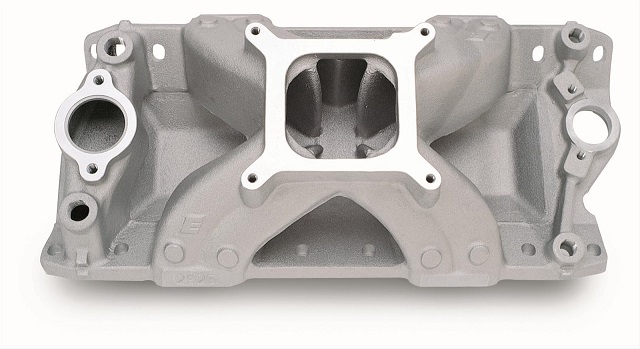

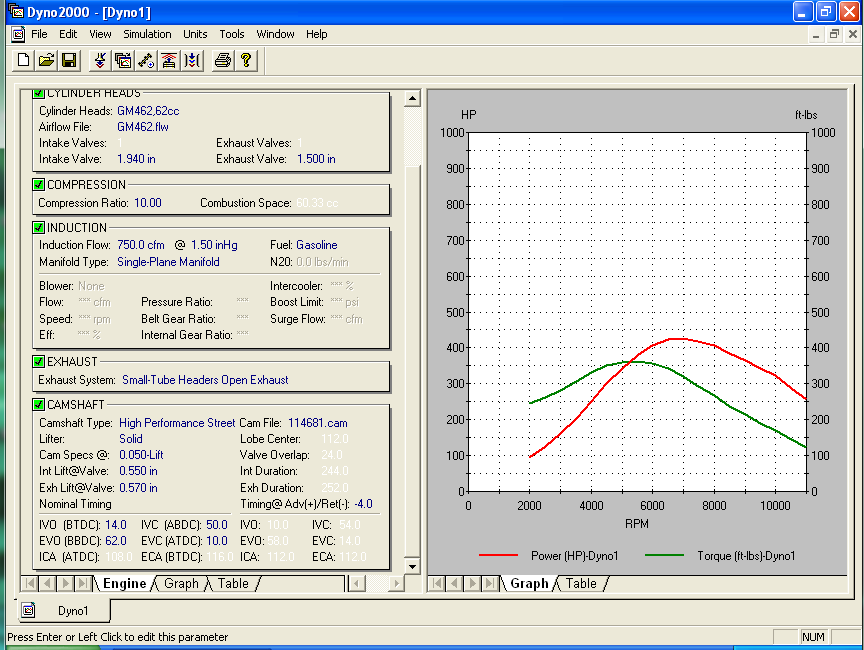

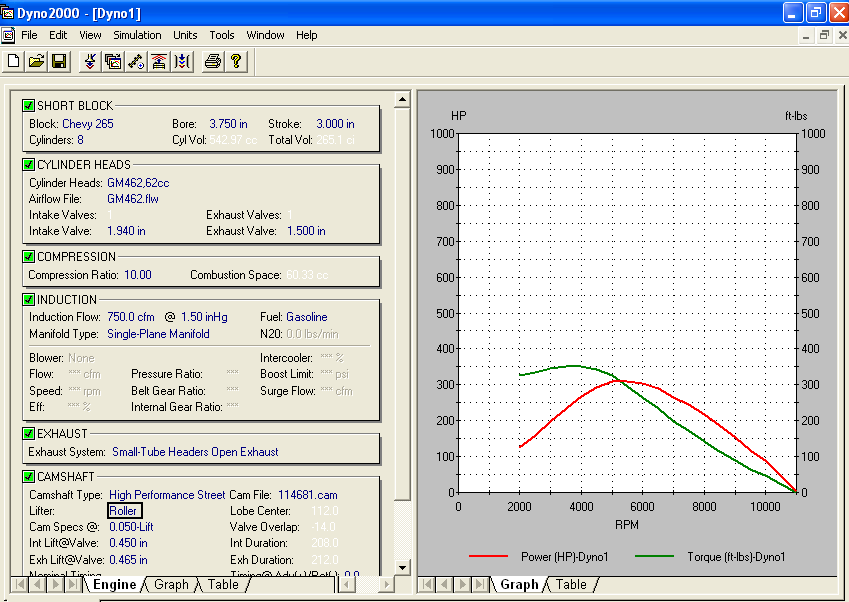

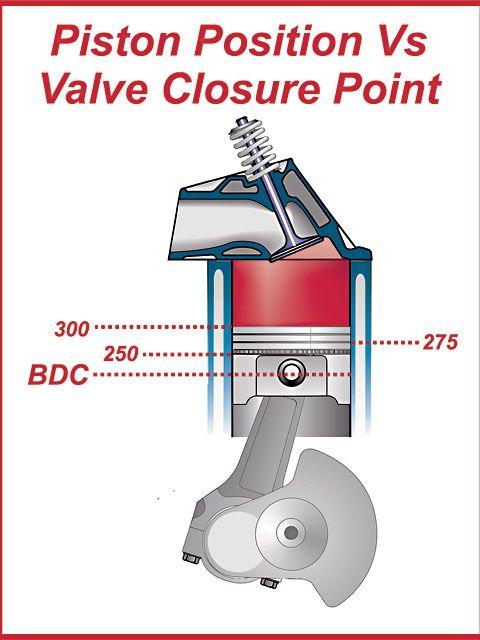

WHY ? Oh why not ! I know "no replacement for displacement" but I like the challenge. Here is the quick story. I actually have the original 265 my dad removed from his 55 in 1960. My father, son and I were going to build it as a fun project to see what we could make of it with modern technology (roller cam, better heads, possible power adders). In the process of drumming up parts I found (2) different 56 265 short blocks and these blocks are a better start for performance. First short block was a wallet killing $100 with old JE cast dome pistons and a fully balanced rotating assembly. Found out one piston was cracked. This lead me to the short block I am going to use. It is a fresh, .060 over, standard deck height, never run, +6cc domed pistons, full race prepped block built to take 10,000 RPM. With it I bought a set of 461 1.94 heads for another wallet killing $500 ! I am going to run this Howards cam: http://www.summitracing.com/parts/hrs-c ... /overview/. It shows some very good Hp and torque numbers for a 265 upwards of the 6000-6500 RPM range unlike the 800-4,200 range it show for a 350. I have the option of 3 sets of heads in my possession. 1 - 461, 64cc 1.94/1.5 heads (these heads have all the porting and bowl work done but need to be cleaned and re-assembled AND the block has unshrouding on the top of the cylinders to acomodate the 1.94's), 2 - 416 casting, 305 heads with 58cc chambers, 1.84/1.5 valves these need to be ported, bowl work and rebuilt) and 3- 601 casting 305 heads with 53cc chambers, 1.84/1.5 valves ( these heads could be used as is but they are not ported or worked on yet). Looking through the TONS of links GrumpyVette has listed on Chevytalk, I ran different numbers to come up with my Dynamic comp. ratio, knowing this is more important than the Static ratio.I can run from 9.48 to 11.17:1 for compression with the thinnest head gasket. the 9.48 is the 1.94 64 cc heads, the 11.17 is the 1.84 53cc chamber 305 heads. I would have a dynamic ratio from 8.03 to 9.45, dynamic cranking pressure from 160 to 197. I think the 9.45 dynamic will put me in the race gas only area unless any of you know otherwise. I am trying to make my 55 a modern day "dual purpose" car but based on the times. I want to drive it to the track and have a solid mid 13 second car. I am in contact with a Nostalgia Super Stock guy who runs a 55 and he feels this goal is no problem with the use of modern parts instead of an old school build.

Everyones input welcome, especially you Grumpy !

Everyones input welcome, especially you Grumpy !