if theres one subject that won,t die, its the constant need for guys to discuss and ask questions,

concerning how to build a lower cost SBC engine.

Ill save you a a great deal of time and effort ,

the KEYS to performance are, AND ROUGHLY IN THIS ORDER

GOOD HEAD FLOW

HIGHER COMPRESSION

CAM TIMING

MATCHING THE DRIVE TRAIN GEARING TO THE POWER BAND

LOW RESTRICTION EXHAUST

HEADERS WITH EXCEPTIONAL CYLINDER SCAVENGING

but all component selections will effect the eventually results

all selections enhance or restrict other parts and power production.

your eventually going to see articles promoting the idea that too large a intake port volume hurts torque,

in most cases the person has mis-matched parts, higher flow and larger ports,

higher flow and larger ports,

when correctly matched to the correct cam timing, higher compression, and lower restriction exhaust,

and correctly matched drive train gearing, and correct converter stall speeds,

almost universally increases power in the use able performance power band.

If you match larger high flow ports to any intake that flows less than the heads,

youve significantly reduced power potential

if you have a cam that will not provide the lift and duration to maximize head flow in the intended rpm band,

youve significantly reduced power potential

think through the selection of the engine block and rotating assembly, those parts are critical to durability

failure in selecting components that easily exceed the stress the parts will be subjected too, is always a mistake

youve significantly reduced power potential

match the valve train components, you select too the intended rpm and head flow and cam timing,failure to maintain control over the valve train at peak rpms is always a quick route to expensive problems.

youve significantly reduced power potential

if the cars drive train gearing or converter stall speed or transmission shift points, are not matched to the engines power band,

youve significantly reduced power potential

if the exhaust and headers are not designed to maximize cylinder scavenging in the entire intended power band,

youve significantly reduced power potential

take the time to think through the engines lubrication and cooling requirements

failure to maintain a significant flow of un-interrupted pressurized oil flowing too the moving components , or failure to cool the oil or coolant,

is always a very expensive route to major component failures,

youve significantly reduced power potential

if your installing your small displacement engine in a very heavy car or the transmission shifts well below the max usable, and designed power peak,

youve significantly reduced power potential

think about your ignition, components, and providing accurate ignition timing, the stock ignition was never designed to provide the spark energy or amps required for true performance applications, especially at higher rpms and cylinder pressure levels.

youve significantly reduced power potential

time spent in careful research well before you start a project,

can save you thousands of dollars and months of problems.

never skip reading sub-links it will eventually come back to bite you financially

http://garage.grumpysperformance.com/index.php?threads/tbucket-engine-project-dart-shp.3814/

http://garage.grumpysperformance.co...-selecting-budget-383-heads.14620/#post-78229

http://garage.grumpysperformance.co...gine-to-match-the-cam-specs.11764/#post-73829

http://garage.grumpysperformance.com/index.php?threads/the-new-215cc-vortec-heads.266/#post-75012

https://www.hotrod.com/articles/ccrp-1209-eight-budget-sbc-head-shootout/

https://www.chevydiy.com/ultimate-chevy-big-inch-small-block-cylinder-heads-cheat-sheet/

https://www.chevydiy.com/the-complete-cylinder-head-guide-for-chevy-small-block-engines/

http://www.superchevy.com/how-to/83138-choosing-best-small-block-heads/

http://www.enginebuildermag.com/2014/05/dont-gamble-when-choosing-cylinder-heads/

https://www.hemmings.com/magazine/m...Chevy-Small-Block-Cylinder-Heads/1848889.html

http://www.enginebuildermag.com/2017/03/cylinder-head-design-selection/

http://garage.grumpysperformance.co...-guys-that-just-slap-on-factory-headers.3155/

https://www.jegs.com/p/ProMaxx-Perf...hevy-Aluminum-Cylinder-Heads/2786544/10002/-1

https://www.flotekheads.com/2016/01/12/best-small-block-chevy-heads/

http://garage.grumpysperformance.co...a-400-sbc-and-a-396-402-bbc.15087/#post-85796

http://garage.grumpysperformance.co...ng-combustion-chambers.2630/page-5#post-82766

http://garage.grumpysperformance.co...-calculators-and-basic-math.10705/#post-72061

http://garage.grumpysperformance.co...ive-train-to-the-engine-combo.741/#post-70350

http://garage.grumpysperformance.co...trans-choice-made-correctly.11697/#post-54833

http://garage.grumpysperformance.co...-that-makes-many-of-the-cars-desirable.11244/

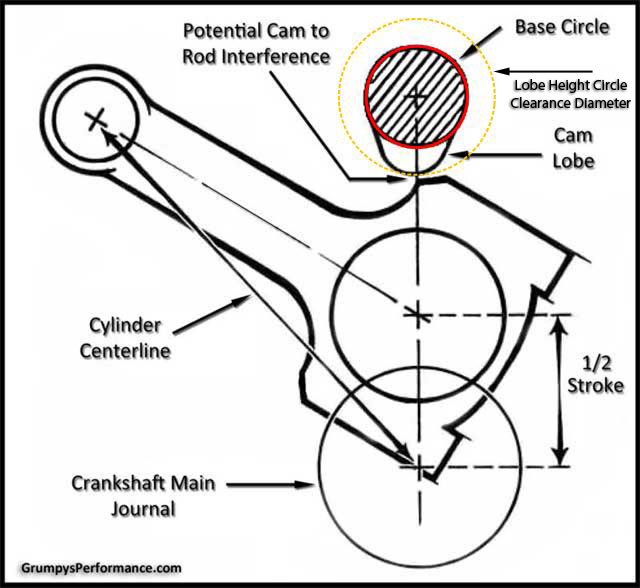

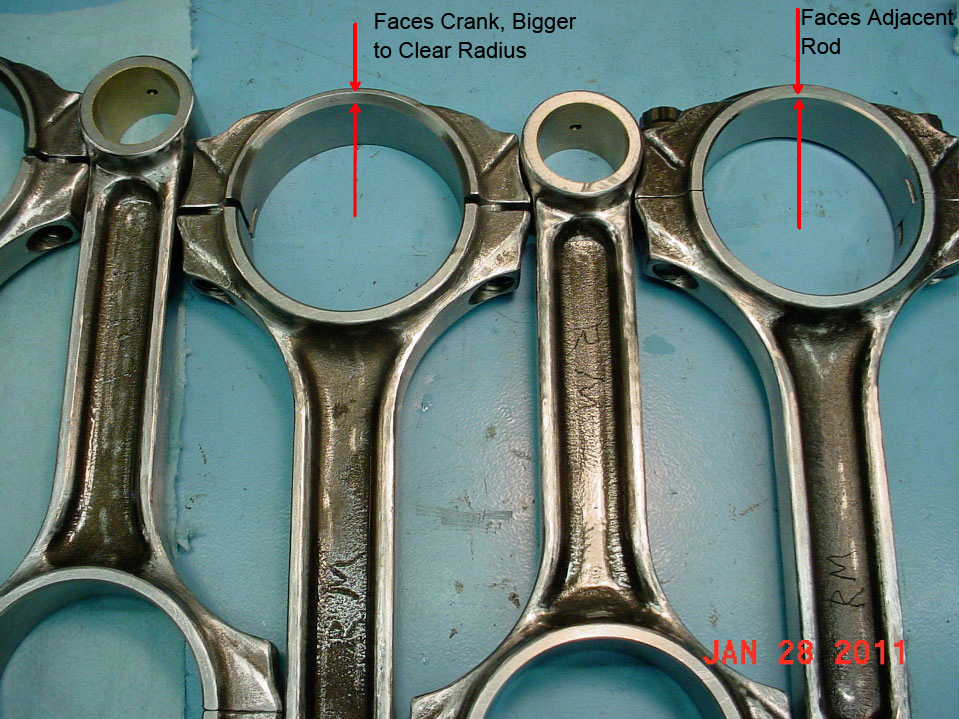

http://garage.grumpysperformance.co...bes-hitting-connecting-rods.14687/#post-79310

concerning how to build a lower cost SBC engine.

Ill save you a a great deal of time and effort ,

the KEYS to performance are, AND ROUGHLY IN THIS ORDER

GOOD HEAD FLOW

HIGHER COMPRESSION

CAM TIMING

MATCHING THE DRIVE TRAIN GEARING TO THE POWER BAND

LOW RESTRICTION EXHAUST

HEADERS WITH EXCEPTIONAL CYLINDER SCAVENGING

but all component selections will effect the eventually results

all selections enhance or restrict other parts and power production.

your eventually going to see articles promoting the idea that too large a intake port volume hurts torque,

in most cases the person has mis-matched parts,

when correctly matched to the correct cam timing, higher compression, and lower restriction exhaust,

and correctly matched drive train gearing, and correct converter stall speeds,

almost universally increases power in the use able performance power band.

If you match larger high flow ports to any intake that flows less than the heads,

youve significantly reduced power potential

if you have a cam that will not provide the lift and duration to maximize head flow in the intended rpm band,

youve significantly reduced power potential

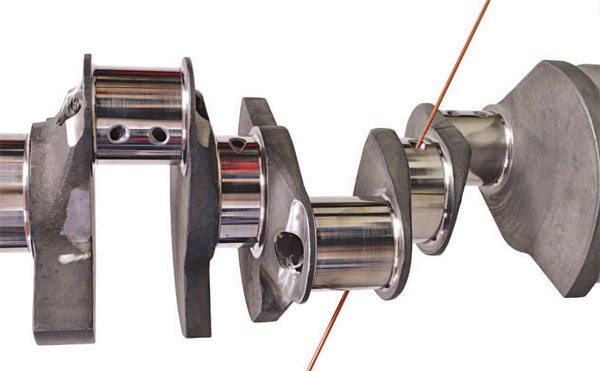

think through the selection of the engine block and rotating assembly, those parts are critical to durability

failure in selecting components that easily exceed the stress the parts will be subjected too, is always a mistake

youve significantly reduced power potential

match the valve train components, you select too the intended rpm and head flow and cam timing,failure to maintain control over the valve train at peak rpms is always a quick route to expensive problems.

youve significantly reduced power potential

if the cars drive train gearing or converter stall speed or transmission shift points, are not matched to the engines power band,

youve significantly reduced power potential

if the exhaust and headers are not designed to maximize cylinder scavenging in the entire intended power band,

youve significantly reduced power potential

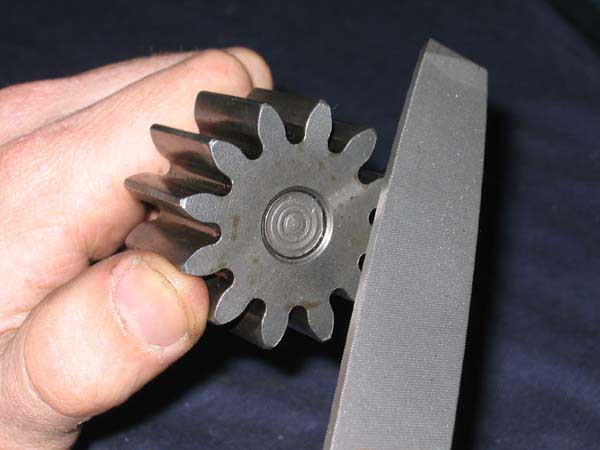

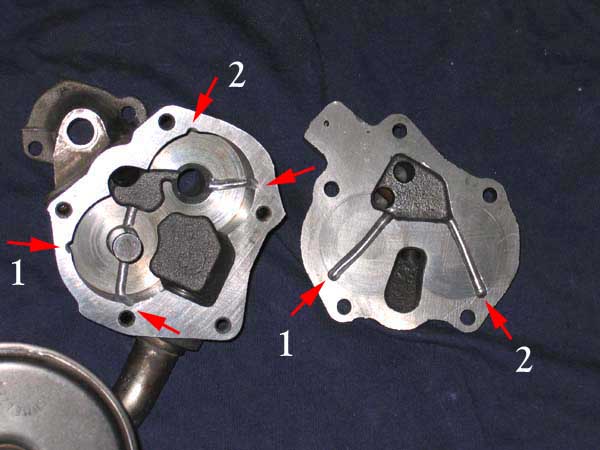

take the time to think through the engines lubrication and cooling requirements

failure to maintain a significant flow of un-interrupted pressurized oil flowing too the moving components , or failure to cool the oil or coolant,

is always a very expensive route to major component failures,

youve significantly reduced power potential

if your installing your small displacement engine in a very heavy car or the transmission shifts well below the max usable, and designed power peak,

youve significantly reduced power potential

think about your ignition, components, and providing accurate ignition timing, the stock ignition was never designed to provide the spark energy or amps required for true performance applications, especially at higher rpms and cylinder pressure levels.

youve significantly reduced power potential

time spent in careful research well before you start a project,

can save you thousands of dollars and months of problems.

never skip reading sub-links it will eventually come back to bite you financially

http://garage.grumpysperformance.com/index.php?threads/tbucket-engine-project-dart-shp.3814/

http://garage.grumpysperformance.co...-selecting-budget-383-heads.14620/#post-78229

http://garage.grumpysperformance.co...gine-to-match-the-cam-specs.11764/#post-73829

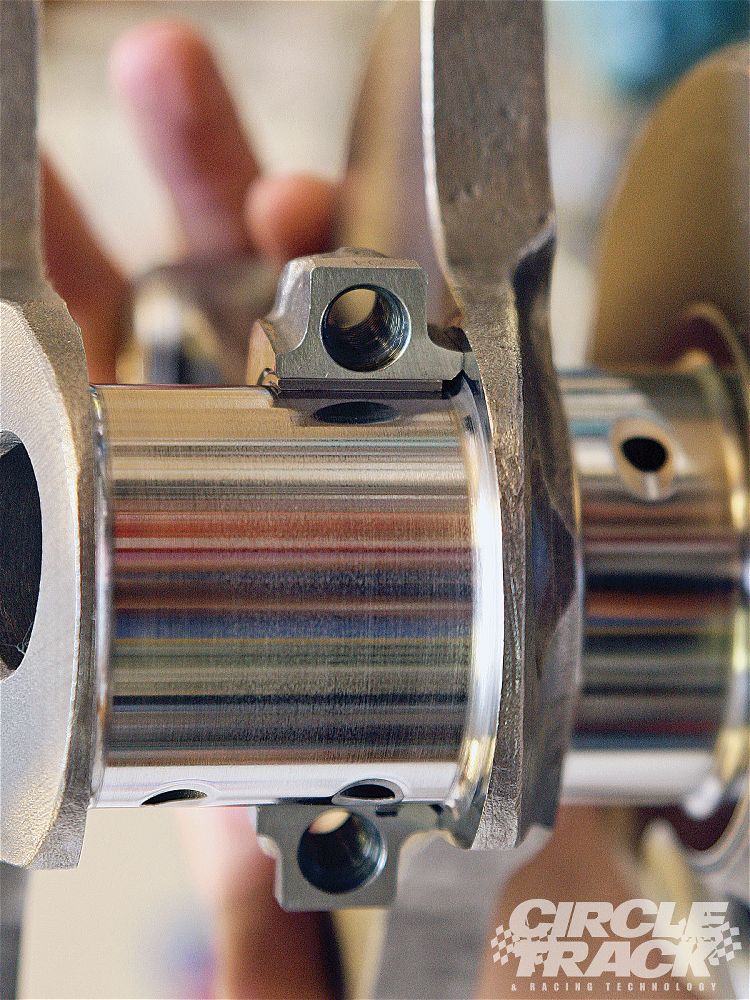

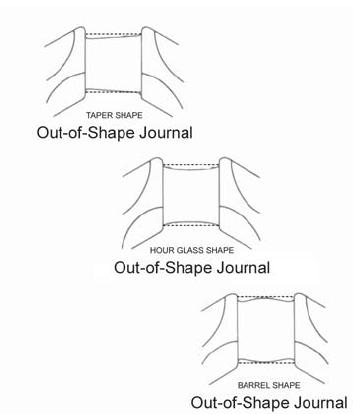

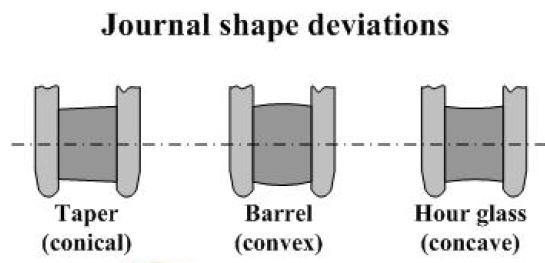

bearings and oil flow

Bearings and oil flow, some of the most important processes in engine assembly are related to getting the bearing clearances and oil flow and pressure rates set up to provide the correct oil flow rates and pressure for cooling and preventing direct surface to surface contact on the rotating...

garage.grumpysperformance.com

http://garage.grumpysperformance.com/index.php?threads/the-new-215cc-vortec-heads.266/#post-75012

https://www.hotrod.com/articles/ccrp-1209-eight-budget-sbc-head-shootout/

https://www.chevydiy.com/ultimate-chevy-big-inch-small-block-cylinder-heads-cheat-sheet/

https://www.chevydiy.com/the-complete-cylinder-head-guide-for-chevy-small-block-engines/

http://www.superchevy.com/how-to/83138-choosing-best-small-block-heads/

http://www.enginebuildermag.com/2014/05/dont-gamble-when-choosing-cylinder-heads/

https://www.hemmings.com/magazine/m...Chevy-Small-Block-Cylinder-Heads/1848889.html

http://www.enginebuildermag.com/2017/03/cylinder-head-design-selection/

http://garage.grumpysperformance.co...-guys-that-just-slap-on-factory-headers.3155/

https://www.jegs.com/p/ProMaxx-Perf...hevy-Aluminum-Cylinder-Heads/2786544/10002/-1

https://www.flotekheads.com/2016/01/12/best-small-block-chevy-heads/

http://garage.grumpysperformance.co...a-400-sbc-and-a-396-402-bbc.15087/#post-85796

http://garage.grumpysperformance.co...ng-combustion-chambers.2630/page-5#post-82766

http://garage.grumpysperformance.co...-calculators-and-basic-math.10705/#post-72061

http://garage.grumpysperformance.co...ive-train-to-the-engine-combo.741/#post-70350

http://garage.grumpysperformance.co...trans-choice-made-correctly.11697/#post-54833

http://garage.grumpysperformance.co...-that-makes-many-of-the-cars-desirable.11244/

http://garage.grumpysperformance.co...bes-hitting-connecting-rods.14687/#post-79310

can you build your custom engine as cheaply as you can have a crate engine built for you?

this is a question I have been asked so many times I can't even remember how often I've heard it asked and of course as with most things, the answer is IT DEPENDS ON... :facepalm: a great many factors , (1) like do you have a decent clean, well lighted and adequate place to work? (2)do you...

garage.grumpysperformance.com

Last edited: