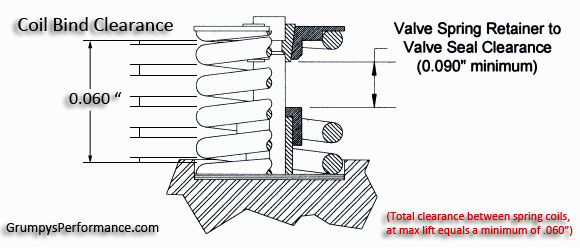

So I have been reading and trying to figure out why I broke 2 valve springs at `1500 miles. Life so much easier for the ignorant, but I have either learned alot or at least became aware of how much there is that I don't know. My original set up had .504" intake/.5184" exhaust valve lift with k-motion700 springs. If my installed height is 1.700 and I use the exhaust lift of .5184

that should get me to an open height of 1.1816". If I include .06" for coil bind freeway space I show 1.1216" as what would be the the max acceptable coil bind height? K-motion shows coil bind at 1.05" so I should be .0716" to the good, above and beyond .06 freeway space. If my math etc is correct so far so good. However Kmotion shows a max lift of .500" for the k-700

spring. Apparently so far is NOT so good since the travel I am generating is over .500 for both, yet should be inside of coil bind problems. So, I look at the k750 which has similar specs as far as installed height and coil bind of 1.05" BUT it has a max lift of .61" which is within any spec I can think of at the moment. Is this a possible solution or is my math and understanding of the problem still wrong? It seems to me there is an issue of not just coil bind, but the overall travel of a spring that needs to be considered, or am I just stupid :lol:

Grumpy this might look familiar to you from another forum and I have read and read on this as you suggested and the above is what I came up with. I know this discussion doesn't consider seat pressure etc but according to cam and spring manuf I should be ok.

1.7000 installed height 1.7

- .06 freeway -0.5184

- .5184 max travel exhaust -----------

--------------------- 1.1816 open height

1.1216 max coil bind heigth available

1.05 spec'd as coil bind by k-motion- (0.0716 excess room) ??

.61 shown as max lift by kmotion leads to 1.7000

-.61

----------

1.09

1.1216

-1.09

--------

.0316 within margin ??

that should get me to an open height of 1.1816". If I include .06" for coil bind freeway space I show 1.1216" as what would be the the max acceptable coil bind height? K-motion shows coil bind at 1.05" so I should be .0716" to the good, above and beyond .06 freeway space. If my math etc is correct so far so good. However Kmotion shows a max lift of .500" for the k-700

spring. Apparently so far is NOT so good since the travel I am generating is over .500 for both, yet should be inside of coil bind problems. So, I look at the k750 which has similar specs as far as installed height and coil bind of 1.05" BUT it has a max lift of .61" which is within any spec I can think of at the moment. Is this a possible solution or is my math and understanding of the problem still wrong? It seems to me there is an issue of not just coil bind, but the overall travel of a spring that needs to be considered, or am I just stupid :lol:

Grumpy this might look familiar to you from another forum and I have read and read on this as you suggested and the above is what I came up with. I know this discussion doesn't consider seat pressure etc but according to cam and spring manuf I should be ok.

1.7000 installed height 1.7

- .06 freeway -0.5184

- .5184 max travel exhaust -----------

--------------------- 1.1816 open height

1.1216 max coil bind heigth available

1.05 spec'd as coil bind by k-motion- (0.0716 excess room) ??

.61 shown as max lift by kmotion leads to 1.7000

-.61

----------

1.09

1.1216

-1.09

--------

.0316 within margin ??