you'll need to know the version/year of the 454, the mark IV sometimes requires a different oil pump than the MARK V-or-MARK VI due to main cap changes,

most BBC oil pumps are designed to fit the early MARK IV series, if you have the later versions there can be clearance issues.

you'll need to know your oil pan depth as the clearance varies

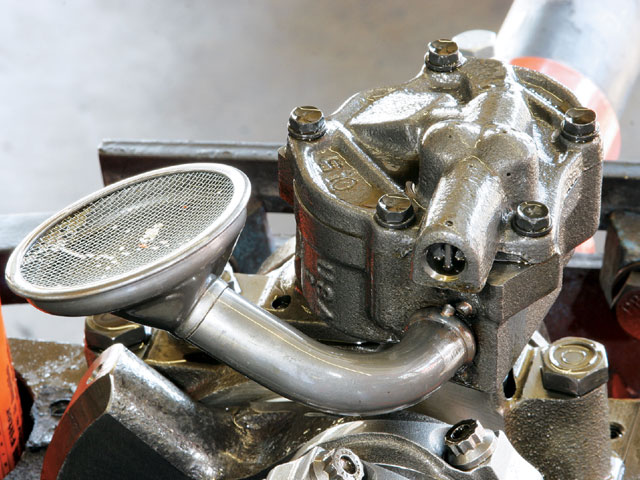

broken , or improperly installed oil pump pick-ups can cause several major oil pressure issues

ITS always a good idea to verify the oil pan floor to oil pump pick-up clearance and to braze the pick-up to the oil pump, to reduce the potential for it to come loose.

yes you can MIG ,TIG or TORCH WELD the pick-up but I found BRAZING works the best and is less likely to warp or crack the pump or pick-up

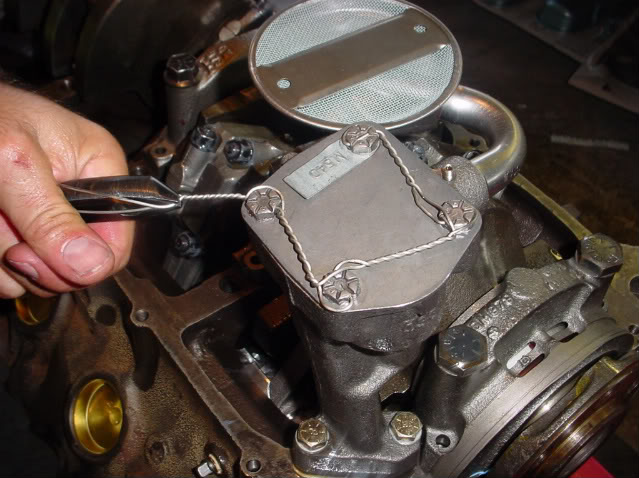

"how in hell do those twisty, safety wire pliers work?"

well a video should be helpful here! Id also point out that you can buy the wire in several diameters and the thicker sizes are far more difficult to use, home depot sells the 22 gauge and 18 gauge, the 22-24 gauge is what youll use far more commonly, as its much easier to use,both stainless (PREFERED) and galvanized are used, and will work on 95% of the applications on a car your likely to use.

using anti-seize paste on bolt or stud threads helps prevent future problems

using safety wire pliers

failure to use the correct oil pump,mounting stud, bolt or nut or

carefully check clearances when mounting an oil pump can cause problems

carefully check clearances when mounting an oil pump can cause problems

ONE RATHER COMMON MISTAKE IS USING THE WRONG OIL PUMP STUD OR BOLT TO MOUNT ,

THE OIL PUMP AS IF EITHER EXTENDS THRU THE REAR MAIN CAP,

IT CAN AND WILL BIND ON THE BEARING ,

AND LOCK OR RESTRICT, SMOOTH ROTATION

as many of you gentlemen know MELLING CHANGED the casting on their standard M55 high volume oil pumps making them weaker and thinner

like the thin casting on the left

like the thin casting on the left

but I understand that it caused a good deal of bad press and they are currently changing back to the thicker castings, but theres still thousands of the thin casting pumps in inventory that should not be use in high performance applications

keep in mind the sbc oil pump has 7 tooth gears and the big block pumps have 12 teeth making the oil flow smoother and less pulsed, plus having larger gears they tend to supply more oil at lower rpms

look closely and youll see the big block oil pump has a 5 bolt lower cover and the oil pump pick-up with its 3/4" feed seats into the main pump casting while the small block oil pump has a 4 bolt cover and the sbc oil pump pick-up with its 5/8" feed seats into the pumps cover plate

http://www.mellingselectperformance.com ... -guide.pdf

http://store.summitracing.com/partdetai ... toview=sku

http://store.summitracing.com/partdetai ... toview=sku

I was asked recently, as to my best guess, as to why a recently installed oil pump was making noise,

oil pumps rarely make much noise, unless, the drive shaft driving the oil pump, is rubbing on the block which will happen if you install a standard drive shaft in a 400 type small block which requires the drive shaft with the smaller diameter midsection. (what was going on in this case) Or you forget to install that little metal or nylon collar that keeps it aligned, or if your drive shaft has one the little spring clip, and remember to install the shaft along with the oil pump from below because the collar is designed to be too large to pass thru the block passage above it to insure the drive shaft stays attached to the oil pump. remember if the clearances inside the oil pump are not checked, and is partly binding or in some cases of the oil pump has ingested, some small bits of metal or other foreign material. the pump might be damaged, the standard high-performance oil pump drive shaft looks like the one below ,it has a steel collar and is made from a stronger than normal steel

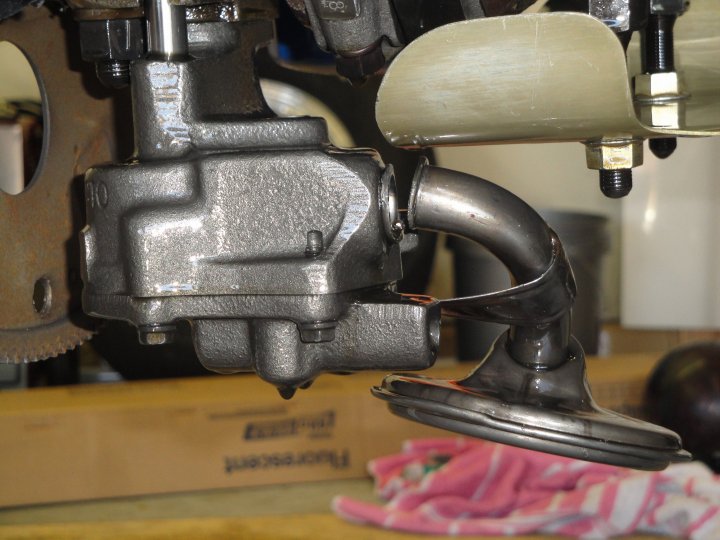

heres a standard volume BBC oil pump which can be used in a small block high performance application provided its matched to the correct oil pan and oil pump pick-up of course.

REMEMBER once the oil pumps installed on the main cap and the distributors test fitted on the intake manifold there should be about .050=.060 vertical clearance remaining on the oil pump drive shaft between the oil pump and distributor with the distributor firmly seated on the intake manifold and at least .060 in all directions around the oil pump drive shaft, "CHECK THE COLLAR" in rare cases it binds

http://m.summitracing.com/parts/mel-m77

http://m.summitracing.com/parts/mel-77060

chevy oil pump drive shafts come in several lengths and styles and some have metal or nylon collars, you should select the oil pump drive shaft that allows about a .050-.060 thousands clearance between the oil pump and distributor when the distributors seated on the intake manifold

its not uncommon for distributor gears and cam gears to not be perfectly lined up as to depth of the distributor or length of the oil pump drive, theres several different pump drive shaft lengths and spacer shims but in many cases a slip collar on the distributor or modifying the oil pump drive shaft will be required to get perfect alignment

your current distributor can usually be easily modified by a local machine shop with a lathe for an adjustable slip collar by carefully machining off the current one and adding a slip collar, if you need to make distributor gear to cam gear engagement or oil pump drive shaft length changes

http://www.summitracing.com/parts/MOR-26217/?rtype=10

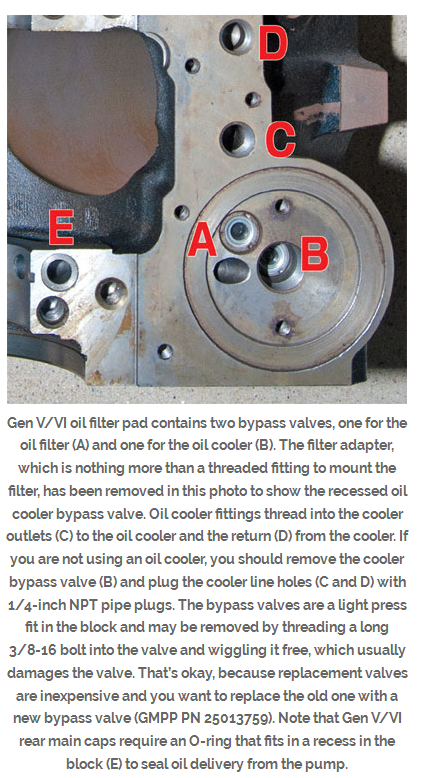

btw this is a good choice as a basic oil pan on a GEN V or GEN VI BBC

Moroso 20411

here more choices

http://www.spiderautomotive.com/oilsystems.html

http://www.spiderautomotive.com/moroso20411.html

Engine Application: Gen V/Gen VI

Fits: Most GM Chassis, including 1965-72 Chevelle, Cutlass, Skylark, Tempest/GTO

Kicked-Out Sump

best used with an oil cooler for more effective volume

Accommodates stock BM main cap mounted windage tray

Removable anti-slosh tray

Trap door baffling for improved oil control

Rear anti-climb baffle

Accepts strokes up to 4.250" with steel rods

Compatible with many starter/flywheel combination's

a high volume pump has slightly longer gears, usually about 10%-20% longer, that build the volume of oil pushed thru the engines oil passages,and engines clearances 10%-20% faster at any given rpm, PRESSURE is a measure of resistance to oil flow thru those clearances, theres a bye-pass circuit in the pump designed to open and limit the pressure at a set pressure level, thats usually 60-65 psi in a high volume pump and at 65-70 psi in a high pressure pump, theres no real disadvantage unless the pumps bye-pass circuit is not functioning correctly and starts to restrict the flow and the pressure builds to higher levels than intended resulting in resistance to the pump which adds drag and eats hp.

theres no lubrication increase past about 55-60 psi of oil flow thru the bearing clearances so the idea is to match the oils viscosity to the engine clearances at the engines operational temperature and to use an oil cooler and the engines oil bye-pass circuit to maintain the pressure and temperature within known, and predicted limits.

generally a high volume oil pump is used in conjunction with a windage screen, crank scraper and high capacity baffled oil pan to control the extra oil flow rates and per mote increase oil cooling and flow control

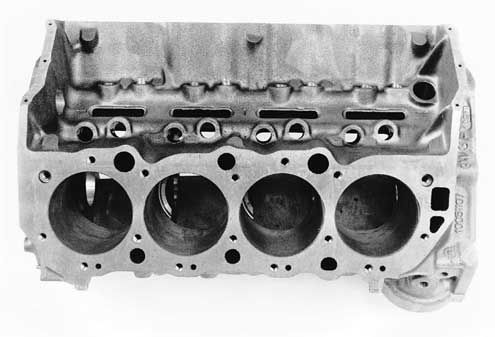

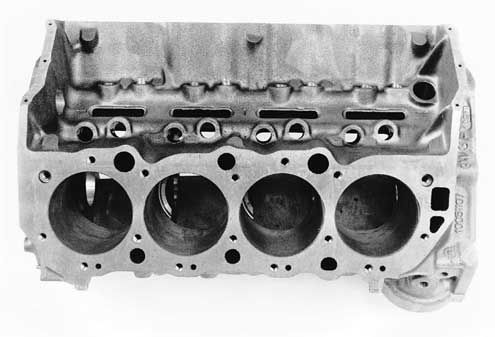

mark iv blocks

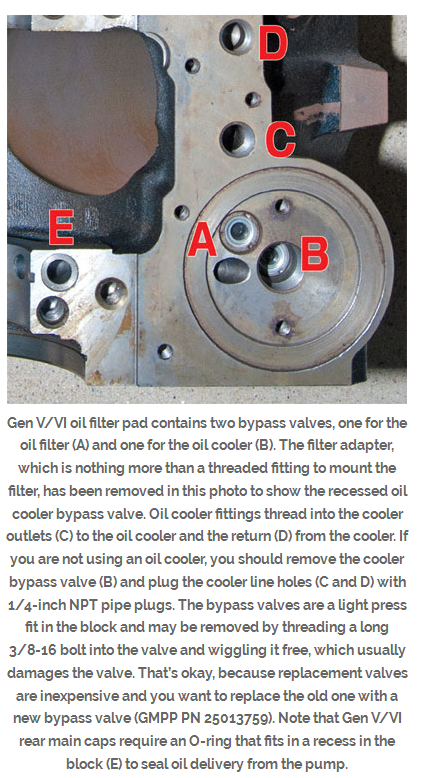

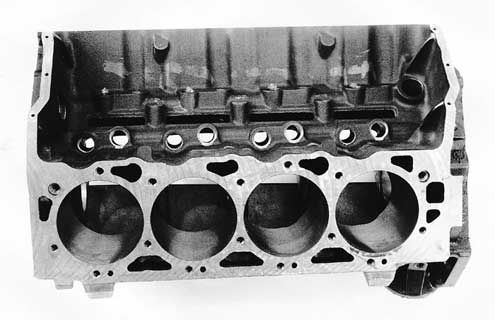

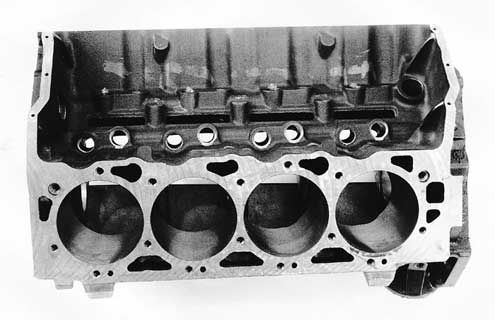

mark v blocks

most BBC oil pumps are designed to fit the early MARK IV series, if you have the later versions there can be clearance issues.

you'll need to know your oil pan depth as the clearance varies

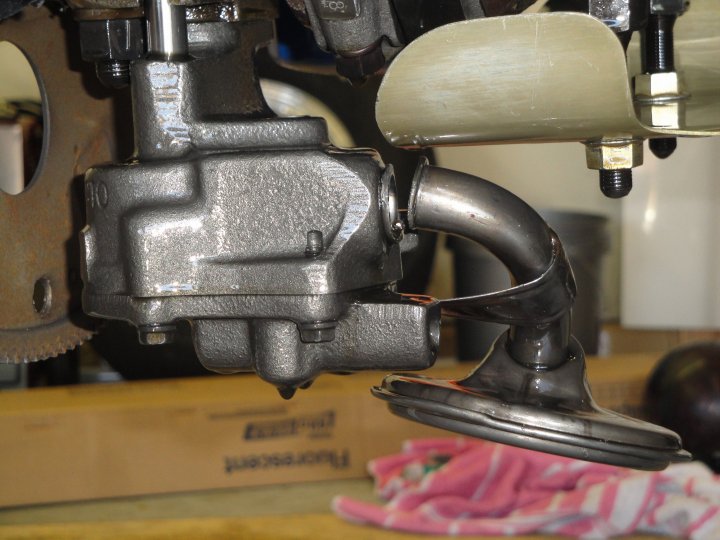

broken , or improperly installed oil pump pick-ups can cause several major oil pressure issues

ITS always a good idea to verify the oil pan floor to oil pump pick-up clearance and to braze the pick-up to the oil pump, to reduce the potential for it to come loose.

yes you can MIG ,TIG or TORCH WELD the pick-up but I found BRAZING works the best and is less likely to warp or crack the pump or pick-up

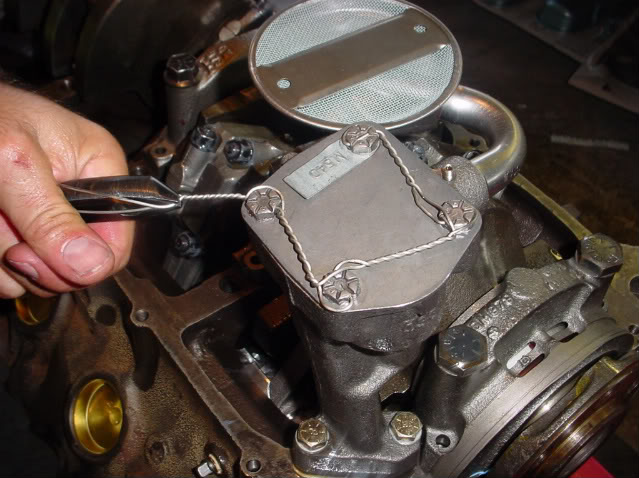

"how in hell do those twisty, safety wire pliers work?"

well a video should be helpful here! Id also point out that you can buy the wire in several diameters and the thicker sizes are far more difficult to use, home depot sells the 22 gauge and 18 gauge, the 22-24 gauge is what youll use far more commonly, as its much easier to use,both stainless (PREFERED) and galvanized are used, and will work on 95% of the applications on a car your likely to use.

using anti-seize paste on bolt or stud threads helps prevent future problems

using safety wire pliers

failure to use the correct oil pump,mounting stud, bolt or nut or

ONE RATHER COMMON MISTAKE IS USING THE WRONG OIL PUMP STUD OR BOLT TO MOUNT ,

THE OIL PUMP AS IF EITHER EXTENDS THRU THE REAR MAIN CAP,

IT CAN AND WILL BIND ON THE BEARING ,

AND LOCK OR RESTRICT, SMOOTH ROTATION

as many of you gentlemen know MELLING CHANGED the casting on their standard M55 high volume oil pumps making them weaker and thinner

but I understand that it caused a good deal of bad press and they are currently changing back to the thicker castings, but theres still thousands of the thin casting pumps in inventory that should not be use in high performance applications

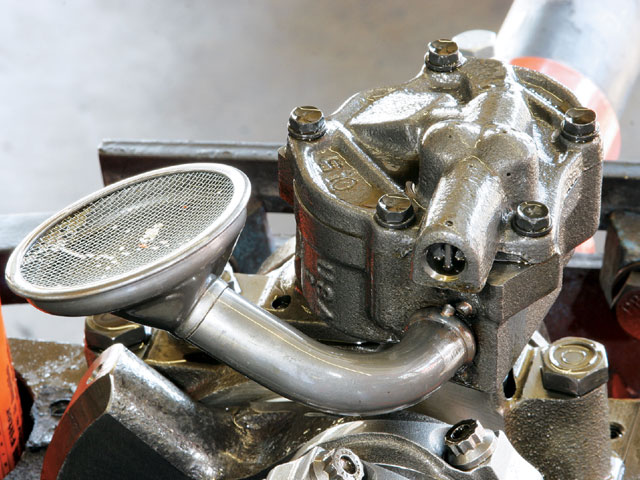

keep in mind the sbc oil pump has 7 tooth gears and the big block pumps have 12 teeth making the oil flow smoother and less pulsed, plus having larger gears they tend to supply more oil at lower rpms

look closely and youll see the big block oil pump has a 5 bolt lower cover and the oil pump pick-up with its 3/4" feed seats into the main pump casting while the small block oil pump has a 4 bolt cover and the sbc oil pump pick-up with its 5/8" feed seats into the pumps cover plate

http://www.mellingselectperformance.com ... -guide.pdf

http://store.summitracing.com/partdetai ... toview=sku

http://store.summitracing.com/partdetai ... toview=sku

I was asked recently, as to my best guess, as to why a recently installed oil pump was making noise,

oil pumps rarely make much noise, unless, the drive shaft driving the oil pump, is rubbing on the block which will happen if you install a standard drive shaft in a 400 type small block which requires the drive shaft with the smaller diameter midsection. (what was going on in this case) Or you forget to install that little metal or nylon collar that keeps it aligned, or if your drive shaft has one the little spring clip, and remember to install the shaft along with the oil pump from below because the collar is designed to be too large to pass thru the block passage above it to insure the drive shaft stays attached to the oil pump. remember if the clearances inside the oil pump are not checked, and is partly binding or in some cases of the oil pump has ingested, some small bits of metal or other foreign material. the pump might be damaged, the standard high-performance oil pump drive shaft looks like the one below ,it has a steel collar and is made from a stronger than normal steel

heres a standard volume BBC oil pump which can be used in a small block high performance application provided its matched to the correct oil pan and oil pump pick-up of course.

REMEMBER once the oil pumps installed on the main cap and the distributors test fitted on the intake manifold there should be about .050=.060 vertical clearance remaining on the oil pump drive shaft between the oil pump and distributor with the distributor firmly seated on the intake manifold and at least .060 in all directions around the oil pump drive shaft, "CHECK THE COLLAR" in rare cases it binds

http://m.summitracing.com/parts/mel-m77

http://m.summitracing.com/parts/mel-77060

chevy oil pump drive shafts come in several lengths and styles and some have metal or nylon collars, you should select the oil pump drive shaft that allows about a .050-.060 thousands clearance between the oil pump and distributor when the distributors seated on the intake manifold

its not uncommon for distributor gears and cam gears to not be perfectly lined up as to depth of the distributor or length of the oil pump drive, theres several different pump drive shaft lengths and spacer shims but in many cases a slip collar on the distributor or modifying the oil pump drive shaft will be required to get perfect alignment

your current distributor can usually be easily modified by a local machine shop with a lathe for an adjustable slip collar by carefully machining off the current one and adding a slip collar, if you need to make distributor gear to cam gear engagement or oil pump drive shaft length changes

http://www.summitracing.com/parts/MOR-26217/?rtype=10

btw this is a good choice as a basic oil pan on a GEN V or GEN VI BBC

Moroso 20411

here more choices

http://www.spiderautomotive.com/oilsystems.html

http://www.spiderautomotive.com/moroso20411.html

Engine Application: Gen V/Gen VI

Fits: Most GM Chassis, including 1965-72 Chevelle, Cutlass, Skylark, Tempest/GTO

Kicked-Out Sump

best used with an oil cooler for more effective volume

Accommodates stock BM main cap mounted windage tray

Removable anti-slosh tray

Trap door baffling for improved oil control

Rear anti-climb baffle

Accepts strokes up to 4.250" with steel rods

Compatible with many starter/flywheel combination's

a high volume pump has slightly longer gears, usually about 10%-20% longer, that build the volume of oil pushed thru the engines oil passages,and engines clearances 10%-20% faster at any given rpm, PRESSURE is a measure of resistance to oil flow thru those clearances, theres a bye-pass circuit in the pump designed to open and limit the pressure at a set pressure level, thats usually 60-65 psi in a high volume pump and at 65-70 psi in a high pressure pump, theres no real disadvantage unless the pumps bye-pass circuit is not functioning correctly and starts to restrict the flow and the pressure builds to higher levels than intended resulting in resistance to the pump which adds drag and eats hp.

theres no lubrication increase past about 55-60 psi of oil flow thru the bearing clearances so the idea is to match the oils viscosity to the engine clearances at the engines operational temperature and to use an oil cooler and the engines oil bye-pass circuit to maintain the pressure and temperature within known, and predicted limits.

generally a high volume oil pump is used in conjunction with a windage screen, crank scraper and high capacity baffled oil pan to control the extra oil flow rates and per mote increase oil cooling and flow control

mark iv blocks

mark v blocks

Last edited by a moderator: