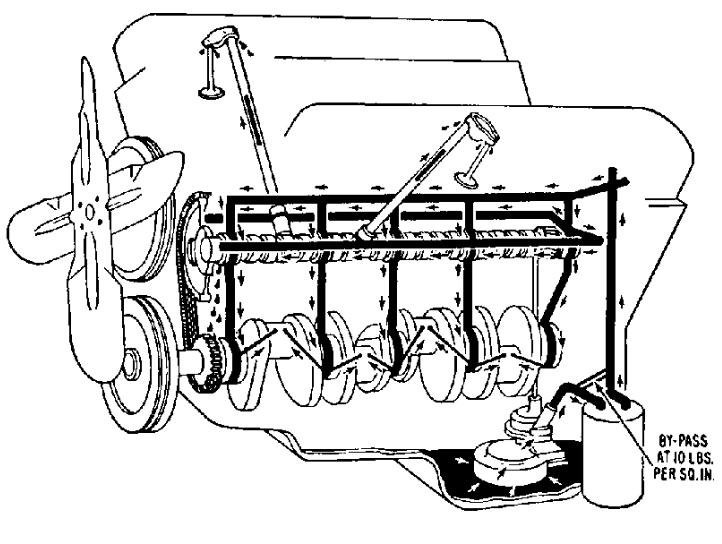

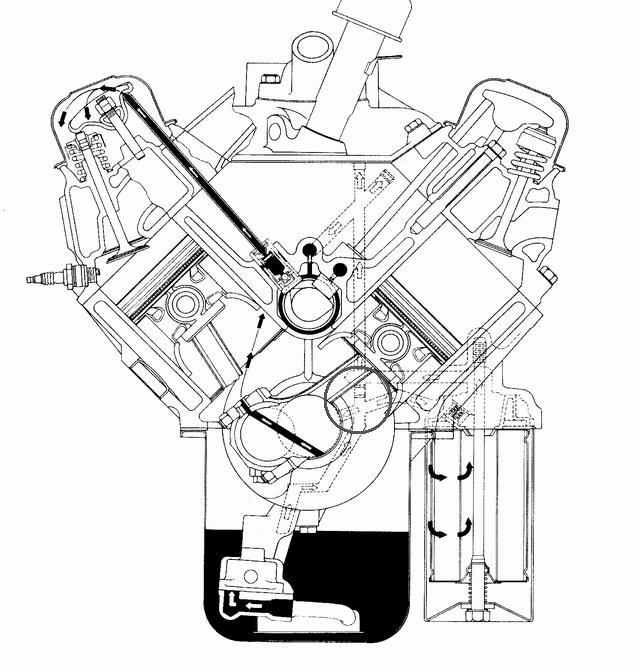

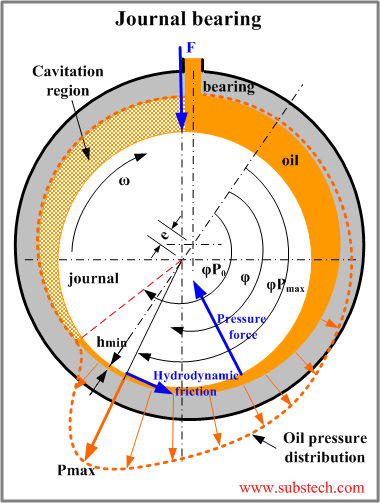

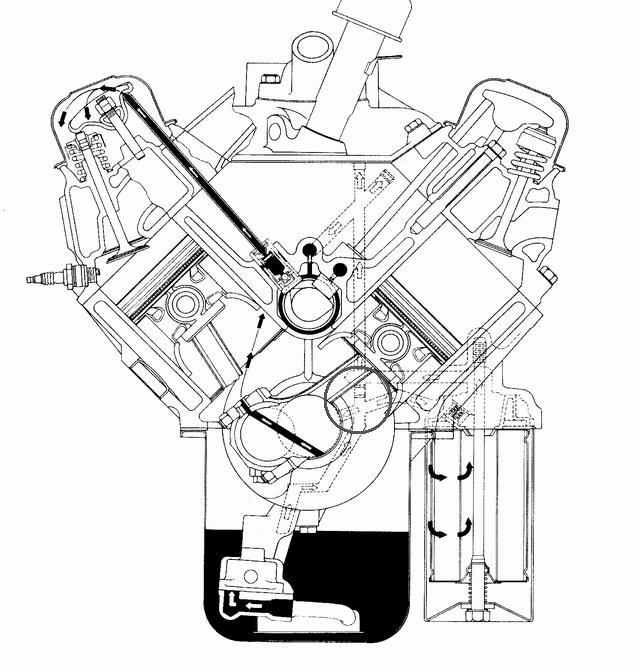

Bearings and oil flow, some of the most important processes in engine assembly are related to getting the bearing clearances and oil flow and pressure rates set up to provide the correct oil flow rates and pressure for cooling and preventing direct surface to surface contact on the rotating assembly and valve train components and maintaining the proper film of oil between moving surfaces of the rotating assembly bearings and piston ring to bore cooling and lubrication to provide the support of the moving components.

getting the engines lubrication, clearances ,and cooling needs, matched to the intended application and stress levels is key to longer term durability

http://www.babcox.com/editorial/us/us90126.htm

http://www.insightservices.net/testoil/ ... cation.htm

http://www.thirskauto.net/BearingPics.html

http://micapeak.com/info/oiled.html

http://www.unofficialbmw.com/all/misc/all_oilfaq.html

http://www.fd3s.net/oil_pressure.html

http://www.aa1car.com/library/us1097.htm

keep in mind both engine oil temps and trans fluid temps seldom reach operational temps,fluid

keep in mind both engine oil temps and trans fluid temps seldom reach operational temps,fluid

and stabilize , for semi consistent data,in under 12-15 minutes of drive time,temps have a huge effect on lubricant viscosity and durability. .

in my opinion , and experience and from lots of G.M. engine, race testing.

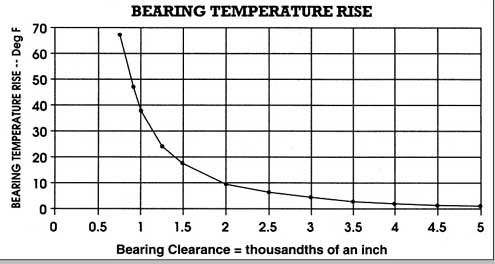

theres no need for oil pressure to exceed about 65 psi,

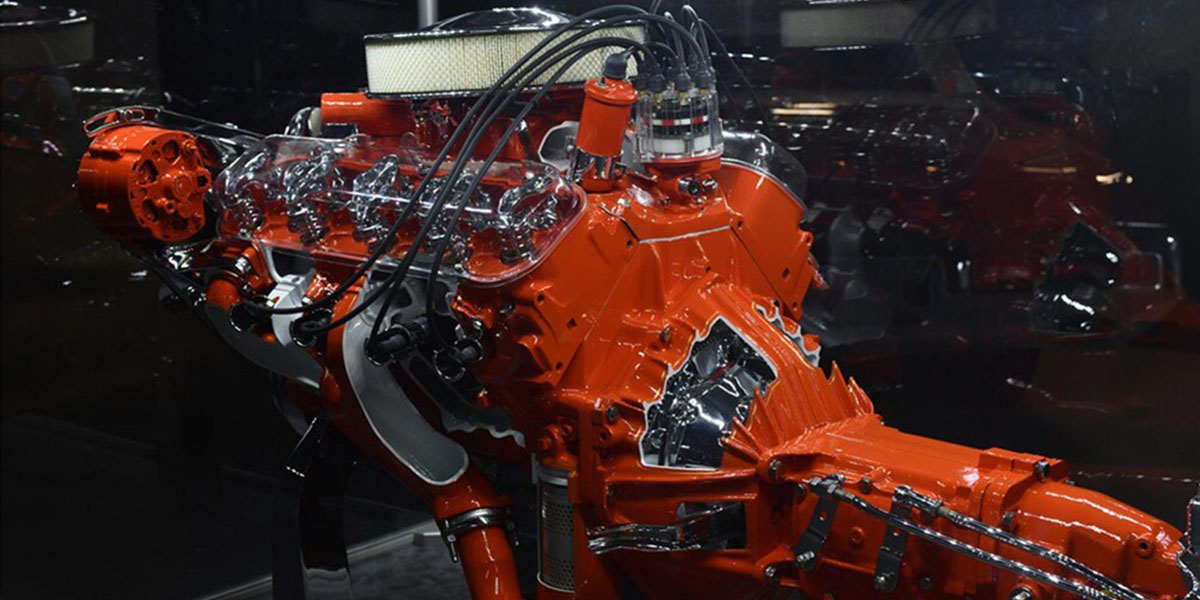

it takes power to spin the oil pump against that extra resistance, it induces extra wear on the distributor and cam gears,

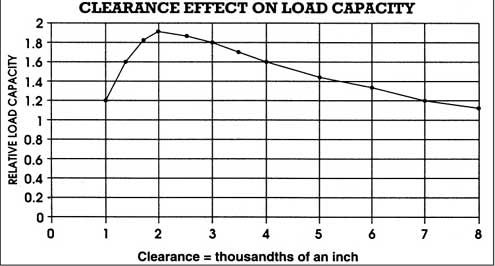

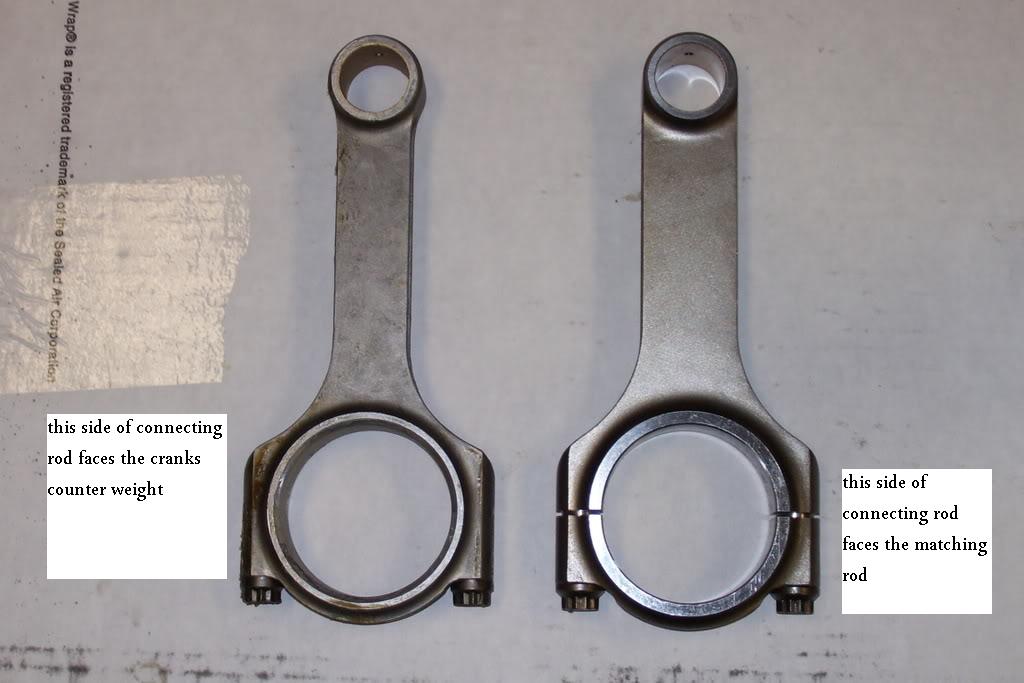

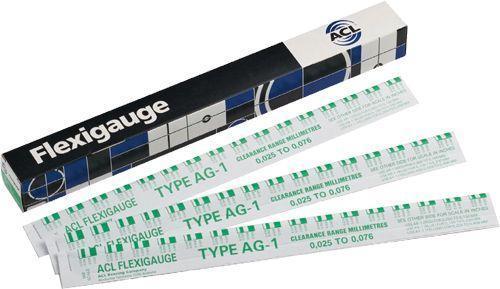

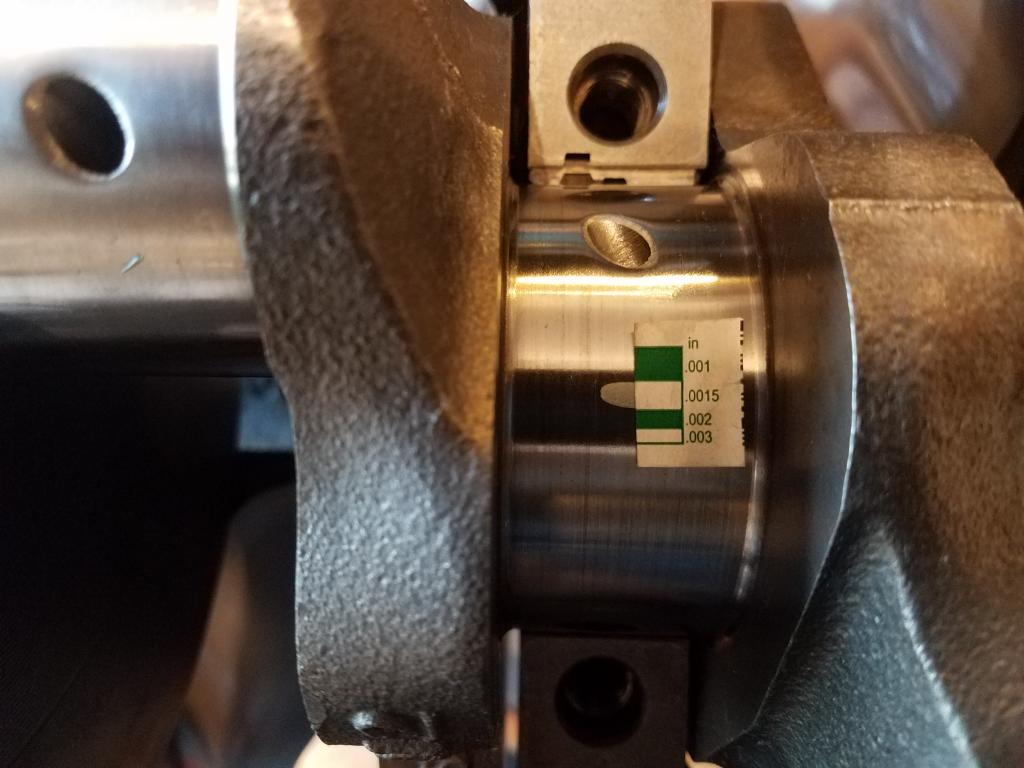

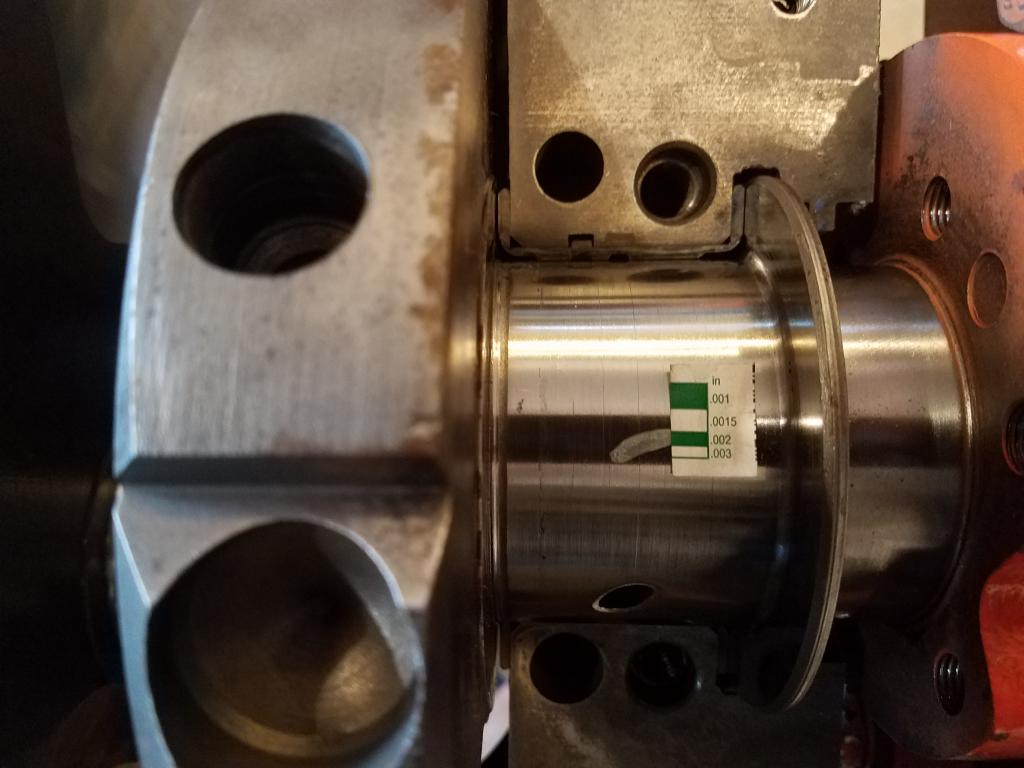

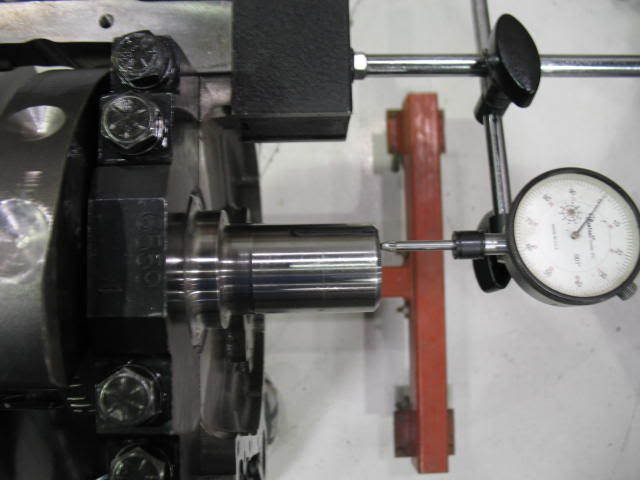

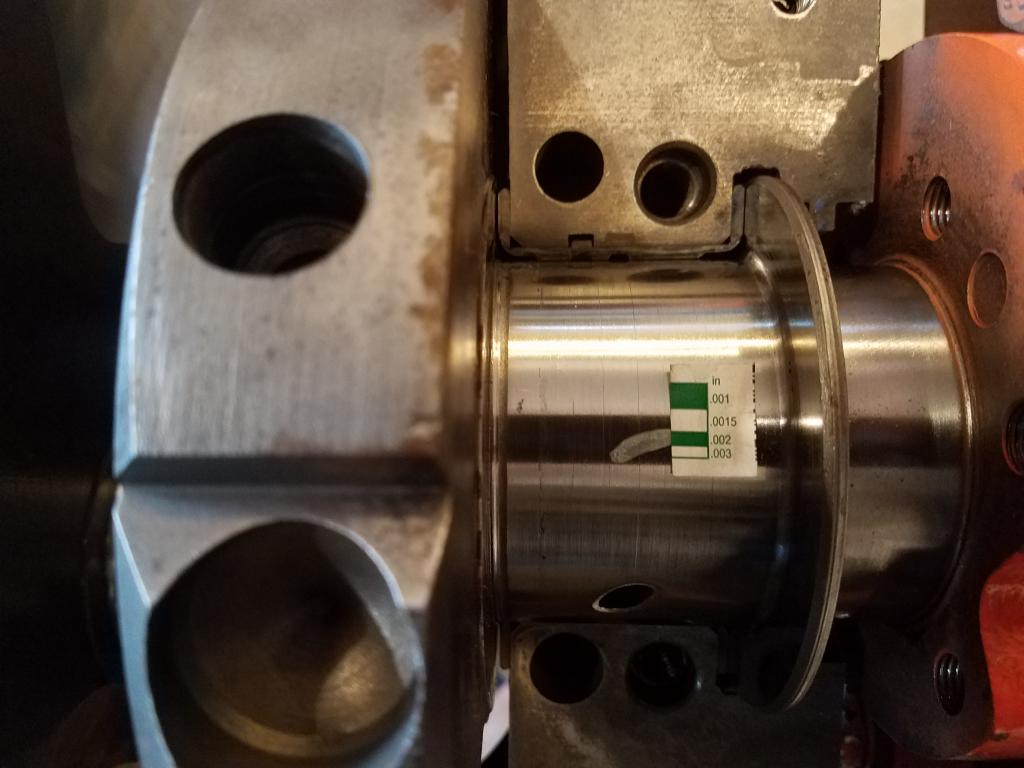

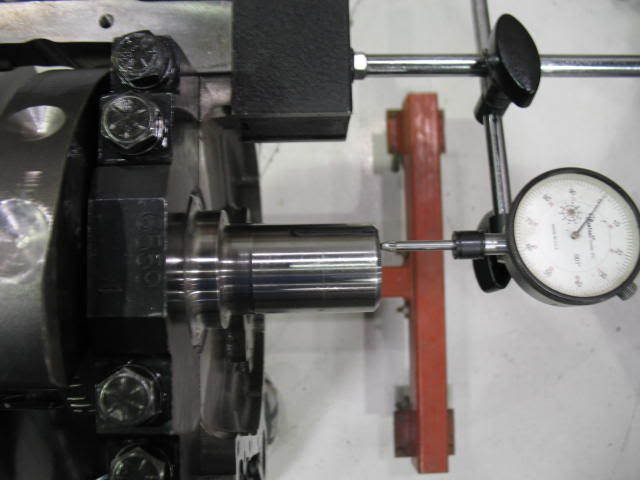

and it does nothing to reduce bearing wear or increase cooling on the bearing surfaces, he should open some bearing clearances marginally

(maybe an extra half thousandth on the mains) to increase oil flow volume reaching the main bearings, and use a lower resistance oil pump bye-pass spring.

extra oil flow volume cooling the bearings and valve train will do more for durability than oil pressure exceeding 65-70 psi

http://engineparts.com/it_crankinstall.asp

http://engineparts.com/it_bearinginstall.asp

http://engineparts.com/techbulletins/CL77-1-205R.pdf

http://www.micapeak.com/info/oiled.html

http://www.nordicgroup.us/oil.htm

http://www.carbibles.com/engineoil_bible.html

http://data.melling.com/Select/small_block_chevy.php

http://data.melling.com/Select/big_block_chevy.php

http://www.thirskauto.net/Engine_Thrust_Bearings.html

http://www.engineparts.com/motorhead/te ... stall.html

http://www.babcox.com/editorial/ar/ar20128.htm

http://www.babcox.com/editorial/cm/cm99828.htm

http://www.thirskauto.net/Engine_Thrust_Bearings.html

http://www.diabolicalperformance.com/clearances.html

http://www.babcox.com/editorial/ar/ar10180.htm

http://data.melling.com/TECH.php

http://www.babcox.com/editorial/ar/eb110127.htm

http://theoildrop.server101.com/forums/ubbthreads.php

http://minimopar.knizefamily.net/oilfilterstudy.html

Id also point out that, if you properly set up an engine's oil system, open the oil drain holes and use the proper oil pan, windage screen and crank scraper, its virtually impossible , in a well designed engine to run the engine "long enough to pump all the oil upstairs."

as with a properly designed baffled oil pan, with a carefully fitted and clearanced windage screen and crank scraper, the oil pump simply reaches a flow rate pumping oil out of about 100 or so potential lubricant flow leakage points

http://garage.grumpysperformance.com/index.php?threads/whats-a-windage-tray-do.64/

thats a very common question but the answers no!

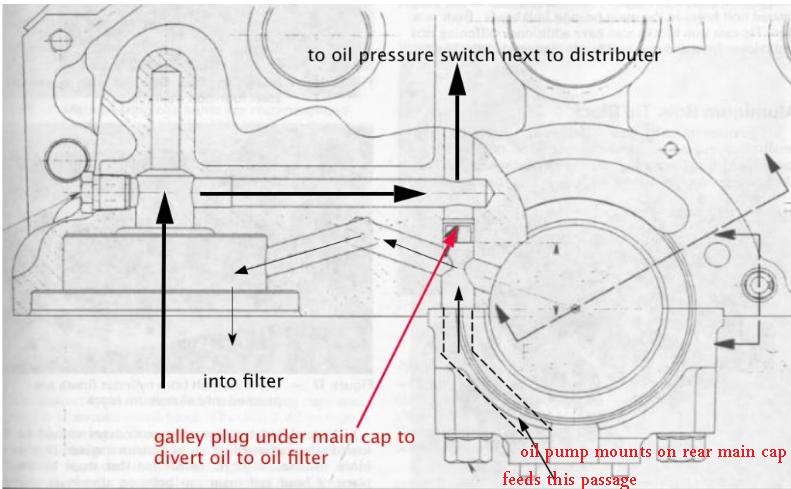

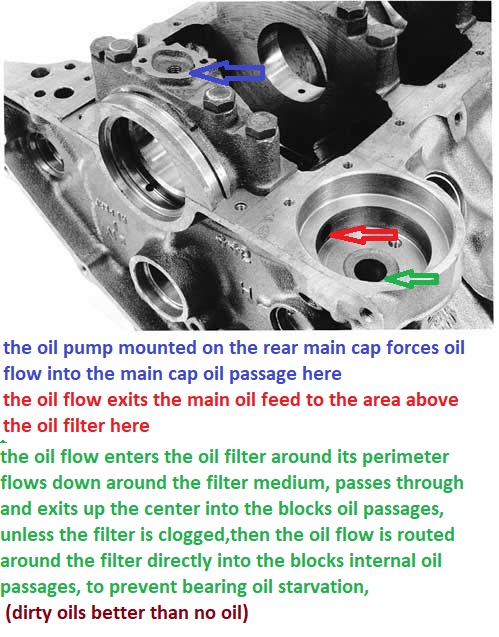

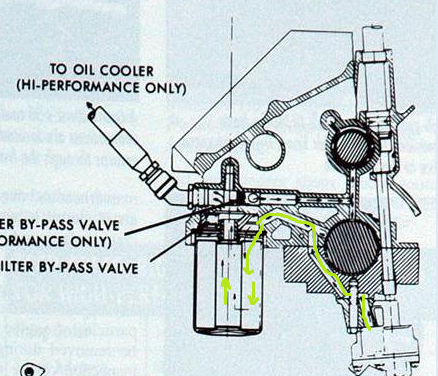

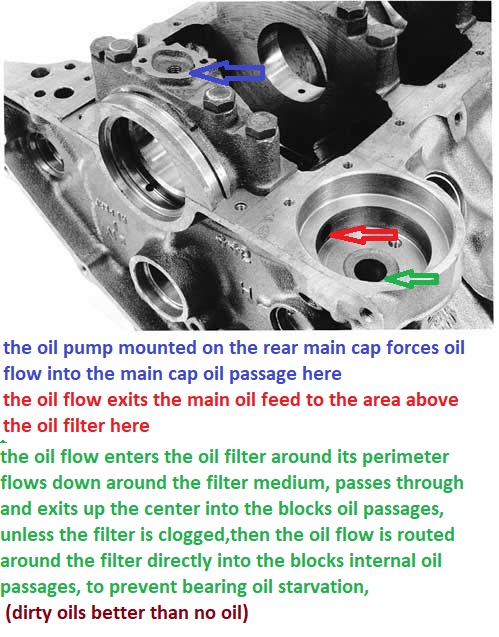

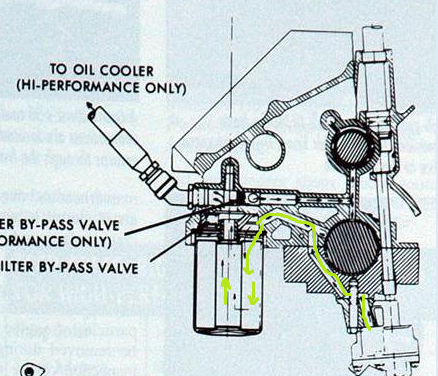

ALL THAT OIL FILTER BYE-PASS VALVE DOES IS ROUTE OIL FLOW PAST THE OIL FILTER

IF IT BECOMES SO CLOGGED WITH TRASH THAT THERES

A 10 PSI DIFFERENCE IN THE RESISTANCE TO OIL FLOW THROUGH THE FILTER

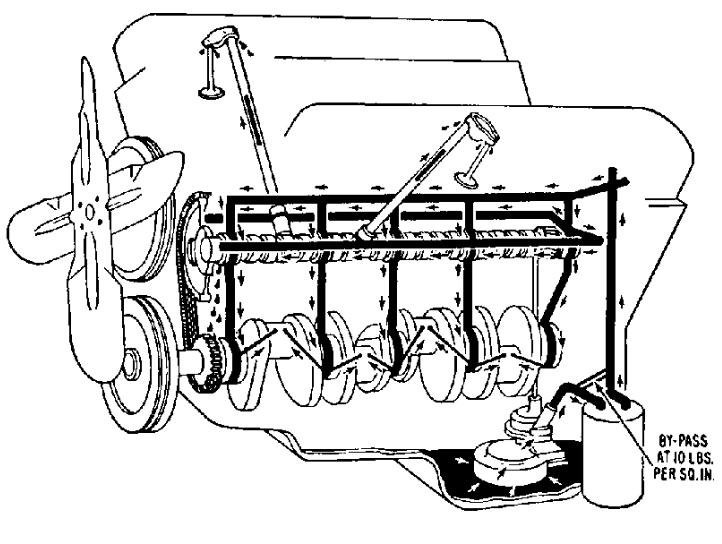

VS AROUND IT INTO THE BLOCKS OIL PASSAGES, oil enters the area over the oil filter in the block and is forced into the outer holes in the oil filter perimeter down through the case and filter element and up through the central hollow screw retention stud into the blocks oil passages, if the resistance too flow is too great the oil filter bye-pass valve routes oil around the filter directly from oil pump to the blocks oil passages.

pressure is a measure of RESISTANCE to oil flow, if the pumps providing flow and yes that needs to be verified,

( because if the oil pump pick-up is less than a 1/4" off the oil pan floor flow is potentially restricted)

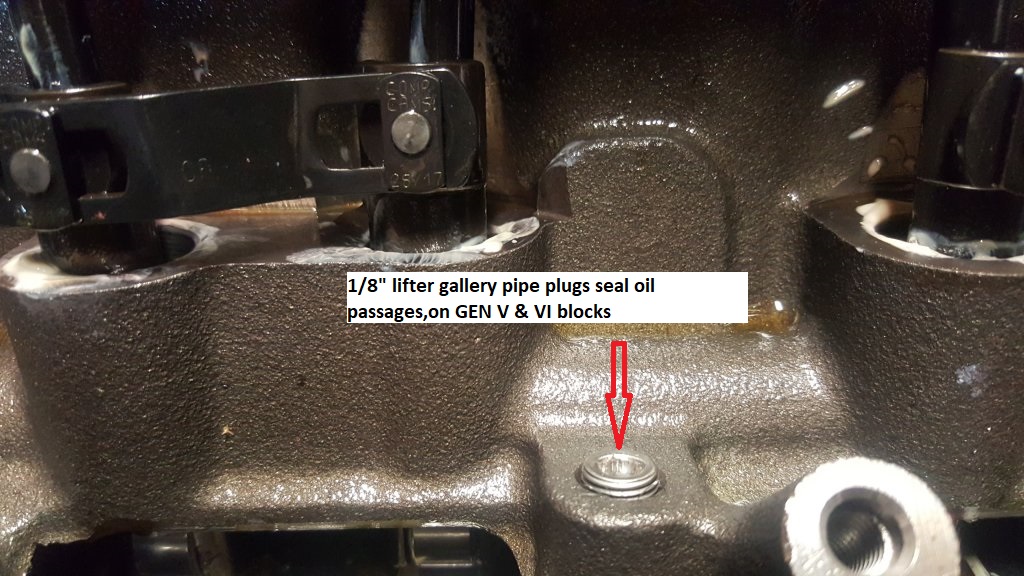

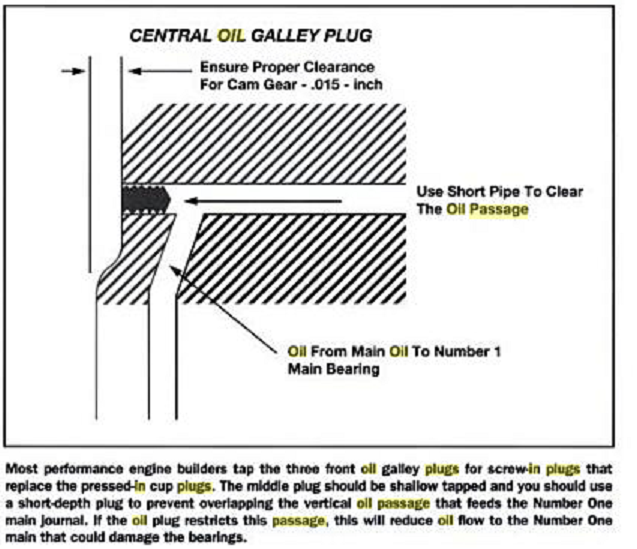

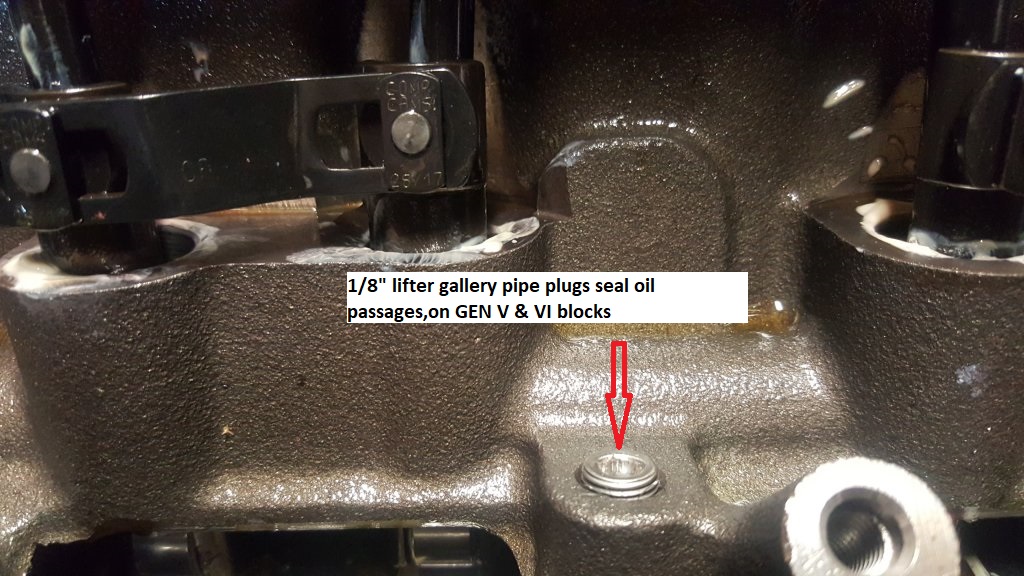

if your getting oil flow from the oil pump and no back pressure Id suggest checking the flow control valves, bearing clearances and oil passage plugs at the ends of the lifter gallery passages, any major open to flow oil passage results in very low oil pressure readings

http://garage.grumpysperformance.co...ark-v-bbc-engine-oil-system-differences.4576/

https://www.chevydiy.com/oil-lubrication-systems-guide-big-block-chevy-engines/

https://paceperformance.com/i-51345...ich-adapter-for-external-oil-cooler-only.html

http://garage.grumpysperformance.com/index.php?threads/basic-info-on-your-v8-lube-system.52/

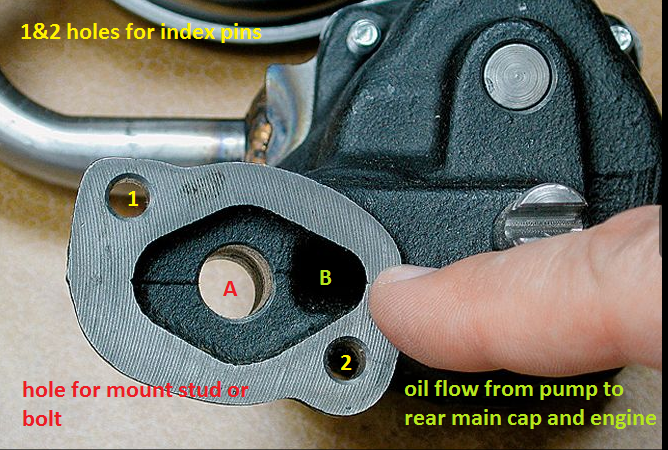

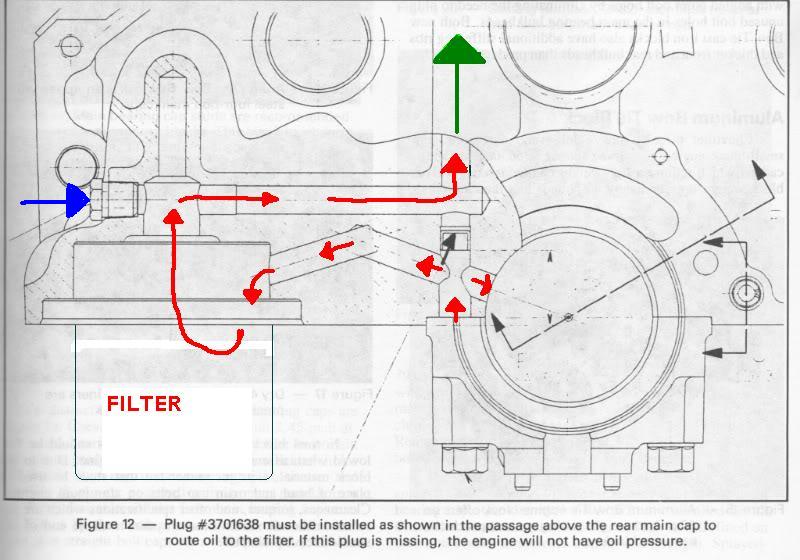

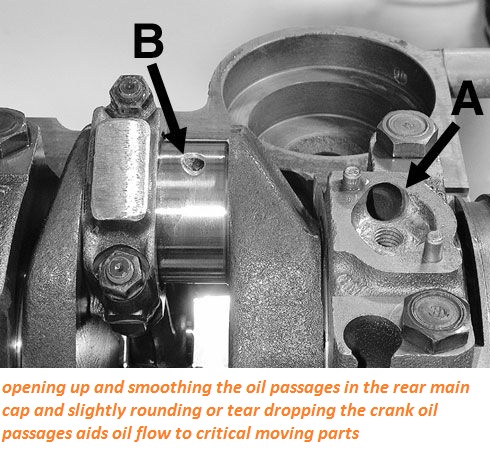

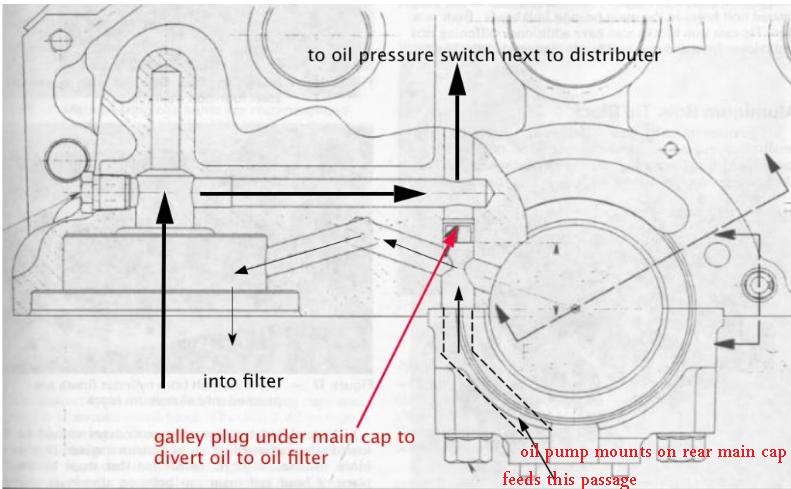

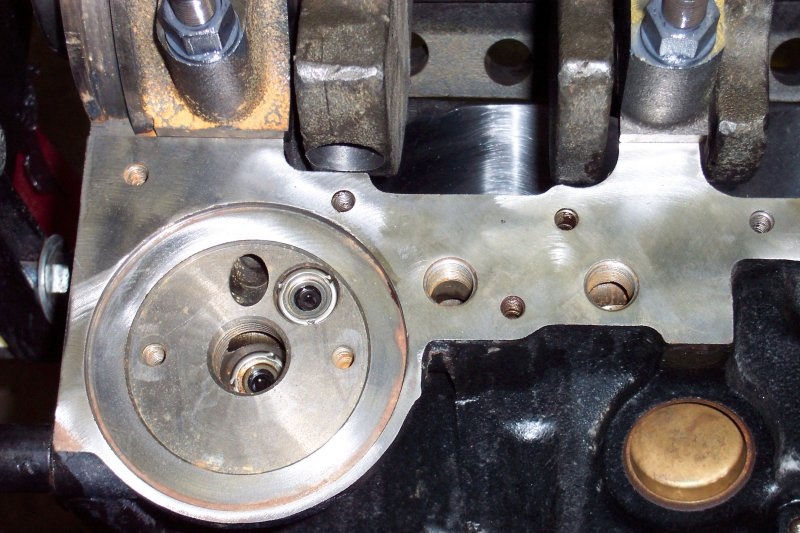

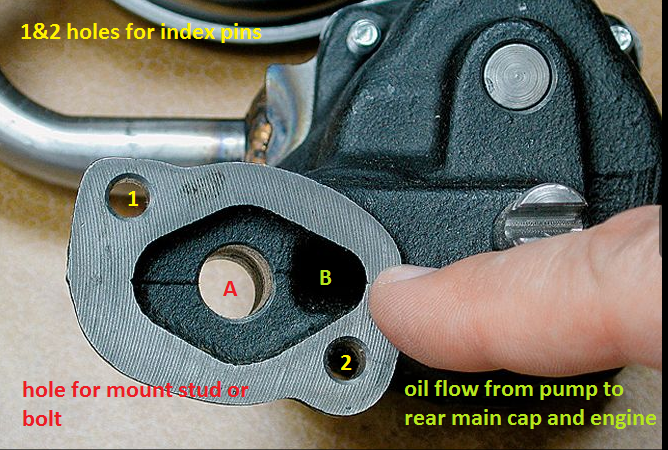

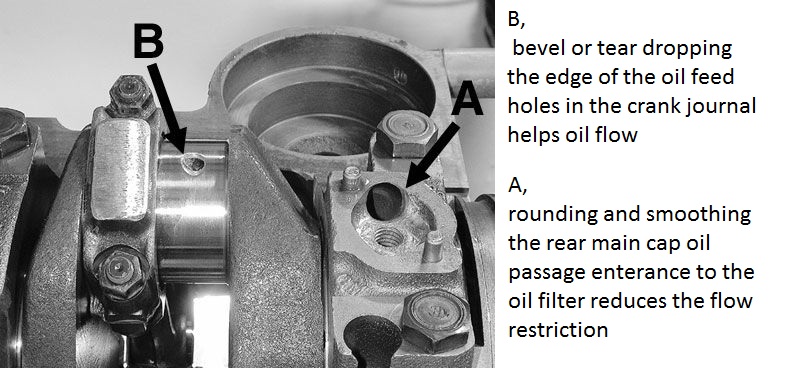

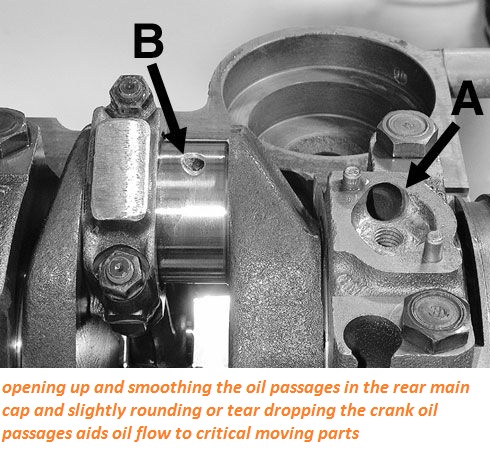

yes the oil flows around the mounting stud,from oil pump to main cap to reach the engine oil passages, thru the oil filter

failure to use the correct oil pump,mounting stud, bolt or nut or carefully check clearances when mounting an oil pump can cause problems

ONE RATHER COMMON MISTAKE IS USING THE WRONG OIL PUMP STUD OR BOLT TO MOUNT THE OIL PUMP AS IF EITHER EXTENDS THRU THE REAR MAIN CAP IT CAN AND WILL BIND ON THE BEARING AND LOCK OR RESTRICT, SMOOTH ROTATION

http://garage.grumpysperformance.co...-friction-and-pumping-losses.8966/#post-31978

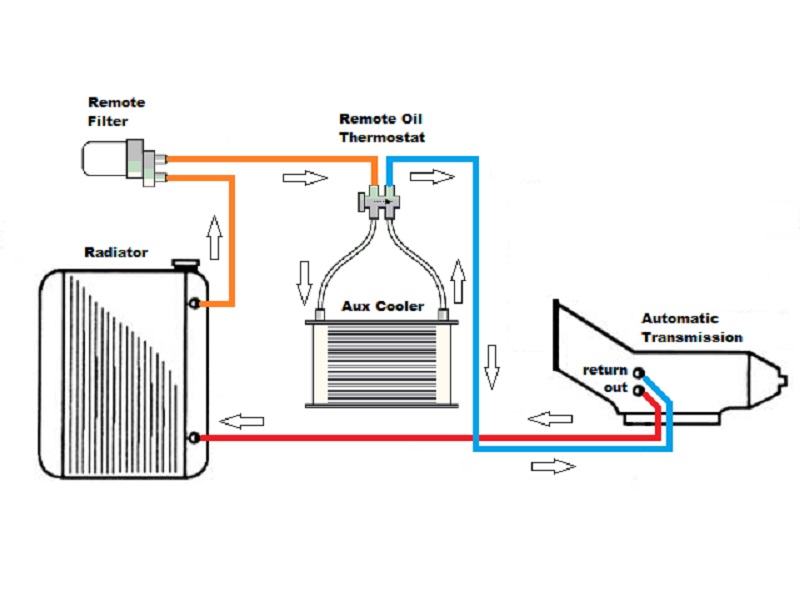

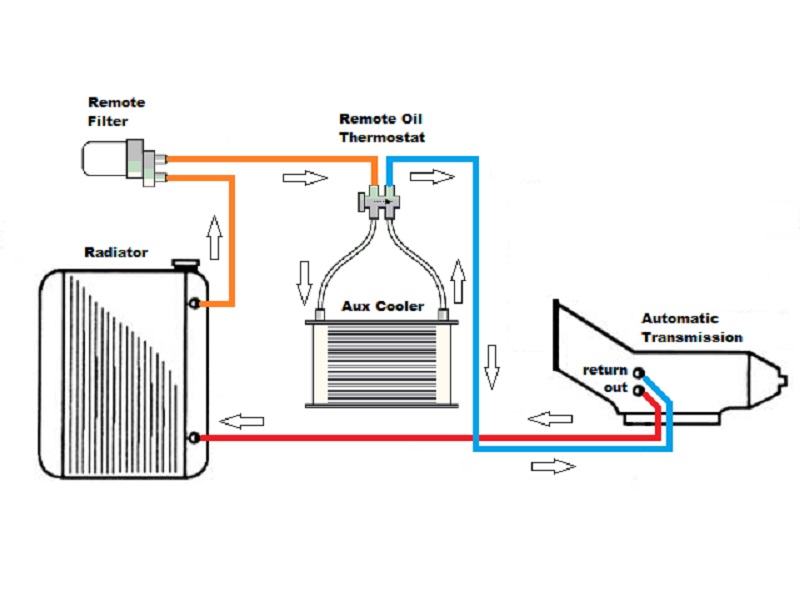

heres a cooler several guys I know use.

https://www.jegs.com/i/Derale/259/15900/10002/-1

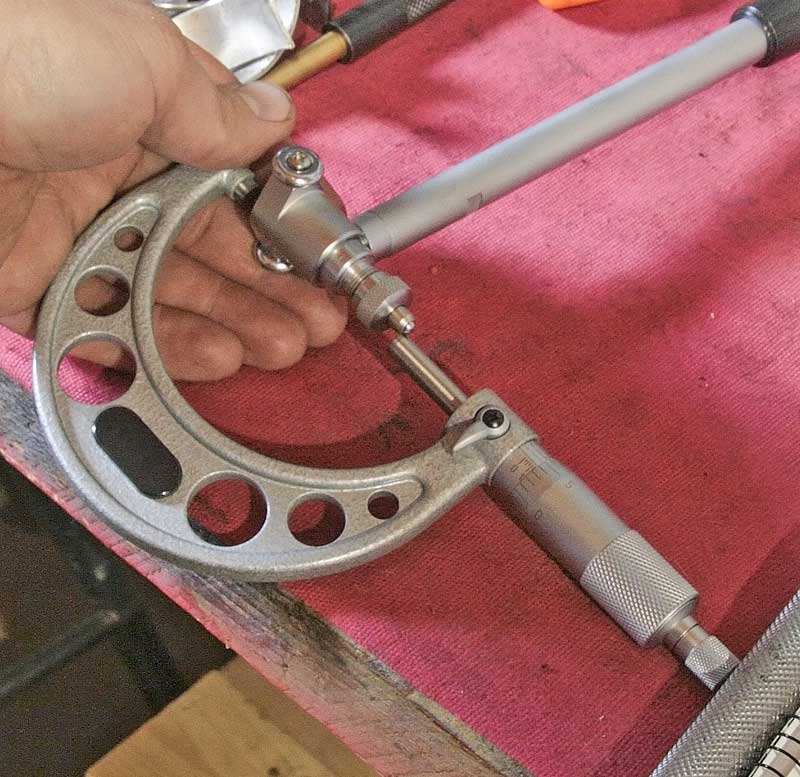

you will rather obviously need to carefully and accurately,

measure the location you want to install any fluid cooler and its fluid line connections, you should seriously consider a AN#8 line size as minimum

you can easily run the trans fluid or oil cooler without the thermostat controlled feed/return lines,

a cooler with AN#8 or 1/2" line size preferred

many guys that do that have a toggle switch that shuts the fan on the auxiliary oil cooler off until the fluid comes up to operational temps.

will a thermostat valve on the auxiliary cooling lines help maintain a stable fluid or oil temp,

and speed up the time it takes for the engine and transmission fluids to come up to operational temps? hell yes

,but theres millions of guys that have run a cooler without one.

on the down side, both engines and transmissions tend to last longer when the lubrication fluids are both stable and consistently in the ideal range.

http://shop.perma-cool.com/1073-Oil-The ... s-1073.htm

heres a cooler several guys I know use.

https://www.jegs.com/i/Derale/259/15900/10002/-1

you will rather obviously need to carefully and accurately,

measure the location you want to install any fluid cooler and its fluid line connections, you should seriously consider a AN#8 line size as minimum

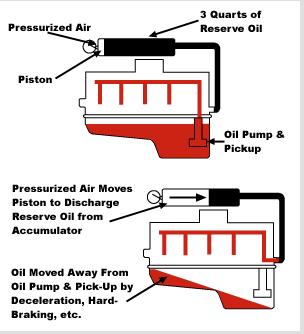

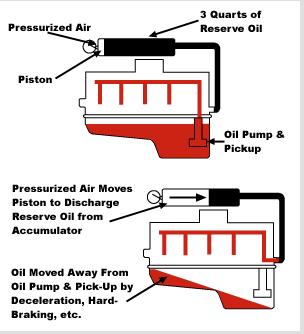

theres zero doubt an accusump oil feed is a good insurance policy to maintain oil pressure at the bearings, but simply having a 7-8 quart baffled oil pan,properly clearanced, windage screen and crank scraper will insure the oil pressure remains consistent , mostly due to the fact that theres always going to be enough oil over the oil pump pick-up, simply because theres really no room to pack most of the available oil volume in the upper engine ,plus the fact that hot oil flows well.

OIL PRESSURE read on the oil pressure gauge is a MEASURE of RESISTANCE to oil flow, you can REDUCE the pressure the gauge reads by either increasing the engine clearances or REDUCING the oil viscosity (thickness) so it flows thru the clearances faster with less resistance.(OR INSTALLING A SLIGHTLY WEAKER OIL PUMP BYE_PASS SPRING,that limits the pump pressure before it allows some oil to re-circulate back through the bye-pass valve ,from the high pressure back to the low pressure side of the pump impellers, but only the max pressure you reach is limited by the bye-pass spring,in your oil pressure bye pass circuit and its that spring resistance determines the point where the bye-pass circuit, opens and limits max oil pressure, but the bye-pass circuit has zero to do with anything else, if its functioning correctly,

there are many oil leakage points(100) in a standard Chevy engine.

16 lifter to push rod points

16 push rod to rocker arm points

32 lifter bores 16 x 2 ends

10 main bearing edges

9 cam bearing edges

16 rod bearing edges

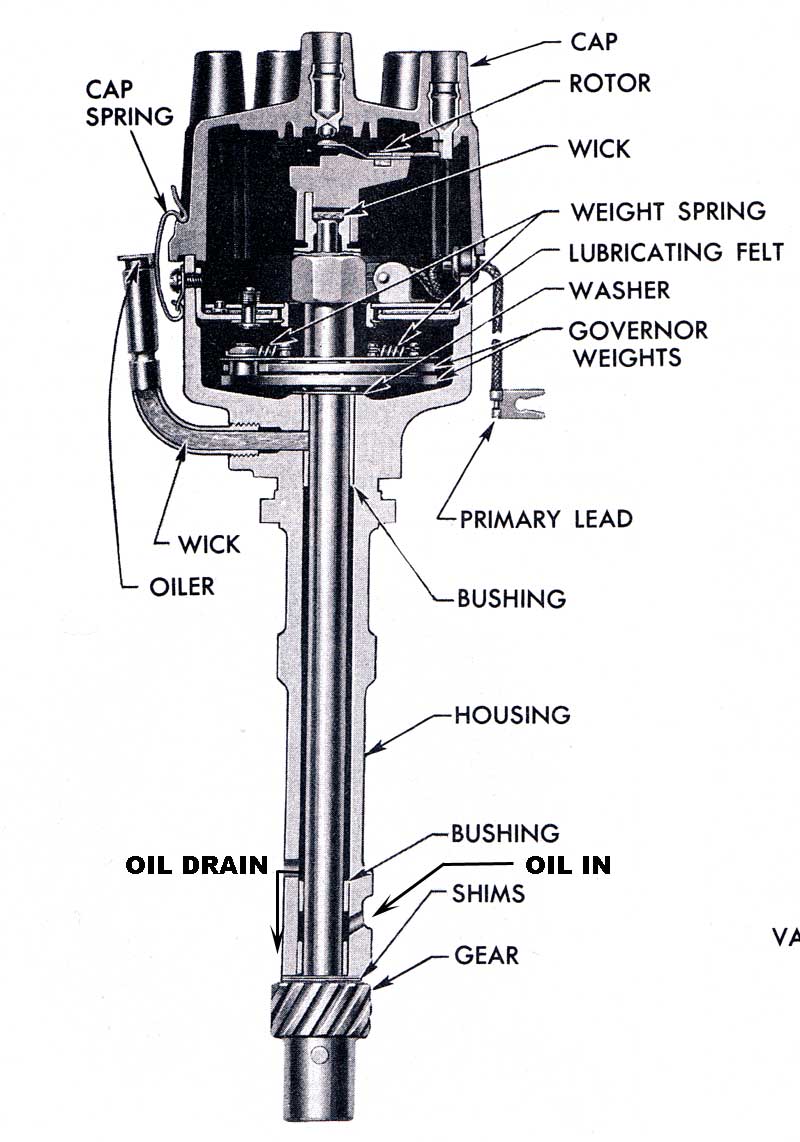

2 distributor shaft leaks

1 distributor shaft to shim above the cam gear(some engines that have an oil pressure feed distributor shaft bearing.)

once oil exits the bearings or valve train it flows mostly by gravity back to the oil pan sump, but a properly designed windage screen and crank scraper correctly clearanced allows the spinning crank/rotating assembly to act like a directional pump that drags the vast majority of the oil flow back to the sump, by design.

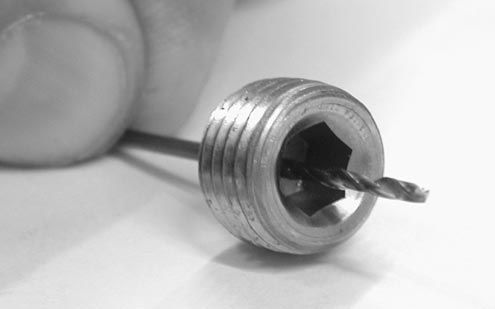

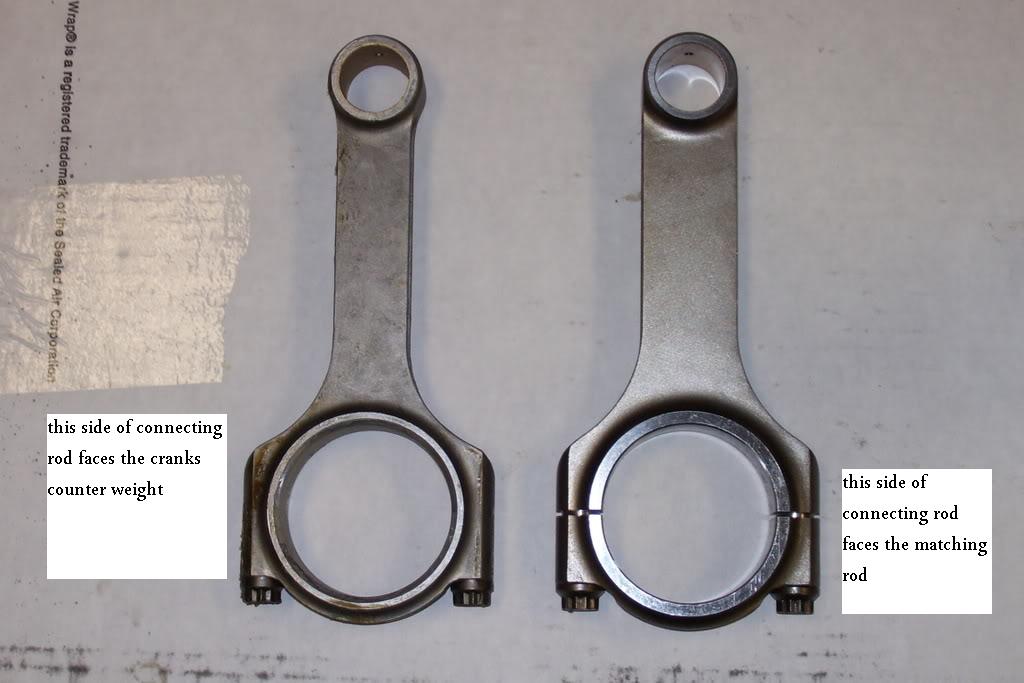

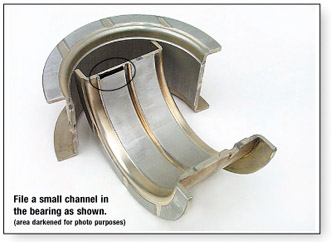

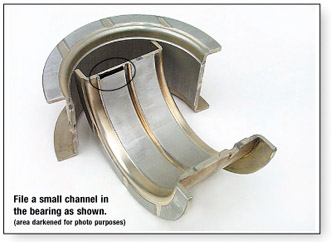

A simple modification to the upper thrust bearing may be beneficial in some engines. Install the upper thrust bearing in the block to determine which thrust face is toward the rear of the engine. Using a small, fine tooth, flat file, increase the amount of chamfer to approximately .040" (1 mm) on the inside diameter edge of the bearing parting line. Carefully file at the centrally located oil groove and stroke the file at an angle toward the rear thrust face only, as shown in the illustration below. It is very important not to contact the bearing surface with the end of the file. The resulting enlarged ID chamfer will allow pressurized engine oil from the pre-existing groove to reach the loaded thrust face. This additional source of oiling will reach the loaded thrust face without passing through the bearing clearance first (direct oiling). Since there may be a load against the rear thrust face, oil flow should be restricted by that load and there should not be a noticeable loss of oil pressure. This modification is not a guaranteed "cure-all". However, the modification should help if all other conditions, such as surface finish, alignment, cleanliness and loading are within required limits.

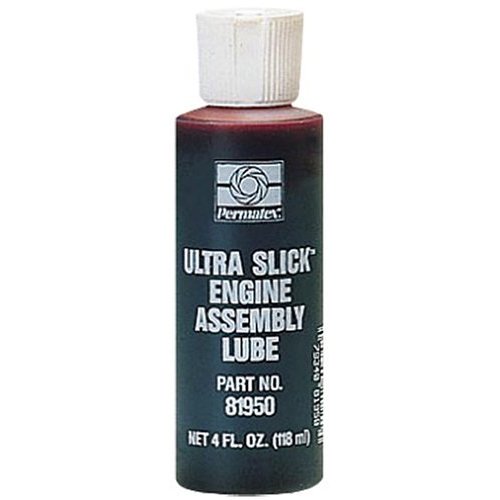

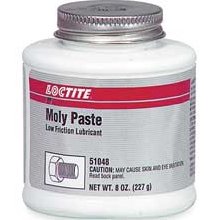

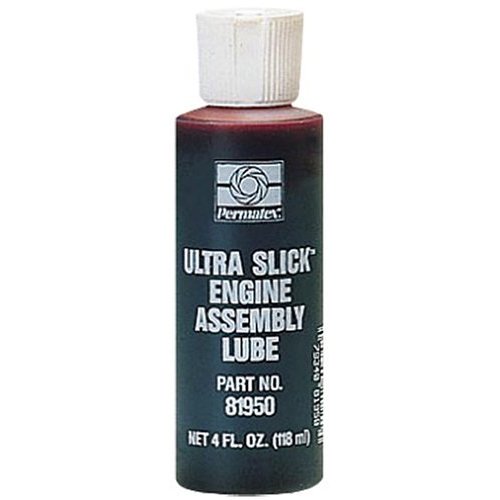

Preference on assembly lube?

50% marvel mystery oil

and 50% crane moly lube, or the paste moly, the mix of moly paste and M.M.O. is generally applied liberally with the paint brush, in multiple applications to surfaces like cam gears, timing chains, lifters, rockers, and cam lobes, to provide an extra layer of lubrication protection on initial engine start up.

what Ive used for decades

but this works

I have used J&B WELD EPOXY on a large magnet

https://www.zoro.com/value-brand-ring-magnet-98-lb-pull-10e797/i/G4187224/

on the base of an aluminum 1/2 cup measuring cup I purchased at a yard sale for 25 cents to mix up the mixture, the magnet allows me to stick the cup to the block oil pan rail or engine stand where its handy too get at, and I simply brush on the mix with a 1" paint brush, with synthetic bristles that won,t shed

OH! slide it off the block don,t try to just pull it off , its going to be much less messy that way trust me!

when your done , wipe it clean and stick it inside the lid of your tool box , after placing it in a ziploc bag to prevent it from picking up trash while in storage

http://garage.grumpysperformance.com/index.php?threads/whats-a-windage-tray-do.64/

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/

http://garage.grumpysperformance.com/index.php?threads/basic-info-on-your-v8-lube-system.52/

from chevy high performance mag

yes Ive seen several cases where guys failed to install the oil pump pick-up at the proper minimum 3/8"-to-1/2" off the oil pan floor clearance,

the result is the pump is starved for oil intake flow.

http://garage.grumpysperformance.co...m-sure-your-convinced-its-the-oil-pump.11085/

http://garage.grumpysperformance.co...m-oil-pump-installed-now-no-oil-pressure.525/

http://garage.grumpysperformance.com/index.php?threads/bbc-oil-pump-in-a-sbc.2598/

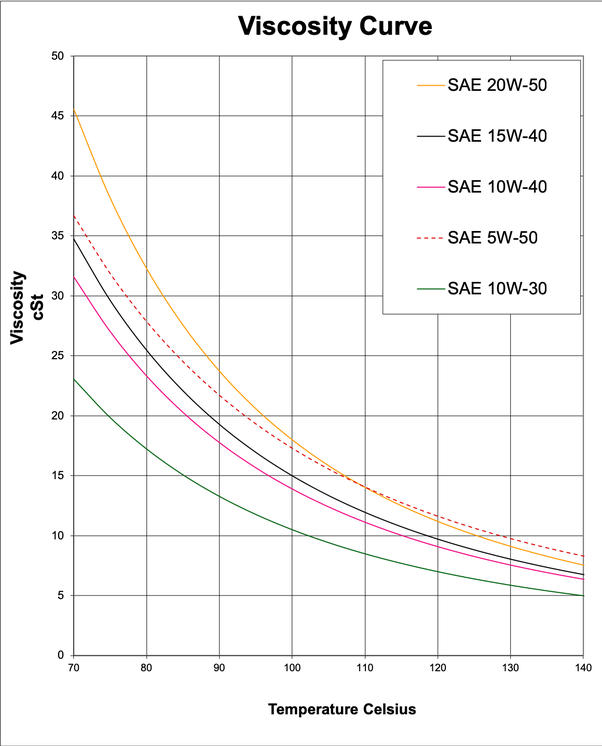

with the engine up to operational temp.of between about 180f-210f

and using an oil viscosity that maintains at least 15-20 psi at hot idle in traffic,

your engine should maintain a MINIMUM of 10 psi per 1000rpm and max out pressure at about 4500-5500rpm at 60psi or higher

remember the thicker the oil the harder it is to force thru the clearances in the engine, and pressure is how you measure the RESISTANCE to oil flow, but you should use an oil viscosity that at least maintains that 15-20 psi at idle

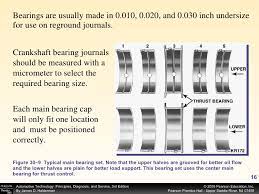

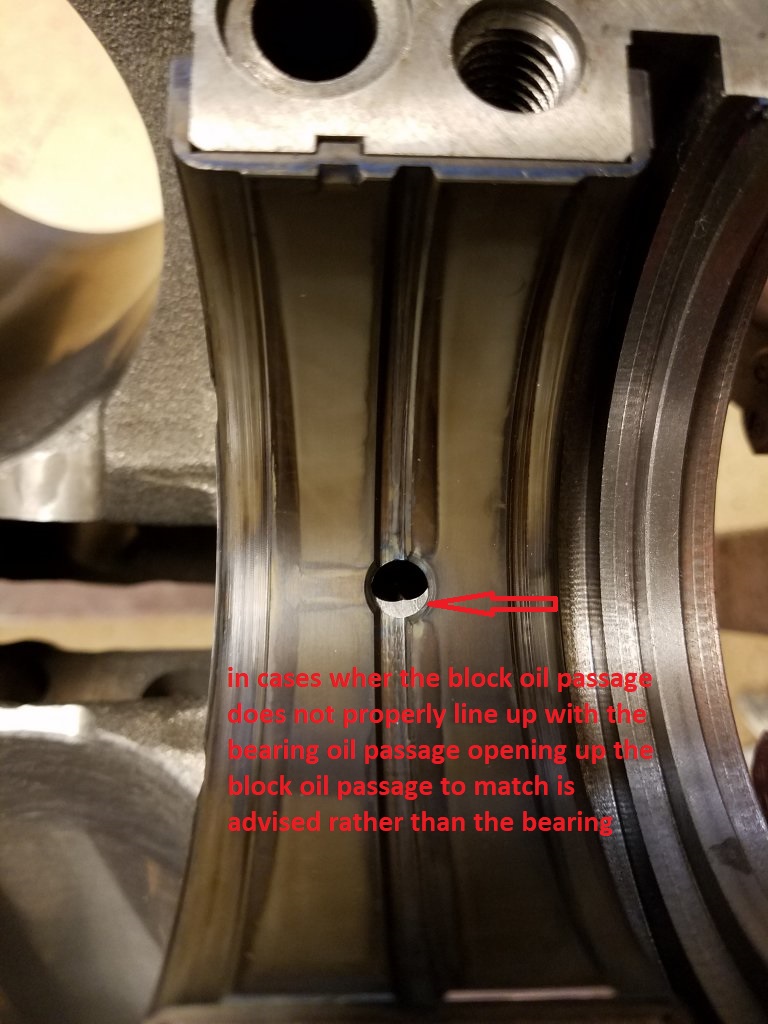

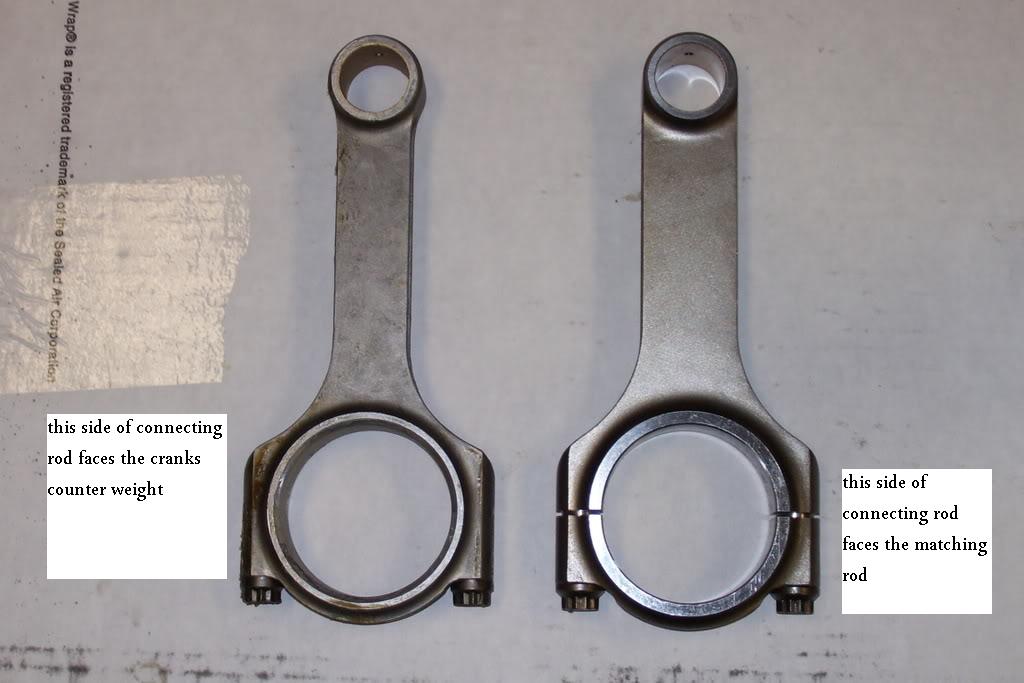

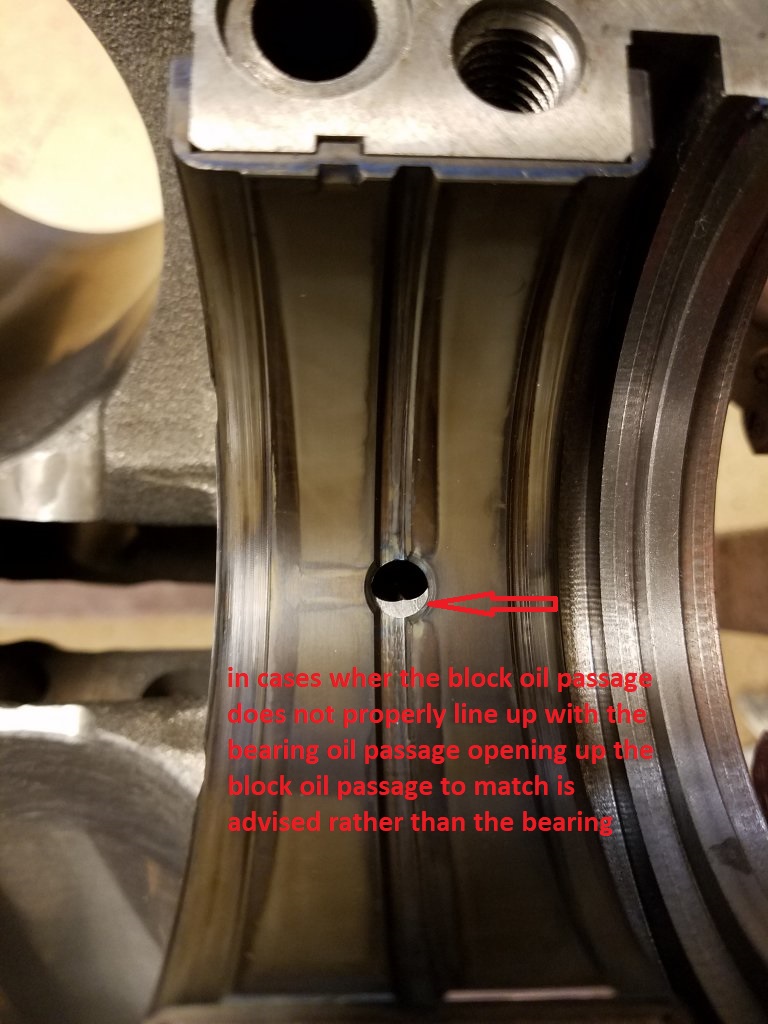

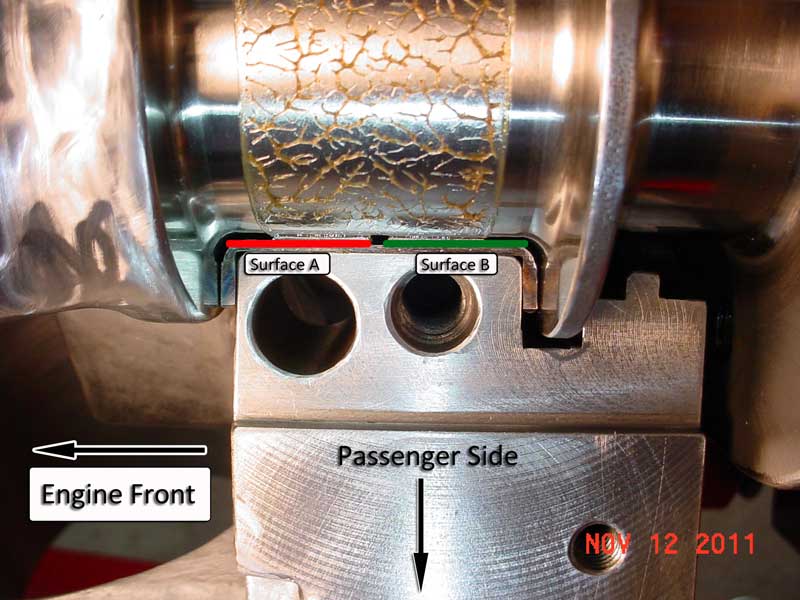

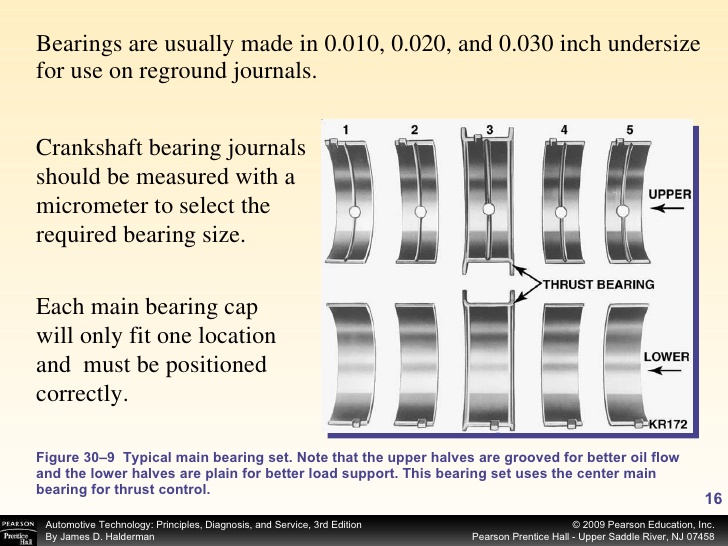

one factor thats frequently over looked is that many bearing manufacturers don,t seem to have placed the bearing oil feed holes in bearing shells so they exactly match the oil feed passages in the engine blocks

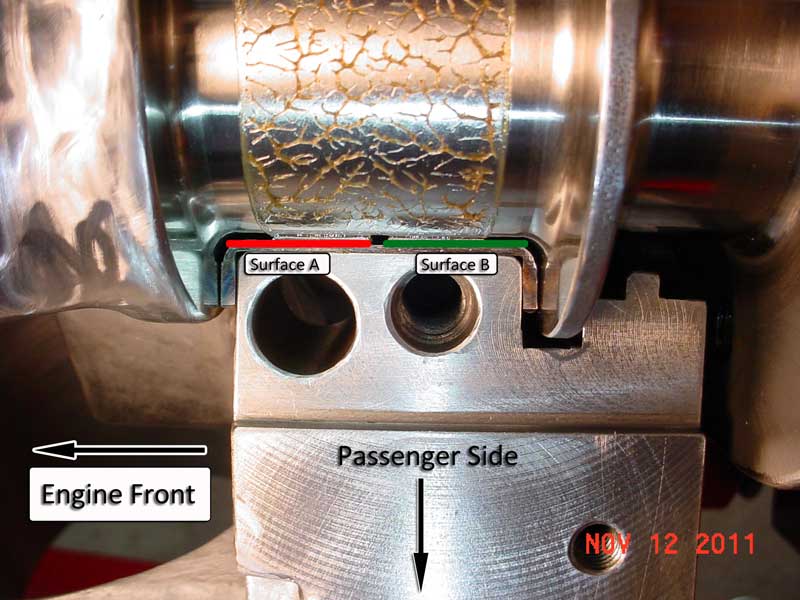

example heres a common minor mis-match on the bearing shell/oil passage alignment

but Ive seen some where over 1/3-to-1/2 the oil feed hole was blocked due to misalignment, thats usually easily cured, by drilling a shallow increased diameter recess in the blocks oil passage to open it to match the bearing or opening up the bearing feed hole, but which ever route you take be sure to carefully clean and deburr both

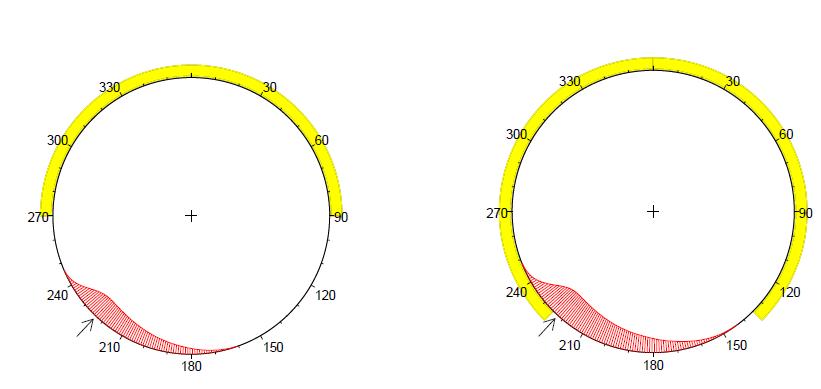

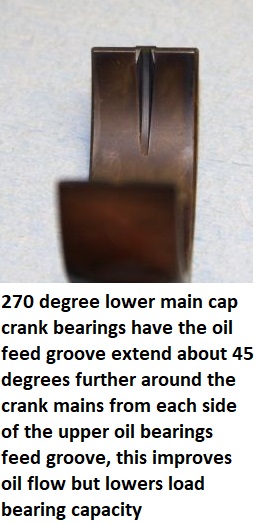

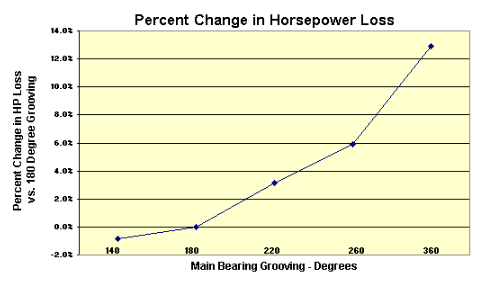

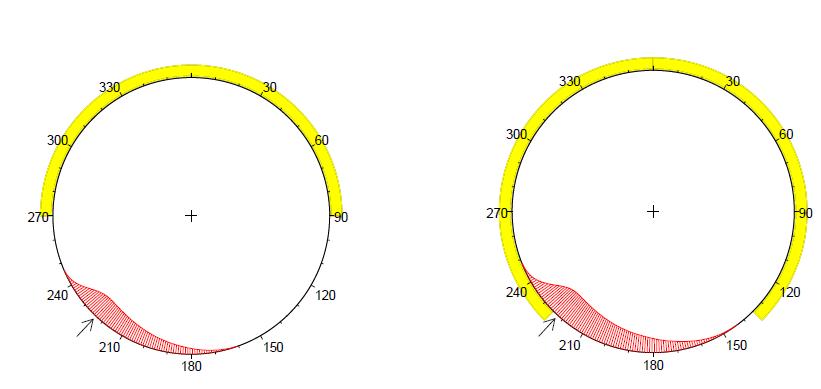

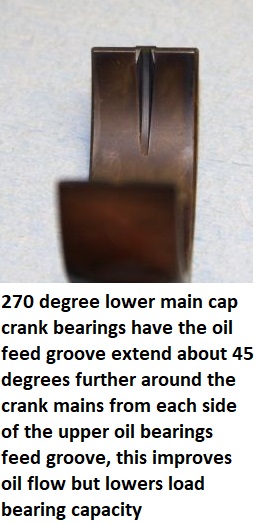

increasing the groove, from 180 deg to 270 deg, lowers bearing support, increases oil flow rates and tends to increase wear

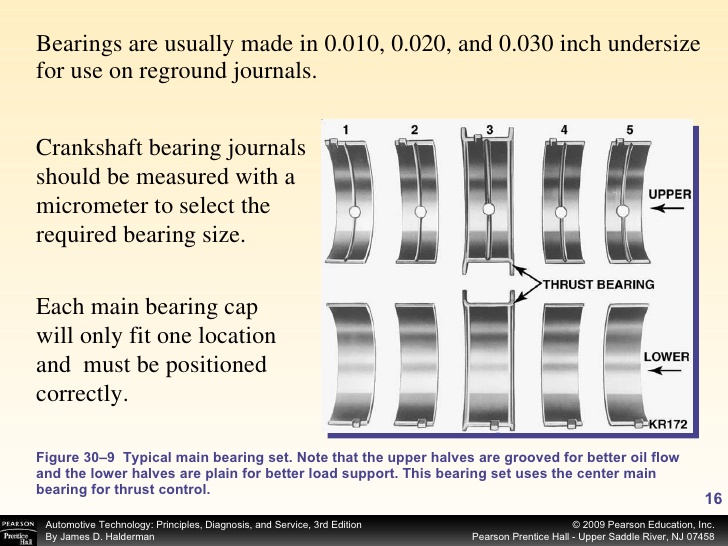

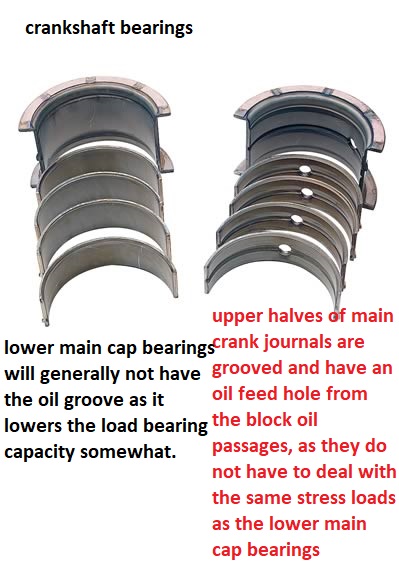

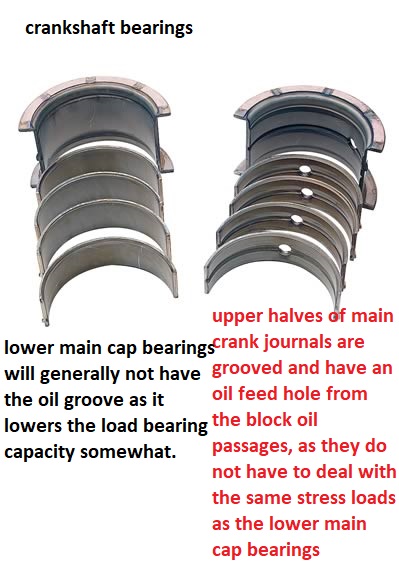

As you'll see in Figure 1, below two different types of grooved upper main bearing shells

the oil groove terminates before it gets to the bearing parting line. This style of main bearing has accounted for a 15 percent or more increase in hot idle oil pressure. So if you're looking to eliminate some of those unexplained low oil pressure gremlins contact your bearing manufacturer and ask about this style bearing and availability for the engine applications that you are building.

keep in mind only the upper main bearing shell should have an oil groove, having a 360 degree oil groove lowers the bearing ability to handle high rpm loads

THESE BEARING PICTURED ABOVE, LOOK GREAT BUT HAVE LOWER LOAD CAPACITY

a 180 degree bearing has only the upper in the block grooved to improve oil flow,a 270 degree has the oil feed groove extend further 45 degrees on each lower bearing shell

MAIN BEARINGS WITH 360 degree oil grooves

these CLEVITE (H) SERIES, ABOVE MAY NOT LOOK AS GOOD BUT HAVE HIGHER LOAD CAPACITY AND BEVELED EDGES FOR THE CRANK FILLETS, or ROUNDED CORNERS ON THE JOURNALS THAT INCREASE STRENGTH LIKE ON THE CRANK BELOW

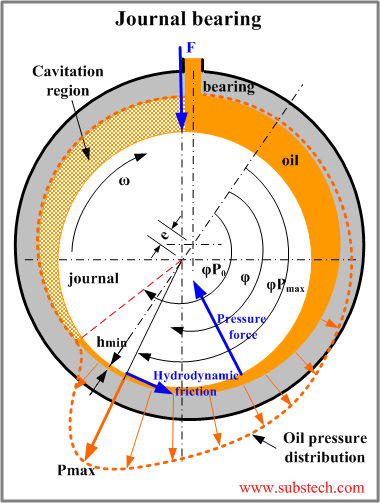

Introduction:

The main bearing oil groove is required for the sole purpose of supplying oil to the

connecting rod big end bearing. At one time it was common to have a full 360° groove on the

main bearing to provide an uninterrupted supply of oil to the big end by means of a single

drilling from the main journal. This was achieved by having identical upper and lower bearing

shells.

As bearing loads increased this design proved unsustainable as the oil film thickness, on

which every crankshaft bearing relies, became insufficient for reliable main bearing

operation. The solution was to increase the bearing area on the more heavily loaded lowerhalf

bearing by reducing the extent of the groove to around 230° or even 180° in order to

provide a single bearing land of greater width. Any increase in bearing width enables a

higher oil film pressure to be sustained as the distance from the centre of the bearing to the

edges, which cannot sustain an oil pressure, is increased. This in effect allows the

generation of a thicker oil film with which to separate the shaft and bearing shell.

The reduced oil groove extent would sometimes be compensated by a cross-drilling on the

main journal in an attempt to maintain an uninterrupted supply of oil to the big end bearing.

However, in many cases it was found that the big end could cope very well with the

subsequent intermittent oil flow offered by a single drilling from a 180° groove.

Nowadays, with the use of computer simulation and engine testing the optimum extent of the

groove may be determined. It is not now just a case of allowing the big end to survive but

that the efficiency of the bearing system can actually be improved by due attention to the

groove geometry. This is because the big end bearing, like any hydrodynamic lubricated

bearing, will use as much oil as it needs to generate an oil film for any given operating

condition. Any less than this amount risks disrupting the oil film and ultimately starving the

bearing of oil, but equally, feeding excessive oil to the bearing simply results in additional

leakage, and reduced efficiency. Therefore, the oil groove, like many other features on a

bearing shell, can be optimised.

read thru these links

http://vandervell.co.uk/images/slidesho ... forman.pdf

http://www.stealth316.com/misc/clevite- ... ooving.pdf

TB 2051 2/10/2000

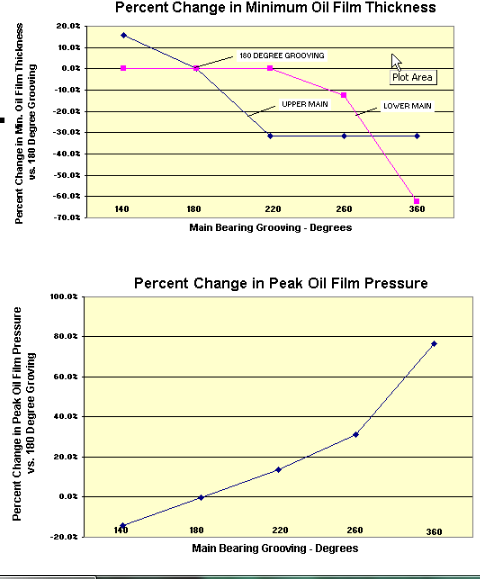

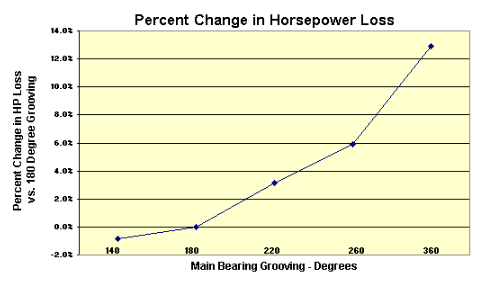

Influence of Grooving on Main Bearing Performance

Various forms of main bearing grooving have been used over the years. We are

frequently asked what difference grooving makes.

First, it’s essential to understand that bearings depend on a film of oil to keep them

separated from the shaft surface. This oil film is developed by shaft rotation. As the shaft

rotates it pulls oil into the loaded area of the bearing and rides up on this film much like a

tire hydroplaning on wet pavement. Grooving in a bearing acts like tread in a tire to break

up the oil film. While you want your tires to grip the road, you don’t want your bearings

to grip the shaft.

The primary reason for having any grooving in a main bearing is to provide oil to the

connecting rods. Without rod bearings to feed, a simple oil hole would be sufficient to

lubricate a main bearing. Many early engines used full grooved bearings and some even

used multiple grooves. As engine and bearing technology developed, bearing grooving

was removed from modern lower main bearings. The result is in a thicker film of oil for

the shaft to ride on. This provides a greater safety margin and improved bearing life.

Upper main shells, which see lower loads than the lowers, have retained a groove to

supply the connecting rods with oil.

In an effort to develop the best possible main bearing designs for High Performance

engines, we’ve investigated the effects of main bearing grooving on bearing performance.

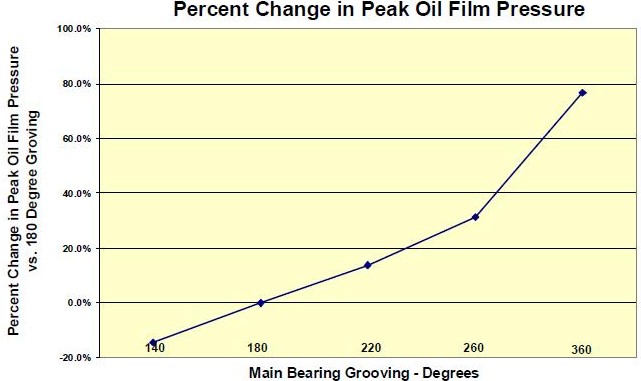

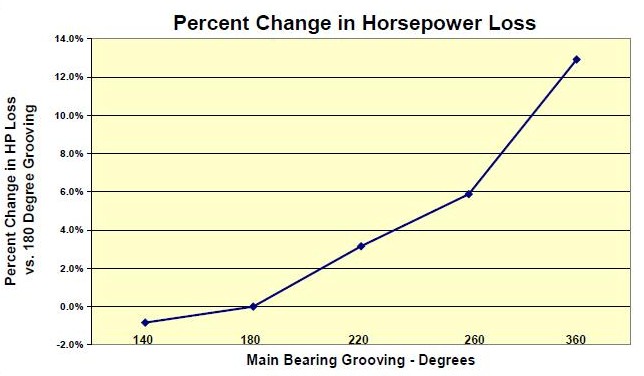

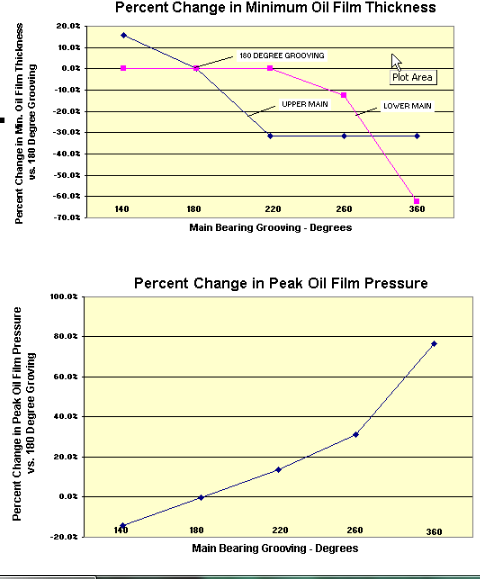

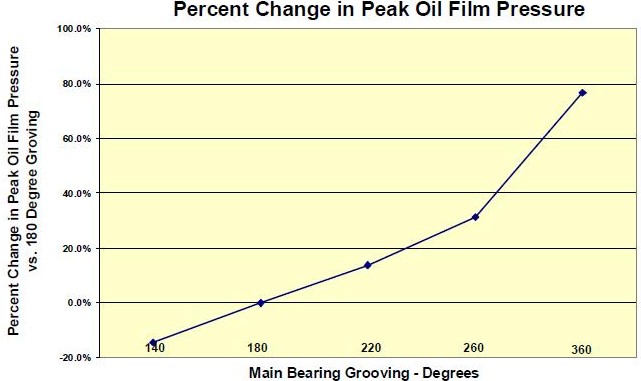

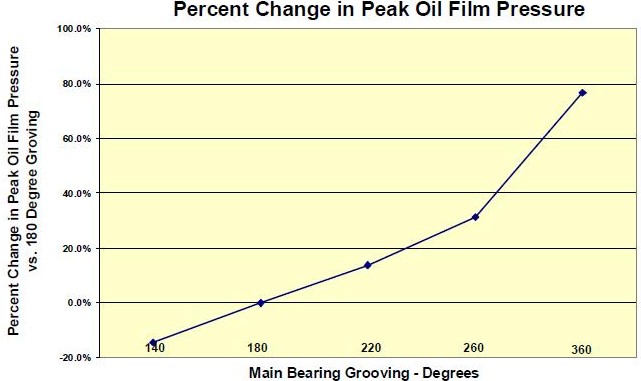

The graphs on the next page illustrate that a simple 180

°

groove in the upper main shell is

still the best overall design.

While a slightly shorter groove of 140

°

provides a marginal gain, most of the benefit is to

the upper shell, which doesn’t need improvement. On the other hand, extending the

groove into the lower half, even as little as 20

°

at each parting line (220

°

in total), takes

away from upper bearing performance without providing any benefit to the lower half.

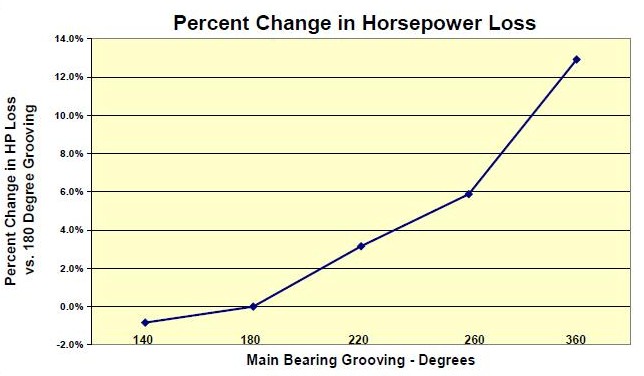

It’s also interesting to note that as groove length increases so do Horsepower Loss and

Peak Oil Film Pressure which is transmitted directly to the bearing

from what I've read pressure over 65 psi at W.O.T.

or over 20PSI at idle for a sbc or BBC adds no benefit.

some ford engines are designed to work with up to 100 psi of oil pressure at peak rpms

added oil flow rate volume helps cool and lubricate to a greater extent than added pressure

www.supergen.in

www.supergen.in

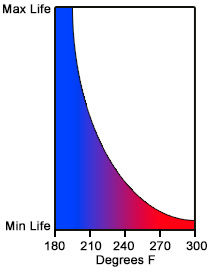

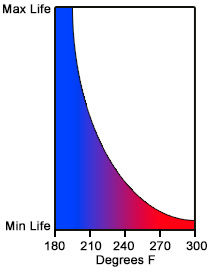

the safe zone for oil temperature is 190-220F. Anything lower and you risk not getting all the moisture out. Anything higher and you're oil is going to degrade faster.

Cold engine oil causes excessive frictional drag on the bearings and cylinder walls.

A quality conventional motor oil will tolerate oil sump temperatures of up to 250 degrees,

but starts breaking down over 275 degrees.

The traditional approach is to try to hold max oil temperatures ,

between 230 and no higher than 260 degree for brief time periods.

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/

www.elephantracing.com

www.elephantracing.com

the safe zone for oil temperature is 190-220F.

Anything lower and you risk not getting all the moisture out.

Anything consistently run higher and you're oil is going to degrade faster.

yeah the linked info holds a great deal more info

http://garage.grumpysperformance.com/index.php?threads/testing-a-chevy-oil-pump.6479/#post-87726

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/

http://garage.grumpysperformance.co...l-pumps-pressure-bye-pass-circuit-works.3536/

http://garage.grumpysperformance.com/index.php?threads/installing-an-oil-pump-pick-up-tube.1800/

http://garage.grumpysperformance.com/index.php?threads/bearings-and-oil-flow.150/

http://garage.grumpysperformance.com/index.php?threads/shimming-an-oil-pump-relief-spring.16240/

http://garage.grumpysperformance.com/index.php?threads/basic-info-on-your-v8-lube-system.52/

getting the engines lubrication, clearances ,and cooling needs, matched to the intended application and stress levels is key to longer term durability

building a custom wet sump oil pan

The question comes up rather frequently when I suggest buying or modifying oil pans as to "WHY BOTHER?" well its simply the fact that most stock oil pans were designed simply to be the cheapest to manufacture component that would function on an engine that would rarely be spinning over 3500rpm...

garage.grumpysperformance.com

Oil Filters - Wix vs Royal Purple

Before I do anything, I like to let the filter drain for several days. It's just easier and not nearly as messy. I don't know how anyone else does the cutting open part, but I like to clamp the cutter in the vise. Then spin the filter with both hands...

garage.grumpysperformance.com

http://www.babcox.com/editorial/us/us90126.htm

http://www.insightservices.net/testoil/ ... cation.htm

http://www.thirskauto.net/BearingPics.html

http://micapeak.com/info/oiled.html

http://www.unofficialbmw.com/all/misc/all_oilfaq.html

http://www.fd3s.net/oil_pressure.html

http://www.aa1car.com/library/us1097.htm

oil pump mods & related info

https://www.summitracing.com/search?SortBy=BestKeywordMatch&SortOrder=Ascending&keyword=3%2F4%22%20tube%20oil%20pump%20pickups https://www.jegs.com/webapp/wcs/stores/servlet/SearchResultsPageCmd?q=big+block+chevy+oil+pumps&storeId=10001&catalogId=10002&langId=-1...

garage.grumpysperformance.com

and stabilize , for semi consistent data,in under 12-15 minutes of drive time,temps have a huge effect on lubricant viscosity and durability. .

in my opinion , and experience and from lots of G.M. engine, race testing.

theres no need for oil pressure to exceed about 65 psi,

it takes power to spin the oil pump against that extra resistance, it induces extra wear on the distributor and cam gears,

and it does nothing to reduce bearing wear or increase cooling on the bearing surfaces, he should open some bearing clearances marginally

(maybe an extra half thousandth on the mains) to increase oil flow volume reaching the main bearings, and use a lower resistance oil pump bye-pass spring.

extra oil flow volume cooling the bearings and valve train will do more for durability than oil pressure exceeding 65-70 psi

http://engineparts.com/it_crankinstall.asp

http://engineparts.com/it_bearinginstall.asp

http://engineparts.com/techbulletins/CL77-1-205R.pdf

http://www.micapeak.com/info/oiled.html

http://www.nordicgroup.us/oil.htm

http://www.carbibles.com/engineoil_bible.html

http://data.melling.com/Select/small_block_chevy.php

http://data.melling.com/Select/big_block_chevy.php

http://www.thirskauto.net/Engine_Thrust_Bearings.html

http://www.engineparts.com/motorhead/te ... stall.html

http://www.babcox.com/editorial/ar/ar20128.htm

http://www.babcox.com/editorial/cm/cm99828.htm

http://www.thirskauto.net/Engine_Thrust_Bearings.html

http://www.diabolicalperformance.com/clearances.html

http://www.babcox.com/editorial/ar/ar10180.htm

http://data.melling.com/TECH.php

http://www.babcox.com/editorial/ar/eb110127.htm

http://theoildrop.server101.com/forums/ubbthreads.php

http://minimopar.knizefamily.net/oilfilterstudy.html

Id also point out that, if you properly set up an engine's oil system, open the oil drain holes and use the proper oil pan, windage screen and crank scraper, its virtually impossible , in a well designed engine to run the engine "long enough to pump all the oil upstairs."

as with a properly designed baffled oil pan, with a carefully fitted and clearanced windage screen and crank scraper, the oil pump simply reaches a flow rate pumping oil out of about 100 or so potential lubricant flow leakage points

http://garage.grumpysperformance.com/index.php?threads/whats-a-windage-tray-do.64/

thats a very common question but the answers no!

ALL THAT OIL FILTER BYE-PASS VALVE DOES IS ROUTE OIL FLOW PAST THE OIL FILTER

IF IT BECOMES SO CLOGGED WITH TRASH THAT THERES

A 10 PSI DIFFERENCE IN THE RESISTANCE TO OIL FLOW THROUGH THE FILTER

VS AROUND IT INTO THE BLOCKS OIL PASSAGES, oil enters the area over the oil filter in the block and is forced into the outer holes in the oil filter perimeter down through the case and filter element and up through the central hollow screw retention stud into the blocks oil passages, if the resistance too flow is too great the oil filter bye-pass valve routes oil around the filter directly from oil pump to the blocks oil passages.

pressure is a measure of RESISTANCE to oil flow, if the pumps providing flow and yes that needs to be verified,

( because if the oil pump pick-up is less than a 1/4" off the oil pan floor flow is potentially restricted)

if your getting oil flow from the oil pump and no back pressure Id suggest checking the flow control valves, bearing clearances and oil passage plugs at the ends of the lifter gallery passages, any major open to flow oil passage results in very low oil pressure readings

http://garage.grumpysperformance.co...ark-v-bbc-engine-oil-system-differences.4576/

https://www.chevydiy.com/oil-lubrication-systems-guide-big-block-chevy-engines/

https://paceperformance.com/i-51345...ich-adapter-for-external-oil-cooler-only.html

http://garage.grumpysperformance.com/index.php?threads/basic-info-on-your-v8-lube-system.52/

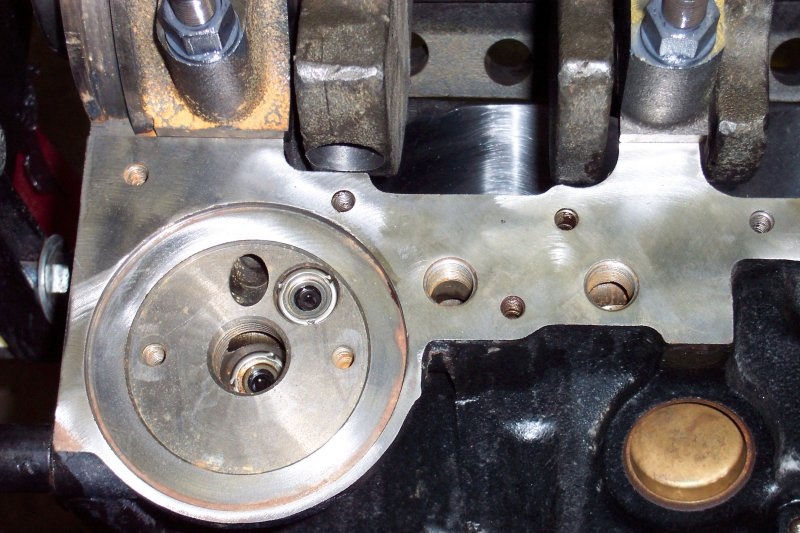

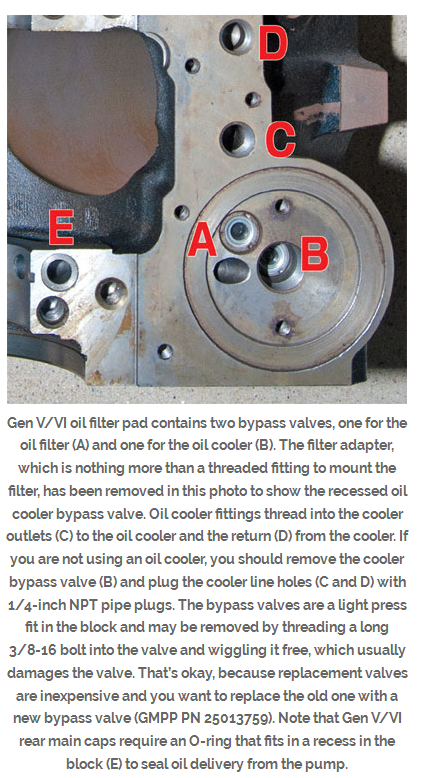

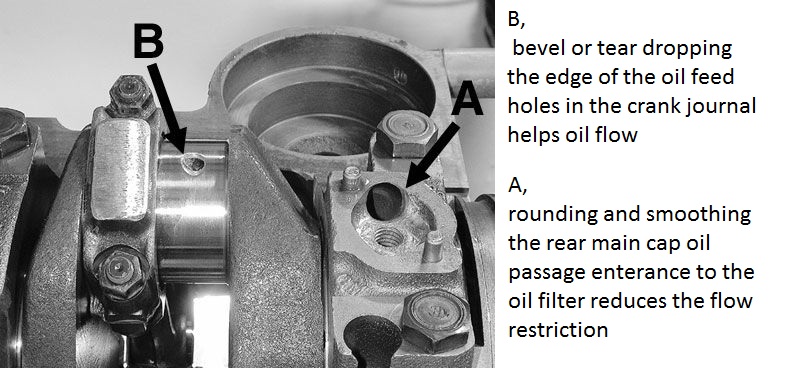

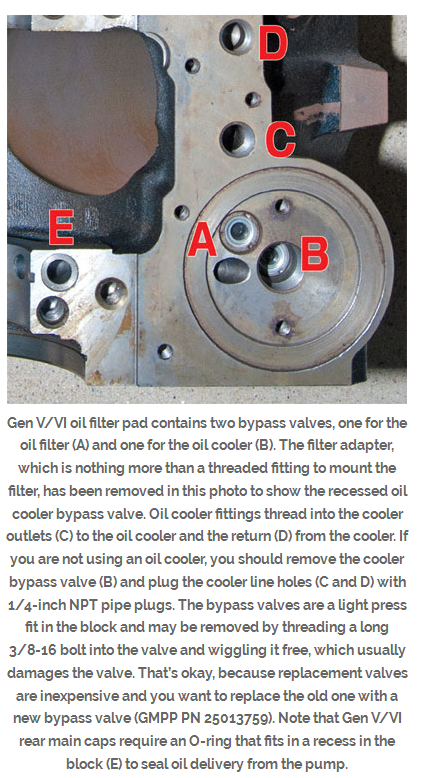

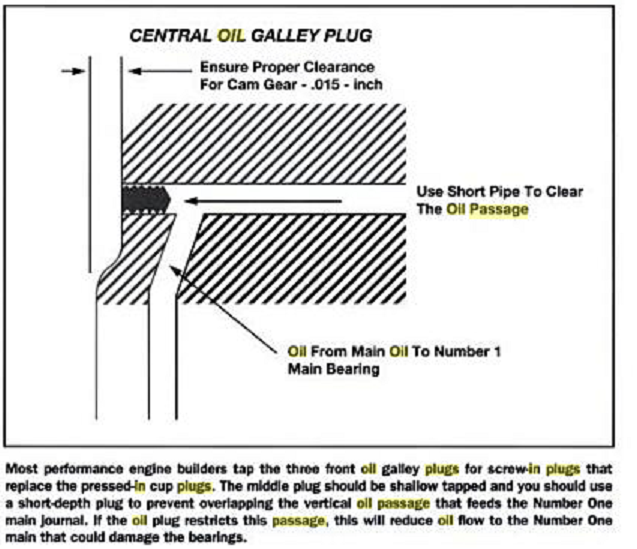

MORE USEFUL INFOBig Block Chevrolet Gen V and Gen VI Oiling SystemSolving the mystery of the Gen V and Gen VI Priority Main Oiling system

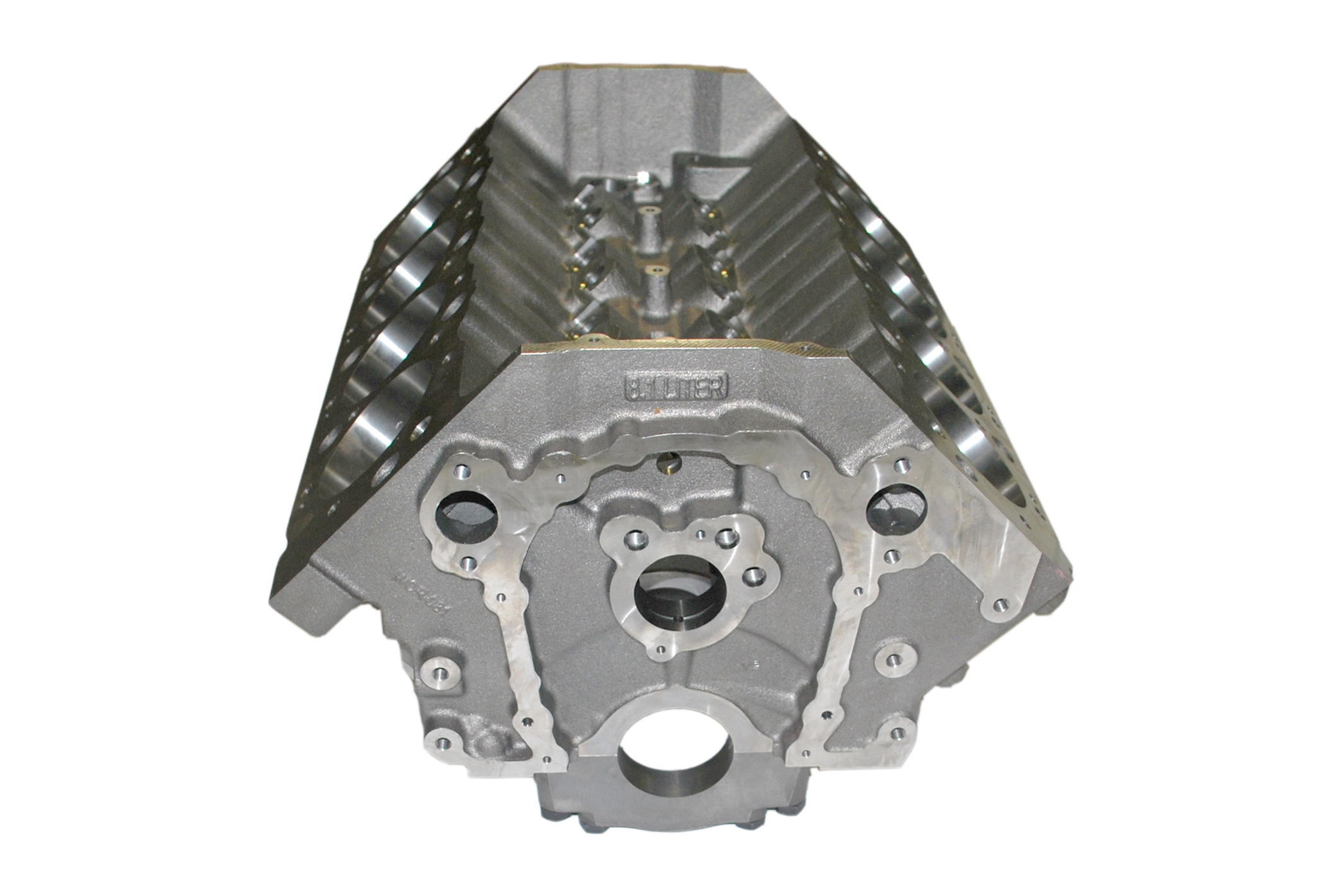

Priority Main Oiling System

The Generation V and VI big block Chevrolet blocks feature a priority main oiling system where the main oil supply passage is located adjacent to the camshaft tunnel. Drilled passages which intersect this large oil tunnel carry oil directly to the main bearings. If you are facing the front of the block with the engine in the upright position, this main oil supply tunnel is located in the 2 o’clock position just below the right hand lifter oil supply line.

Oil Cooler Plumbing

Located along the oil pan rail just ahead of the oil filter pad are two drilled and tapped (3/8” NPT) oil passages for routing oil to an external oil cooler. The hole located closest to the oil filter pad (#2) is for the outgoing supply line to the oil cooler. The front passage (#1), which is farthest from the filter pad, is the return line from the oil cooler.

Careful examination reveals that these two passages intersect the same return line that feeds oil back to the main oil tunnel. This requires that a special fitting be used in the #2 supply line to prevent oil from short circuiting the oil cooler.

Part number SD1540 provides the necessary diverter basket to prevent the supply oil from entering the return line before going to the oil cooler. This fitting has a dash 10AN thread to allow the use of aftermarket components to plumb your external oil cooler. The front passage #1 will require a 3/8” NPT by dash 10AN adapter (#FCM2185), which is available from Scoggin-Dickey.

Understanding By-pass Valve Locations

Factory assembled 454, 502 engines and short blocks have two by-pass valves installed in the block. These factory installed by-pass valves (#25013759) will open at an 11 psi pressure differential. One by-pass valve is installed in the center hole on the oil filter pad (#4). This hole is the oil return passage from the oil filter. The second by-pass valve is installed in the adjacent hole (#3). The egg shaped hole (#5) is the high pressure oil supply passage from the oil pump.

For all racing application that will NOT use an oil cooler but will maintain the stock oil filter location, you must remove the center by-pass valve in location #4. Removing this valve eliminates three redundant right runs in the oil system. However, if you leave this by-pass in place the oil system will still function as it was intended, but a loss of oil pressure can result from the four right angle turns required for oil to return to the main oil tunnel.

If you intend to use a remote oil filter, a high pressure by-pass valve part number 25161284 must be installed in position #3. This valve will open at a 30 psi pressure differential. A plug will be installed in position #4 to prevent oil flow thru this passage. Oil should be returned to the block in the 3/8” hole located just able the oil filter pad. An oil filter block off plate kit (#SD3891) can be purchased from Scoggin-Dickey for Gen V and VI blocks to plumb your external oil filter.

If you intend to maintain the stock filter location and will use the factory provided oil cooler passages to install your oil cooler, then you must install two high pressure by-pass valves (#25161284). One will be installed in location #3 and the second in location #4.

yes the oil flows around the mounting stud,from oil pump to main cap to reach the engine oil passages, thru the oil filter

failure to use the correct oil pump,mounting stud, bolt or nut or carefully check clearances when mounting an oil pump can cause problems

ONE RATHER COMMON MISTAKE IS USING THE WRONG OIL PUMP STUD OR BOLT TO MOUNT THE OIL PUMP AS IF EITHER EXTENDS THRU THE REAR MAIN CAP IT CAN AND WILL BIND ON THE BEARING AND LOCK OR RESTRICT, SMOOTH ROTATION

http://garage.grumpysperformance.co...-friction-and-pumping-losses.8966/#post-31978

heres a cooler several guys I know use.

https://www.jegs.com/i/Derale/259/15900/10002/-1

you will rather obviously need to carefully and accurately,

measure the location you want to install any fluid cooler and its fluid line connections, you should seriously consider a AN#8 line size as minimum

you can easily run the trans fluid or oil cooler without the thermostat controlled feed/return lines,

a cooler with AN#8 or 1/2" line size preferred

many guys that do that have a toggle switch that shuts the fan on the auxiliary oil cooler off until the fluid comes up to operational temps.

will a thermostat valve on the auxiliary cooling lines help maintain a stable fluid or oil temp,

and speed up the time it takes for the engine and transmission fluids to come up to operational temps? hell yes

,but theres millions of guys that have run a cooler without one.

on the down side, both engines and transmissions tend to last longer when the lubrication fluids are both stable and consistently in the ideal range.

http://shop.perma-cool.com/1073-Oil-The ... s-1073.htm

heres a cooler several guys I know use.

https://www.jegs.com/i/Derale/259/15900/10002/-1

you will rather obviously need to carefully and accurately,

measure the location you want to install any fluid cooler and its fluid line connections, you should seriously consider a AN#8 line size as minimum

theres zero doubt an accusump oil feed is a good insurance policy to maintain oil pressure at the bearings, but simply having a 7-8 quart baffled oil pan,properly clearanced, windage screen and crank scraper will insure the oil pressure remains consistent , mostly due to the fact that theres always going to be enough oil over the oil pump pick-up, simply because theres really no room to pack most of the available oil volume in the upper engine ,plus the fact that hot oil flows well.

OIL PRESSURE read on the oil pressure gauge is a MEASURE of RESISTANCE to oil flow, you can REDUCE the pressure the gauge reads by either increasing the engine clearances or REDUCING the oil viscosity (thickness) so it flows thru the clearances faster with less resistance.(OR INSTALLING A SLIGHTLY WEAKER OIL PUMP BYE_PASS SPRING,that limits the pump pressure before it allows some oil to re-circulate back through the bye-pass valve ,from the high pressure back to the low pressure side of the pump impellers, but only the max pressure you reach is limited by the bye-pass spring,in your oil pressure bye pass circuit and its that spring resistance determines the point where the bye-pass circuit, opens and limits max oil pressure, but the bye-pass circuit has zero to do with anything else, if its functioning correctly,

there are many oil leakage points(100) in a standard Chevy engine.

16 lifter to push rod points

16 push rod to rocker arm points

32 lifter bores 16 x 2 ends

10 main bearing edges

9 cam bearing edges

16 rod bearing edges

2 distributor shaft leaks

1 distributor shaft to shim above the cam gear(some engines that have an oil pressure feed distributor shaft bearing.)

once oil exits the bearings or valve train it flows mostly by gravity back to the oil pan sump, but a properly designed windage screen and crank scraper correctly clearanced allows the spinning crank/rotating assembly to act like a directional pump that drags the vast majority of the oil flow back to the sump, by design.

A simple modification to the upper thrust bearing may be beneficial in some engines. Install the upper thrust bearing in the block to determine which thrust face is toward the rear of the engine. Using a small, fine tooth, flat file, increase the amount of chamfer to approximately .040" (1 mm) on the inside diameter edge of the bearing parting line. Carefully file at the centrally located oil groove and stroke the file at an angle toward the rear thrust face only, as shown in the illustration below. It is very important not to contact the bearing surface with the end of the file. The resulting enlarged ID chamfer will allow pressurized engine oil from the pre-existing groove to reach the loaded thrust face. This additional source of oiling will reach the loaded thrust face without passing through the bearing clearance first (direct oiling). Since there may be a load against the rear thrust face, oil flow should be restricted by that load and there should not be a noticeable loss of oil pressure. This modification is not a guaranteed "cure-all". However, the modification should help if all other conditions, such as surface finish, alignment, cleanliness and loading are within required limits.

Preference on assembly lube?

50% marvel mystery oil

and 50% crane moly lube, or the paste moly, the mix of moly paste and M.M.O. is generally applied liberally with the paint brush, in multiple applications to surfaces like cam gears, timing chains, lifters, rockers, and cam lobes, to provide an extra layer of lubrication protection on initial engine start up.

what Ive used for decades

but this works

I have used J&B WELD EPOXY on a large magnet

https://www.zoro.com/value-brand-ring-magnet-98-lb-pull-10e797/i/G4187224/

on the base of an aluminum 1/2 cup measuring cup I purchased at a yard sale for 25 cents to mix up the mixture, the magnet allows me to stick the cup to the block oil pan rail or engine stand where its handy too get at, and I simply brush on the mix with a 1" paint brush, with synthetic bristles that won,t shed

OH! slide it off the block don,t try to just pull it off , its going to be much less messy that way trust me!

when your done , wipe it clean and stick it inside the lid of your tool box , after placing it in a ziploc bag to prevent it from picking up trash while in storage

http://garage.grumpysperformance.com/index.php?threads/whats-a-windage-tray-do.64/

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/

http://garage.grumpysperformance.com/index.php?threads/basic-info-on-your-v8-lube-system.52/

from chevy high performance mag

yes Ive seen several cases where guys failed to install the oil pump pick-up at the proper minimum 3/8"-to-1/2" off the oil pan floor clearance,

the result is the pump is starved for oil intake flow.

http://garage.grumpysperformance.co...m-sure-your-convinced-its-the-oil-pump.11085/

http://garage.grumpysperformance.co...m-oil-pump-installed-now-no-oil-pressure.525/

http://garage.grumpysperformance.com/index.php?threads/bbc-oil-pump-in-a-sbc.2598/

with the engine up to operational temp.of between about 180f-210f

and using an oil viscosity that maintains at least 15-20 psi at hot idle in traffic,

your engine should maintain a MINIMUM of 10 psi per 1000rpm and max out pressure at about 4500-5500rpm at 60psi or higher

remember the thicker the oil the harder it is to force thru the clearances in the engine, and pressure is how you measure the RESISTANCE to oil flow, but you should use an oil viscosity that at least maintains that 15-20 psi at idle

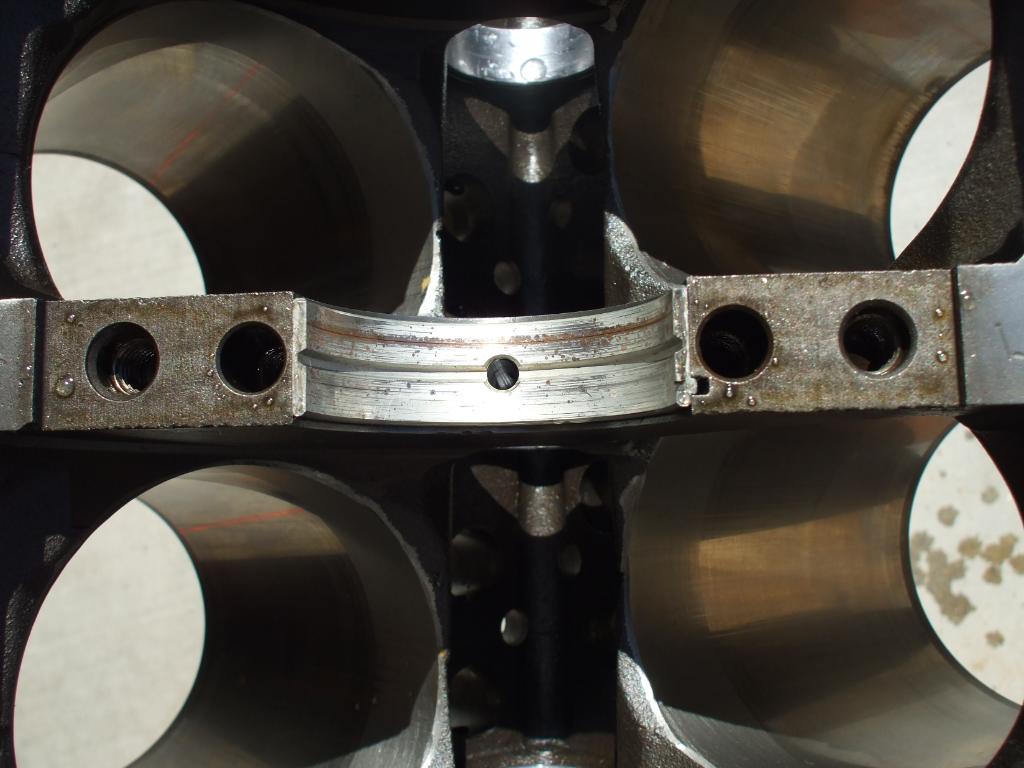

one factor thats frequently over looked is that many bearing manufacturers don,t seem to have placed the bearing oil feed holes in bearing shells so they exactly match the oil feed passages in the engine blocks

example heres a common minor mis-match on the bearing shell/oil passage alignment

but Ive seen some where over 1/3-to-1/2 the oil feed hole was blocked due to misalignment, thats usually easily cured, by drilling a shallow increased diameter recess in the blocks oil passage to open it to match the bearing or opening up the bearing feed hole, but which ever route you take be sure to carefully clean and deburr both

increasing the groove, from 180 deg to 270 deg, lowers bearing support, increases oil flow rates and tends to increase wear

Bosch 1/2 in. Titanium Countersink Drill Bit CST1 - The Home Depot

The self-starting point and five-fluted design on the Bosch 1/2 in. Titanium Countersink allow it to make clean, accurate cuts in even the toughest materials. It leaves smooth, burr-free edges on soft

www.homedepot.com

As you'll see in Figure 1, below two different types of grooved upper main bearing shells

the oil groove terminates before it gets to the bearing parting line. This style of main bearing has accounted for a 15 percent or more increase in hot idle oil pressure. So if you're looking to eliminate some of those unexplained low oil pressure gremlins contact your bearing manufacturer and ask about this style bearing and availability for the engine applications that you are building.

keep in mind only the upper main bearing shell should have an oil groove, having a 360 degree oil groove lowers the bearing ability to handle high rpm loads

THESE BEARING PICTURED ABOVE, LOOK GREAT BUT HAVE LOWER LOAD CAPACITY

a 180 degree bearing has only the upper in the block grooved to improve oil flow,a 270 degree has the oil feed groove extend further 45 degrees on each lower bearing shell

MAIN BEARINGS WITH 360 degree oil grooves

these CLEVITE (H) SERIES, ABOVE MAY NOT LOOK AS GOOD BUT HAVE HIGHER LOAD CAPACITY AND BEVELED EDGES FOR THE CRANK FILLETS, or ROUNDED CORNERS ON THE JOURNALS THAT INCREASE STRENGTH LIKE ON THE CRANK BELOW

Introduction:

The main bearing oil groove is required for the sole purpose of supplying oil to the

connecting rod big end bearing. At one time it was common to have a full 360° groove on the

main bearing to provide an uninterrupted supply of oil to the big end by means of a single

drilling from the main journal. This was achieved by having identical upper and lower bearing

shells.

As bearing loads increased this design proved unsustainable as the oil film thickness, on

which every crankshaft bearing relies, became insufficient for reliable main bearing

operation. The solution was to increase the bearing area on the more heavily loaded lowerhalf

bearing by reducing the extent of the groove to around 230° or even 180° in order to

provide a single bearing land of greater width. Any increase in bearing width enables a

higher oil film pressure to be sustained as the distance from the centre of the bearing to the

edges, which cannot sustain an oil pressure, is increased. This in effect allows the

generation of a thicker oil film with which to separate the shaft and bearing shell.

The reduced oil groove extent would sometimes be compensated by a cross-drilling on the

main journal in an attempt to maintain an uninterrupted supply of oil to the big end bearing.

However, in many cases it was found that the big end could cope very well with the

subsequent intermittent oil flow offered by a single drilling from a 180° groove.

Nowadays, with the use of computer simulation and engine testing the optimum extent of the

groove may be determined. It is not now just a case of allowing the big end to survive but

that the efficiency of the bearing system can actually be improved by due attention to the

groove geometry. This is because the big end bearing, like any hydrodynamic lubricated

bearing, will use as much oil as it needs to generate an oil film for any given operating

condition. Any less than this amount risks disrupting the oil film and ultimately starving the

bearing of oil, but equally, feeding excessive oil to the bearing simply results in additional

leakage, and reduced efficiency. Therefore, the oil groove, like many other features on a

bearing shell, can be optimised.

read thru these links

http://vandervell.co.uk/images/slidesho ... forman.pdf

http://www.stealth316.com/misc/clevite- ... ooving.pdf

TB 2051 2/10/2000

Influence of Grooving on Main Bearing Performance

Various forms of main bearing grooving have been used over the years. We are

frequently asked what difference grooving makes.

First, it’s essential to understand that bearings depend on a film of oil to keep them

separated from the shaft surface. This oil film is developed by shaft rotation. As the shaft

rotates it pulls oil into the loaded area of the bearing and rides up on this film much like a

tire hydroplaning on wet pavement. Grooving in a bearing acts like tread in a tire to break

up the oil film. While you want your tires to grip the road, you don’t want your bearings

to grip the shaft.

The primary reason for having any grooving in a main bearing is to provide oil to the

connecting rods. Without rod bearings to feed, a simple oil hole would be sufficient to

lubricate a main bearing. Many early engines used full grooved bearings and some even

used multiple grooves. As engine and bearing technology developed, bearing grooving

was removed from modern lower main bearings. The result is in a thicker film of oil for

the shaft to ride on. This provides a greater safety margin and improved bearing life.

Upper main shells, which see lower loads than the lowers, have retained a groove to

supply the connecting rods with oil.

In an effort to develop the best possible main bearing designs for High Performance

engines, we’ve investigated the effects of main bearing grooving on bearing performance.

The graphs on the next page illustrate that a simple 180

°

groove in the upper main shell is

still the best overall design.

While a slightly shorter groove of 140

°

provides a marginal gain, most of the benefit is to

the upper shell, which doesn’t need improvement. On the other hand, extending the

groove into the lower half, even as little as 20

°

at each parting line (220

°

in total), takes

away from upper bearing performance without providing any benefit to the lower half.

It’s also interesting to note that as groove length increases so do Horsepower Loss and

Peak Oil Film Pressure which is transmitted directly to the bearing

from what I've read pressure over 65 psi at W.O.T.

or over 20PSI at idle for a sbc or BBC adds no benefit.

some ford engines are designed to work with up to 100 psi of oil pressure at peak rpms

added oil flow rate volume helps cool and lubricate to a greater extent than added pressure

How Oil Viscosity & Temperature Influence Bearing Function

Some will know from their experience with automobiles that thicker oils, such as Society of Automotive Engineers (SAE) 30, are more appropriate for warm summer months. But thinner oils, perhaps SAE 10, can help prepare a vehicle for winter driving. Figure 1 illustrates where these motor oils fit...

www.pumpsandsystems.com

HOW TO CHOOSE THE RIGHT ENGINE OIL FOR YOUR VEHICLE?

Ever wondered how to choose the right engine oil for your bike or car? If yes, we have explained the different types & uses of engine oils

www.supergen.in

www.supergen.in

the safe zone for oil temperature is 190-220F. Anything lower and you risk not getting all the moisture out. Anything higher and you're oil is going to degrade faster.

Cold engine oil causes excessive frictional drag on the bearings and cylinder walls.

A quality conventional motor oil will tolerate oil sump temperatures of up to 250 degrees,

but starts breaking down over 275 degrees.

The traditional approach is to try to hold max oil temperatures ,

between 230 and no higher than 260 degree for brief time periods.

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/

Elephant Racing • Oil Temperature and Engine Life: Why is proper temperature so important?

Why is proper temperature so important?

www.elephantracing.com

www.elephantracing.com

the safe zone for oil temperature is 190-220F.

Anything lower and you risk not getting all the moisture out.

Anything consistently run higher and you're oil is going to degrade faster.

yeah the linked info holds a great deal more info

http://garage.grumpysperformance.com/index.php?threads/testing-a-chevy-oil-pump.6479/#post-87726

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/

http://garage.grumpysperformance.co...l-pumps-pressure-bye-pass-circuit-works.3536/

http://garage.grumpysperformance.com/index.php?threads/installing-an-oil-pump-pick-up-tube.1800/

http://garage.grumpysperformance.com/index.php?threads/bearings-and-oil-flow.150/

http://garage.grumpysperformance.com/index.php?threads/shimming-an-oil-pump-relief-spring.16240/

http://garage.grumpysperformance.com/index.php?threads/basic-info-on-your-v8-lube-system.52/

Last edited by a moderator: