you must keep in mind that studs generally have two types of threads, one on the end that threads into the block,

and one end with a finer thread that uses a washer and nut assembly,

generally, if properly installed, studs allow the whole length of the lower course threaded stud to apply tension to the block,

so you get max retention strength, bolts apply marginally more stress to the first few course threads as they engage the blocks threads.

studs almost always have at least, potentially marginally more clamp force, but only if studs are properly installed.

studs must never be inserted into and tightened in the bolt hole threads until they bottom in the thread holes.

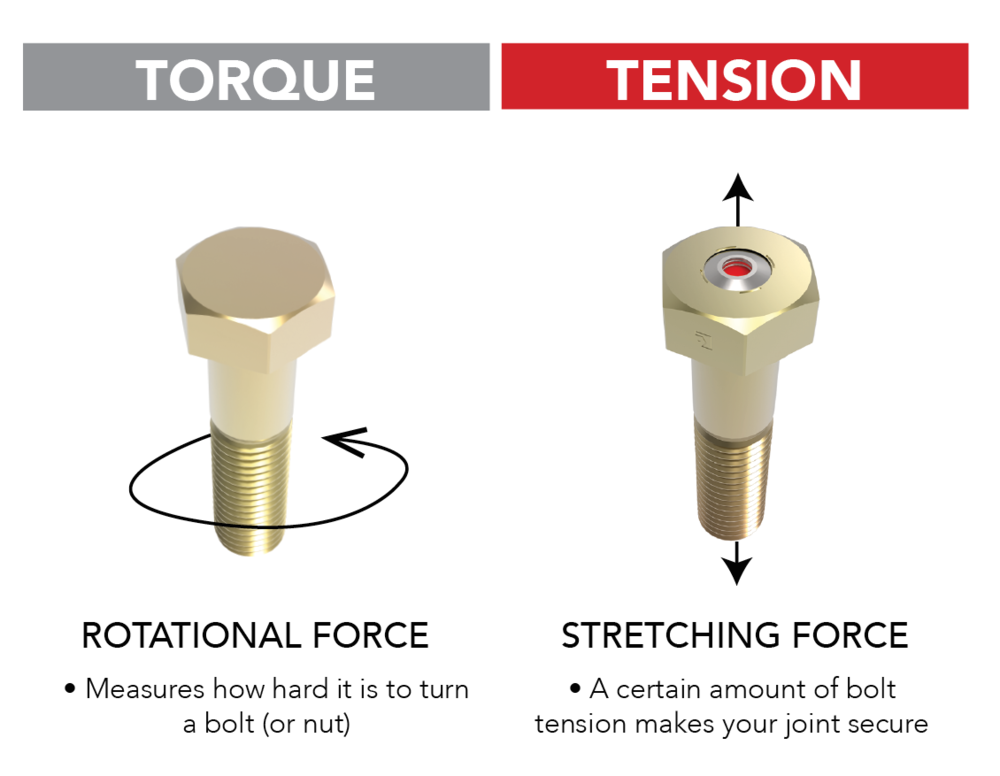

on applications like connecting rod bolts a stretch gauge rather than a torque wrench is used as the clamping forces are much more accurately measured that way

http://garage.grumpysperformance.com/index.php?threads/which-torque-wrench.342/#post-87029

Studs provide the ability to obtain much more accurate torque values because the studs don't twist or have added torsional stress applied during tightening as do bolts. Because the studs remain stationary during nut tightening, the studs stretch in one axis alone, providing much more even and accurate clamping forces.

but remember the finer threads, on the upper stud, the nut providing clamp forces on the threads onto ,

the stud will require a different torque value applied to provide the same clamp forces

www.autoserviceprofessional.com

www.autoserviceprofessional.com

www.maracing.net

www.maracing.net

as a general rule you insert and thread main cap studs into the block until the stud course thread bottom out on the shank or bottom of the block female threads then back out the stud at least 3/4 of a turn, back out, before you use them,

as the stud must not be bottom out on the shank or bottom of the block female threads while its under tension to function correctly

and one end with a finer thread that uses a washer and nut assembly,

generally, if properly installed, studs allow the whole length of the lower course threaded stud to apply tension to the block,

so you get max retention strength, bolts apply marginally more stress to the first few course threads as they engage the blocks threads.

studs almost always have at least, potentially marginally more clamp force, but only if studs are properly installed.

studs must never be inserted into and tightened in the bolt hole threads until they bottom in the thread holes.

on applications like connecting rod bolts a stretch gauge rather than a torque wrench is used as the clamping forces are much more accurately measured that way

measuring rod bolt stretch & preload

http://arp-bolts.mobi/p/tech.php?page=3 http://arp-bolts.mobi/p/tech.php?page=2 http://www.hotrod.com/how-to/engine/116 ... etch-tool/ http://arp-bolts.com/ http://www.harborfreight.com/1-inch-tra ... r-623.html...

garage.grumpysperformance.com

http://garage.grumpysperformance.com/index.php?threads/which-torque-wrench.342/#post-87029

Studs provide the ability to obtain much more accurate torque values because the studs don't twist or have added torsional stress applied during tightening as do bolts. Because the studs remain stationary during nut tightening, the studs stretch in one axis alone, providing much more even and accurate clamping forces.

but remember the finer threads, on the upper stud, the nut providing clamp forces on the threads onto ,

the stud will require a different torque value applied to provide the same clamp forces

Engine studs: Understanding the advantages of using studs vs. bolts, and tips on achieving proper clamping loads

In far too many cases, the engine builder’s attention focuses only on selection of the proper components for a specific engine build, determining proper clearances, intake...

Choosing the right head stud — Mechanical Advantage Racing

as the stud must not be bottom out on the shank or bottom of the block female threads while its under tension to function correctly

Last edited: