you should very carefully inspect any used rockers or push rods before you use the two, as any previous wear areas will in most cases cause rapid wear on the new component mated to the worn surface, and obviously the rockers must be clearanced correctly and have obvious oil flow from the push rods

its not horsepower, its the stress on the valve train, that makes a rocker stud girdle and its increased rigidity useful,

and thats more closely related to average stress levels, RPM and VALVE SPRING LOAD RATES

any time your occasionally exceeding 6000rpm or getting close too 330 lbs of open valve load rate Id strongly suggest screw in rocker studs

any time your intentionally exceeding 6000rpm and exceeding 350 lbs of open valve spring rate a rocker stud girdle might be a good idea.

and if your regularly exceeding 6500rpm and 400 lbs of open valve spring load rate its use is going to become almost mandatory

http://www.summitracing.com/parts/pro-66950

http://www.summitracing.com/parts/sum-141010

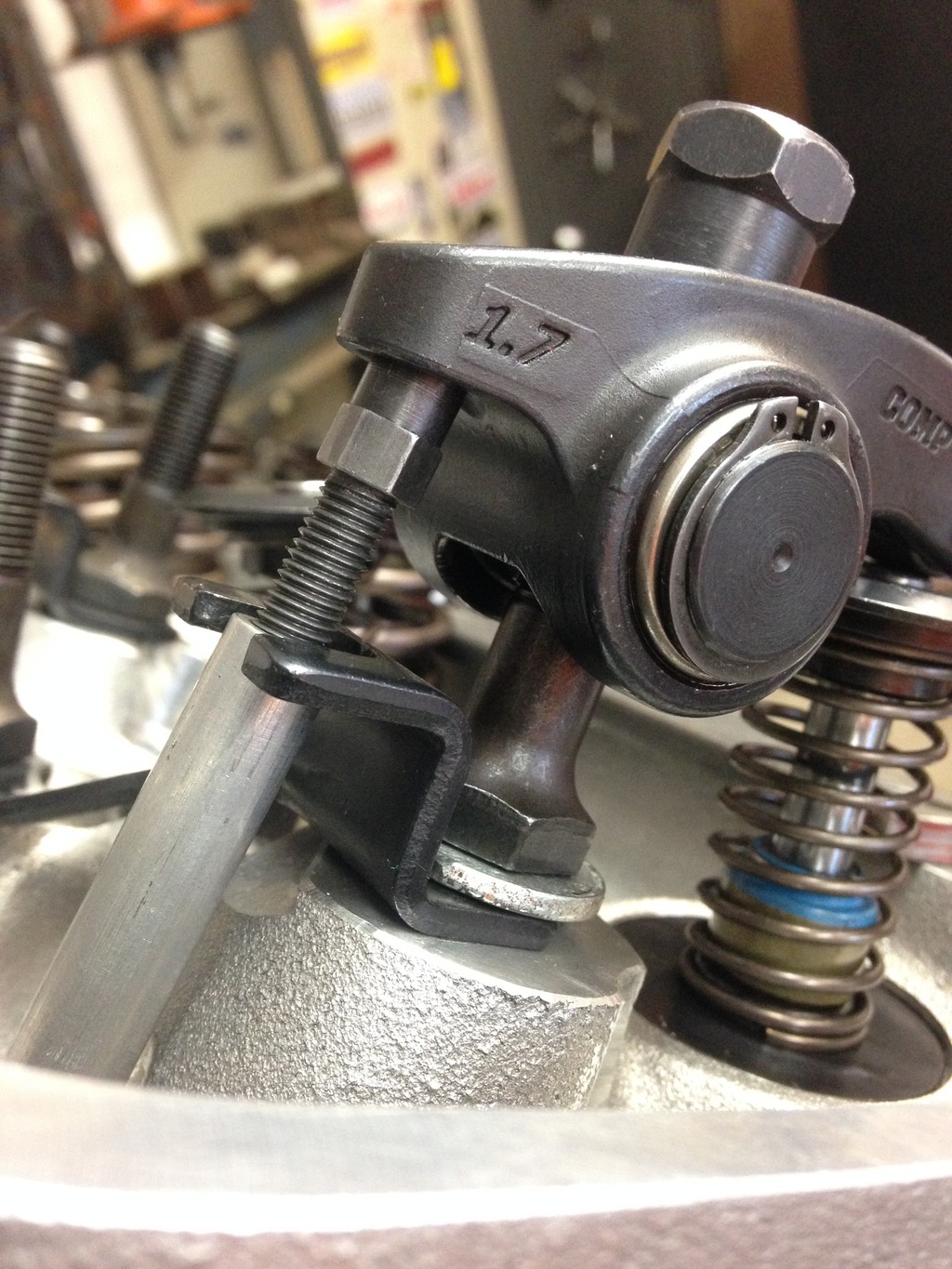

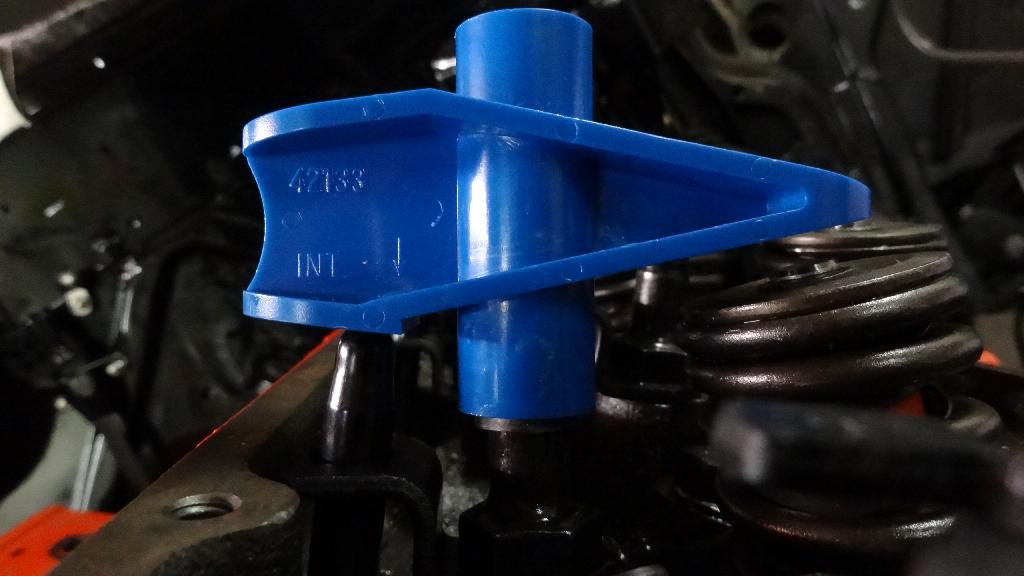

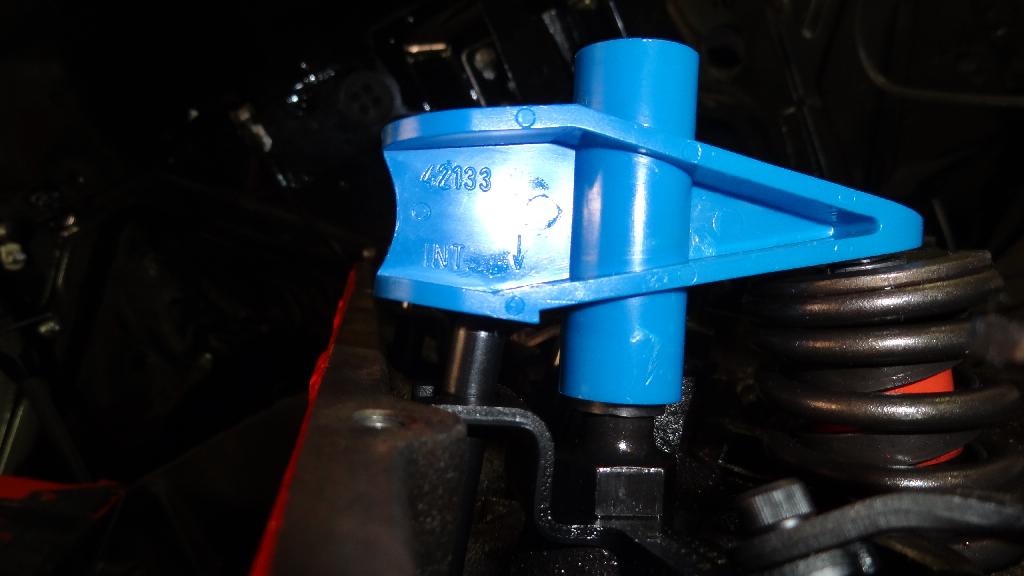

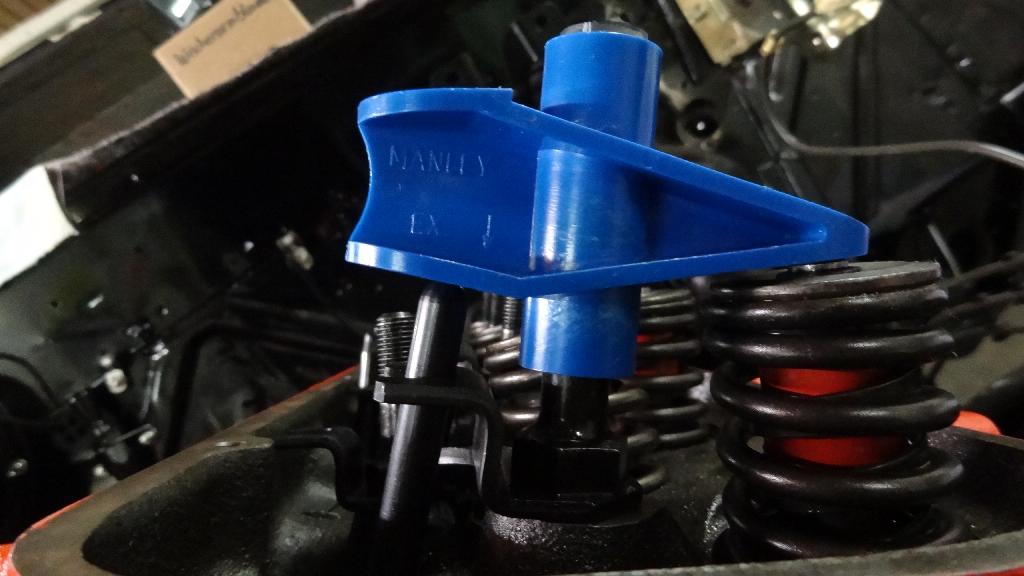

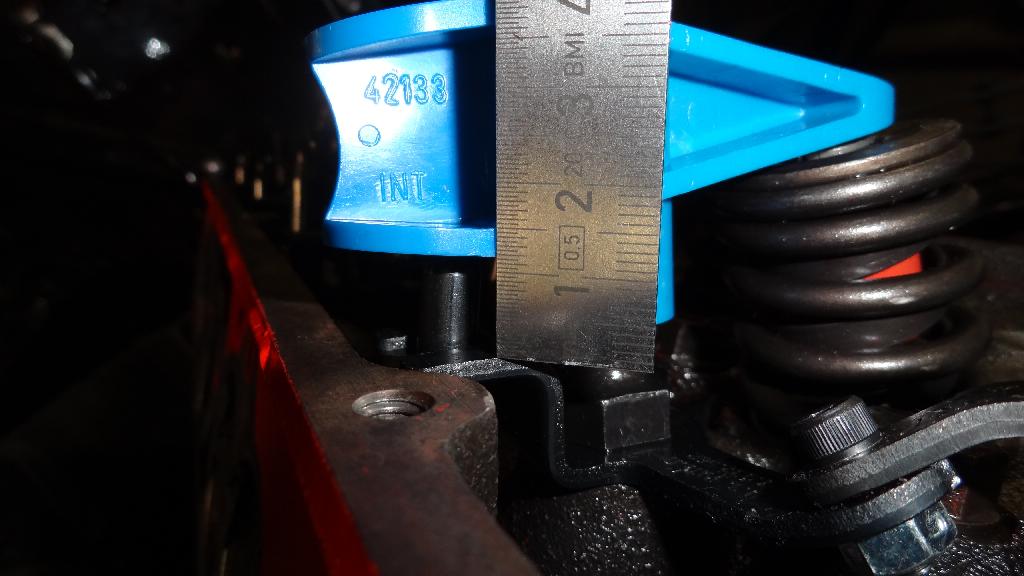

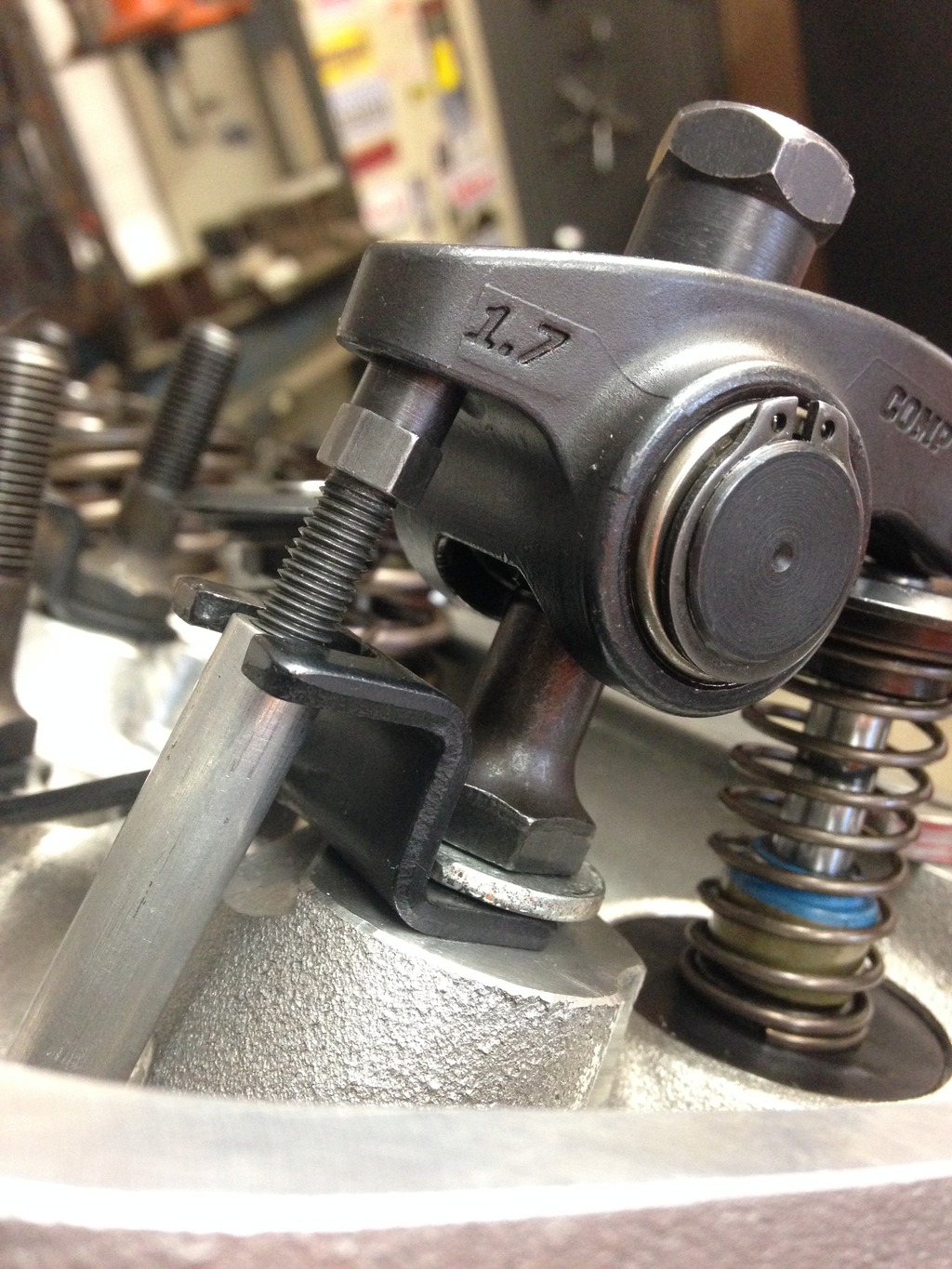

HERES A SBC with a push rod checker installed showing an obviously too long for the application push rod.

http://www.summitracing.com/search/...d-length-checkers?autoview=SKU&ibanner=SREPD5

Proform Pushrod Length Checkers 66789 SBC 3/8" rocker studs

Proform Pushrod Length Checkers 66790 SBC 7/16" rocker studs

Proform Pushrod Length Checkers 66806 BBC 7/16" rocker studs

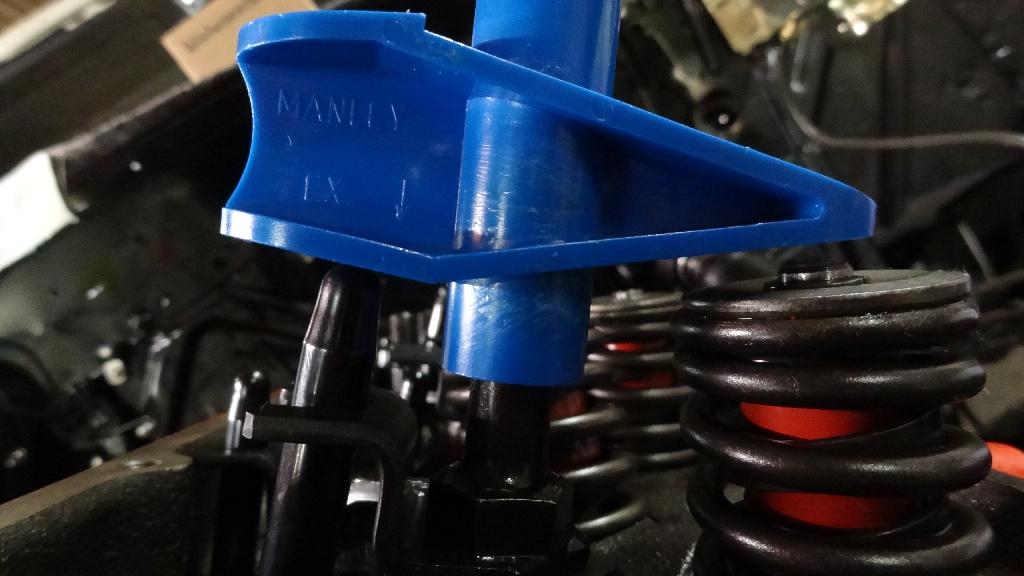

since the early mark IV BIG BLOCK engines use two different length push rods (INTAKE/EXHAUST) the checker is designed to be reversible, and marked to indicate which position it needs to be used with, to indicate the correct length push rods

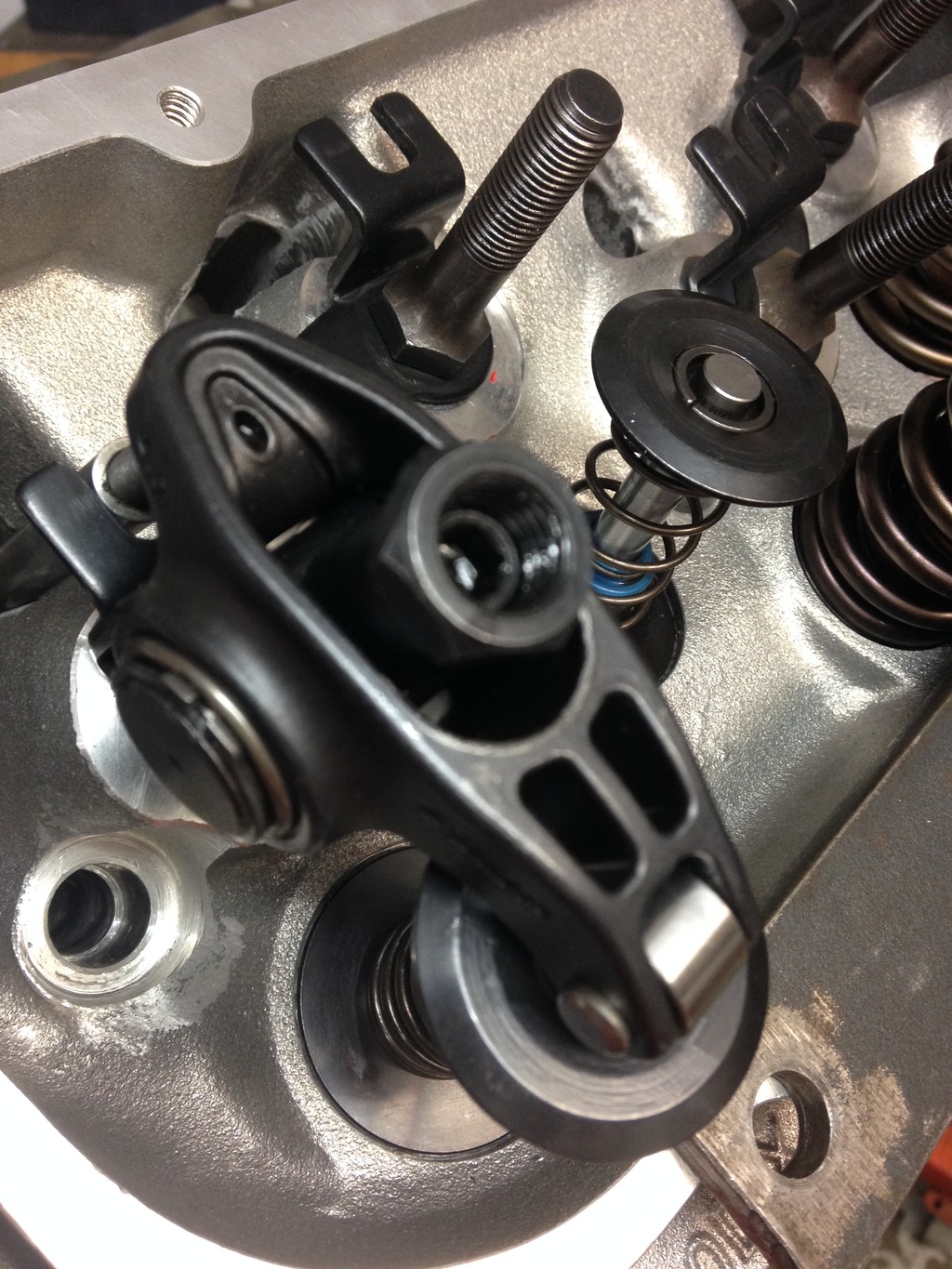

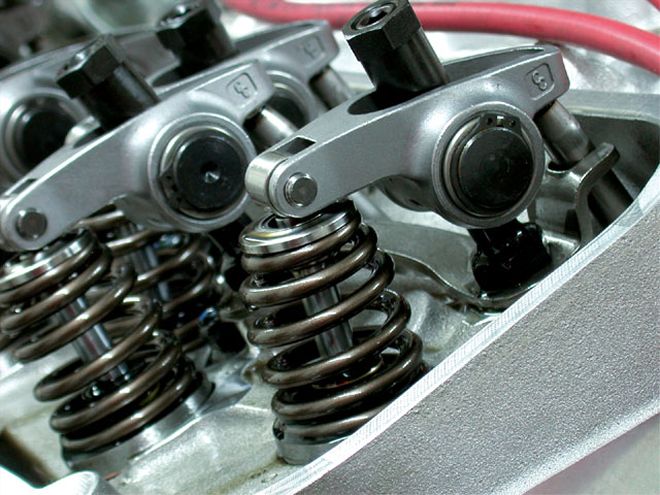

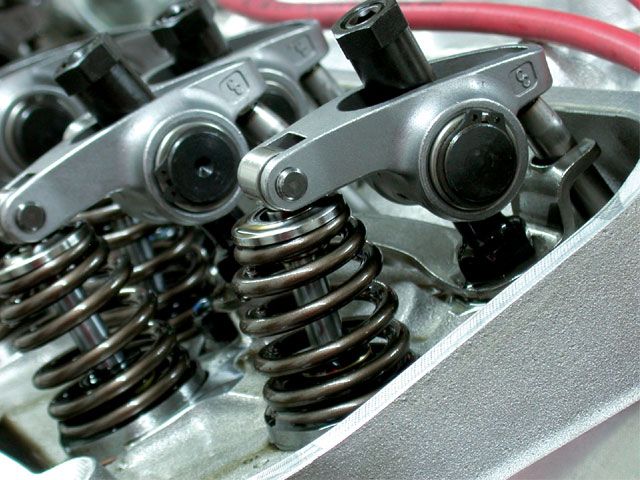

notice in the pictures directly above and below it appears the push rods are a bit too long

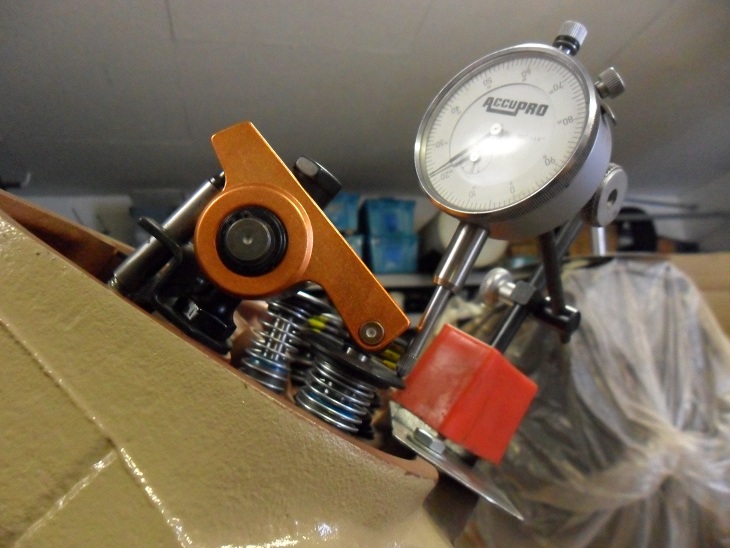

notice in the two pictures above the pushrods are the correct length as the checker sits on both the valve tip and push rod tip

heres a bit of useful related push rod length info

Big Block Chevy, Standard Length Big Block Intake 3/8" / .080" 8.275"

295-7941-8 Big Block Chevy, Standard Length Big Block

Exhaust 3/8" / .080" 9.250"

295-7969-8 Big Block Chevy, Standard Big Block +.100" Long Intake 3/8" / .080" 8.375"

295-7979-8 Big Block Chevy, Standard Big Block +.100" Long Exhaust 3/8" / .080" 9.350"

295-7951-8 Big Block Chevy, Standard Length Big Block Tall Deck Intake 3/8" / .080" 8.675"

295-7961-8 Big Block Chevy, Standard Length Big Block Tall Deck Exhaust 3/8" / .080" 9.650"

295-7800 V8 396-454 Retro Fit Pushrod Set, Intake & Exhaust, 1965-Present

3/8" / .080"

3/8" / .080" 7.725 Int.

8.675 Exh

295-7913-16

Small Block Chevy, Standard Length

Small Block Chevy 3/8" / .080" 7.800"

295-7984-16 Small Block Chevy, +.100" Long 3/8" / .080" 7.900"

295-7934-16 Big Block Ford, Standard Length Ford `72-'78 429-460 3/8" / .080" 8.550"

295-7951-16 Big Block Ford, Standard Length Ford `69-'71 429-460 3/8" / .080" 8.675"

295-7582-16 Oldsmobile, Std Length 455 5/16" 9.550"

obviously the push rods must be long enough to clear the push rod guide plates rockers through the full arc of movement and not bind on the springs retainers or rocker stud at full lift or while the lifters seated

push rods should also not rub on the guide plates at any point in the arc as it moves the valve from seated to full lift and back too seated

http://garage.grumpysperformance.com/index.php?threads/valve-train-clearances-and-problems.528/

http://garage.grumpysperformance.com/index.php?threads/rocker-push-rod-wear-issues.9815/#post-54232

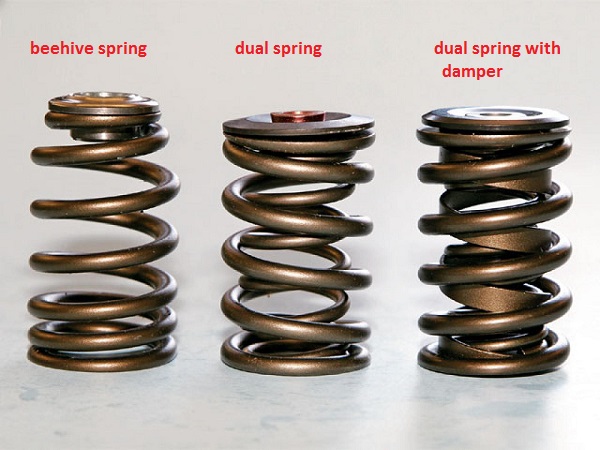

some roller rocker too retainer combo clearance issues cause problems easily solved with beehive springs and smaller retainer diameters

the reduced diameter of beehive valve springs usually eliminates the rocker too retainer clearance issue

BEEHIVE SPRINGS GIVE A GOOD DEAL MORE ROCKER TO RETAINER CLEARANCE

http://www.kmotion.biz/instht.htm

http://garage.grumpysperformance.co...swap-in-1-6-1-ratio-rockers.10671/#post-46039

http://garage.grumpysperformance.com/index.php?threads/checking-piston-to-valve-clearances.399/

DON"T FORGET TO VERIFY SPRING BIND CLEARANCE AND PISTON TO VALVE CLEARANCE ETC>

youll need these also

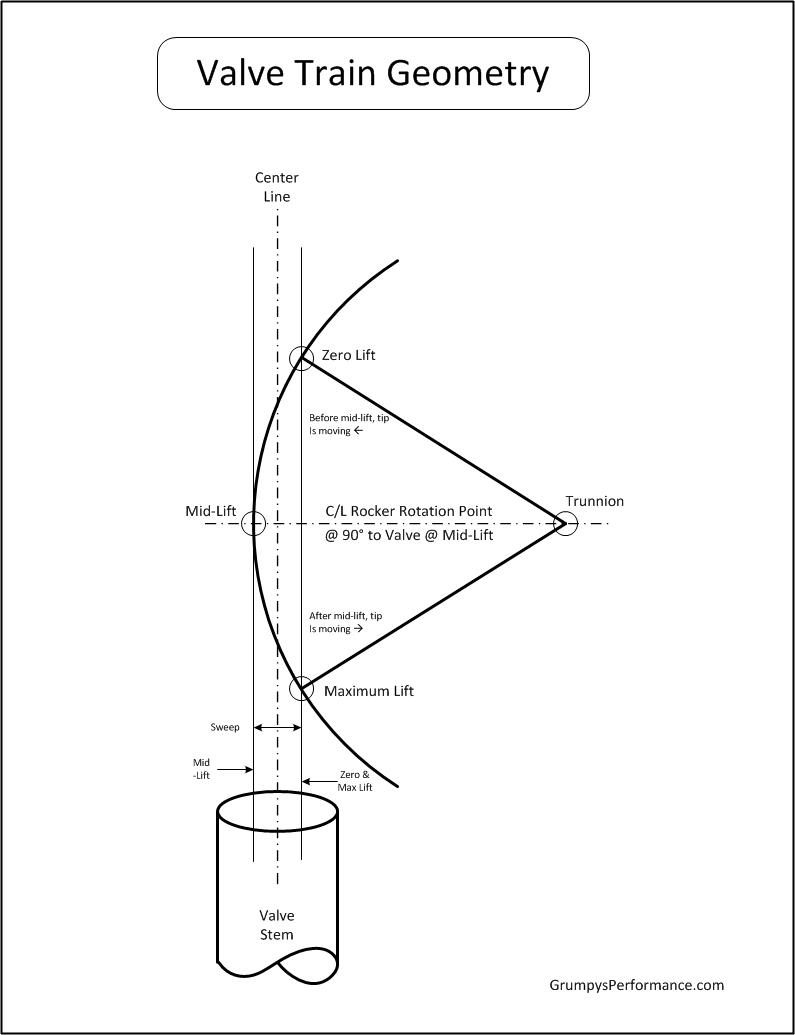

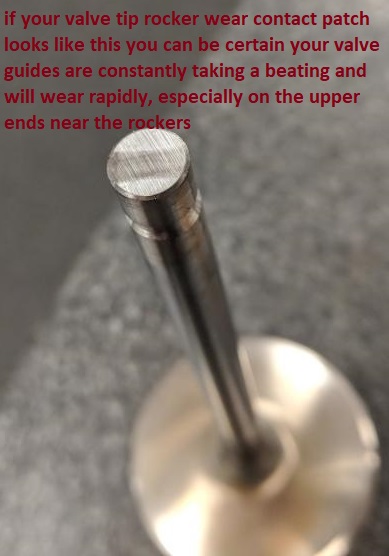

in an ideal valve train geometry set-up the sweep mark on the valve tip will be very narrow and close to the valve center-line , but having the sweep mark narrow is more important than keeping it centered on the valve stem tip, the valve train does not like lateral or side ways loads on the valves and the wider sweep is an indicator of that issue, while a correctly set up valve train may have components that result in the valve tip sweep mark being slightly off the valve center-line this is not a major concern.

Its checking and verifying the valve train clearances and basic geometry that should be your major concern

the clearances and rocker geometry (push rod length,spring bind rocker to rocker stud clearance, etc.) must be checked carefully prior to starting the engine

http://www.summitracing.com/search/...d-length-checkers?autoview=SKU&ibanner=SREPD5

Proform Pushrod Length Checkers 66789 SBC 3/8" rocker studs

Proform Pushrod Length Checkers 66790 SBC 7/16" rocker studs

Proform Pushrod Length Checkers 66806 BBC 7/16" rocker studs

"THAT PLASTIC THING" is a PUSH ROD LENGTH CHECKER, THE PUSH ROD LENGTH CHECKING, AND ROCKER GEOMETRY TOOL, ARE ENGINE SPECIFIC, so you MUST USE ONE DESIGNED FOR THE SAME STUD DIAM. SPECIFICALLY FOR YOUR SPECIFIC ENGINE, to find the correct rocker geometry and push rod length. If you for example use one designed for 7/16" studs on a SBC and used it on a BBC with 7/16" rocker studs the result would not be close to correct, if the tool designed for one engine is used on the wrong engine, so be damn sure you use the correct tool.

look through this thread

http://garage.grumpysperformance.com/index.php?threads/two-loose-valve-locks.9687/#post-47884

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/