jjay2145 said:I'm needing some help with my 383 stroker of all the block is Bored 30 over the stroker kit is a 3.75 inch stroke with 6-inch rods and -10 CC dish top pistons the heads I went with some edelBrock E210 witch are a 64 CC chamber and a 210 cc intake runner with maximum lift 650. I have 1.5 roller rockers I also have an elder Brock RPM air gap intake I need some help figuring out my compression ratio to know if I have to run pump gas or racing fuel and I need some help on picking out a cam thanks

youll need to post a great deal more info to get a valid suggestion, as to the best matching cam, yes you can get a really good matching cam suggestion, but without knowing exactly what your intended use for the engine is and what the application is your going to get at best guess work.

simply because all the components must be matched to an intended power range and rpm band, and of course the components must be made for that intended application and rpm/power band.

yes I have to admit that when I personally swapped from a stock stall speed converter

,in my 383 sbc corvette and a 3200 rpm stall speed converter the difference in performance was amazingly better.

swap too a 3.73:1 rear gear and you've noticeably further enhanced that seat of the pants and slam in the back acceleration.

people tend to not fully appreciate the fact that the performance cars drive train gearing, power to weight ratio and the converter stall

(in the case of automatic transmission) must match the engine torque curve if the car is to perform to anything close to its best potential

keep in mind theres a big difference between STATIC compression and DYNAMIC COMPRESSION,for a street performance car , a static compression near 9:1-9.6:1 and a dynamic compression in the 8:1-8.2:1 range with aluminum heads is a ball park range to shoot for.

it helps a great deal if you take the time and effort to find a trust worthy and reasonably priced local machine shop , and trust me when I say this is critical, and yes, the machinist will seem to point out endless things that should be done to increase durability, or just allow proper component function,and a good machinist will try to guide you in component selection to help avoid mis-matched parts and low quality parts being used, yes quality parts and machine work, ALWAYS COST more than you may expect them too!

a week spent reading reference material before you start buying parts will likely save you thousands of dollars and weeks of wasted work, the more carefully you research and detail what you want to accomplish the more likely youll find the finished engine build, you build matches your intended results.

knowing exactly what parts you need and WHY you selected them goes a long way towards building an engine that will match your needs

DEAL IN PROVEN FACTS NEVER GUESS , NEVER ASSUME

first step.

before you start panicking and potentially wasting money and time.

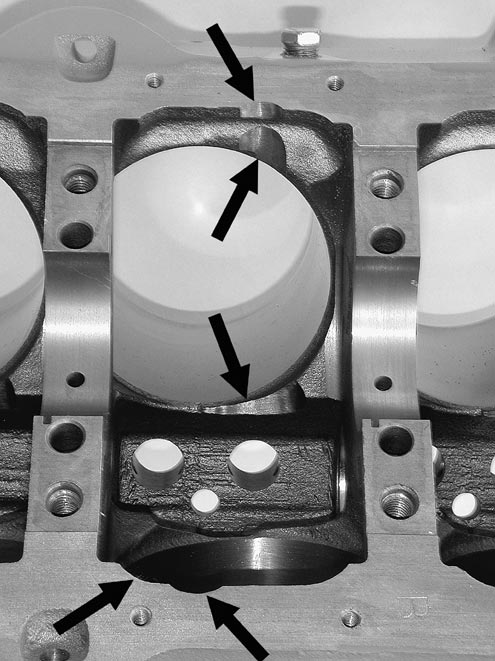

would be to assemble a single piston and rod assembly without rings,

but ideally with some old bearings on the crank and connecting rod and install the cam, in the block

( indexed with a simple,dot to dot timing on the timing gear sets should be ok at this point)

its all a learning process, you want too simply want to mentally take a step back, take a deep breath or two,

and start testing to find out whats working correctly,in your current combo,

whats not working up to your expectations,and if its not meeting your goals, logically calculate what should change,

and then calculate what can be adjusted or if necessary parts that can be logically replaced, and re-tested,

if that required too improve the performance.

don,t make the all too common mistake of thinking adding horsepower is the only route to improved performance.

suspension mods, better shocks, better brakes, a stiffer frame, larger diameter and wider tires, and drive train gearing and removing weight,

and correctly setting up the cars chassis to more effectively apply weight transfer ratios,

swapping to lower weight parts,or stronger , or more durable parts, use of stronger drive train components, better matched gear ratios, all help

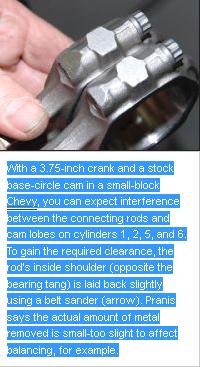

some of the newer stroker rods do in most cases let you avoid the use of a smaller base circle cam, but because there's dozens of different connecting rod designs and different types of rods and rod bolts clearances vary a good deal,

as alway you'll need to check & verify the clearances, once the cam is degreed in, and rods are installed in your particular engine.

Big-Inch Chevy Small-Block Cheat Sheet: Connecting Rods

Big-Inch Chevy Small-Block Cheat Sheet: Connecting Rods- Step by Step How-To Instructions, Images, Examples, and Checklists

Chevy Small Block Cranks, Rods, and Piston Guide

Chevy Small Block Cranks, Rods, and Piston Guide- How to Build Max Performance Chevy Small Blocks on a Budget

383 Stroker Small Block Chevy - Car Craft Magazine

A 383 Stroker Small Block Chevy is analyzed, assembled and dynoed. Follow along and get every fact and trick you wanted to know about a 383 build. - Car Craft Magazine

should you re-use stock connecting rods?

I get asked all the time, "should you re-use those stock rods, when I rebuild my 350 or when I build my 383 stroker" or "Ive got a 325hp 396 BBC,Im rebuilding, should I upgrade or rebuild the connecting rods" most sbc and many BBC stock rods are designed to be cheap, and dependable in engines...

garage.grumpysperformance.com

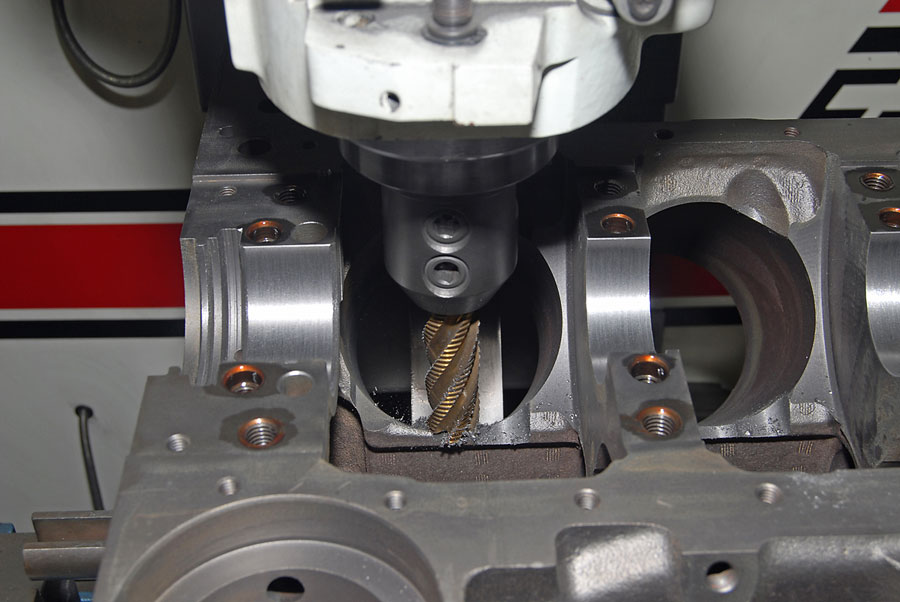

move that connecting rod and piston to all 8 locations and very carefully verify clearances (remember the rod clearance bevel faces the crank counter weight and the piston valve clearances face the outer block)through the full 720 degree rotational cycle, remember the cam spins at 1/2 the crank speed so the cam lobe comes close to the rod every other rotation,

and actually verify you DO, have or DON,T have a potential clearance problem

theres zero sense in runninbg around pulling your hair out and screaming until,

theres actually a PROVEN ISSUE too SOLVE (THERE MAY NOT BE!)

now if you find theres an issue to be solved you proceed using facts

and while your checking the cam lobe to connecting rod clearance check the connecting rod to block clearance ....yes the same minimum .060-.080 clearance is suggested

http://garage.grumpysperformance.co...earances-and-journal-surface.9955/#post-38385

rods that use bolts with nuts like pictured below will be weakened if excessively clearance ground

stroker profile rods offer more clearance to cam lobes, and yes the stroker clearanced profile rods are available in both (h) and (I ) beam designs

generally its a minor easily done clearance job

http://www.scatcrankshafts.com/index.htm

don,t forget to verify the cam to connecting rod clearances

a cams VALVE LIFT is determined by the DISTANCE the lifter moves as the cam rotates under the lifter base as it moves from the cam lobe base circle

(the closest the lifter comes to the cams center line)

up to the cam lobes ramp to the lobes peak,

(the furthest the lifter up off or from the cams center line)

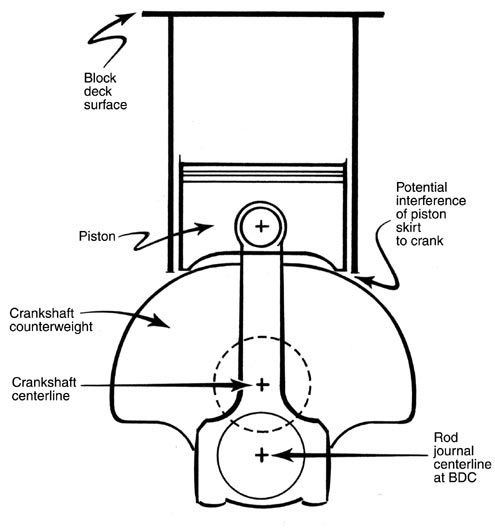

don,t forget to carefully check the piston skirt to crank counter weight clearance, it should be a MINIMUM of .080 thousands

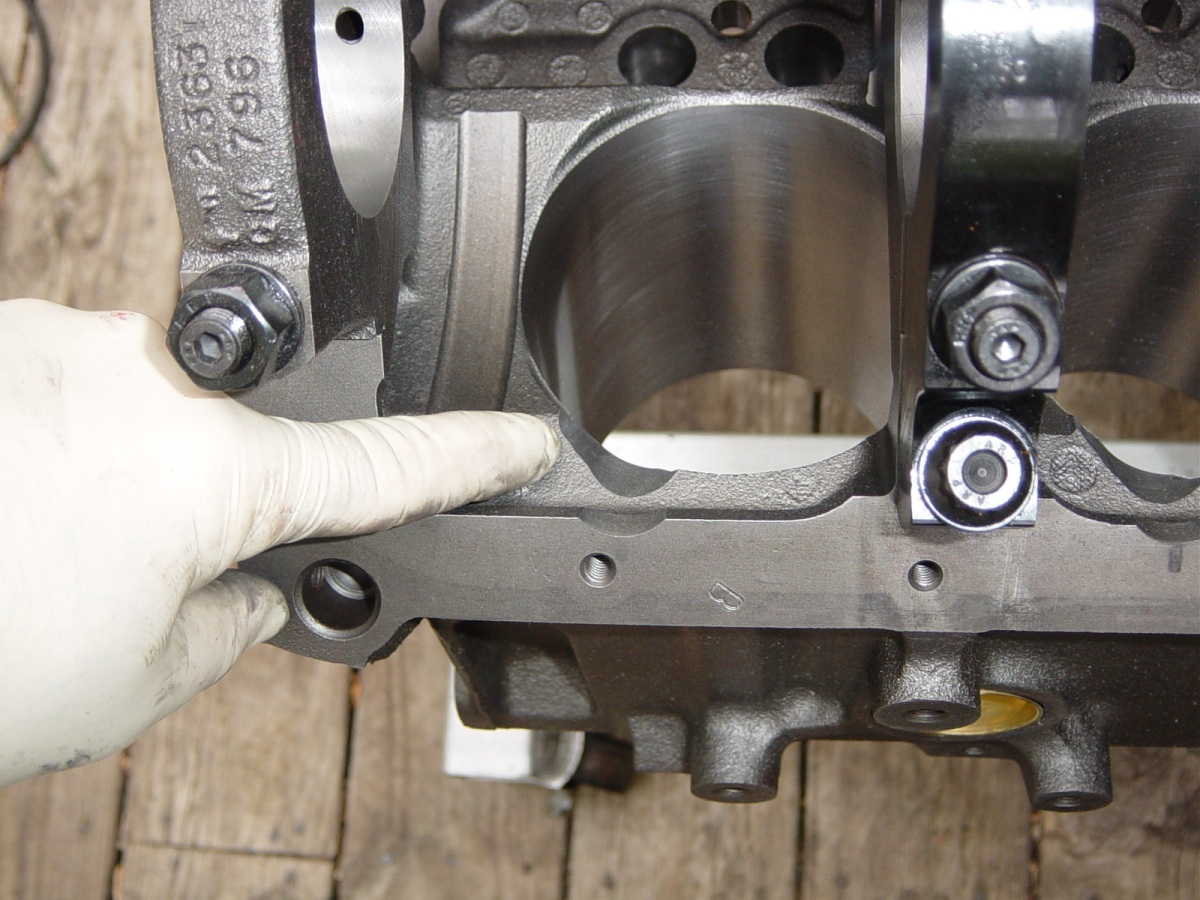

heres some pictures taken of an engine assembly that use a crank designed for a MINIMUM of a 6.25" connecting rod that was used with a 6.135" connecting rod

http://www.enginebuildermag.com/201...ton-compression-height-and-crankshaft-stroke/

you can clearly see where the piston pin boss was being hit bye the counter weights, even though the builder checked one piston and found it had .025 clearance during assembly

yes it costs more but BUT the quality of the steel and machine work tends to be far more consistent, so I generally advise use of a SCAT FORGED 4340 steel crank ,internally balanced for use with 6" connecting rods using 7/16" ARP rod bolts,

I've found the cost well worth the increased quality and lack of clearance issues

MATERIAL....................TENSILE STRENGTH.....PSI.

CAST

CAST IRON.....................APROX 75,000

NODULAR IRON................APROX 95,000

CAST STEEL...................APROX 105,000

FORGED

5140 forged steel.............APROX 115,000

4130.forged.....................aprox 123,000

4340 forged.....................aprox 143,000

types of crankshaft steel

I POSTED THIS BEFORE, when shopping for a rotating assembly , it pays too carefully compare features, read the fine print carefully ,and do some careful pre-purchase research. price is NOT the most important consideration, value per dollar spent, quality and durability would be far higher on my...

garage.grumpysperformance.com

An Option On A Source For Cranks Etc.

just pointing out a few component options A couple local guys suggested using these cranks and rods, I have looked over a few and the quality looks decent, but I have no personal experience, using the components YET. https://www.molnartechnologies.com/...

garage.grumpysperformance.com

connecting rod & rod length too stroke info

I build mostly BBC engines, but most of this info also applies to SBC connecting rod selection, I was asked if stock rods were ok or should they swap to better ARP bolts or BUY the BETTER RODS WITH THE UPGRADED BOLTS, the first thing Id point out is that, in most cases, when I diagnose engine...

garage.grumpysperformance.com

cast or forged rotating assembly?

I was recently asked if the difference between a cast crank and rods at $1200, vs FORGED at $1600 was worth the difference in cost by a guy who fully intends to race the car and has a high probability of using nitrous... " Engine Balance: Internal vs. External An engine must be balanced to...

garage.grumpysperformance.com

tips on building a 383 sbc stroker

STOP AND ACKNOWLEDGE THE FACT YOU NEED BOTH TOOLS AND KNOWLEDGE, THAT WILL TAKE TIME AND RESEARCH AND SOME EXPERIENCE, AS I've stated before, I could have you watch me build a kick-ass race engine and then let you try and duplicate the effort, the problem is not in your new found skills its in...

garage.grumpysperformance.com

bearing clearances

Rod bearings 0.002 - 0.025" , side clearance 0.010 - 0.020" Main bearings 0.002 - 0.003" for most engines ( 0.020-0.025 bearing clearance on small blocks, .025-.027 bearing clearance is about ideal, on...

garage.grumpysperformance.com

how strong will a SCAT rotating assembly be?

How much boost will Scat pro comp rods & Scat forged crank be reliable to? SB around a 421. I use SCAT rotating assembly's almost exclusively in my engine builds. the rigidity of the block casting the fasteners used, the main cap design, I have to point out theres a wide variation in the...

garage.grumpysperformance.com

scat cranks & related info

Chevy V8 bore & stroke chart Chevy V8 Crankshaft Journal Sizes Here's a list of Chevy V-8 crankshaft journal sizes. All journal sizes are given in "STANDARD" sizes. Your crankshaft may have been cut down in size previously by a machine shop. Make sure your crank will work in the block you...

garage.grumpysperformance.com

When your planing to build a performance car, I've found it helps,

you see progress being made and prevents you from getting discouraged as easily,

if you work on accumulating components for each of the 8 basic sub assemblies,

and checking off your list those components and grouping those on a separate shelf,

as doing so tends to allow you to see more consistent progress,

being made, and you get a feeling your getting someplace.

(1) BLOCK (bearings, freeze plugs main caps and machine work)

(2) ROTATING ASSEMBLY (crank, rods pistons, rings, flywheel,damper etc.)

(3) CYLINDER HEADS and VALVE TRAIN ( valves, valve springs, cam, timing gears, rockers, valve guides, push-rods lifters . etc.)

(4)INDUCTION(manifold, throttle body, sensors, carbs, supercharger, injection , fuel pump, fuel pressure regulator injectors etc.)

(5) DRIVE TRAIN ASSEMBLY COMPONENTS(clutch, stall converter, transmission ETC.)

(6) ignition system (distributor,coils, ignition wires, magneto etc.)

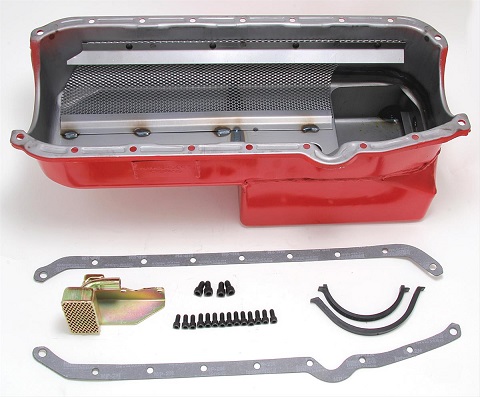

(7) LUBE SYSTEM (oil pan, oil pump, windage tray,oil cooler, ETC.)

these threads and links and sub-links might help

(8) EXHAUST (headers and exhaust system, mufflers ETC.)

rebuilt or new chevy 383 crank

http://www.superchevy.com/how-to/project-cars/sucp-0706-small-block-chevy-stroker-kit/

On oil pans I prefer studs, and an oil pan back plate

you might want to Use with P/N 12553058 RH and P/N 12553059 LH oil pan reinforcement plates to distribute the bolt stress on the oil pan rail for 1985 and earlier oil pans P/N 14088501 (LH) and P/N 14088502 (RH).1986 and newer

I think the hamburger oil pan is a better value At $242 than most of the common mid priced oil pans

notice the better oil control features

https://www.summitracing.com/parts/ham-1088/overview/

http://www.milodon.com/oil-pans/street-oil-pans-sbchevy.asp

http://www.jegs.com/p/Moroso/Moroso-Street-Strip-Oil-Pans/763991/10002/-1

https://www.summitracing.com/search/brand/hamburgers-performance/part-type/oil-pans

https://www.cantonracingproducts.com/cgi-bin/commerce.cgi?search=action&category=1301

http://www.stefsperformance.net/ste...oil-pans/aluminum-oil-pans-pumps#!prettyPhoto

youll want to take the time to do the math and compare components, lets for a second assume your,debating these two heads,

if you compare the 195cc vs 210cc AFR heads, all the way

theres a significant improvement in flow and a negligible decrease in port flow speed

theres always a compromise made between cost and potential power,

and obviously you want to match components to the intended power and rpm range,

but having seen a bunch of 383 builds use both AFR heads,

I think the 210cc choice here, is a no brainer if you can afford the price.

heres a chart FROM THE BOOK,HOW TO BUILD BIG-INCH CHEVY SMALL BLOCKS with some common cross sectional port sizes

(measured at the smallest part of the ports)

Potential HP based on Airflow (Hot Rod, Jun '99, p74):

Airflow at 28" of water x 0.257 x number of cylinders = potential HP

or required airflow based on HP:

HP / 0.257 / cylinders = required airflow

if we compare the head air flow rates between a 195cc and 210cc head on a 383-406 SBC and assuming a decent roller cam with the lift and duration,required, and intake that allows the heads to flow at their full potential,

195cc Street Head Flow Chart

.200 .300 .400 .500 .550

Int 146 201 247 275 280

Exh 119 166 197 213 218

210cc Race Ready Head Flow Chart

.200 .300 .400 .500 .550 .600 .650

Int 145 199 255 292 301 309 311

Exh 110 158 192 210 214 220 222

if you compare peak intake rated flow at .550 lift

280 cfm vs 301 cfm (about a 9% increase) youll see why

thats in theory potentially a 43 hp gain

http://garage.grumpysperformance.co...hing-the-drive-train-to-the-engine-combo.741/

http://garage.grumpysperformance.co...electing-a-torque-converter-stall-speed.1715/

http://garage.grumpysperformance.co...late-gear-ratios-and-when-to-shift-calcs.555/

all it takes is a tiny bit of research and some math to calculate the ideal rear differential gearing, tires size etc. and transmission gear ratios, and you can certainly select the correct torque converter stall speed if you have a dyno graph of your engines power curve without much difficulty, an hour or so spent in reading and research will provide you with a great deal better performance from most cars.

and a couple days worth of research and doing some math on all of the power trains component parts will provide you with a wealth of info that can prevent you from making costly mistakes.

what transmission?

IF automatic will you use a non-stock. higher stall speed converter?

what rear gear ratio?

what tire diameter?

do you need to pass emission testing?

will you be towing anything heavy?

what altitude do you live at?

whats the truck used for?

is this a weekend toy or daily transportation?

posting a good deal more info on what your trying to accomplish,

a brief suggestion on your current personal skills,

and previous experience, access to tools, etc.,

budget limitations and other info will insure you get far more accurate advise!

Im not trying to be a P.I.T.A.

I'm only trying to match the completed project goals with the realistic expectations and budget and what knowledge and physical assets you have to work with.

matching the intake design to the application

what is the max piston speed, the rotating assembly and valve train are designed for?

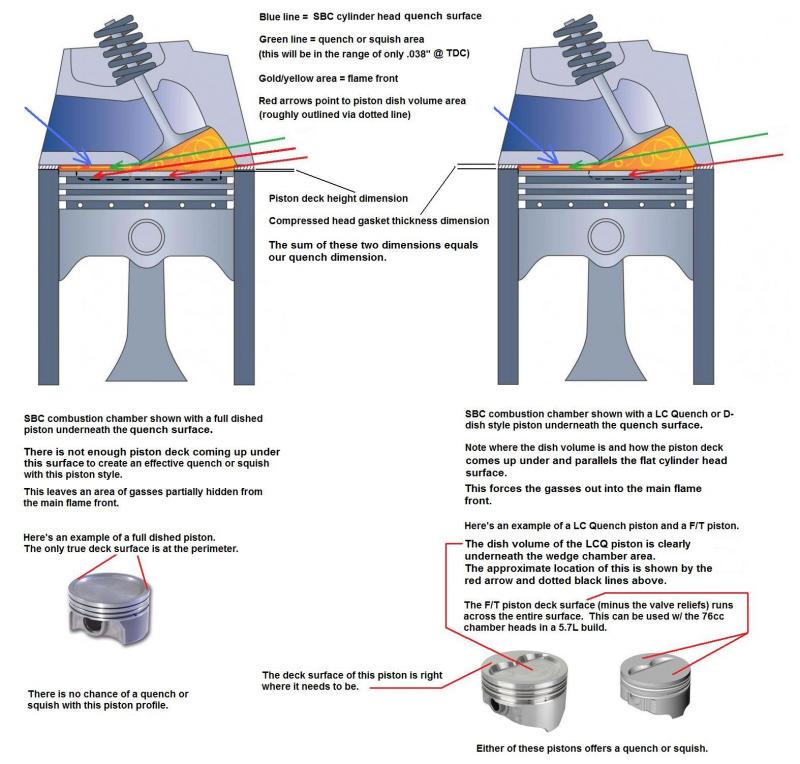

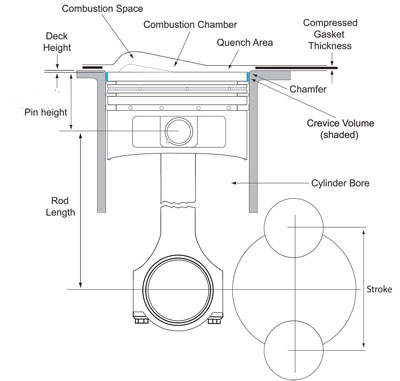

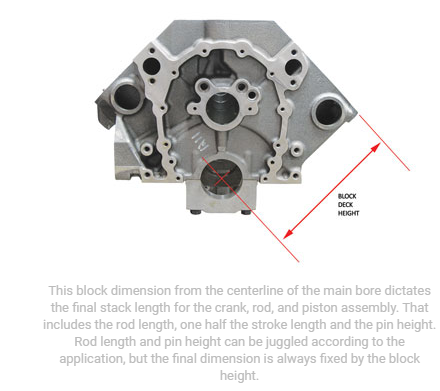

getting the quench and valve train geometry and clearance correct,

matter to getting the engine built correctly.

SMALL BLOCK REFERENCE BOOKS YOULL WANT

start by buying these books and watching the video

http://www.themotorbookstore.com/resmchstvi.html

http://www.amazon.com/David-Vizards...8&qid=1456194032&sr=8-5&keywords=DAVID+VIZARD

HOW TO BUILD MAX PERFORMANCE CHEVY SMALL BLOCKS ON A BUDGET by DAVID VIZARD

.

JOHN LINGENFELTER on modifying small-block chevy engines

http://www.amazon.com/Lingenfelter-...=1456193940&sr=8-1&keywords=JOHN+LINGENFELTER

http://www.amazon.com/Smokey-Yunick...2&sr=8-1&keywords=smokey+yunick+power+secrets

http://www.amazon.com/Chevrolet-Rac...ords=The-Chevrolet-Racing-Engine-Bill-Jenkins

http://www.northernautoparts.com/part/ek-ek1097alb

https://www.rbracing-rsr.com/compstaticcalc.html

http://www.csgnetwork.com/compcalc.html

always, if you deal with any machine shop, assume your dealing with a guy who really doesn,t give a crap,

and print out in fine detail , what you want done ,,EXACTLY....with specific dimensions and a diagram,

with ALL those dimensions printed boldly , try hard to get both a firm delivery date and a agreed upon total price

IN WRITING WITH HIS SIGNATURE, and several pictures of the parts and him holding the parts and a receipt

that the parts listed individually, to be worked on are in what ever condition they were in, TAKE LOTS OF PICTURES

this will be a minor P.I.T.A. but it will save you a whole lot of misunderstandings and arguments

never deal with any shop that says things like,

"come back next week I should get too it by then"

or "stuff like that generally costs about$300-$400, but I won,t know until I get into the project"

or won,t give a firm delivery date, price or sign a

receipt, or agree to a firm price... youll see why if you ignore this advice in spades

as you read through most of the builds listed and discussed on this web site,

youll eventually see a strong trend, towards what I and many other knowledgeable engine builders have been forced over time into recognizing.

the trend is simply that only engines built for max long term durability and max torque in the useful rpm range are making any financial sense.

as Ive stated many times, you have to finish a race to win it! and your never going to build a client base ,

if the engines you build make killer power on a dyno but need rebuilding in a couple months time.

theres several threads on builds here on this web site, and a great deal of time and research is devoted to extended durability, cooling and lubrication ,

and carefully selecting components, and machine work done, designed for max strength, for the dollars spent!

I used to ask guys

"would you prefer to build an engine that if you keep it well tuned and change the oil regularly,

will most likely still be running in 10-12 years, without changing major components, or

would you rather have an additional 25-30 hp,and need a rebuild every 3-6 years,

but have a much better chance it won,t last half that time span....

especially in a muscle car driven on the street,

where either engine choice will destroy street tires effortlessly,

and get you a ticket effortlessly for speeding any time you get stupid?"

READING THE LINKS AND SUB LINKS WHILE IT TAKES TIME WILL SAVE YOU A GREAT DEAL OF CASH AND WASTED TIME.

BUY THE BOOKS IN THE LINKS. and READ THEM

its the combo of the engines,

compression,

displacement ,

cam timing

and the exhaust scavenging ,

and the intake manifold design,

NOT the intake port cross sectional area,

that are the most critical factors, in the engines lower rpm and mid rpm torque.

but for damn sure an intake runner port can be small enough to noticeably restrict upper mid range and peak power significantly,

For 5 decades I've heard endlessly about how installing larger free flowing cylinder heads would devastate the engines ability to make any low or mid rpm torque.

especially when Id suggest using a set of smaller 300cc-320cc, aluminum,rectangle port heads on a 496 BBC, or 200 cc-210cc heads on a 406 sbc, I was asked to build

yet on every engine I've ever had built or had some guy ask me to look at, to see why it ran a great deal less impressively than he expected it too,

they brought into my shop its was very obvious (at least to me) that it was the combo of low compression, too little displacement, with too much cam duration ,

a restrictive exhaust or some guy who was trying to save money and continuing to use a stock stall speed torque converter, or retain a badly mis-matched 2.87:1-3.08:1 rear gear ratio,

with an engine that he miss matched components by slapping a large carburetor , and a single plane intake on,an engine that will rarely exceed 6000 rpm, that was the major reason.

if you want an engine combo to run your first step is to logically match the list of components you,ll use to the application,

and that requires you stop, engage the brain and think things through carefully,

and the most common way to screw up the process is to over cam a low compression engine,

have a restrictive exhaust or mis-match the drive train gearing to the engines power band.

the links below and the sub links they contain could easily take a week to read through but it would be time VERY WELL SPENT, and the knowledge gained will be far more useful than almost anything else you could do with that time in relation to the project

http://garage.grumpysperformance.com/index.php?threads/dynamic-vs-static-compression.727/

http://www.wallaceracing.com/Calculators.htm

http://garage.grumpysperformance.co...ads-tuned-intake-turbulence.12998/#post-67611

http://garage.grumpysperformance.co...gine-to-match-the-cam-specs.11764/#post-55651

http://garage.grumpysperformance.co...y-in-building-a-good-engine.11682/#post-54682

http://garage.grumpysperformance.com/index.php?threads/tbucket-engine-project-dart-shp.3814/

http://garage.grumpysperformance.com/index.php?threads/repair-or-replace-350-crank.14181/

http://garage.grumpysperformance.com/index.php?threads/bits-of-383-info.38/

http://garage.grumpysperformance.co...ing-parts-and-a-logical-plan.7722/#post-51341

http://garage.grumpysperformance.com/index.php?threads/tips-on-building-a-383-sbc-stroker.428/

http://garage.grumpysperformance.com/index.php?threads/finding-a-machine-shop.321/

http://garage.grumpysperformance.com/index.php?threads/what-to-look-for-in-a-good-engine-combo.9930/

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

http://garage.grumpysperformance.com/index.php?threads/383-information-overload.11137/

http://garage.grumpysperformance.com/index.php?threads/can-you-plan-for-quench.11298/

RELATED INFO

viewtopic.php?f=52&t=4081&p=13147&hilit=quench+swirl#p13147

viewtopic.php?f=52&t=399&p=21603&hilit=compression+height+piston#p21603

viewtopic.php?f=53&t=5064&p=14370&hilit=compression+height+piston#p14370

http://garage.grumpysperformance.co...piston-to-bore-clearance-on-your-block.14251/

viewtopic.php?f=53&t=3760&p=9968&hilit=compression+height+piston+measure+deck+height#p9968

viewtopic.php?f=53&t=509&p=11324&hilit=compression+height+piston+measure+deck+height#p11324

Last edited: