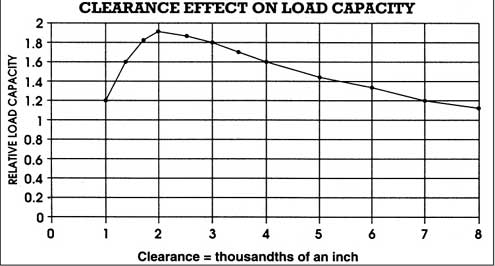

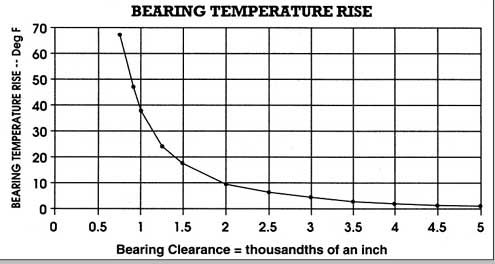

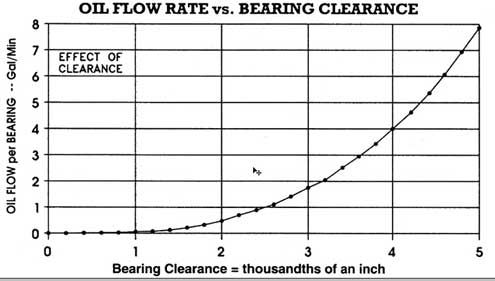

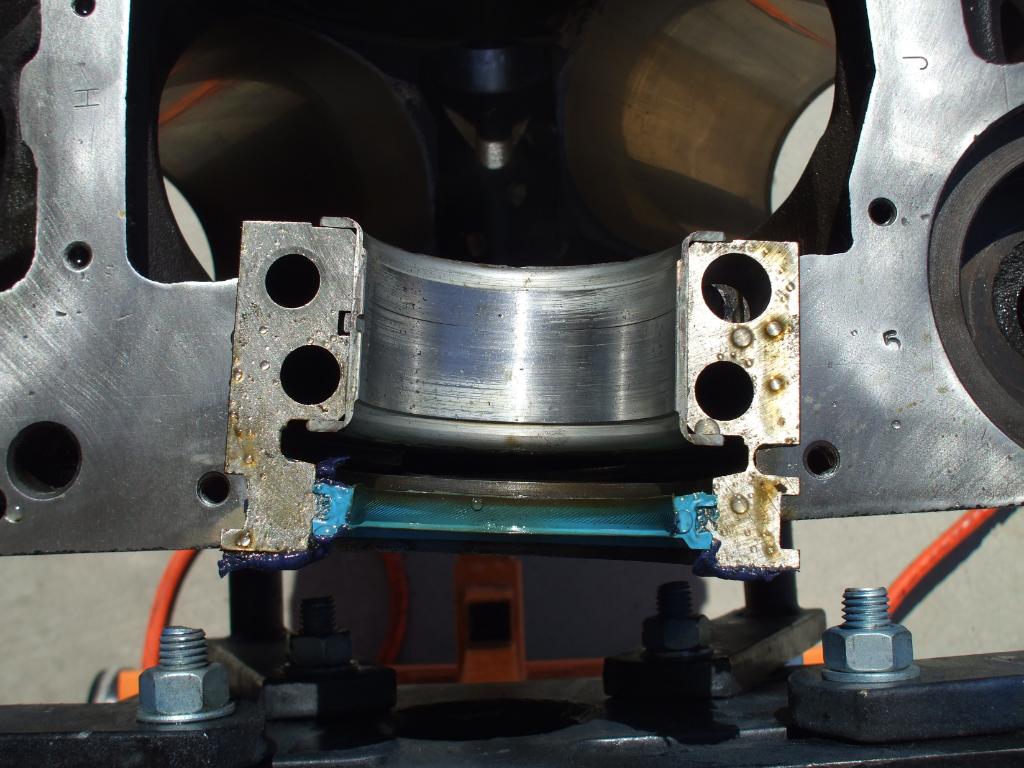

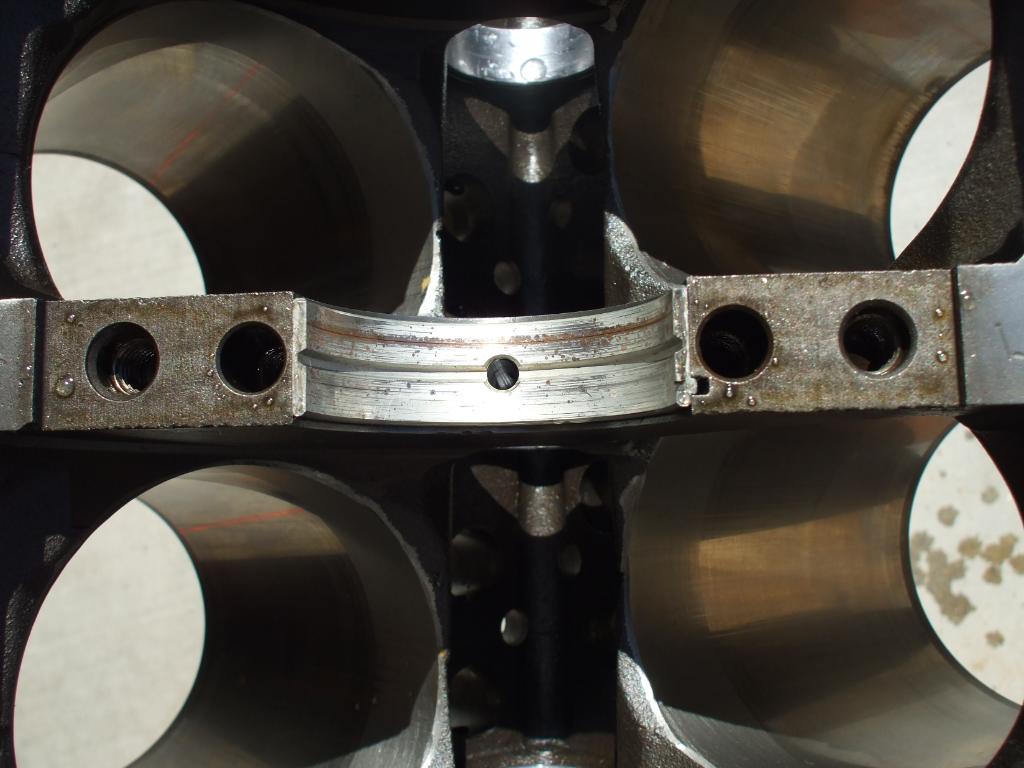

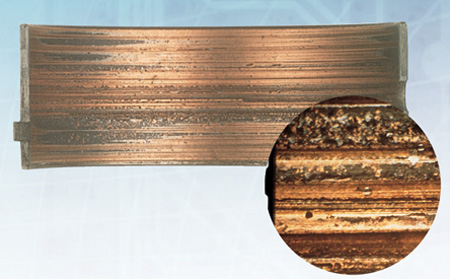

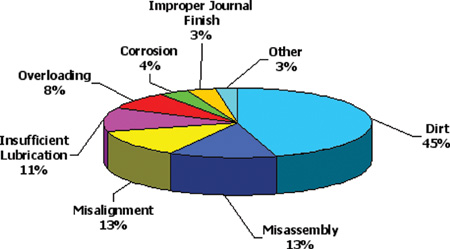

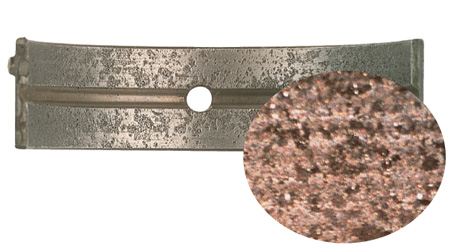

more info, read thru the links and sub linked info, keep in mind the oil flow rates and pressure effect bearing life and for a bearing to function properly there needs to be a constant flow of pressurized oil forming a layer between the bearing surface and the crank journals or similar moving components, its that boundary film that draws heat and crud from the surfaces and prevents contact that results in rapid wear, read these links theres a great deal of useful info contained within them

http://www.thewarfields.com/HotRodBlogEngineAssy4.htm

http://www.reliabilitydirect.com/appnotes/jb.html

http://www.bobistheoilguy.com/bearingwe ... alysis.htm

viewtopic.php?f=53&t=2726

http://automotiveindustry-search.blogsp ... place.html

http://engineparts.com/solutions/US-C77-03.pdf

http://copper.org/publications/pub_list ... _701-4.pdf

http://www.bobistheoilguy.com/bearingwe ... alysis.htm

http://www.themotorbookstore.com/resmchstvi.html

(A GREAT IDEA TO BUY AND LOOK THRU THIS DVD IF YOUR NOT REALLY EXPERIENCED)

http://engineparts.com/solutions/US-C77-02.pdf

http://www.carcraft.com/techarticles/cc ... _tips.html

viewtopic.php?f=59&t=1390

viewtopic.php?f=54&t=150

http://www.aclperformance.com.au/us/Che ... ingsus.htm

http://www.babcox.com/editorial/ar/ar20128.htm''

http://engineparts.com/it_crankinstall.asp

viewtopic.php?f=50&t=1027&p=2393#p2393

http://engineparts.com/it_bearinginstall.asp

http://engineparts.com/techbulletins/CL77-1-205R.pdf

http://www.babcox.com/editorial/cm/cm99828.htm

http://www.thirskauto.net/Engine_Thrust_Bearings.html

http://www.thirskauto.net/BearingPics.html

http://members.rennlist.com/v1uhoh/cranksha.htm

http://www.babcox.com/editorial/us/us90126.htm

http://www.maintenanceresources.com/Ref ... s/oa-m.htm

http://www.circletrack.com/tipstricks/4 ... tion_tips/

http://www.thewarfields.com/HotRodBlogEngineAssy4.htm

http://www.reliabilitydirect.com/appnotes/jb.html

http://www.bobistheoilguy.com/bearingwe ... alysis.htm

viewtopic.php?f=53&t=2726

http://automotiveindustry-search.blogsp ... place.html

http://engineparts.com/solutions/US-C77-03.pdf

http://copper.org/publications/pub_list ... _701-4.pdf

http://www.bobistheoilguy.com/bearingwe ... alysis.htm

http://www.themotorbookstore.com/resmchstvi.html

(A GREAT IDEA TO BUY AND LOOK THRU THIS DVD IF YOUR NOT REALLY EXPERIENCED)

http://engineparts.com/solutions/US-C77-02.pdf

http://www.carcraft.com/techarticles/cc ... _tips.html

viewtopic.php?f=59&t=1390

viewtopic.php?f=54&t=150

http://www.aclperformance.com.au/us/Che ... ingsus.htm

http://www.babcox.com/editorial/ar/ar20128.htm''

http://engineparts.com/it_crankinstall.asp

viewtopic.php?f=50&t=1027&p=2393#p2393

http://engineparts.com/it_bearinginstall.asp

http://engineparts.com/techbulletins/CL77-1-205R.pdf

http://www.babcox.com/editorial/cm/cm99828.htm

http://www.thirskauto.net/Engine_Thrust_Bearings.html

http://www.thirskauto.net/BearingPics.html

http://members.rennlist.com/v1uhoh/cranksha.htm

http://www.babcox.com/editorial/us/us90126.htm

http://www.maintenanceresources.com/Ref ... s/oa-m.htm

http://www.circletrack.com/tipstricks/4 ... tion_tips/