Ive never understood why many guys turn up there nose at building a 396 based BIG BLOCK for a hot street car engine combo,and then build a 383 SMALL BLOCK and think they made the correct choice, the far stronger components, and in many cases the better flowing heads provide the basic 396 BBC with a distinct power advantage or at lease the potential to produce superior power, especially if your limiting your choices to mostly low buck$ O.E.M. components

most street cars with the 450-500hp a 396 can easily produce are more than competitive.

the basic 396-402 big block block engines have been mostly over looked in the rush to get the larger bore size blocks from the 427-454-502 engines so prices have not risen nearly as fast due to far lower demand.

finding a complete 396 will generally take less effort and cost less than a 454-502 because of that lower demand, but that doesn,t indicate the 396-402-434BBC combos can,t produce impressive horsepower levels if the correct parts are selected.

ive generally found a moderate flat tappet solid lifter cam can be used to produce impressive power gains at minimal cost.

If your going to build a 396 based street performance engine you've got many options,youll generally want a set of decent flowing oval port heads a matching oval port intake and a cam, and matching compression level that will unlock the engines full potential

Ive generally found trying to base the basic build on a 9.7:1-10.7:1 compression level and a cam with a 236-245 duration @.050 lift on a fairly tight LSA of 108-110 with a 750-850cfm carb and a 3.54-4.11:1 rear gear in the drive train, and decent headers, produces good results.

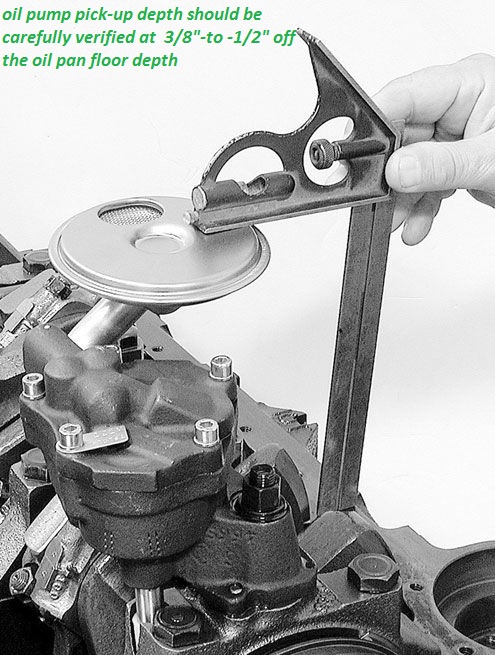

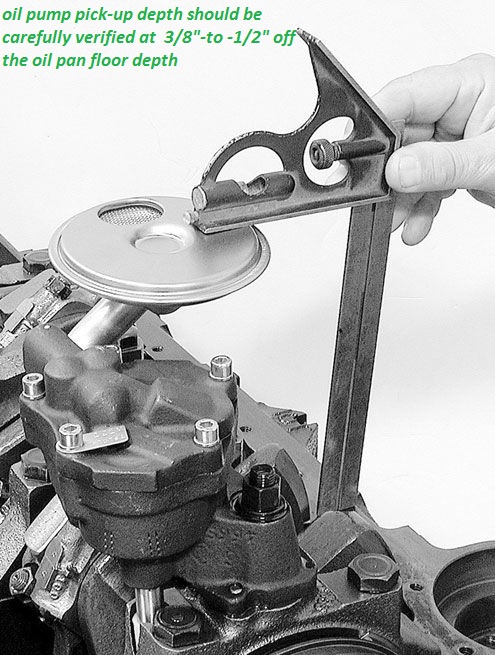

yes Ive seen several cases where guys failed to install the oil pump pick-up at the proper minimum 3/8"-to-1/2" off the oil pan floor clearance,

the result is the pump is starved for oil intake flow.

almost every mechanics tool box needs a few basic measuring tools and supplies

https://www.amazon.com/Claytoon-Set...d=1466872286&sr=8-17&keywords=plastilina+clay

https://www.amazon.com/Claytoon-Set...d=1466872286&sr=8-17&keywords=plastilina+clay

http://www.utrechtart.com/Plastalin...currency=USD&gclid=CN3G75zOw80CFQgaaQodKbgFjA

http://garage.grumpysperformance.co...m-sure-your-convinced-its-the-oil-pump.11085/

http://garage.grumpysperformance.co...m-oil-pump-installed-now-no-oil-pressure.525/

http://garage.grumpysperformance.com/index.php?threads/bbc-oil-pump-in-a-sbc.2598/

EXAMPLE

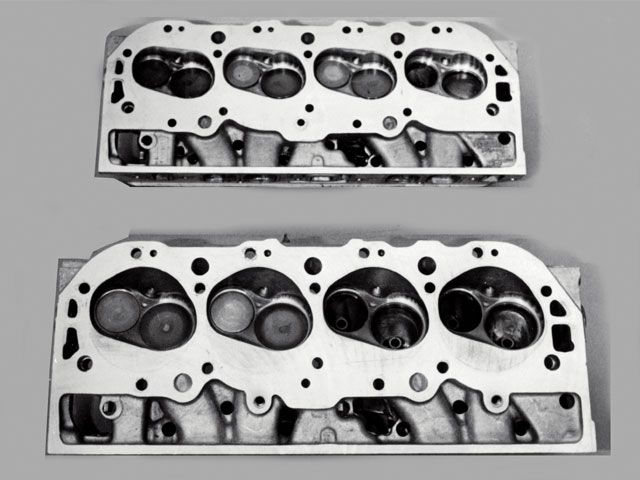

heads like this set below are great but cost a bit more than most of us can afford

http://www.summitracing.com/parts/AFR-3620/

but even PEANUT PORT oval port heads with minor port and bowl work clean ups can significantly out flow the well respected SBC VORTEC HEADS, and a good set of carefully reworked O.E.M. iron oval port heads can flow over 300cfm, and decent headers,besting most aftermarket SBC heads

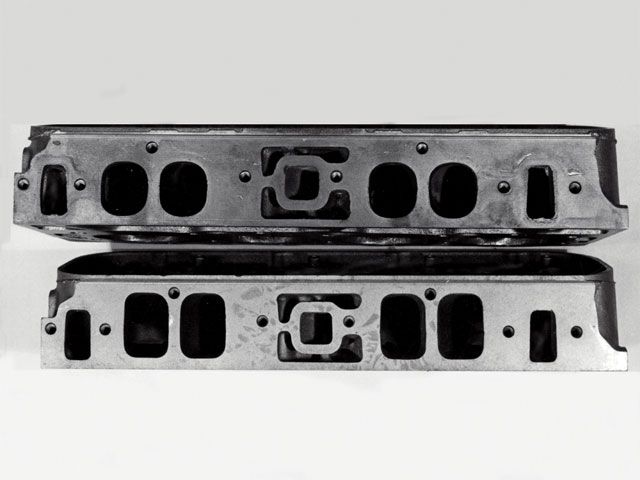

these intakes usually give very good results

http://www.summitracing.com/parts/EDL-7561/

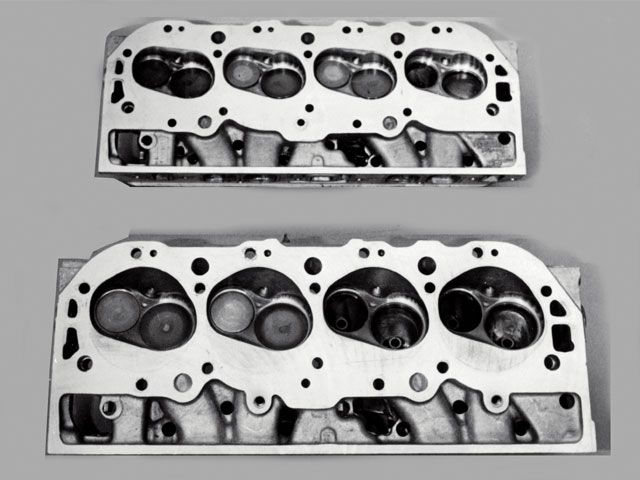

closed chamber on top open on the bottom

oval port on top/ rectangle port on the bottom

a cam like this, crane cam below in a 10.5:1 cpr 396-434 bbc, matched to a manual transmission, or a 2500 stall converter and a 3.73-4.11:1 rear gear and decent headers,will usually make a nice street combo

http://www.cranecams.com/product/cart.p ... il&p=24435

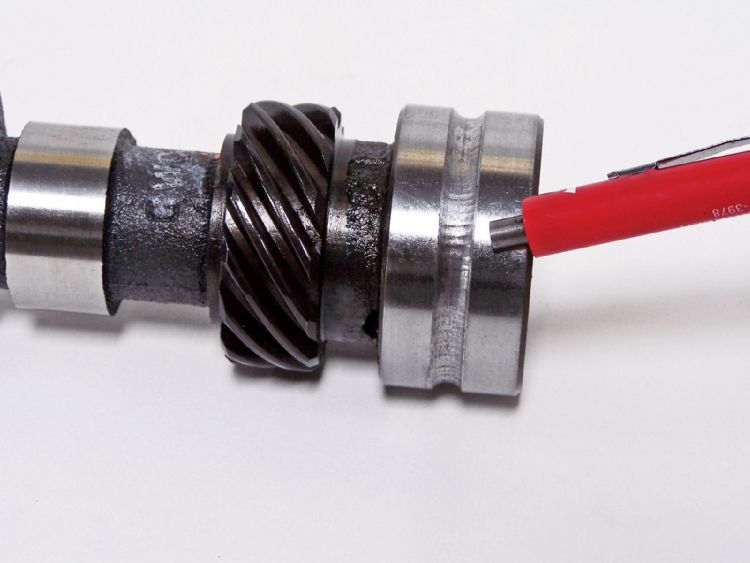

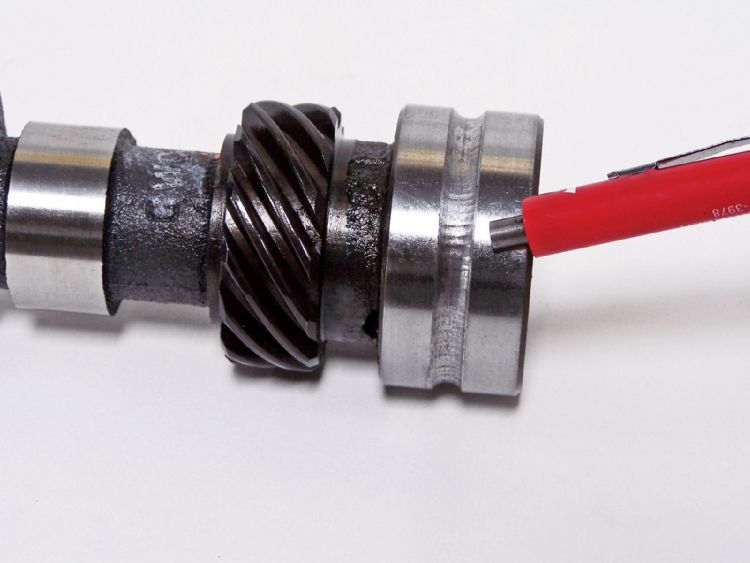

btw if your dealing with a 1965-66 big block 396 make sure what year the block is from,

what year was the engine block and cam bearings, are is important because

on the 396, early 65-66 396 engines REQUIRED a GROOVED REAR CAM JOURNAL AND CAM, or they starved for upper engine oil flow, if you installed a standard bbc cam or standard cam bearings your screwed

viewtopic.php?f=54&t=2600&p=6732&hilit=+bearing+rear+groove#p6732

read thru these links

http://www.speedomotive.com/ps-75-7-che ... r-kit.aspx

http://www.carcraft.com/techarticles/cc ... index.html

http://www.classictrucks.com/tech/0605c ... index.html

http://www.superchevy.com/technical/eng ... index.html

http://maliburacing.com/patrick_budd_article.htm

viewtopic.php?f=52&t=3960

http://www.youtube.com/watch?v=dMBK5Ksa ... re=related

viewtopic.php?f=69&t=2165

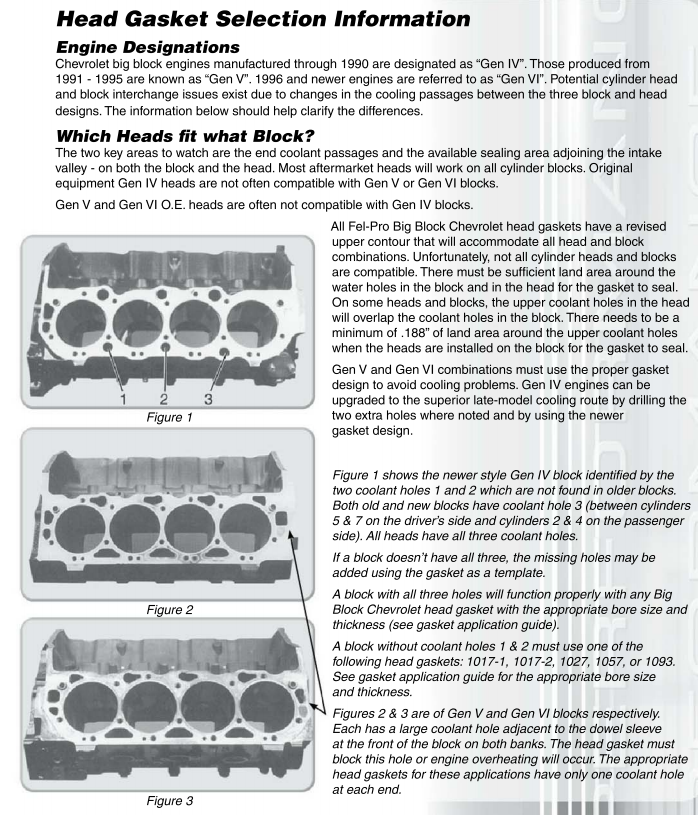

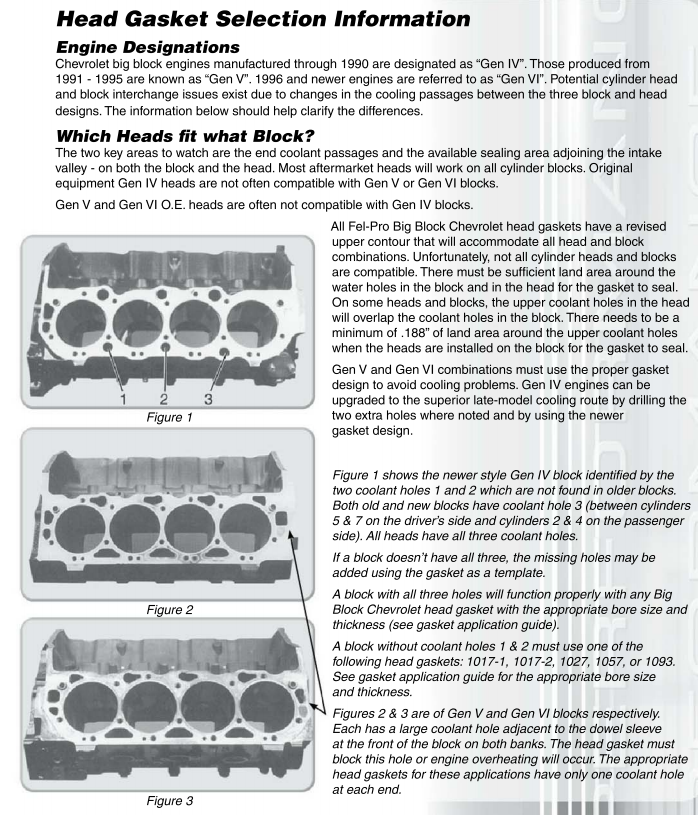

I think it is 80 & up mark IV big block engines that has the later improved cooling with the three extra holes.

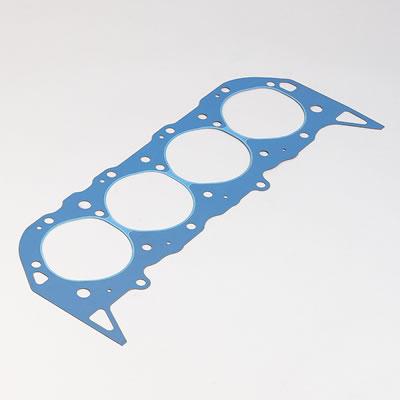

(look at the gasket info below)

ITS Real easy to drill the holes in the earlier blocks if you don,t have then with a 3/8" drill , using the gasket as a pattern as it was found to increase cooling.

BTW fritz1990 posted this info

Top gasket pic is one with the extra cooling holes. Can use this gasket as a template to drill these 1/2" holes in the deck of the block. All heads already have these holes just some blocks don't.

The holes are the three on the bottom side of the gasket right below the ones between the cyls. The ends of the gasket are also different.

Just don't use the top gasket on your block without drilling the holes. I have to run to work and I can explain the difference later. The top setup is suppose to give you a lil' better cooling but there are many like yours running around, not a real big issue, just better to do it now.

If you have the three holes in the block you can run either gasket.

There are gaskets made specifically for this swap. Use other gaskets at you're own risk- these are what you want (from a V/R press release, presumably prior to the Gen 6 engine release):

General Motors 7.4L Head Gasket

Issue:

General Motors (GM) 7.4L (454 CID) engines use two types of engine blocks: the Mark IV and Mark V. The Mark IV is found on 7.4L engines in model years from 1965 to 1990, and the Mark V is found on 7.4L engines in model years from 1991 and newer.

Often, installers will attempt to adapt a Mark IVcylinder head for a Mark V block. This conversion can be made if attention is paid to the coolant circulation. Mark IV and Mark V have different coolant flows and were originally designed for different head gaskets. If the conversion is not performed correctly, the engine will overheat, causing premature engine wear and damage.

Resolution:

Victor Reinz has designed two Nitroseal® head gaskets to specifically allow for this conversion. The installation requires Victor Reinz part number 4918 be installed on the right cylinder bank to maintain proper coolant circulation, and part number 4923 to be installed on the left cylinder bank for the correct coolant flow.

Application:

Victor Reinz part numbers 4918(right bank) and 4923 (left bank) are available for GM 7.4L (454 CID)

engines.

The bottom gasket is the one you will need to use if you don't drill the holes.

be aware that head bolts enter the block coolant passages,

so if you failed to dip the bolt threads in sealant when they were assembled,

through the heads coolant can seep up along the head bolts,

into the area under the valve cover

btw read this

both of these work great at sealing head bolt threads, and freeze plugs etc.

BBC HEAD GASKETS READ THIS LINK

http://www.cartechbooks.com/vstore/show ... apter=7174

Three types of gasket materials are generally available, steel shim, composition and copper gaskets. Cast iron heads can use all three types of gasket materials. Aluminum cylinder heads require the use of composition or copper gaskets. Various compressed gasket thicknesses are offered. Remember that you should have a minimum clearance of .035"-.040" between the top of the piston deck and the deck of the cylinder head when using steel rods. Aluminum connecting rods typically require a larger clearance.

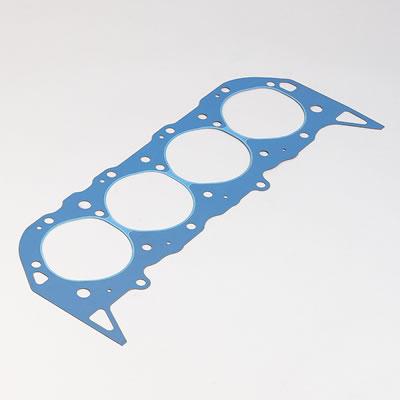

Fel-Pro composition head gasket (PN-8180-PT) for 4.250" bore Mark IV engines. It has two additional holes for head bolts that go into the lifter valley found on some high performance Bowtie and aftermarket blocks.

Different head gasket bore sizes are offered. Mark IV head gaskets have different coolant core hole passages than gaskets for Gen.V engines, blocking some passages and opening other coolant passages. Some block deck coolant core holes are round, while on Gen.V production blocks the holes are irregularly shaped on the block deck. Mark IV heads and head gaskets should be used on Mark IV blocks. Likewise Gen.V style cylinder heads and gaskets should be used on Gen.V blocks. There are exceptions. Mark IV heads can be used on Gen.V "Bowtie" and on Gen.VI HO blocks because the core holes in these block decks will seal the water core holes found on Mark IV heads. If you build this combination then use a Mark IV style head gasket and plug the core hole in the Gen.V "Bowtie" block deck located near the front head dowel pin location (see photo). Otherwise coolant entering the front of the block can bypass the rest of the block and exit out thru the head and intake manifold.

Steel shim gaskets and copper gaskets require the use of head gasket sealant. Composition gaskets do not require sealant.

Head bolts should be completely cleaned and then torqued down in the proper sequence and to the correct torque values. Head bolts or studs, used on aluminum heads, need to have a hardened steel flat washer (PN-3899696) under each bolt head or nut, to prevent damage to the aluminum head surface. Head bolt threads going into water passages should be coated with sealant and head bolts going into blocks with "blind" holes should be coated with moly lube or oil. Some head gaskets do not need retorquing, but it is a good practice to retorque all of the head bolts after the motor has been heated up the first time and allowed to cool down. Remember, do not try to put Mark IV heads on a production Gen.V block and visa versa. You can use Mark IV heads on the new Gen.VI 454 and 502 HO blocks or on "Bowtie" blocks.

most street cars with the 450-500hp a 396 can easily produce are more than competitive.

the basic 396-402 big block block engines have been mostly over looked in the rush to get the larger bore size blocks from the 427-454-502 engines so prices have not risen nearly as fast due to far lower demand.

finding a complete 396 will generally take less effort and cost less than a 454-502 because of that lower demand, but that doesn,t indicate the 396-402-434BBC combos can,t produce impressive horsepower levels if the correct parts are selected.

ive generally found a moderate flat tappet solid lifter cam can be used to produce impressive power gains at minimal cost.

If your going to build a 396 based street performance engine you've got many options,youll generally want a set of decent flowing oval port heads a matching oval port intake and a cam, and matching compression level that will unlock the engines full potential

Ive generally found trying to base the basic build on a 9.7:1-10.7:1 compression level and a cam with a 236-245 duration @.050 lift on a fairly tight LSA of 108-110 with a 750-850cfm carb and a 3.54-4.11:1 rear gear in the drive train, and decent headers, produces good results.

yes Ive seen several cases where guys failed to install the oil pump pick-up at the proper minimum 3/8"-to-1/2" off the oil pan floor clearance,

the result is the pump is starved for oil intake flow.

almost every mechanics tool box needs a few basic measuring tools and supplies

http://www.utrechtart.com/Plastalin...currency=USD&gclid=CN3G75zOw80CFQgaaQodKbgFjA

http://garage.grumpysperformance.co...m-sure-your-convinced-its-the-oil-pump.11085/

http://garage.grumpysperformance.co...m-oil-pump-installed-now-no-oil-pressure.525/

http://garage.grumpysperformance.com/index.php?threads/bbc-oil-pump-in-a-sbc.2598/

EXAMPLE

heads like this set below are great but cost a bit more than most of us can afford

http://www.summitracing.com/parts/AFR-3620/

but even PEANUT PORT oval port heads with minor port and bowl work clean ups can significantly out flow the well respected SBC VORTEC HEADS, and a good set of carefully reworked O.E.M. iron oval port heads can flow over 300cfm, and decent headers,besting most aftermarket SBC heads

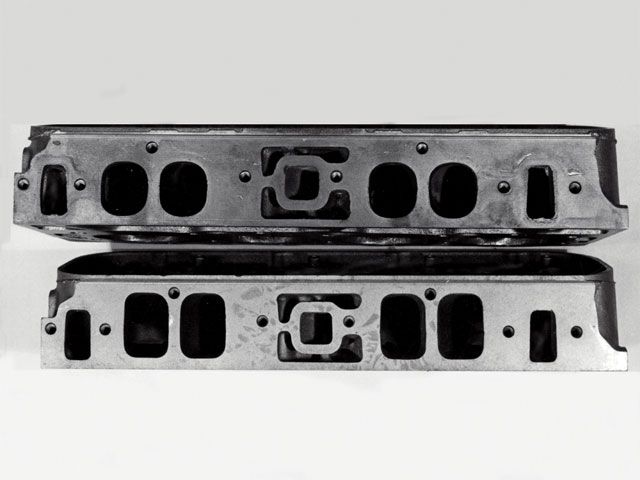

these intakes usually give very good results

http://www.summitracing.com/parts/EDL-7561/

closed chamber on top open on the bottom

oval port on top/ rectangle port on the bottom

a cam like this, crane cam below in a 10.5:1 cpr 396-434 bbc, matched to a manual transmission, or a 2500 stall converter and a 3.73-4.11:1 rear gear and decent headers,will usually make a nice street combo

http://www.cranecams.com/product/cart.p ... il&p=24435

btw if your dealing with a 1965-66 big block 396 make sure what year the block is from,

what year was the engine block and cam bearings, are is important because

on the 396, early 65-66 396 engines REQUIRED a GROOVED REAR CAM JOURNAL AND CAM, or they starved for upper engine oil flow, if you installed a standard bbc cam or standard cam bearings your screwed

viewtopic.php?f=54&t=2600&p=6732&hilit=+bearing+rear+groove#p6732

read thru these links

http://www.speedomotive.com/ps-75-7-che ... r-kit.aspx

http://www.carcraft.com/techarticles/cc ... index.html

http://www.classictrucks.com/tech/0605c ... index.html

http://www.superchevy.com/technical/eng ... index.html

http://maliburacing.com/patrick_budd_article.htm

viewtopic.php?f=52&t=3960

http://www.youtube.com/watch?v=dMBK5Ksa ... re=related

viewtopic.php?f=69&t=2165

I think it is 80 & up mark IV big block engines that has the later improved cooling with the three extra holes.

(look at the gasket info below)

ITS Real easy to drill the holes in the earlier blocks if you don,t have then with a 3/8" drill , using the gasket as a pattern as it was found to increase cooling.

BTW fritz1990 posted this info

Top gasket pic is one with the extra cooling holes. Can use this gasket as a template to drill these 1/2" holes in the deck of the block. All heads already have these holes just some blocks don't.

The holes are the three on the bottom side of the gasket right below the ones between the cyls. The ends of the gasket are also different.

Just don't use the top gasket on your block without drilling the holes. I have to run to work and I can explain the difference later. The top setup is suppose to give you a lil' better cooling but there are many like yours running around, not a real big issue, just better to do it now.

If you have the three holes in the block you can run either gasket.

There are gaskets made specifically for this swap. Use other gaskets at you're own risk- these are what you want (from a V/R press release, presumably prior to the Gen 6 engine release):

General Motors 7.4L Head Gasket

Issue:

General Motors (GM) 7.4L (454 CID) engines use two types of engine blocks: the Mark IV and Mark V. The Mark IV is found on 7.4L engines in model years from 1965 to 1990, and the Mark V is found on 7.4L engines in model years from 1991 and newer.

Often, installers will attempt to adapt a Mark IVcylinder head for a Mark V block. This conversion can be made if attention is paid to the coolant circulation. Mark IV and Mark V have different coolant flows and were originally designed for different head gaskets. If the conversion is not performed correctly, the engine will overheat, causing premature engine wear and damage.

Resolution:

Victor Reinz has designed two Nitroseal® head gaskets to specifically allow for this conversion. The installation requires Victor Reinz part number 4918 be installed on the right cylinder bank to maintain proper coolant circulation, and part number 4923 to be installed on the left cylinder bank for the correct coolant flow.

Application:

Victor Reinz part numbers 4918(right bank) and 4923 (left bank) are available for GM 7.4L (454 CID)

engines.

The bottom gasket is the one you will need to use if you don't drill the holes.

be aware that head bolts enter the block coolant passages,

so if you failed to dip the bolt threads in sealant when they were assembled,

through the heads coolant can seep up along the head bolts,

into the area under the valve cover

btw read this

both of these work great at sealing head bolt threads, and freeze plugs etc.

BBC HEAD GASKETS READ THIS LINK

http://www.cartechbooks.com/vstore/show ... apter=7174

Three types of gasket materials are generally available, steel shim, composition and copper gaskets. Cast iron heads can use all three types of gasket materials. Aluminum cylinder heads require the use of composition or copper gaskets. Various compressed gasket thicknesses are offered. Remember that you should have a minimum clearance of .035"-.040" between the top of the piston deck and the deck of the cylinder head when using steel rods. Aluminum connecting rods typically require a larger clearance.

Fel-Pro composition head gasket (PN-8180-PT) for 4.250" bore Mark IV engines. It has two additional holes for head bolts that go into the lifter valley found on some high performance Bowtie and aftermarket blocks.

Different head gasket bore sizes are offered. Mark IV head gaskets have different coolant core hole passages than gaskets for Gen.V engines, blocking some passages and opening other coolant passages. Some block deck coolant core holes are round, while on Gen.V production blocks the holes are irregularly shaped on the block deck. Mark IV heads and head gaskets should be used on Mark IV blocks. Likewise Gen.V style cylinder heads and gaskets should be used on Gen.V blocks. There are exceptions. Mark IV heads can be used on Gen.V "Bowtie" and on Gen.VI HO blocks because the core holes in these block decks will seal the water core holes found on Mark IV heads. If you build this combination then use a Mark IV style head gasket and plug the core hole in the Gen.V "Bowtie" block deck located near the front head dowel pin location (see photo). Otherwise coolant entering the front of the block can bypass the rest of the block and exit out thru the head and intake manifold.

Steel shim gaskets and copper gaskets require the use of head gasket sealant. Composition gaskets do not require sealant.

Head bolts should be completely cleaned and then torqued down in the proper sequence and to the correct torque values. Head bolts or studs, used on aluminum heads, need to have a hardened steel flat washer (PN-3899696) under each bolt head or nut, to prevent damage to the aluminum head surface. Head bolt threads going into water passages should be coated with sealant and head bolts going into blocks with "blind" holes should be coated with moly lube or oil. Some head gaskets do not need retorquing, but it is a good practice to retorque all of the head bolts after the motor has been heated up the first time and allowed to cool down. Remember, do not try to put Mark IV heads on a production Gen.V block and visa versa. You can use Mark IV heads on the new Gen.VI 454 and 502 HO blocks or on "Bowtie" blocks.

Last edited by a moderator: