YES ITS REALLY WORTH THE TIME AND EFFORT TO READ THRU THE SUB LINKED INFO

http://garage.grumpysperformance.com/index.php?threads/a-brief-look-at-clutches.447/

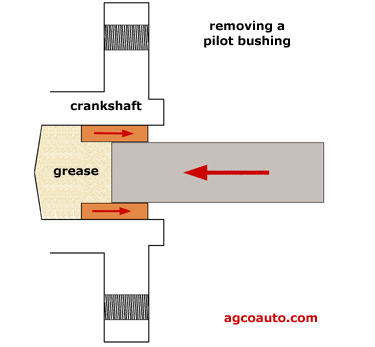

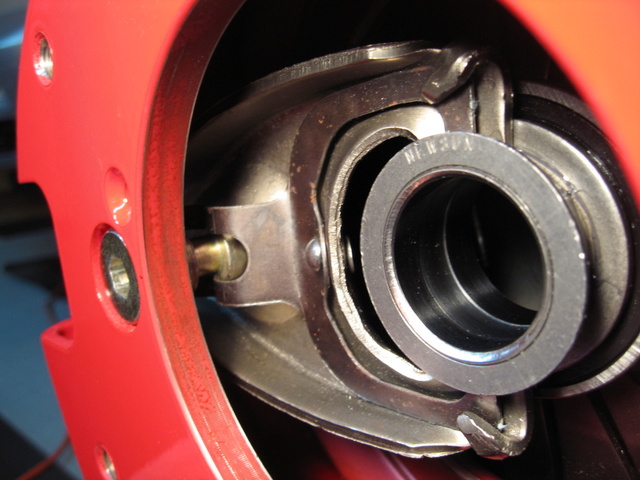

Pilot bushing clearance to trans input shaft should be .001 to .004

...with .002-.003 being considered about ideal

Default SBC Flywheel & Flexplate part numbers

http://www.chevelles.com/forums/showthread.php?t=142525

Small Block Chevy Flywheel Part Numbers

Part # DIA. Teeth Comments

3991406 Flywheel, LW Nodular Iron for HD 10.5" Clutch

3991469 14" 168 two-piece seal, internally balanced

3986394 14" 168 400 External balance, two-piece seal

10105832 14" 168 86-later, one-piece rear seal, ext. balance

14088671 12.75" 153 86-later, one piece rear seal, int. balance

14085720 12.75" 153 Lightweight (15 lbs.), nodular iron, two-piece seal, int bal Will work with a clutch diameter of 10.4" only. Crank flange bolt pattern is 3.58". Will work with a clutch diameter of 10.4" OR 11.0". Crank flange bolt pattern is 3.0"

14088646 12.75" 153 86-up, Lightweight (15 lbs.), nodular iron, one-piece rear seal, ext bal

14088648 14" 168 86-up, one-piece rear seal, ext. balance

14088650 12.75" 153 86-up, one-piece rear seal, ext balance Will work with a clutch diameter of 10.4" only. Crank flange bolt pattern is 3.0"

10174482 89-up with six-speed m/t, requires starter (10455709)

Common clutch sizes are: 10.4", 11.0", and 11.85". Some flywheels are drilled for two different clutch patterns.

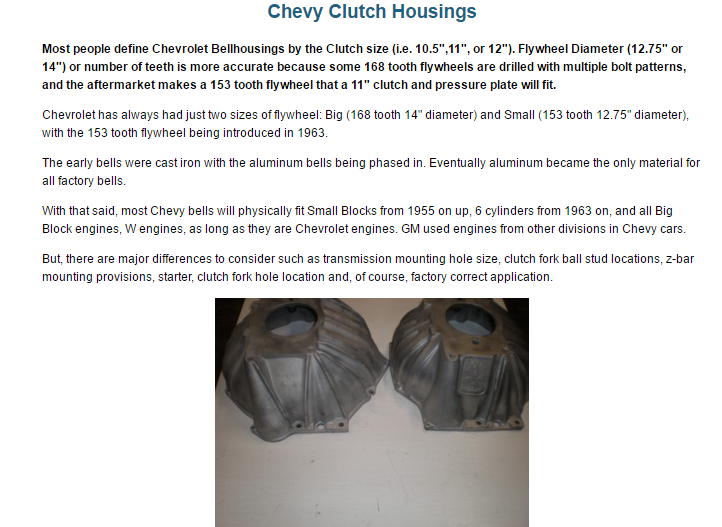

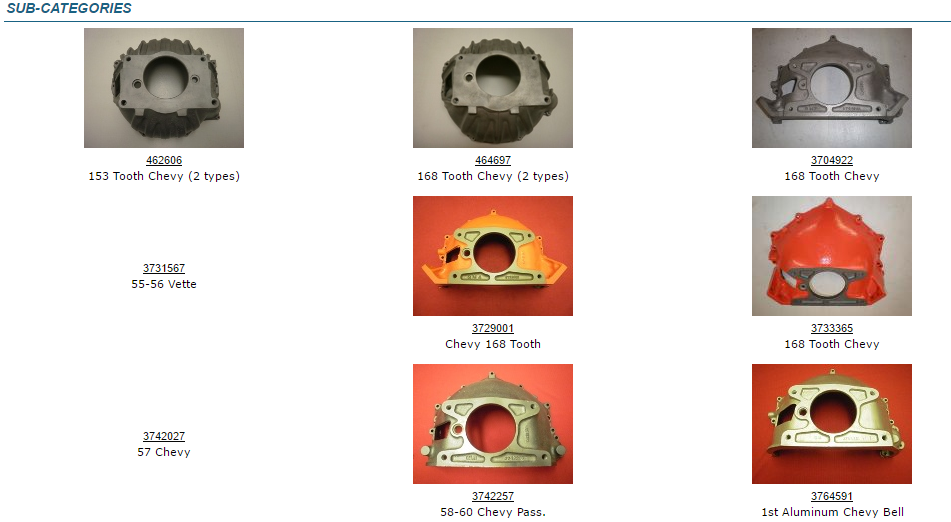

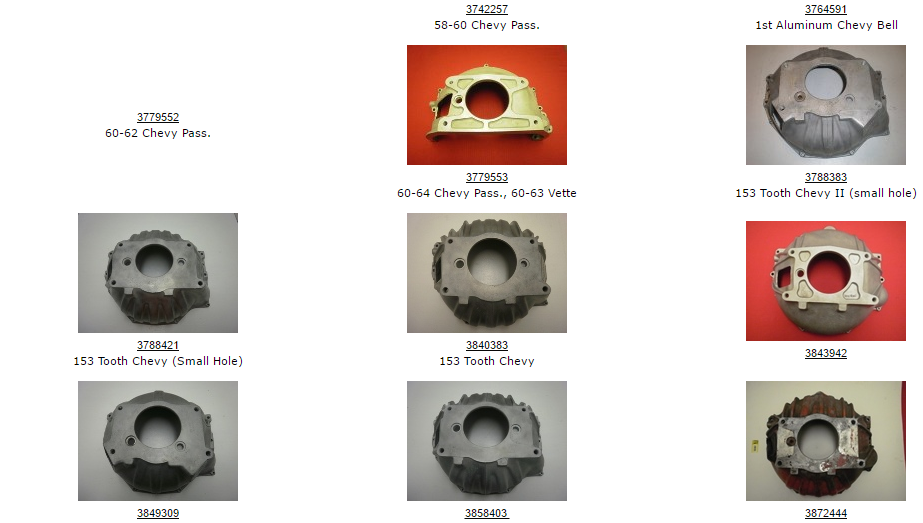

12.75" are usually 153 tooth and the other larger 14" diam. are 168 tooth flywheel or flex plate designs, the larger 14"/168 tooth designs fit the much stronger 11" clutches.... obviously the 14" can use a larger clutch, but require a larger bell housing that is why some stock bell housings won,t fit the larger fly wheels and of course the starter used must match

Small Block Chevy Flexplate Part Numbers

Part # DIA. Teeth Comments

471529 12.75" 153 Two-piece seal blocks, int balance

471578 14" 168 400 ext. bal, two-piece rear seal

471598 14" 168 Two-piece seal blocks, internal balance

10128412 12.75" 153 86-up, one-piece rear seal ext. balance

10128413 14" 168 86-up, one-piece seal, extra thick, HD, ext bal

10128414 14" 168 86-96, one-piece rear seal, ext. balance

14088761 14" 168 89-up 350 HO, one-piece rear seal, ext. bal.

14088765 12.75" 153 86-up, one-piece rear seal, ext. bal.

14088767 14" 168 89-up 350 HO, one-piece rear seal, HD, ext. bal

WATCH THE VIDEOS , AND READ THRU THE LINKS AND TAKE A FEW NOTES

http://www.lakewoodindustries.com/Catal ... 74437G.pdf

http://www.youtube.com/watch?feature=pl ... TdTBq6-EI#!

http://www.youtube.com/watch?v=3sTdTBq6 ... e=youtu.be

viewtopic.php?f=71&t=584&p=21690&hilit=bell+housing#p21690

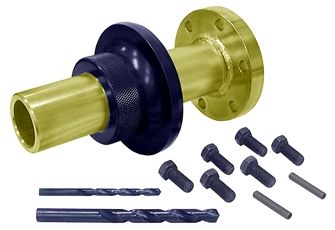

http://www.robbmcperformance.com/products/dowels.html

http://www.hotrod.com/news/1405-postage-paid-may-2014/

http://www.colemanracing.com/Alignment- ... P4573.aspx

http://www.camaros.org/bellhousings.shtml

http://www.camaros.org/bellhousings.shtml

http://www.browellbellhousing.com/components.html

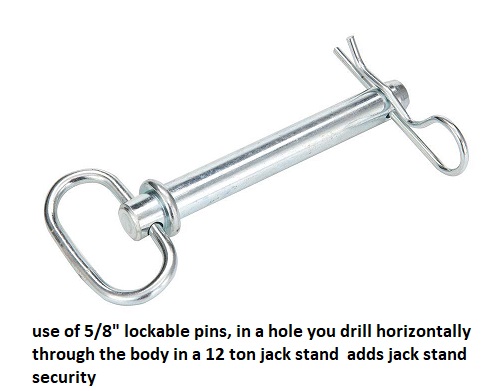

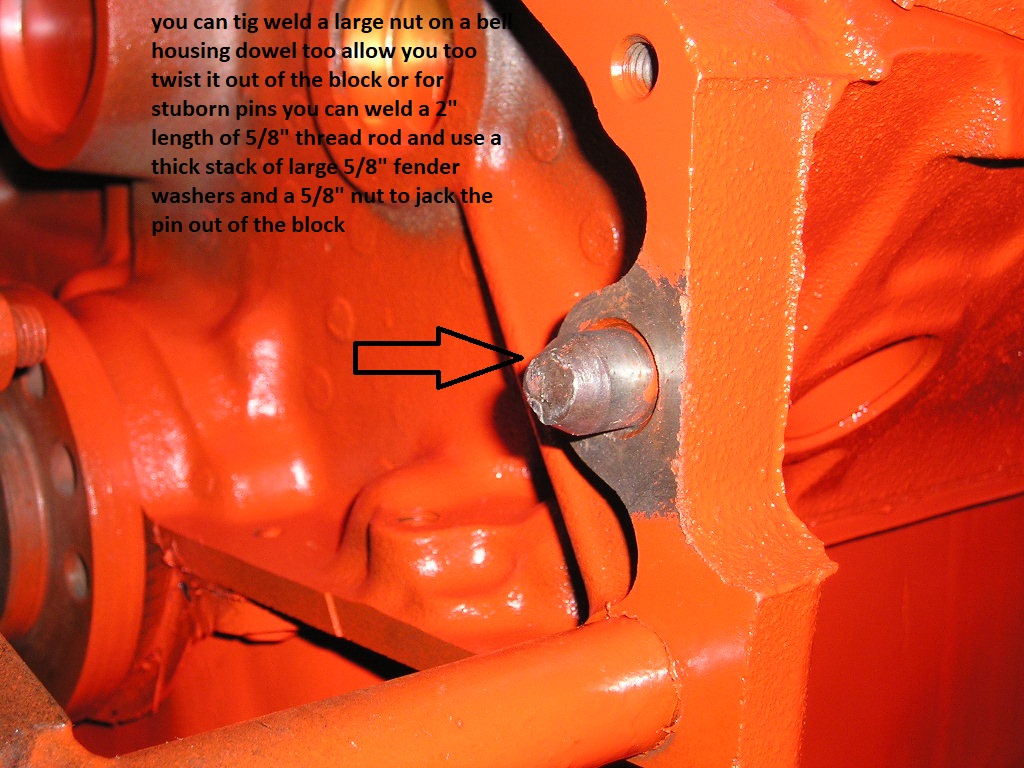

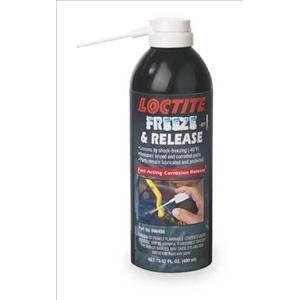

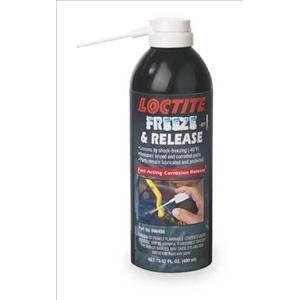

)to get the old rusted bell housing alignment pins loose heat them with a propane torch for about 2 minutes then spray the pins with freeze spray for a minimum of 8-9 seconds with

http://www.loctitefreezeandrelease.com/

http://www.amazon.com/Loctite-Freeze-Re ... B001VXU474

http://www.summitracing.com/parts/LAK-15907/?rtype=10

after rapid heat and cool cycles, they should easily twist out with vise grips or punch out with a hammer and drift. the new pins use locking expansion allen key locks, once correctly indexed

http://www.robbmcperformance.com/products/dowels.html

http://www.robbmcperformance.com/products/dowels.html

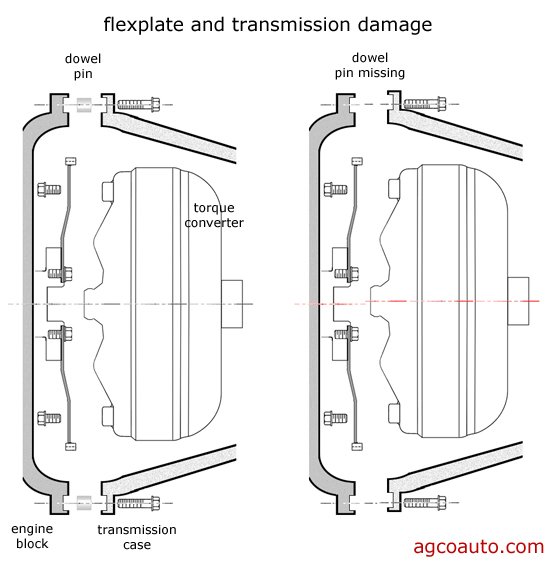

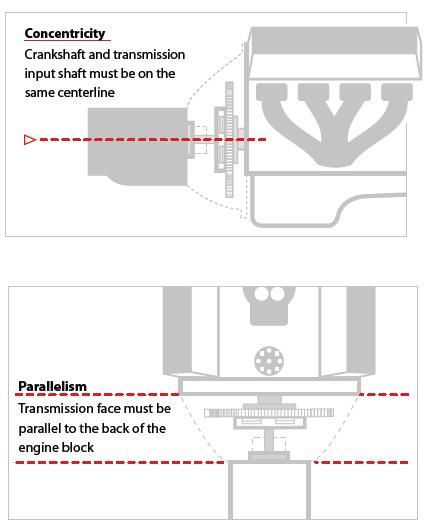

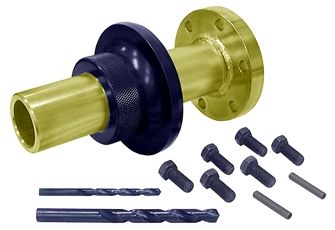

Due to manufacturers’ machining tolerances of engine blocks in relationship to dowel pin location, it is quite possible for

the crankshaft centerline and bellhousing bore to be misaligned. With the transmission installed in a misaligned condition,

several problems can occur, such as pilot bearing and main shaft bearing wear, difficulty in shifting, and in extreme cases

breakage of transmission gears and cases. While most housings will fall within the allowable limits, it is good insurance to

check for register bore runout whenever any housing or engine block is installed. Most factory service manuals will outline

the checking procedure, but will not give correctional measures necessary to ensure trouble-free standard transmission

operation, short of trial and error with switching of various O.E. housings.

NOTE: ADJUSTABLE DOWELS ARE USED TO DIAL IN BELLHOUSINGS BECAUSE THE ENGINE BLOCKS CASTED FROM THE

OEM FACTORY CAN BE OUT OF TOLERANCE. SO, YOU WILL NEED TO ALIGN ENGINE AND BELLHOUSING.

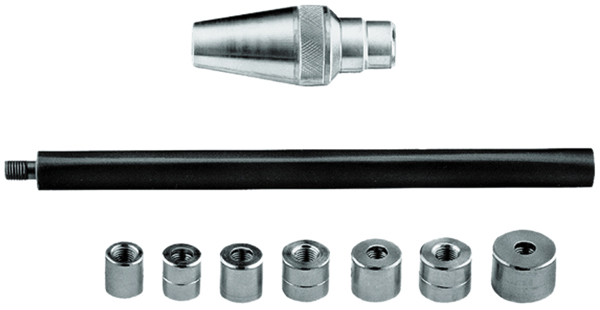

Offset dowel pins are available from Lakewood Industries to ensure correct adapter housing installation. For checking, you

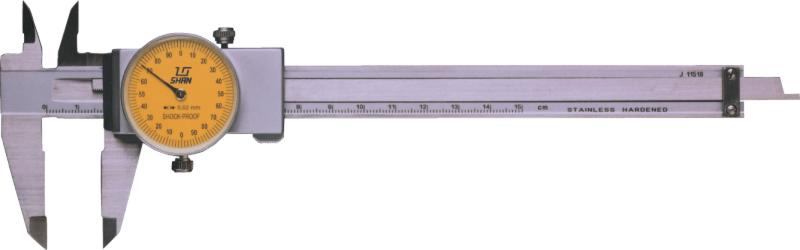

will need a dial indicator (preferably

INSTRUCTIONS

1. Remove clutch assembly from flywheel and install bellhousing on engine block.

(It is easier when you leave the clutch assembly off the flywheel.)

2. Install dial indicator base on the flywheel and adjust plunger to contact the register

bore of the housing. (See photo.)

3. Rotate the flywheel and note indicator reading. Misalignment is one-half of the

indicator reading (maximum allowable is .005â€).

4. To correct off-center condition, select the offset dowel pin pair that is closest to onehalf

of the indicator reading. (i.e., if reading is .016â€, 1/2R=.008†use .007†dowels.

If reading is .024â€, 1/2R=.012†use .014†dowels).

5. Remove stock dowel pins by driving from back side or pulling with gripper

pliers.

6. Clean engine block dowel holes and coat lightly with lubricant.

7. Lubricate dowel pins and install in block. The slot in the dowel pins indicates the

direction of maximum offset. They should be installed parallel to one another,

and in pairs (both .007†or both .014†and .021â€).

8. Install and tighten bellhousing securely. Remount the dial indicator and recheck

the register bore runout (Repeat step 3).

9. To make small corrections or adjustments to the alignment, you will need to

remove the bellhousing and drive the offset dowels out of the block. Reposition

the dowels using the slot as a reference point and re-install. Re-check register

bore run-out. Repeat this procedure until the register bore is within limits

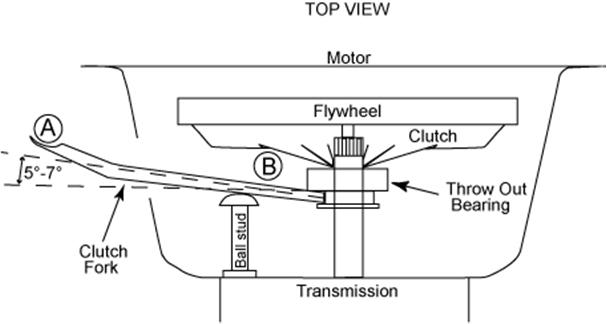

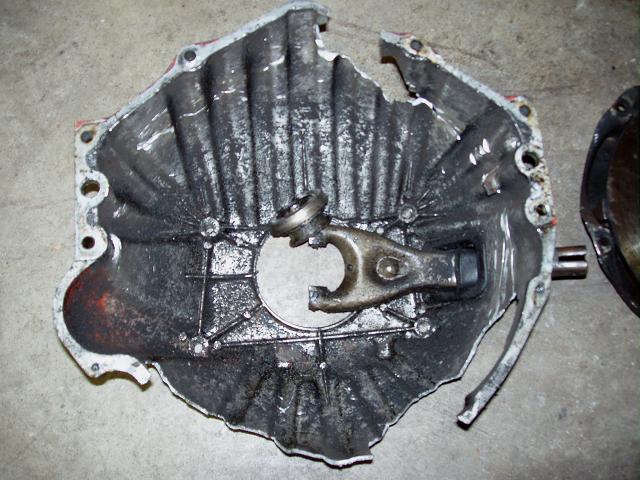

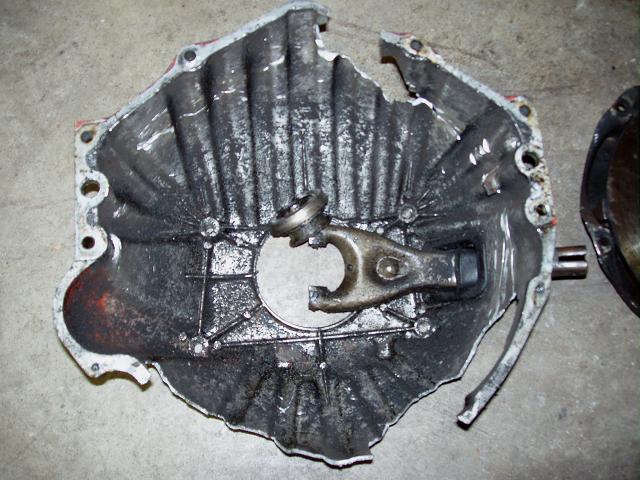

clutch fork stud:

http://www.jegs.com/InstallationInstructions/600/620/620-15500.pdf

http://www.4speedconversions.com/62-67_nova_linkage.html

http://www.4speedconversions.com/chevy_2_linkage_kit_r1.html

http://www.modernperformanceclassics.net/ShowItem/102808 62-67 Nova Clutch Adapter Bracket.aspx

You want 4.75 inches from the flange to the top of the ball stud thats if you have not had any work done to your flywheel or pressure plate

the 4.75" is from the flange of the bellhouseing to the top of the ball stud.

lay a straight edge across the flange of the bellhousing and measure down to the ball stud

http://www.allpar.com/mopar/shield.html

http://www.lakewoodindustries.com/pdf/b ... cedure.pdf

http://www.priveye.com/images/lakewood.htm

http://www.usaperform.com/clutches-bell ... c-468.html

http://www.hurst-drivelines.com/files/G ... 15-09A.pdf

http://www.circletrack.com/drivetrainte ... index.html

http://www.quicktimeinc.com/products.html#chevy

http://www.priveye.com/images/lakewood.htm

http://andysgd427.blogspot.com/2009/08/ ... nment.html

http://www.superchevy.com/technical/add ... ewall.html

http://www.camaros.org/bellhousings.shtml

viewtopic.php?f=39&t=1122&hilit=bellhousing

viewtopic.php?f=53&t=1042&p=1969#p1969

http://www.summitracing.com/parts/LAK-15907/

http://www.camaros.org/bellhousings.shtml

viewtopic.php?f=71&t=447

980300 UNIVERSAL TRANSMISSION BLANKET SFI APPROVED $94.43 (http://www.comteck.com/~trans/adapter_plates.htm ) (kevlar scatter shield, the same thing bullet proof vests are made of)

http://www.browellbellhousing.com/pages ... -page.html

http://store.summitracing.com/egnsearch ... 5&x=27&y=9

Lakewood bellhousing is about $329. This one from Speedway is $249.

http://www.speedwaymotors.com/p/545,36_Explosion-Proof-Chevy-Bellhousing-with-Plate.html#feedback

keep in mind you want a SFI BILLET flywheel and a BLOW-PROOF BELL HOUSING

"Lakewood Bellhousings have been tested and meet or exceed S.F.I. Spec. 6.1, when used with approved block plate. Lakewood Bellhousings are designed to contain a clutch or flywheel explosion, bellhousings include the block plate and are marked with an S.F.I. Spec. 6.1 serial number " and have a certification label that some tracks require

I think thats a CHINESE COPY, I don,t see it advertised as MEETING the S.F.I. Spec 6.1 which MIGHT mean its not up to the strength, thickness or temper and heat treatment or same level of dimensional tollerance control, its obviously better than the stock aluminum but it might not be nearly as strong as the certified bell housing

BTW

http://www.jegs.com/webapp/wcs/stores/servlet/product_10001_10002_24568_-1

http://store.summitracing.com/partdetail.asp?autofilter=1&part=LAK-15000&N=700+4294822099+115&autoview=sku

theres DOZENS of differant models , SIZES ETC. but LAKEWOODS about the best known brand and JEGS AND SUMMIT HAVE THEM

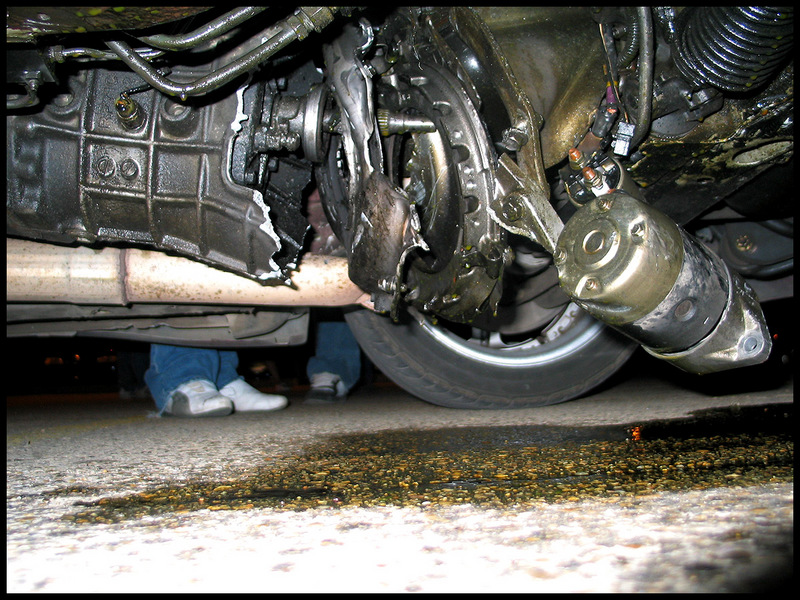

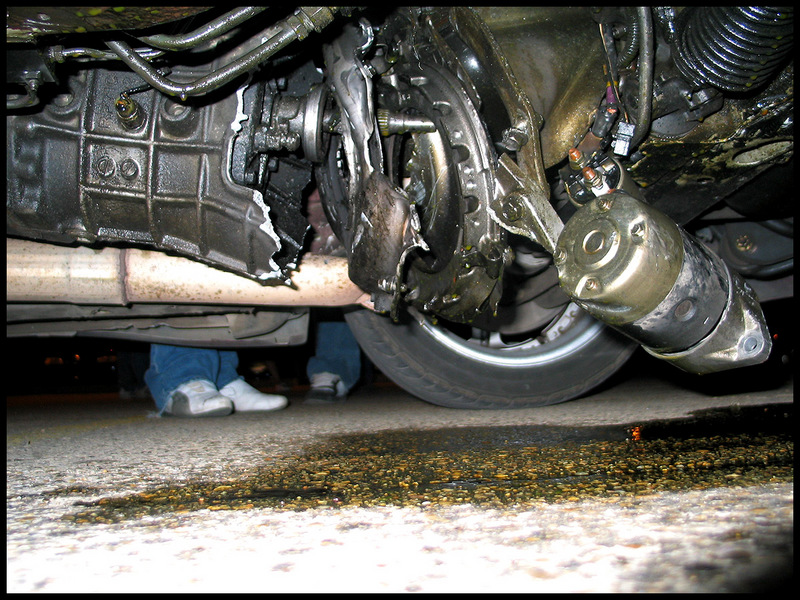

most of us old timers have seen what happends to a car when a flywheel/clutch blows and Ive seen a chunk of flywheel or clutch take the windshield and dash right out of a 283/57 chevy so if you plan on walking around in your old age without prosthesis legs use a lakewood houseing, youll find that the cost is very small compared to new legs. btw running your fuel lines where the frame protects them, haveing the electric fuel pump with a minimal oil pressure cut on pressure switch and carrying a 10lb co2 extinguisher is also a good idea,at least that way if the engine/flywheel blows you don,t have gas continuing to pump out everywhare from cut fuel lines.look here,

http://www.jegs.com/cgi-bin/ncommerce3/ProductDisplay?prrfnbr=2141&prmenbr=361

--------------------------------------------------------------------------------

Grumpy, funny you should mention that. 20 years ago a friends brother had th ebody and paint done on his 57 (BRIGHT ORANGE) and had a hot 283 in the car with a Muncie.

He was out on the highway running it hard and the flywheel let go (stock piece, I'd bet) and it took out the windshield, cowl, firewall, crushed the frame on each side, cut the headers as if they were paper, and left a nice hole in the pavement. Yep. Stock bellhousing.

I have the Lakewood in my Z and it was hardly a problem fitting it. I did cut the flange off of about 6" of the bottom portion, parallel with the ground, for ground clearance (I know that killed the SFI rating, but it's still alot safer than an AL bellhousing) and had to just slightly bump the tunnel in one area on the passenger side to make some clearance.

http://www.jegs.com/p/J-W-Performance/J ... 7/10002/-1

you TH350 and TH400 guys need this also

viewtopic.php?f=71&t=447&p=5542&hilit=lakewood&sid=5b1f4d4cbc68b8f1722cca315fc912de#p5542

http://garage.grumpysperformance.co...l-oil-soaked-clutch-dry-out.11603/#post-54020

keep in mind a SFI SCATTER SHIELD to protect your feet is almost mandatory, on a high performance engine combo

watch THESE (found on youtube)

http://www.youtube.com/watch?v=tDbrvUtN ... r_embedded

http://garage.grumpysperformance.com/index.php?threads/what-fly-wheel.6124/#post-35034

viewtopic.php?f=71&t=2596&p=6695&hilit=bell+housing#p6695

383RAM posted this bit of info

"Most factory stuff is usually close enough for factory parts. When you start upgrading power and clutches, it would be foolish not to check it. My one old Ansen steel bellhousing was .062 out of spec. I used the Lakwood extra long dowel pins with weld on sleeves to straighten it out. It requires all the mounting holes to be hoged out or enlongated. Then you cemter the housing and tack weld the sleeves to the bellhousing.

You have to remember, the steel housings are stamped rather than having a casting machined like the stock aluminum bellhousing. The stampings by nature are going to be off a little more. Just like a stamped quarter panel, no two are exacrtly alike.

BTW, some of the better known converter companies really prefer you dial in your automatic trans case too. I have done a couple of them, but that requires the trans to be disassembled to dial in off the front pump flange. "

http://garage.grumpysperformance.com/index.php?threads/a-brief-look-at-clutches.447/

Pilot bushing clearance to trans input shaft should be .001 to .004

...with .002-.003 being considered about ideal

Default SBC Flywheel & Flexplate part numbers

http://www.chevelles.com/forums/showthread.php?t=142525

Small Block Chevy Flywheel Part Numbers

Part # DIA. Teeth Comments

3991406 Flywheel, LW Nodular Iron for HD 10.5" Clutch

3991469 14" 168 two-piece seal, internally balanced

3986394 14" 168 400 External balance, two-piece seal

10105832 14" 168 86-later, one-piece rear seal, ext. balance

14088671 12.75" 153 86-later, one piece rear seal, int. balance

14085720 12.75" 153 Lightweight (15 lbs.), nodular iron, two-piece seal, int bal Will work with a clutch diameter of 10.4" only. Crank flange bolt pattern is 3.58". Will work with a clutch diameter of 10.4" OR 11.0". Crank flange bolt pattern is 3.0"

14088646 12.75" 153 86-up, Lightweight (15 lbs.), nodular iron, one-piece rear seal, ext bal

14088648 14" 168 86-up, one-piece rear seal, ext. balance

14088650 12.75" 153 86-up, one-piece rear seal, ext balance Will work with a clutch diameter of 10.4" only. Crank flange bolt pattern is 3.0"

10174482 89-up with six-speed m/t, requires starter (10455709)

Common clutch sizes are: 10.4", 11.0", and 11.85". Some flywheels are drilled for two different clutch patterns.

12.75" are usually 153 tooth and the other larger 14" diam. are 168 tooth flywheel or flex plate designs, the larger 14"/168 tooth designs fit the much stronger 11" clutches.... obviously the 14" can use a larger clutch, but require a larger bell housing that is why some stock bell housings won,t fit the larger fly wheels and of course the starter used must match

Small Block Chevy Flexplate Part Numbers

Part # DIA. Teeth Comments

471529 12.75" 153 Two-piece seal blocks, int balance

471578 14" 168 400 ext. bal, two-piece rear seal

471598 14" 168 Two-piece seal blocks, internal balance

10128412 12.75" 153 86-up, one-piece rear seal ext. balance

10128413 14" 168 86-up, one-piece seal, extra thick, HD, ext bal

10128414 14" 168 86-96, one-piece rear seal, ext. balance

14088761 14" 168 89-up 350 HO, one-piece rear seal, ext. bal.

14088765 12.75" 153 86-up, one-piece rear seal, ext. bal.

14088767 14" 168 89-up 350 HO, one-piece rear seal, HD, ext. bal

WATCH THE VIDEOS , AND READ THRU THE LINKS AND TAKE A FEW NOTES

http://www.lakewoodindustries.com/Catal ... 74437G.pdf

http://www.youtube.com/watch?feature=pl ... TdTBq6-EI#!

http://www.youtube.com/watch?v=3sTdTBq6 ... e=youtu.be

viewtopic.php?f=71&t=584&p=21690&hilit=bell+housing#p21690

http://www.robbmcperformance.com/products/dowels.html

http://www.hotrod.com/news/1405-postage-paid-may-2014/

http://www.colemanracing.com/Alignment- ... P4573.aspx

http://www.camaros.org/bellhousings.shtml

http://www.camaros.org/bellhousings.shtml

http://www.browellbellhousing.com/components.html

)to get the old rusted bell housing alignment pins loose heat them with a propane torch for about 2 minutes then spray the pins with freeze spray for a minimum of 8-9 seconds with

http://www.loctitefreezeandrelease.com/

http://www.amazon.com/Loctite-Freeze-Re ... B001VXU474

http://www.summitracing.com/parts/LAK-15907/?rtype=10

after rapid heat and cool cycles, they should easily twist out with vise grips or punch out with a hammer and drift. the new pins use locking expansion allen key locks, once correctly indexed

http://www.robbmcperformance.com/products/dowels.html

Due to manufacturers’ machining tolerances of engine blocks in relationship to dowel pin location, it is quite possible for

the crankshaft centerline and bellhousing bore to be misaligned. With the transmission installed in a misaligned condition,

several problems can occur, such as pilot bearing and main shaft bearing wear, difficulty in shifting, and in extreme cases

breakage of transmission gears and cases. While most housings will fall within the allowable limits, it is good insurance to

check for register bore runout whenever any housing or engine block is installed. Most factory service manuals will outline

the checking procedure, but will not give correctional measures necessary to ensure trouble-free standard transmission

operation, short of trial and error with switching of various O.E. housings.

NOTE: ADJUSTABLE DOWELS ARE USED TO DIAL IN BELLHOUSINGS BECAUSE THE ENGINE BLOCKS CASTED FROM THE

OEM FACTORY CAN BE OUT OF TOLERANCE. SO, YOU WILL NEED TO ALIGN ENGINE AND BELLHOUSING.

Offset dowel pins are available from Lakewood Industries to ensure correct adapter housing installation. For checking, you

will need a dial indicator (preferably

INSTRUCTIONS

1. Remove clutch assembly from flywheel and install bellhousing on engine block.

(It is easier when you leave the clutch assembly off the flywheel.)

2. Install dial indicator base on the flywheel and adjust plunger to contact the register

bore of the housing. (See photo.)

3. Rotate the flywheel and note indicator reading. Misalignment is one-half of the

indicator reading (maximum allowable is .005â€).

4. To correct off-center condition, select the offset dowel pin pair that is closest to onehalf

of the indicator reading. (i.e., if reading is .016â€, 1/2R=.008†use .007†dowels.

If reading is .024â€, 1/2R=.012†use .014†dowels).

5. Remove stock dowel pins by driving from back side or pulling with gripper

pliers.

6. Clean engine block dowel holes and coat lightly with lubricant.

7. Lubricate dowel pins and install in block. The slot in the dowel pins indicates the

direction of maximum offset. They should be installed parallel to one another,

and in pairs (both .007†or both .014†and .021â€).

8. Install and tighten bellhousing securely. Remount the dial indicator and recheck

the register bore runout (Repeat step 3).

9. To make small corrections or adjustments to the alignment, you will need to

remove the bellhousing and drive the offset dowels out of the block. Reposition

the dowels using the slot as a reference point and re-install. Re-check register

bore run-out. Repeat this procedure until the register bore is within limits

clutch fork stud:

http://www.jegs.com/InstallationInstructions/600/620/620-15500.pdf

http://www.4speedconversions.com/62-67_nova_linkage.html

http://www.4speedconversions.com/chevy_2_linkage_kit_r1.html

http://www.modernperformanceclassics.net/ShowItem/102808 62-67 Nova Clutch Adapter Bracket.aspx

You want 4.75 inches from the flange to the top of the ball stud thats if you have not had any work done to your flywheel or pressure plate

the 4.75" is from the flange of the bellhouseing to the top of the ball stud.

lay a straight edge across the flange of the bellhousing and measure down to the ball stud

http://www.allpar.com/mopar/shield.html

http://www.lakewoodindustries.com/pdf/b ... cedure.pdf

http://www.priveye.com/images/lakewood.htm

http://www.usaperform.com/clutches-bell ... c-468.html

http://www.hurst-drivelines.com/files/G ... 15-09A.pdf

http://www.circletrack.com/drivetrainte ... index.html

http://www.quicktimeinc.com/products.html#chevy

http://www.priveye.com/images/lakewood.htm

http://andysgd427.blogspot.com/2009/08/ ... nment.html

http://www.superchevy.com/technical/add ... ewall.html

http://www.camaros.org/bellhousings.shtml

viewtopic.php?f=39&t=1122&hilit=bellhousing

viewtopic.php?f=53&t=1042&p=1969#p1969

http://www.summitracing.com/parts/LAK-15907/

http://www.camaros.org/bellhousings.shtml

viewtopic.php?f=71&t=447

980300 UNIVERSAL TRANSMISSION BLANKET SFI APPROVED $94.43 (http://www.comteck.com/~trans/adapter_plates.htm ) (kevlar scatter shield, the same thing bullet proof vests are made of)

http://www.browellbellhousing.com/pages ... -page.html

http://store.summitracing.com/egnsearch ... 5&x=27&y=9

Lakewood bellhousing is about $329. This one from Speedway is $249.

http://www.speedwaymotors.com/p/545,36_Explosion-Proof-Chevy-Bellhousing-with-Plate.html#feedback

keep in mind you want a SFI BILLET flywheel and a BLOW-PROOF BELL HOUSING

"Lakewood Bellhousings have been tested and meet or exceed S.F.I. Spec. 6.1, when used with approved block plate. Lakewood Bellhousings are designed to contain a clutch or flywheel explosion, bellhousings include the block plate and are marked with an S.F.I. Spec. 6.1 serial number " and have a certification label that some tracks require

I think thats a CHINESE COPY, I don,t see it advertised as MEETING the S.F.I. Spec 6.1 which MIGHT mean its not up to the strength, thickness or temper and heat treatment or same level of dimensional tollerance control, its obviously better than the stock aluminum but it might not be nearly as strong as the certified bell housing

BTW

http://www.jegs.com/webapp/wcs/stores/servlet/product_10001_10002_24568_-1

http://store.summitracing.com/partdetail.asp?autofilter=1&part=LAK-15000&N=700+4294822099+115&autoview=sku

theres DOZENS of differant models , SIZES ETC. but LAKEWOODS about the best known brand and JEGS AND SUMMIT HAVE THEM

most of us old timers have seen what happends to a car when a flywheel/clutch blows and Ive seen a chunk of flywheel or clutch take the windshield and dash right out of a 283/57 chevy so if you plan on walking around in your old age without prosthesis legs use a lakewood houseing, youll find that the cost is very small compared to new legs. btw running your fuel lines where the frame protects them, haveing the electric fuel pump with a minimal oil pressure cut on pressure switch and carrying a 10lb co2 extinguisher is also a good idea,at least that way if the engine/flywheel blows you don,t have gas continuing to pump out everywhare from cut fuel lines.look here,

http://www.jegs.com/cgi-bin/ncommerce3/ProductDisplay?prrfnbr=2141&prmenbr=361

--------------------------------------------------------------------------------

Grumpy, funny you should mention that. 20 years ago a friends brother had th ebody and paint done on his 57 (BRIGHT ORANGE) and had a hot 283 in the car with a Muncie.

He was out on the highway running it hard and the flywheel let go (stock piece, I'd bet) and it took out the windshield, cowl, firewall, crushed the frame on each side, cut the headers as if they were paper, and left a nice hole in the pavement. Yep. Stock bellhousing.

I have the Lakewood in my Z and it was hardly a problem fitting it. I did cut the flange off of about 6" of the bottom portion, parallel with the ground, for ground clearance (I know that killed the SFI rating, but it's still alot safer than an AL bellhousing) and had to just slightly bump the tunnel in one area on the passenger side to make some clearance.

http://www.jegs.com/p/J-W-Performance/J ... 7/10002/-1

you TH350 and TH400 guys need this also

viewtopic.php?f=71&t=447&p=5542&hilit=lakewood&sid=5b1f4d4cbc68b8f1722cca315fc912de#p5542

http://garage.grumpysperformance.co...l-oil-soaked-clutch-dry-out.11603/#post-54020

keep in mind a SFI SCATTER SHIELD to protect your feet is almost mandatory, on a high performance engine combo

watch THESE (found on youtube)

http://www.youtube.com/watch?v=tDbrvUtN ... r_embedded

http://garage.grumpysperformance.com/index.php?threads/what-fly-wheel.6124/#post-35034

viewtopic.php?f=71&t=2596&p=6695&hilit=bell+housing#p6695

383RAM posted this bit of info

"Most factory stuff is usually close enough for factory parts. When you start upgrading power and clutches, it would be foolish not to check it. My one old Ansen steel bellhousing was .062 out of spec. I used the Lakwood extra long dowel pins with weld on sleeves to straighten it out. It requires all the mounting holes to be hoged out or enlongated. Then you cemter the housing and tack weld the sleeves to the bellhousing.

You have to remember, the steel housings are stamped rather than having a casting machined like the stock aluminum bellhousing. The stampings by nature are going to be off a little more. Just like a stamped quarter panel, no two are exacrtly alike.

BTW, some of the better known converter companies really prefer you dial in your automatic trans case too. I have done a couple of them, but that requires the trans to be disassembled to dial in off the front pump flange. "

Last edited by a moderator: