READ THIS THREAD BELOW ALSO

viewtopic.php?f=63&t=526

brake fluid info

https://blog.amsoil.com/dot-3-and-dot-4-brake-fluid-whats-the-difference/

http://www.afcoracing.com/tech_pages/fluid.shtml

http://en.wikipedia.org/wiki/Brake_fluid

http://www.stoptech.com/tech_info/wp_br ... d_1a.shtml

http://www.motorcycleproject.com/motorc ... fluid.html

http://www.familycar.com/brakes.htm

http://www.timskelton.com/lightning/rac ... _fluid.htm

http://www.aa1car.com/library/bfluid.htm

http://www.ehow.com/how_1846_check-brake-fluid.html

http://www.buckeyetriumphs.org/technica ... /Fluid.htm

http://www.v8sho.com/SHO/Brake_Fluid2.htm

http://www.shotimes.com/SHO3brakefluid.html

KEEP IN MIND most types of brake fluid absorb moisture over time, this WILL result in rust if the brake fluids not changed and your brakes hydraulic system will rust if its not flushed out regularly.(at least every 40 k mikes, or every 18 months-to- two years is usually safe on a street car)

you generally DON,T WANT TO MIX brake fluid types.

moisture , that's been absorbed by brake fluid will turn to steam destroying your ability to brake the car if the fluid gets hot enough and it CAN under hard repeat braking!

flush the master cylinder and brake lines with the new fluid DON,T MIX THEM

yes some dot 3 and dot 4 brake fluids are fully compatible but you'll generally find you get far more responsive brakes if the fluids fresh, moisture free and all one type, keep in mind the brake pad, brake caliper, size, design,and material and rotor design will also effect your results.

rotors can glow dull red hot on a race car, wheel bearing grease must also be designed to handle the heat range on a car that's driven hard

https://www.machinerylubrication.com/Read/30614/know-brake-fluids

https://help.summitracing.com/app/answers/detail/a_id/414/~/what-is-the-difference-between-brake-fluids?

DOT 3 vs. DOT 4 vs. DOT 5 vs. DOT 5.1

Obviously, the braking system on any vehicle is a critical safety system. It becomes even more critical in race and performance applications. Bringing your car to a stop generates a lot of heat. The heavier the vehicle and the faster it is going, the more heat is created. Brake fluid must be able to stand up to all this heat and still do its job: transfer force from the brake pedal to the caliper or wheel cylinder.

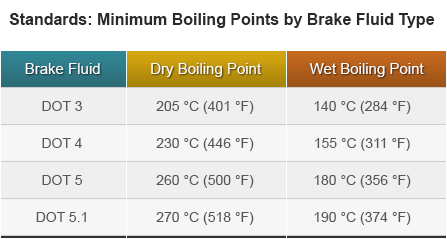

To ensure everyone's safety, brake fluid must meet certain standards. The standards are set by organizations like the SAE and the Department of Transportation (DOT). The standards are what designates the fluid as DOT 3, DOT 4, DOT 5, and DOT 5.1.

The important factors involved when comparing brake fluids are:

- Boiling Point

- Viscosity

- Corrosion Prevention

- Compressibility

Before we get into the specific standards, it is important to know what the different fluids are made from. DOT 3, DOT 4, and DOT 5.1 are all glycol-ether based. DOT 5 brake fluid is silicone based.

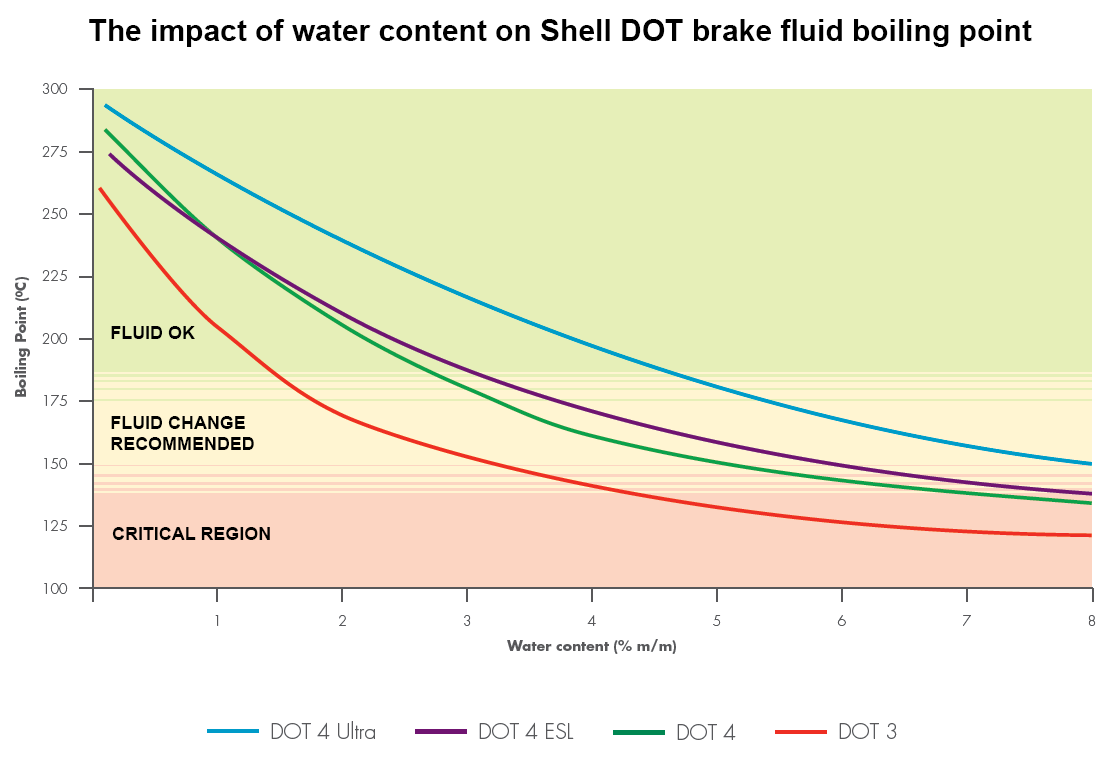

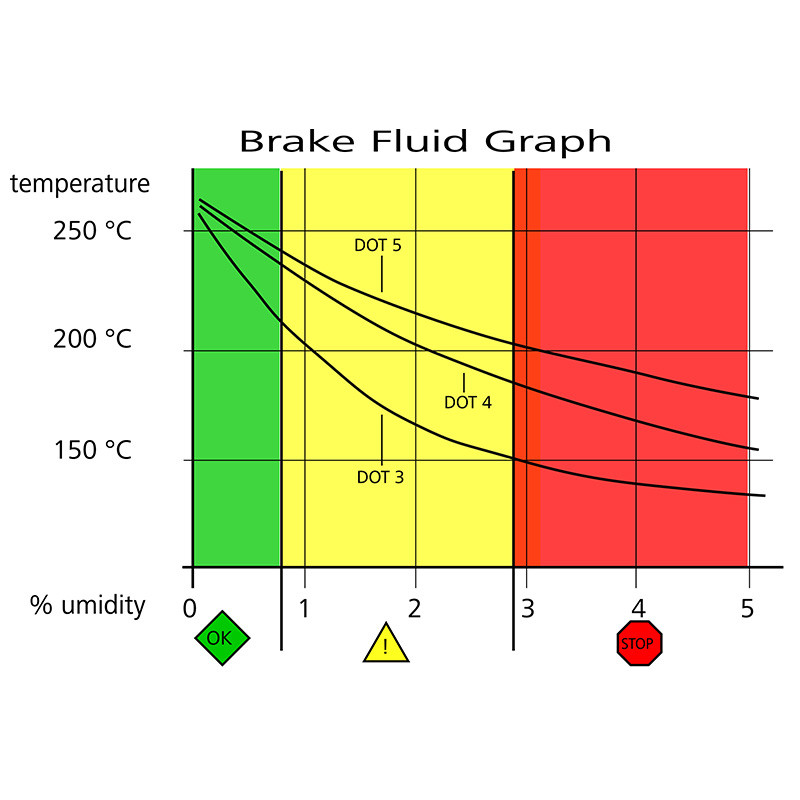

Glycol based fluids are hygroscopic, meaning they gradually absorb moisture from the atmosphere and disperse it throughout the system. As the water content of the fluid increases, its boiling point decreases. The additional moisture in the fluid will also start to corrode the metal components of the system.

The silicone based fluid is hydrophobic, meaning it will not absorb moisture. If any moisture is introduced into the system, it can collect in pockets that can either freeze or boil off. This can lead to damage to the brake system and/or brake failure. Silicone is also more compressible than glycol, which can lead to a "spongy" feeling brake pedal.

Because of the way they deal with water, glycol and silicone based fluids are NOT compatible with each other. Never mix the 2 types of fluid. Only add DOT 5 silicone brake fluid to a completely dry system or a vehicle that already has DOT 5 in it. Do not add anything other than DOT 5 to a system that calls for DOT 5 brake fluid.

Boiling Point

When it comes to performance applications, boiling point is probably the most critical. Brake fluid must withstand very high temperatures without vaporizing in the lines. Vapor is highly compressible, compared to fluid. So, if the fluid is vaporized, it fails to transfer the force from the pedal to the caliper or wheel cylinder and the car will not stop.

Don't forget to consider the water content of the fluid. Remember that the glycol based fluids will absorb moisture over time. Brake fluid must meet standards for both a wet and dry boiling point. The wet boiling point is defined as 3.7% water by volume.

Dry Boiling Point

Wet Boiling Point

DOT 3

401° F

284° F

DOT 4

446° F

311° F

DOT 5

500° F

356° F

DOT 5.1

500° F

356° F

**Some manufacturers sell brake fluid with much higher boiling points. These fluids are intended for use in race vehicles only and should not be used in daily drivers or street vehicles.**

Viscosity

Viscosity is basically the thickness of the fluid. For example, oil has a higher viscosity than water. Brake fluid must maintain its viscosity through both extreme heat and cold to provide reliable, safe braking. DOT 3 has the highest viscosity. As the DOT number increases, the viscosity goes down.

Corrosion Prevention

In addition to withstanding heat, brake fluid must also not corrode the metal brake system components. Additives are added to the fluid to accomplish this. The added chemicals protect the metal parts from corrosion, but they will damage painted surfaces.

The glycol based fluids are very harmful to paint. If the fluid is spilled, or leaks onto a painted surface of your vehicle, the paint will be damaged. DOT 5 silicone based fluid is much less harmful to paint.

Compressibility

Brake fluid is intended to transfer force. If the fluid compresses, even a little bit, the force is reduced. Brake fluid must maintain a low level of compressibility to maintain the feel of the brake pedal and provide consistent performance.

Dry Boiling Point Wet Boiling Point

DOT 3 401ºF ....... 284º F

DOT 4 446º F....... 311º F

DOT 5 500º F....... 356º F

DOT 5.1 518º F ...... 375º F

A Primer on Brake Fluids: DOT, DOT, Who's Got the DOT?

By Mike Allen

Like most automotive fluids, brake fluids carry specific ratings, in this case prefixed by the letters DOT, for Department of Transportation. Follow the car manufacturer's recommendations as to the type you need, which will be either DOT 3 or DOT 4.

DOT 3 fluid has a dry boiling point of 205 C and a wet boiling point of 140 C. Most normal-duty cars and trucks should use DOT 3 fluid.

DOT 4 fluid has a higher boiling point, 230 C (dry) and 155 C (wet), but it is also slightly more viscous, making it less suitable for some vehicles.

DOT 5 (silicone) fluids are popular with restorers. They don't attract moisture, which is good for cars that are stored for much of the time and not driven often. Do not use silicone fluid in ABS-equipped vehicles. It's too viscous and gives a mushy pedal.

Last edited by a moderator: