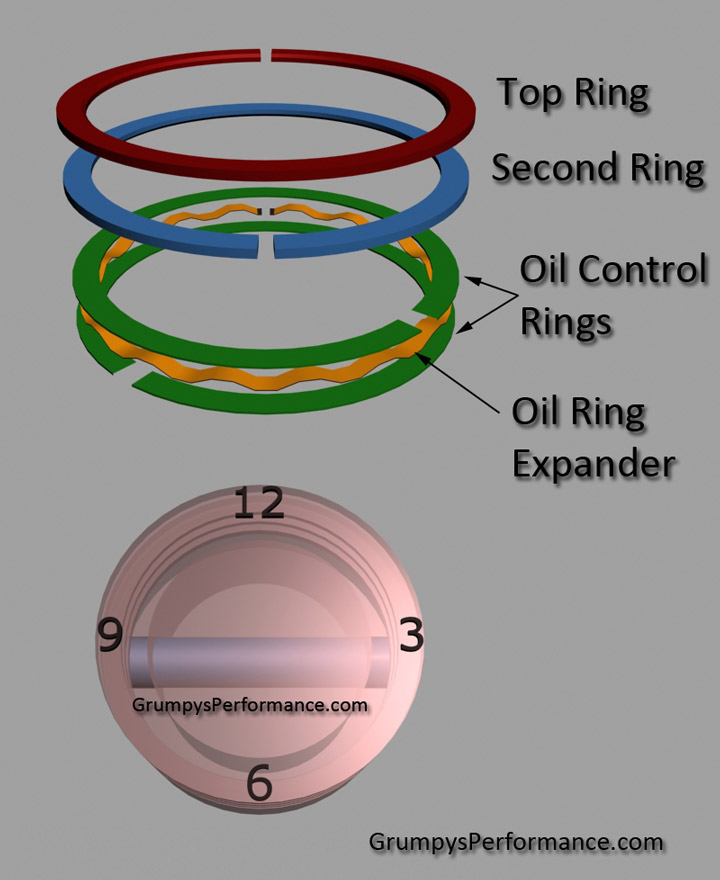

rings

damper,

flywheel/flex-plate

and mounting bolts,

bearings

lube system ,

oil pump,

oil pan,

oil pump mount stud,

oil pump pick-up,

windage screen,

crank scraper

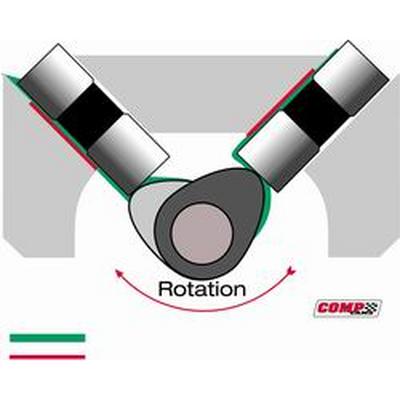

cam assembly,

lifters,

push rods,

timing chain

and timing gears,

cam bearings

offset bushings

cam button

retaining lock plate

intake assembly, linkage, carb , or MPFI

sensors...as required

(2)verify you have all the tools required

sturdy engine stand (grade 8 mount bolts/washers)

large engine bag for storage and moisture control

feeler gauges

snap gauges

ring compressor

true loc tool or snap ring pliers

majic marker

push rod length checker

torque wrench

crank socket

ring grinder

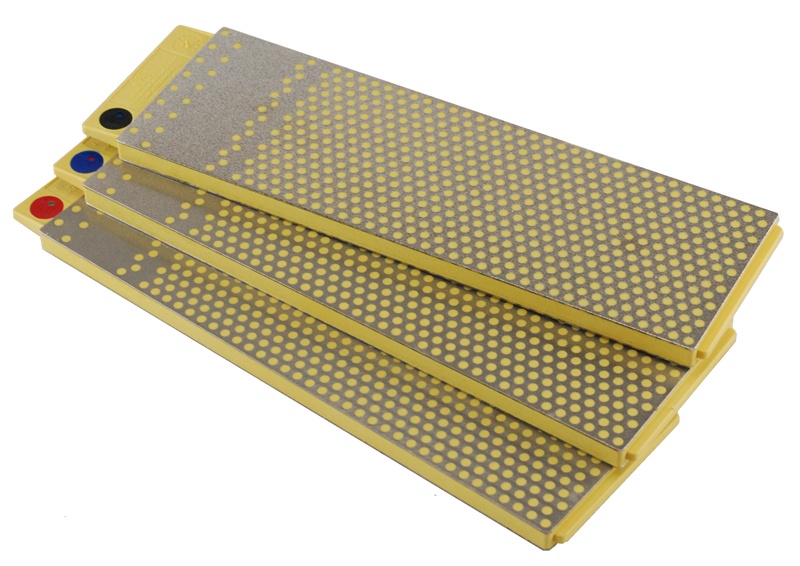

hone stone

mics

calipers

rubber mallet

rod bolt guides

damper puller/installer

assembly lube

model clay

wd40

plasti gauge

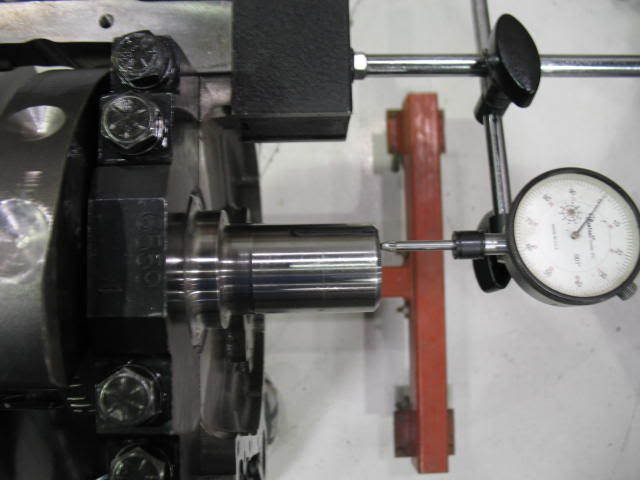

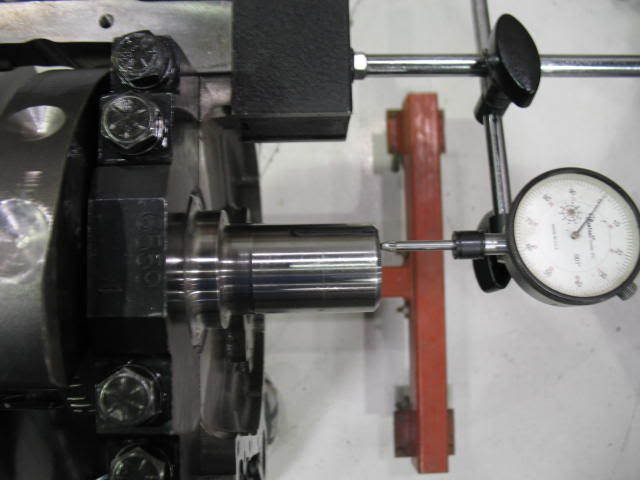

dial indicator and stand

dial indicator deck bridge

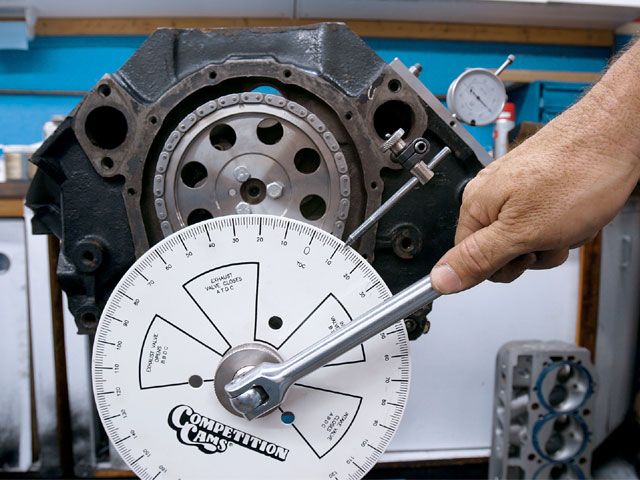

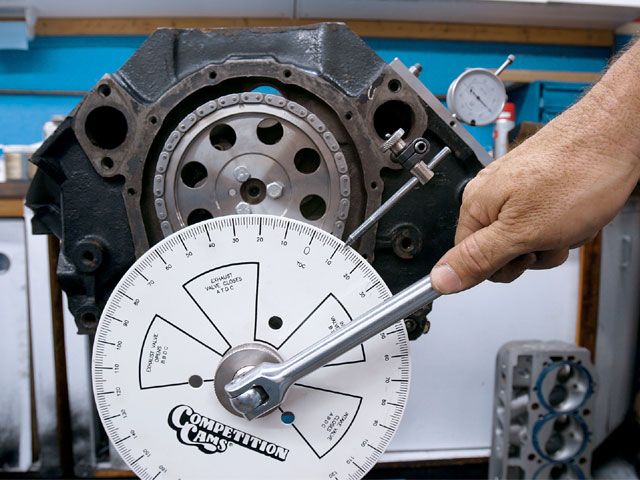

cam degree wheel and pointer

lifter/mic tool

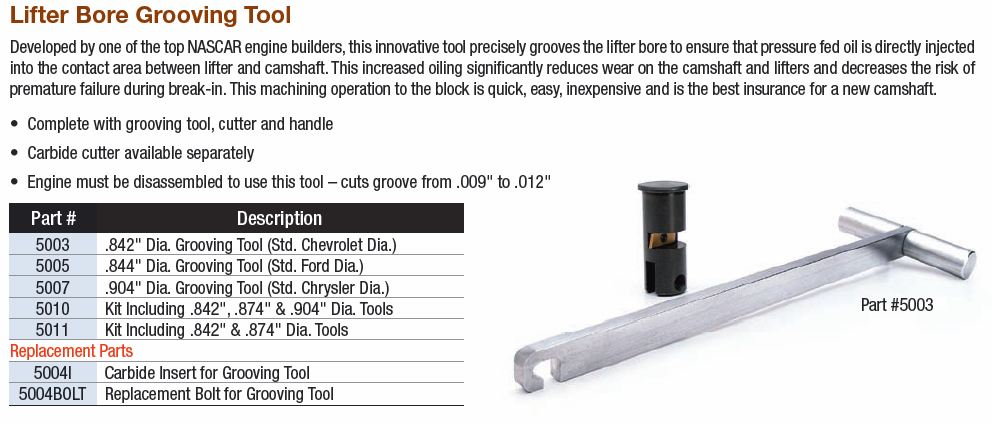

lifter bore groove tool

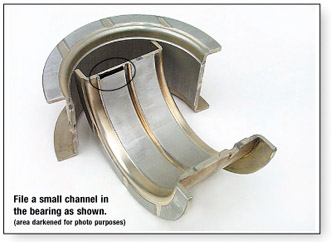

small jewelers files

drill and bit assortment

valve spring mic

TAPS

valve spring compressor

related info

http://www.popularhotrodding.com/engine ... index.html

viewtopic.php?f=51&t=7697&p=26187#p26187

head assembly,

valve cover & bolts

rockers,

rocker studs

stud girdle,

guide plates

valves,

springs,

retainers

keepers,

shims,

head bolts

etc.

block ,

viewtopic.php?f=51&t=7697&p=26187#p26187

with all machine work and clearance work and honing done and well cleaned

main caps and mount studs & nuts

freeze plugs

oil gallery plugs

timing cover and bolts

shrapnel screens

magnets

oil filter mount adapter and bolts

j&b weld epoxy

rotating assembly,

crank

connecting rods,

pistons,

pins,

snap rings or true locs

rings

damper,

flywheel/flex-plate

and mounting bolts,

bearings

lube system ,

oil pump,

oil pan,

oil pump mount stud,

oil pump pick-up,

windage screen,

crank scraper

cam assembly,

lifters,

push rods,

timing chain

and timing gears,

cam bearings

offset bushings

cam button

retaining lock plate

intake assembly, linkage, carb , or MPFI

sensors...as required

(2)verify you have all the tools required

sturdy engine stand (grade 8 mount bolts/washers)

large engine bag for storage and moisture control

feeler gauges

snap gauges

ring compressor

true loc tool or snap ring pliers

majic marker

push rod length checker

torque wrench

crank socket

ring grinder

hone stone

mics

calipers

rubber mallet

rod bolt guides

damper puller/installer

assembly lube

model clay

wd40

plasti gauge

dial indicator and stand

dial indicator deck bridge

cam degree wheel and pointer

lifter/mic tool

lifter bore groove tool

small jewelers files

drill and bit assortment

valve spring mic

TAPS

valve spring compressor

related info

http://www.popularhotrodding.com/engine ... index.html

Last edited by a moderator: