having taken a great deal of engineering classes in college , I can point out a few flaws in the discussion

first , Id point out that

your comparing APPLES TO ORANGES ,

if your comparing rod BOLTS to studs in connecting rod applications

rod bolts are designed to have some stretch,

most of the length or in a few cases half the rod bolt is designed to slide in the rod this allows the stress, (tension )

forces to be distributed over a large percentage of the connecting rod fastener body,

and as long as the bolts elastic limits are never exceeded

they perform as intended, BUT if you use of a STUD in a connecting rod

all the stress is concentrated at the shear plane

between the two connecting rod components

as a stud is threaded into both sections, leaving only the single stress point.

point two

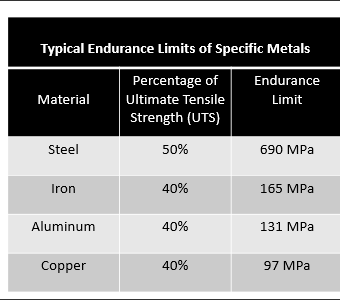

when using a main cap or main cap girdle steel is far stronger than aluminum and has

a far higher and longer term endurance limit

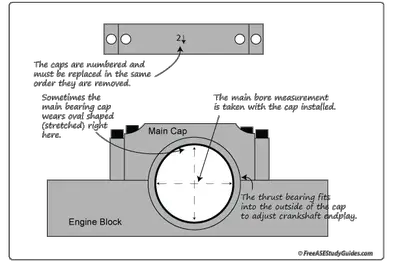

main cap studs allow the whole threaded length in the block to hold the tension stress,

while the unthreaded length extending through the main cap or through the main cap and stud girdle under it absorbs the shock and stress loads.

but use of aluminum main caps do have the ability to reduce or cushion the impact stress on crank bearing over a short term.

this is also why nitrous engines frequently use aluminum connecting rods, but remember the aluminum connecting rods,

in a race engine and crank bearings are considered a replaceable wear item like brake shoes or fan belts and they get replaced on a regular basis

main cap studs, studs are NOT torqued into the block!

studs are screwed into the block for the full thread length then backed out 1/2 turn,

STUDS are installed through the main caps, before the nuts and washers are installed,

I generally oil the threads on the lower stud threads in the block,

but no loads are applied to the studs until the threads in the block are full length engaged,

into the block and the washers & nuts on the studs are tightened.

Serious race engine builders mostly use high strength ARP studs to anchor the main caps. Studs provide a more even clamping force with higher tensile strength than most bolts and they are less highly stressed in the block ...

hotrodenginetech.com

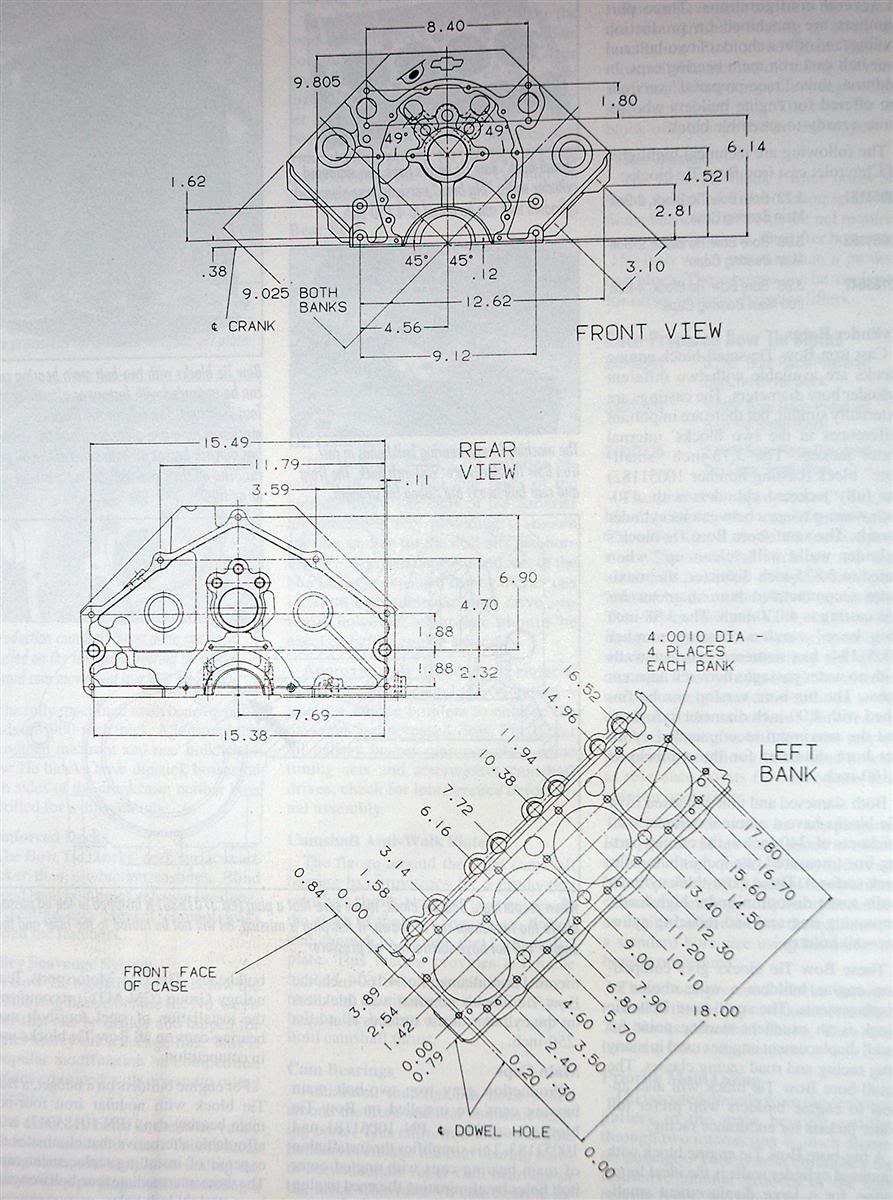

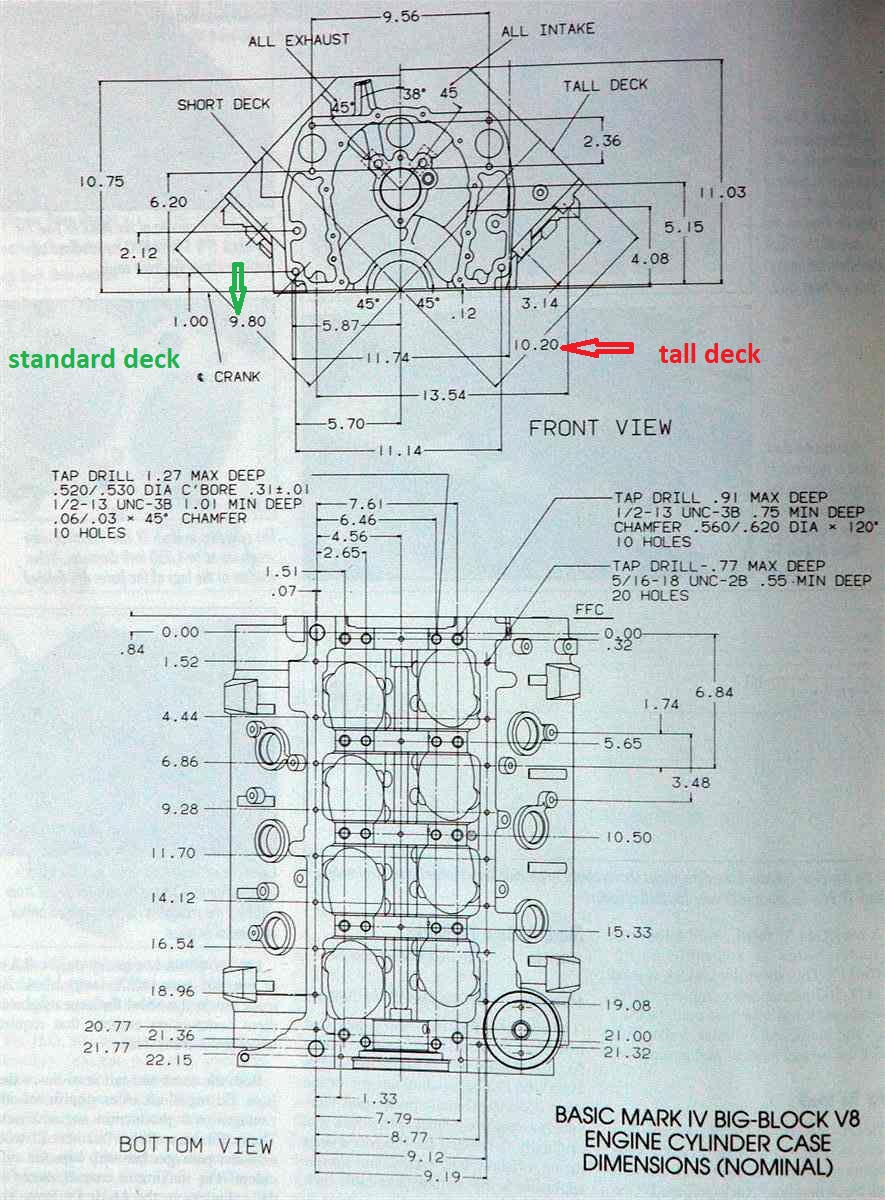

UN-machined SBC blocks have a nominal 9.0" deck height,

its very common to have the deck on a previously undecked block actually measure 9.022"-9.025"

UN-machined BBC blocks have a nominal 9.8" deck height,

its very common to have the deck on a previously undecked block actually measure 9.822-9.825

How to Install ARP Main Cap Studs

Serious race engine builders mostly use high strength

ARP studs to anchor the main caps.

Studs provide a more even clamping force with higher tensile strength than most bolts and they are less highly stressed in the block .

1.

1. Clean and inspect ALL threads in the cylinder block thoroughly. After initial tank cleaning, dry the block and inspect threads closely. Chase the threads

with the appropriate size ARP thread chaser if necessary.

2. To prepare the threaded holes select a small stiff bristle nylon cleaning brush as found in engine brush kits available from online retailers.

We prefer to scrub the main cap bolt threads with a brush and brake cleaner and then blow them out with air to get them spotlessly clean prior to assembly. At this point you should also ensure that the main cap mounting surfaces are spotlessly clean and free of any nicks, burrs or other contamination. This step is important to ensure perfect seating of the main caps.

3. Clean and inspect ALL studs and verify all dimensions. Remove all shipping lubrication from the studs until they are squeaky clean.

4. Screw the studs into the appropriate holes HAND TIGHT ONLY! While not specified by the manufacturer,

we prefer to brush a very thin coating of ARP Ultra-Torque fastener assembly lube on the threads. Do not over-tighten the studs in the block.

Note: If permanent mounting of the studs is desired, Loctite may be applied to the threads.

If you do this the fasteners must be final torqued before the Loctite sets up.

5.

5. Install the main caps and check for proper fit and alignment.

Splayed bolt main caps require outer stud installation after each main cap is installed.

Install the inner studs and use them as a guide for the main cap.

Tap the cap into place and then install the outer studs. (USE A DEAD BLOW MALLET)

6. Use a small application brush to coat the stud threads and washers with assembly lube and install the nuts finger tight.

Whether using

ARP fasteners or others,

we recommend ARP Ultra-Torque fastener assembly lubricant to ensure consistent torque readings.

Lubing with regular motor oil is discouraged due to inconsistent clamping forces. (THIS IS REFERING TO THE UPPER FINER THREADS< NOT THE

CORSER STUD THREADS IN THE BLOCK

7. To apply the proper preload to the studs follow the manufacturer’s recommendations.

Torque the nuts in three even steps until you reach the recommended torque spec.

Note: clamping forces will change when installing new studs. Check the main bearing housing bores for proper size and out of round condition. In most cases align honing the mains with the new studs properly torqued will be necessary to ensure proper fit and clamping forces.

Editors note: If you found this article helpful, please click HERE to let them know and to order you copy of their 2013 catalog.

the answer depends on what your intending to do with that engine build and your budget.

think through your choices carefully.

chevy rates the two bolt SBC blocks at 350hp, but everyone has seen two bolt blocks built to produce 450 hp,

and stand up to that power level for short term stress.

the stock two bolt main cap block works ok up to about 400-maybe occasionally 450hp, if its only run hard occasionally.

adding splayed main caps aids the lower end rigidity, but its likely to cost you over $600 in parts and machine work costs

and might allow that original block to handle 500hp-550hp

(yeah I hear all the screams about guys who swear they build 500 hp sbc engine with two bolt main caps all the time)

theres a huge difference between hitting 6000 rpm plus occasionally vs regularly, and pushing 500 hp every once in awhile,

and running an engine hard/frequently at that power level like a dirt track cars engine! STRESS IS CUMULATIVE

if your intention is to build a daily driver , get main cap studs and use the block,

if your intention is to run the crap out of the engine added splayed main caps and spending $600 plus on caps and machine work might make sense, if your goal really exceeds 500 hp or you want a heavy use of nitrous buy a

Dart or BOWTIE 4 bolt block

DART blocks are built with better quality cast iron, higher nickel alloy and have much thicker castings

http://mitsubishilinks.com/fsm/arp_catalog_rodbolts.pdf

http://garage.grumpysperformance.co...connecting-rods-pistons.247/page-2#post-99062

http://garage.grumpysperformance.co...market-4340-connecting-rods.13321/#post-72047

http://garage.grumpysperformance.com/index.php?threads/rod-bolts-rpm-vs-stress.341/

http://garage.grumpysperformance.com/index.php?threads/rod-bolts-rpm-vs-stress.341/

Since you have studs, can you measure the stretch instead of measuring the torque

since you can't get access to the other end of the stud ,

(unlike rod bolts)

as its threaded into the block web,

even if you placed a dial indicator stand

Amazon.com

on the block and use the dial indicator on the stud, you don't know how much movement is related to stud stretch or block web deformation as the load is increased. on the block web and main cap being squashed

.https://www.cpgnation.com/how-to-measure-bolt-stretch-for-proper-torque/

http://garage.grumpysperformance.com/index.php?threads/rod-bolts-rpm-vs-stress.341/

http://garage.grumpysperformance.co...onnecting-rod-rod-length-too-stroke-info.510/

https://www.hotrod.com/articles/using-rod-bolt-stretch-tool/

.https://www.cpgnation.com/how-to-measure-bolt-stretch-for-proper-torque/

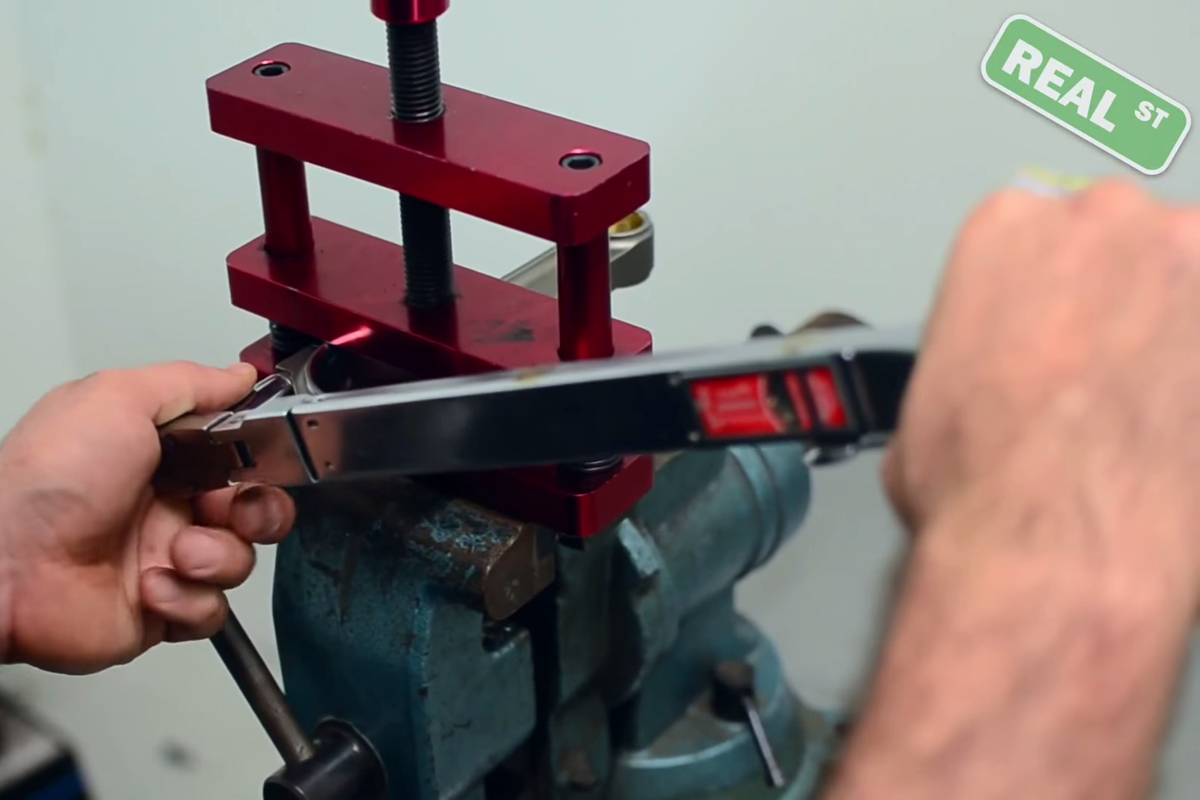

In this quick-hit video how-to, Real Street Performance's Jay Meagher shows how to measure rod bolt stretch, and provides a number of tech tips in the process.

www.enginelabs.com

Car Craft magazine takes a closer look on why to use a a rod bolt stretch tool

www.motortrend.com

Most engine builders concede that torquing rod bolts during final assembly is no longer an accepted practice. While no doubt adequate for general engine rebuilding where loading rarely approaches that of competition levels, basic rod bolt torquing simply cannot account for...

hotrodenginetech.com

Stretching Exercise

Quote Reply

Select for moderation

Report Edit Delete IP