you might want to read through this thread also.

a couple KEY factors in getting any smaller displacement SBC engine to perform well, is your going to have to get the static compression ratio up in the 10.5:1 or higher range and match the cam duration and lift to maximize the port air flow rates in the upper rpm range, and that will generally require selecting a solid lifter cam, use of tuned headers with a low restriction exhaust, and gearing the cars drive train to allow it to maximize, the engines ability to breath in the 4500 rpm-7500 rpm, range that a short stroke 3"-3.25" SBC engine is capable of if properly designed and constructed

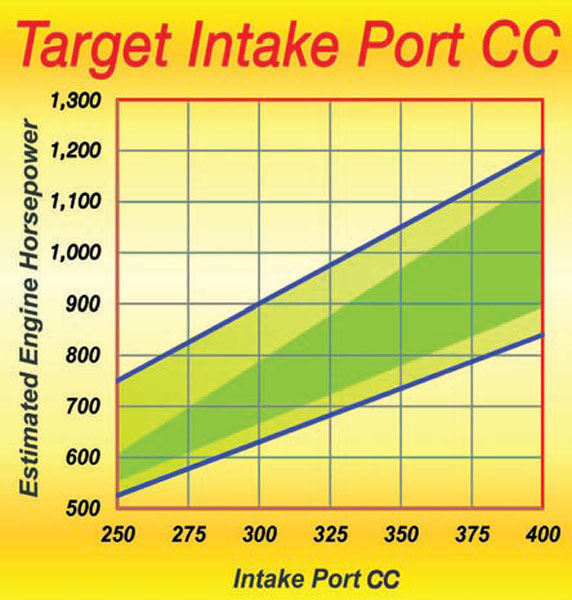

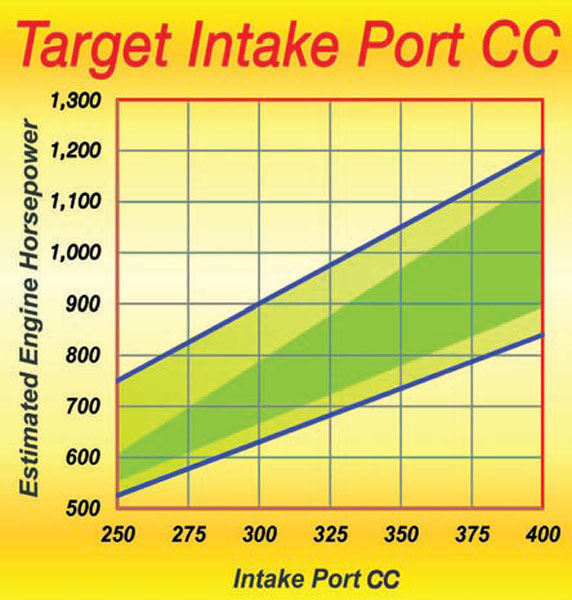

the cylinder head port size required can be easily calculated,many guys seem to think your limited to a certain size port for a certain displacement, but the fact is that theres far more factors that effect the correct port configuration and port size than engine displacement alone.

the bore size of the smaller SBC engines like a 265 or 283 won,t physically allow the use of the larger 2.02" intake and 1.60" exhaust valves, especially with longer duration high lift cam profiles.

if you do the research youll find that carefully matched cam timing,and header design can be used to increase the cylinder fill efficiency.

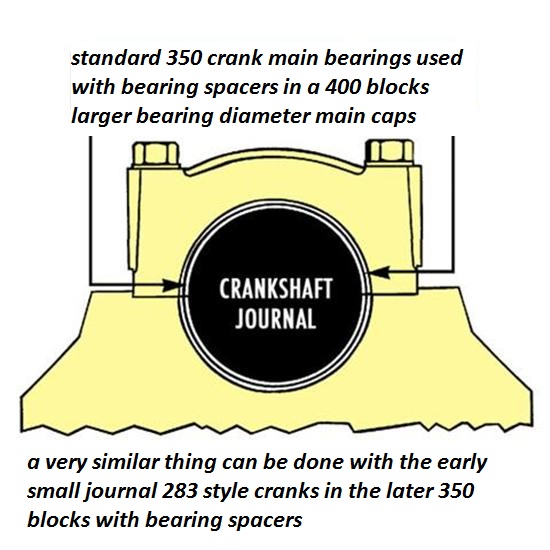

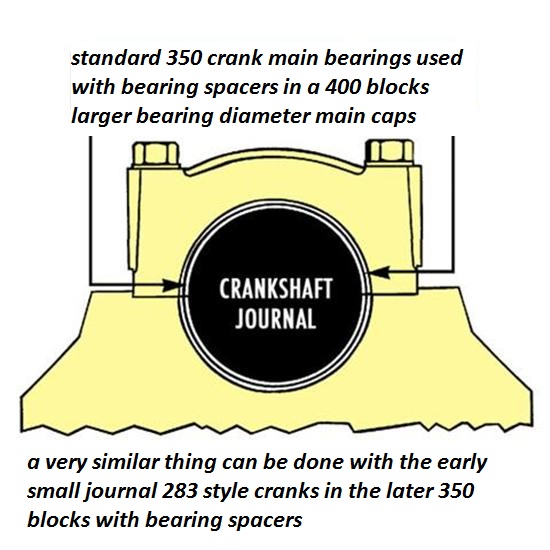

always accurately measure the crank main journals, and remember the crank and block bearing sizes on a 400 sbc and 350 smc are different as are the early 283-327 sbc

USE THE CALCULATORS to match port size to intended rpm levels... but keep in mind valve lift and port flow limitations

http://www.wallaceracing.com/runnertorquecalc.php

http://www.wallaceracing.com/ca-calc.php

http://www.wallaceracing.com/area-under-curve.php

http://www.wallaceracing.com/chokepoint.php

http://www.wallaceracing.com/header_length.php

http://www.circletrack.com/enginetech/1 ... ch_engine/

While cheat sheets might have frowned upon in your sixth-grade classroom, we strongly encourage them in the garage, shop, or pits. That’s why we’ve put together this list of 13 key performance formulas you should know when building or tuning your street or race vehicle.

http://garage.grumpysperformance.co...lap-on-factory-headers.3155/page-2#post-66722

http://www.race-cars.net/calculators/compression_calculator.html

http://garage.grumpysperformance.com/index.php?threads/a-few-calculator-links.7108/#post-27382

http://www.projectpontiac.com/ppsite15/compression-ratio-calculator

http://www.wallaceracing.com/dynamic-cr.php

http://www.rbracing-rsr.com/comprAdvHD.htm

http://performancetrends.com/Compression_Ratio_Calculator_V2.3.htm

http://www.wallaceracing.com/cr_test2.php

http://www.pcengines.com.au/calculators/Calculate dynamic Comp Ratio.htm

http://www.csgnetwork.com/compcalc.html

http://www.diamondracing.net/tools/

https://www.uempistons.com/index.php?main_page=calculators&type=comp

https://www.rbracing-rsr.com/compstaticcalc.html

Racing Carburetor CFM

Racing Carburetor CFM = RPM x Displacement ÷ 3456 x 1.1

Note: Summit Racing also offers this CFM Calculator to make the job easier.

Displacement

Displacement = .7854 x Bore2 x Stroke x Number of Cylinders

Correct Compression Ratio (CCR)

CCR = FCR (Altitude/1,000) x .2

Note: You can also take this Compression Ratio Calculator tool for a spin.

Tire Diameter

Tire Diameter = (MPH x Gear Ratio x 336) ÷ RPM

Rocker Arm Ratio and Valve Lift

Gross Valve Lift = Camshaft Lobe Lift x Rocker Arm Ratio

Horsepower

Horsepower = (RPM x Torque) ÷ 5,252

Torque

Torque = (5,252 x HP) ÷ RPM

Rod Ratio

Rod Ratio = Rod Length ÷ Crank Stroke Length

Average Piston Speed

Average Piston Speed = Crank Stroke x RPM ÷ 6

Rear Gear Ratio

Rear Gear Ratio = (RPM at Finish Line x Tire Diameter) ÷ (MPH x 336)

Note: You can also save this link to a handy Gear Ratio calculator.

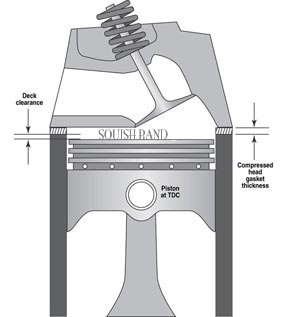

Volume (CCs) of Deck Clearance

CCs of Deck Clearance = Bore x Bore x 12.87 x Depth of Deck Clearance

Volume (CCs) of Head Gasket

CCs of Head Gasket = Bore x Bore x 12.87 x Thickness of Head Gasket

Intake Port to Torque Peak

here's a chart FROM THE BOOK,HOW TO BUILD BIG-INCH CHEVY SMALL BLOCKS with some common cross sectional port sizes

(measured at the smallest part of the ports)

...........................sq inches........port cc

edelbrock performer rpm ....1.43.............170

vortec......................1.66.............170

tfs195......................1.93.............195

afr 180.....................1.93.............180

afr 195.....................1.98.............195

afr 210.....................2.05.............210

dart pro 200................2.06.............200

dart pro 215................2.14.............215

brodix track 1 .............2.30.............221

dart pro 1 230..............2.40.............230

edelbrock 23 high port .....2.53.............238

edelbrock 18 deg............2.71.............266

tfs 18 deg..................2.80.............250

COMMON SBC INTAKE PORTS

felpro # 1204=Port Size: 1.23" x 1.99"=2.448 sq inches

felpro # 1205=Port Size: 1.28" x 2.09"=2.67 sq inches

felpro # 1206=Port Size: 1.34" x 2.21"=2.96 sq inches

felpro # 1207=Port Size: 1.38" x 2.28"=3.146 sq inches

felpro # 1209=Port Size: 1.38" x 2.38"=3.28 sq inches

felpro # 1255 VORTEC=Port Size: 1.08" x 2.16"-2.33 sq inches

felpro # 1263=Port Size: 1.31" x 2.02"=2.65 sq inches

felpro # 1266=Port Size: 1.34" x 2.21"=2.96 sq inches

felpro # 1284 LT1=Port Size: 1.25 x 2.04''=2.55 sq inches

felpro # 1289 FASTBURN=Port Size: 1.30" x 2.31" 3.00 sq inches

http://garage.grumpysperformance.co...ut-building-a-283-305-or-307-this-may-be.427/

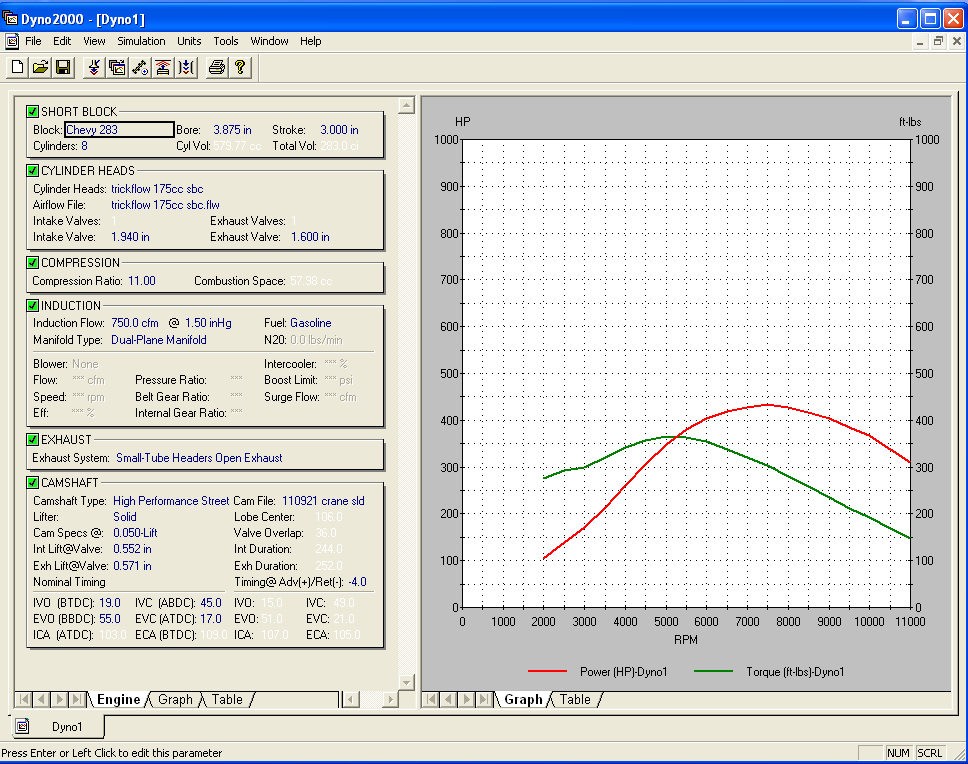

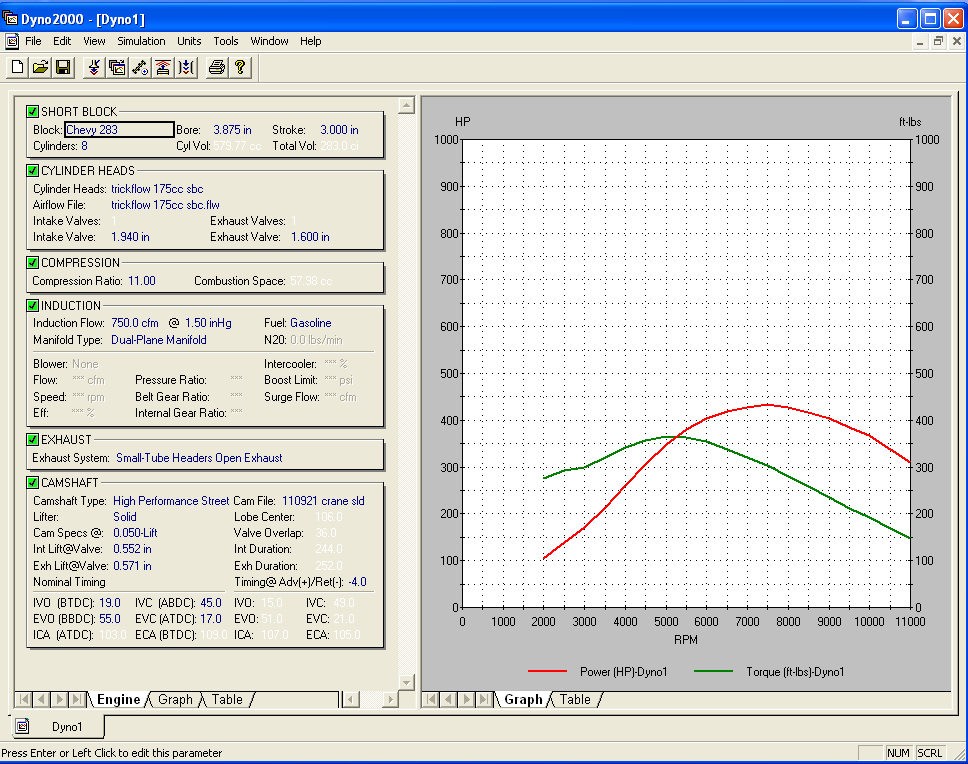

If your looking to build a rather serious 283 sbc in a light weight car

, yes you can get good power,the potential strong suite of the 283 sbc is it potential to rpm in the 5000 rpm-to-8000 rpm range with its short 3" stroke with the proper matching valve train and compression

but it won,t be very useful below about 4500rpm,

and hardly ideal for daily street driving or useful on pump octane fuel

the heads you select will be rather critical here so don,t scrimp, youll need decent roller rockers AND a matching rocker stud girdle,

http://www.summitracing.com/parts/tfs-30400700/overview/

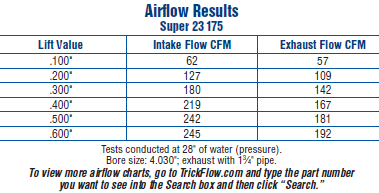

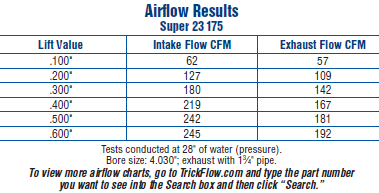

the 175cc port and 56cc combustion chamber sbc trick flow cylinder heads that are about $590 EACH or about $1200 for a pair fit the application well

and yes some time spent , by a reasonably skilled porting specialist or your machine shop or you, in port and bowl area clean-up port work and plenum clean up, port matching, on the intake manifold, and use of open headers, will be nearly mandatory

http://www.grumpysperformance.com/tfsairflows.pdf

http://www.summitracing.com/parts/tfs-30310002

YES THE tfs-30310002 with the 1.47 better valve springs

YES YOULL NEED to swap the valve retainers and install even better and stronger valve springs, but of the correct load rate for the cam and lifters, that handle a .600 lift with additional clearance,

this engines going to be shifting at about 8k rpm

with a 3" stroke you have the potential to build a decent high rpm engine so you may as well take advantage of the engines true potential.

http://www.summitracing.com/parts/crn-11759-16

http://www.summitracing.com/parts/crn-110921

crane solid lifter cam

http://www.summitracing.com/parts/cro-66909x980-16

crower cool face solids

intake manifold

http://www.summitracing.com/parts/edl-7501/overview/make/chevrolet

For a Chevrolet 350, the traditional rod journal size is 2.1 inches. Engine builders have found there are numerous advantages of a smaller journal size, the most significant being that it slows the bearing speed. there are spacer rod bearings to use the 2.1" connecting rods on the 283 & 327 sbc smaller 2.0 rod journal diam.

http://www.lunatipower.com/Product.aspx?id=309

rods

http://www.jegs.com/i/Scat/942/26000716/10002/-1?parentProductId=761557

If I was building it ID want 1 5/8" long tube open headers, youll want J&E forged pistons that produce 11:1 compression

low drag rings, Id suggest a .120 valve to piston clearance on both valves.

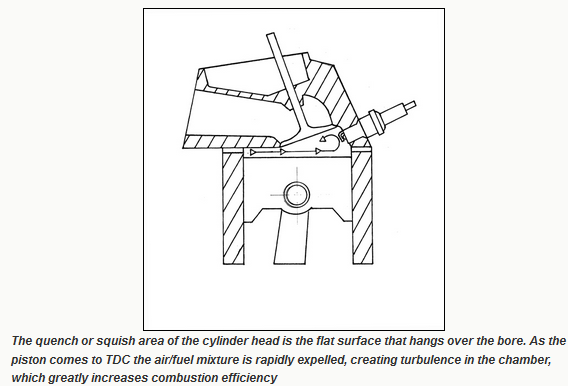

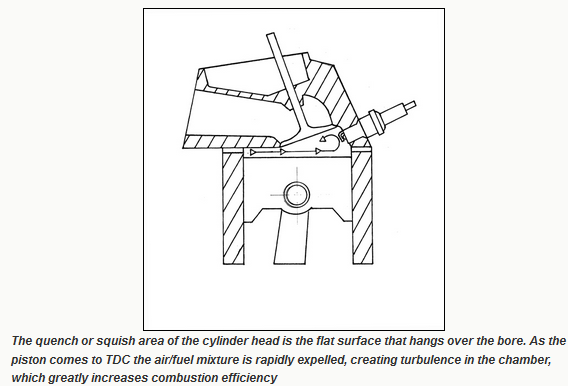

a heat barrier piston deck coating, a .044 quench

youll want a 7-8 quart baffled oil pan with a windage tray

you'll

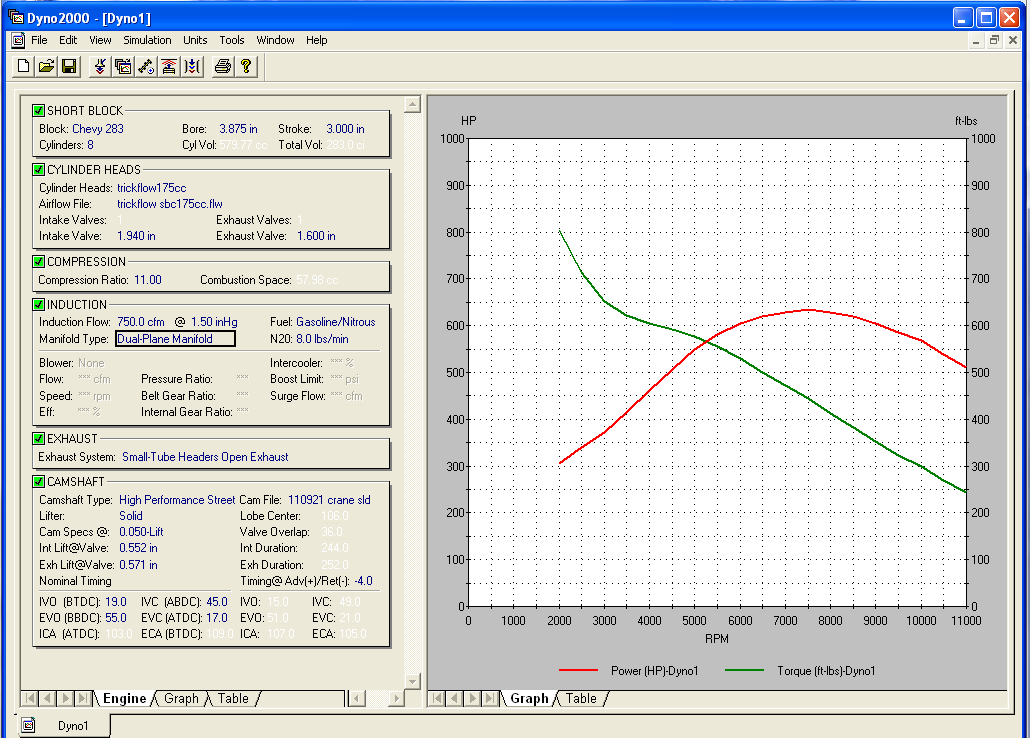

want a 750 cfm holley carburetor.

a manual transmission, in the lightest car available, like a T-BUCKET,

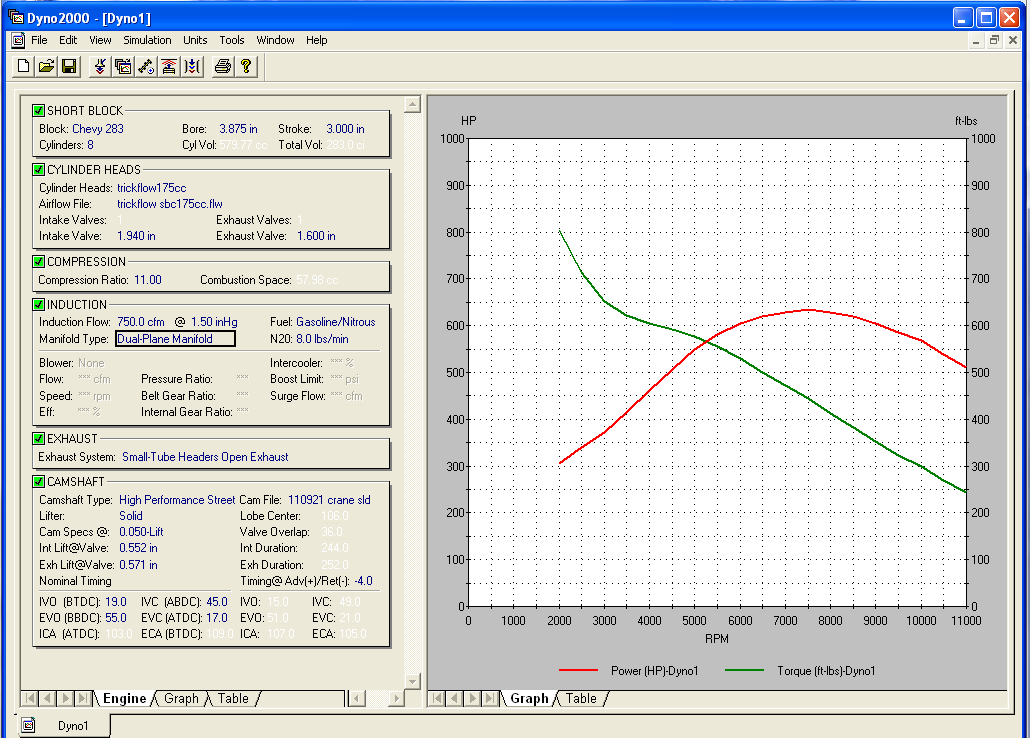

with at least a 28"-29" tire and a 4.88:1 rear gear, and your launching at about 4500 rpm off the line, internal balance and a 30 lb steel billet flywheel and sfi flywheel and clutch and blow proof bell housing, and a 200 hp wet nitrous plate system

N/A (hell yes you need race gas octane)

with race octane gas and WET 200HP nitrous plate

http://www.summitracing.com/parts/zex-82040

a 302 can be built to provide an impressive power curve but it will need to operate in the 4500 rpm-7500 rpm power band to maximize its power potential

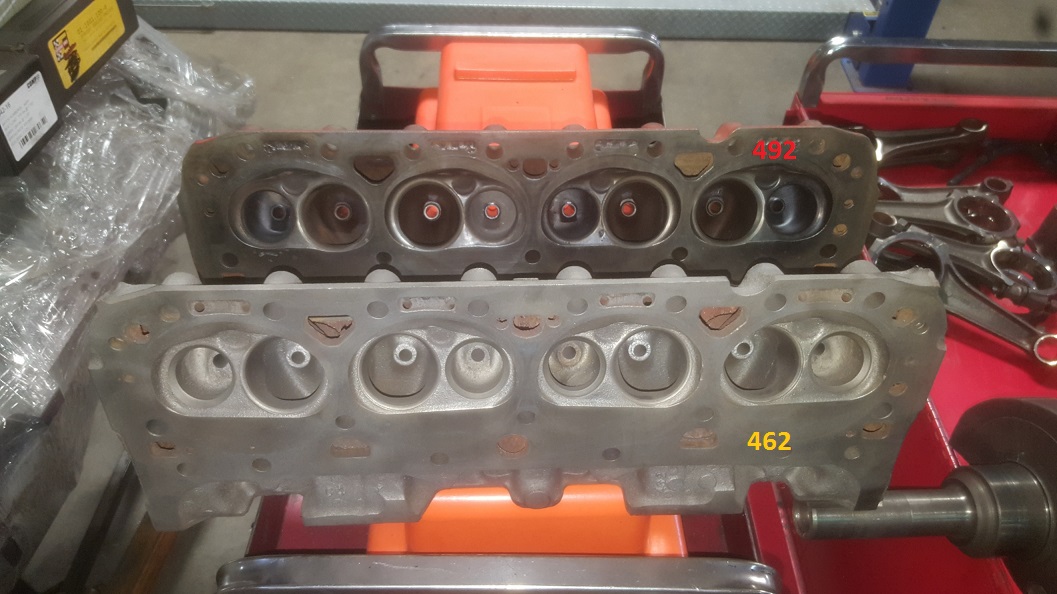

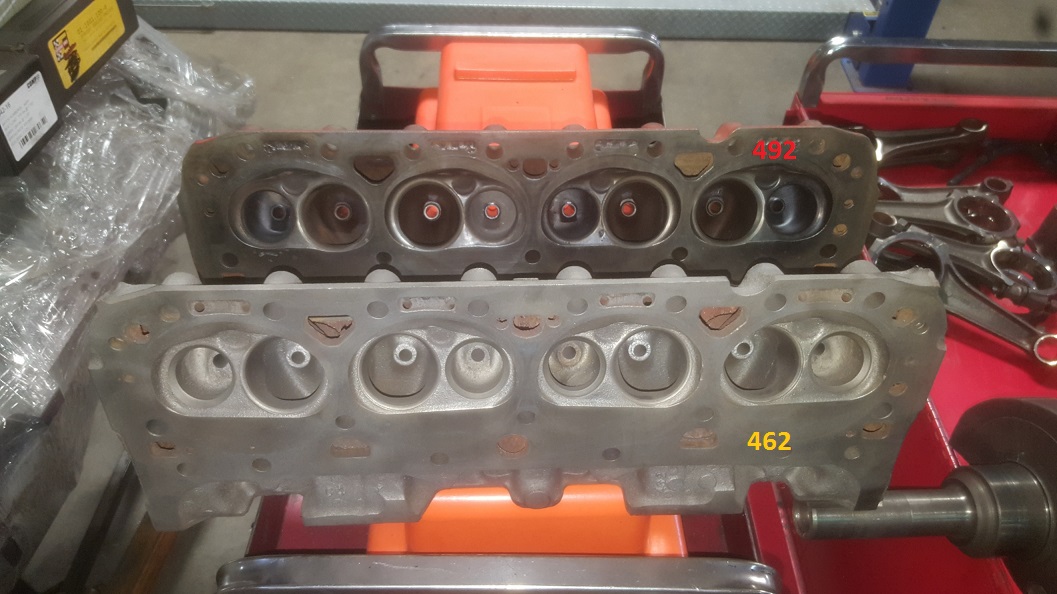

back in the 1970s a great many of us , looking for better power in a 302 or the high performance and high compression versions of the 327 ,swapped the valve springs out for much better valve springs, installed rocker stud girdles, extra tall valve covers, on mildly ported fuelie heads or if you were bucks up you bought CRANE fireball PORTED heads , (usually Casting Number 3890462) CANDFIELD OR or brownfield aluminum heads and installed long tube headers, and low restriction exhaust systems in Z28"s, and VEGAS with 4 speed transmissions and used 11:1 compression 302-327 and a few 377 engines and we used a 780 cfm holley or dual 500 cfm carter carb dual quads, we installed a 4.11:1 -4.56:1 rear gear's we used the bigest slicks that would fit the cars, and used a crane 110921 solid lifter cam and 1.6:1 roller rockers (that was a very well respected combo) (a few of us used SMOKEY RAM INTAKES) and we had very noticeable improvements in the cars performance.

keep in mind that youll want a 7-8 quart capacity , baffled oil pan with a windage tray thats been carefully installed with the correct clearances anda balanced rotating assembly with ideally 6" connecting rods and forged components for the crank rods and pistons and use of ARP 7/16" rod bolts, and a manual transmission, SFI certified billet flywheel and a blow proof bell housing, too maintain consistent oil pressure, and keep your toes attached to your feet, and increase durability as stock O.E.M. components will not last forever if your spinning the engine north of 7500 rpm consistently

if you could tune and set up a suspension, had decent traction bars ,etc. , had decent slicks and you had the skills too drive well, ten second 1/4 mile time slips were occasionally seen, even back them , in a vega or lightened camaro or nova.

of course with the better cylinder heads now available like the 215CC large port vorted or 210cc AFR or 215cc BRODIX adding an aditional 60 hp-100hp to those older engines would be rather easy.

http://garage.grumpysperformance.com/index.php?threads/long-rod-302.12866/

http://garage.grumpysperformance.com/index.php?threads/smokeram-or-str10.3431/#post-9088

http://www.superchevy.com/how-to/project-cars/sucp-1004-high-rpm-302-engine-build/

http://www.superchevy.com/how-to/project-cars/sucp-0903-302-small-block-engine-build/

http://www.superchevy.com/how-to/project-cars/sucp-0903-302-small-block-engine-build/

a couple KEY factors in getting any smaller displacement SBC engine to perform well, is your going to have to get the static compression ratio up in the 10.5:1 or higher range and match the cam duration and lift to maximize the port air flow rates in the upper rpm range, and that will generally require selecting a solid lifter cam, use of tuned headers with a low restriction exhaust, and gearing the cars drive train to allow it to maximize, the engines ability to breath in the 4500 rpm-7500 rpm, range that a short stroke 3"-3.25" SBC engine is capable of if properly designed and constructed

the cylinder head port size required can be easily calculated,many guys seem to think your limited to a certain size port for a certain displacement, but the fact is that theres far more factors that effect the correct port configuration and port size than engine displacement alone.

the bore size of the smaller SBC engines like a 265 or 283 won,t physically allow the use of the larger 2.02" intake and 1.60" exhaust valves, especially with longer duration high lift cam profiles.

if you do the research youll find that carefully matched cam timing,and header design can be used to increase the cylinder fill efficiency.

always accurately measure the crank main journals, and remember the crank and block bearing sizes on a 400 sbc and 350 smc are different as are the early 283-327 sbc

USE THE CALCULATORS to match port size to intended rpm levels... but keep in mind valve lift and port flow limitations

http://www.wallaceracing.com/runnertorquecalc.php

http://www.wallaceracing.com/ca-calc.php

http://www.wallaceracing.com/area-under-curve.php

http://www.wallaceracing.com/chokepoint.php

http://www.wallaceracing.com/header_length.php

http://www.circletrack.com/enginetech/1 ... ch_engine/

While cheat sheets might have frowned upon in your sixth-grade classroom, we strongly encourage them in the garage, shop, or pits. That’s why we’ve put together this list of 13 key performance formulas you should know when building or tuning your street or race vehicle.

http://garage.grumpysperformance.co...lap-on-factory-headers.3155/page-2#post-66722

http://www.race-cars.net/calculators/compression_calculator.html

http://garage.grumpysperformance.com/index.php?threads/a-few-calculator-links.7108/#post-27382

http://www.projectpontiac.com/ppsite15/compression-ratio-calculator

http://www.wallaceracing.com/dynamic-cr.php

http://www.rbracing-rsr.com/comprAdvHD.htm

http://performancetrends.com/Compression_Ratio_Calculator_V2.3.htm

http://www.wallaceracing.com/cr_test2.php

http://www.pcengines.com.au/calculators/Calculate dynamic Comp Ratio.htm

http://www.csgnetwork.com/compcalc.html

http://www.diamondracing.net/tools/

https://www.uempistons.com/index.php?main_page=calculators&type=comp

https://www.rbracing-rsr.com/compstaticcalc.html

Racing Carburetor CFM

Racing Carburetor CFM = RPM x Displacement ÷ 3456 x 1.1

Note: Summit Racing also offers this CFM Calculator to make the job easier.

Displacement

Displacement = .7854 x Bore2 x Stroke x Number of Cylinders

Correct Compression Ratio (CCR)

CCR = FCR (Altitude/1,000) x .2

Note: You can also take this Compression Ratio Calculator tool for a spin.

Tire Diameter

Tire Diameter = (MPH x Gear Ratio x 336) ÷ RPM

Rocker Arm Ratio and Valve Lift

Gross Valve Lift = Camshaft Lobe Lift x Rocker Arm Ratio

Horsepower

Horsepower = (RPM x Torque) ÷ 5,252

Torque

Torque = (5,252 x HP) ÷ RPM

Rod Ratio

Rod Ratio = Rod Length ÷ Crank Stroke Length

Average Piston Speed

Average Piston Speed = Crank Stroke x RPM ÷ 6

Rear Gear Ratio

Rear Gear Ratio = (RPM at Finish Line x Tire Diameter) ÷ (MPH x 336)

Note: You can also save this link to a handy Gear Ratio calculator.

Volume (CCs) of Deck Clearance

CCs of Deck Clearance = Bore x Bore x 12.87 x Depth of Deck Clearance

Volume (CCs) of Head Gasket

CCs of Head Gasket = Bore x Bore x 12.87 x Thickness of Head Gasket

Intake Port to Torque Peak

- Long Port Length: Improve low RPM range

- Short Port Length: Improve high RPM range

- Large Cross Section: Works better on larger CID and higher RPM

- Too large of a cross section can cause reversion and less power

- Small Cross Section: Works better on smaller CID and lower RPM

- Smallest cross section without losing HP is the best size

here's a chart FROM THE BOOK,HOW TO BUILD BIG-INCH CHEVY SMALL BLOCKS with some common cross sectional port sizes

(measured at the smallest part of the ports)

...........................sq inches........port cc

edelbrock performer rpm ....1.43.............170

vortec......................1.66.............170

tfs195......................1.93.............195

afr 180.....................1.93.............180

afr 195.....................1.98.............195

afr 210.....................2.05.............210

dart pro 200................2.06.............200

dart pro 215................2.14.............215

brodix track 1 .............2.30.............221

dart pro 1 230..............2.40.............230

edelbrock 23 high port .....2.53.............238

edelbrock 18 deg............2.71.............266

tfs 18 deg..................2.80.............250

COMMON SBC INTAKE PORTS

felpro # 1204=Port Size: 1.23" x 1.99"=2.448 sq inches

felpro # 1205=Port Size: 1.28" x 2.09"=2.67 sq inches

felpro # 1206=Port Size: 1.34" x 2.21"=2.96 sq inches

felpro # 1207=Port Size: 1.38" x 2.28"=3.146 sq inches

felpro # 1209=Port Size: 1.38" x 2.38"=3.28 sq inches

felpro # 1255 VORTEC=Port Size: 1.08" x 2.16"-2.33 sq inches

felpro # 1263=Port Size: 1.31" x 2.02"=2.65 sq inches

felpro # 1266=Port Size: 1.34" x 2.21"=2.96 sq inches

felpro # 1284 LT1=Port Size: 1.25 x 2.04''=2.55 sq inches

felpro # 1289 FASTBURN=Port Size: 1.30" x 2.31" 3.00 sq inches

http://garage.grumpysperformance.co...ut-building-a-283-305-or-307-this-may-be.427/

If your looking to build a rather serious 283 sbc in a light weight car

, yes you can get good power,the potential strong suite of the 283 sbc is it potential to rpm in the 5000 rpm-to-8000 rpm range with its short 3" stroke with the proper matching valve train and compression

but it won,t be very useful below about 4500rpm,

and hardly ideal for daily street driving or useful on pump octane fuel

the heads you select will be rather critical here so don,t scrimp, youll need decent roller rockers AND a matching rocker stud girdle,

http://www.summitracing.com/parts/tfs-30400700/overview/

the 175cc port and 56cc combustion chamber sbc trick flow cylinder heads that are about $590 EACH or about $1200 for a pair fit the application well

and yes some time spent , by a reasonably skilled porting specialist or your machine shop or you, in port and bowl area clean-up port work and plenum clean up, port matching, on the intake manifold, and use of open headers, will be nearly mandatory

http://www.grumpysperformance.com/tfsairflows.pdf

http://www.summitracing.com/parts/tfs-30310002

YES THE tfs-30310002 with the 1.47 better valve springs

YES YOULL NEED to swap the valve retainers and install even better and stronger valve springs, but of the correct load rate for the cam and lifters, that handle a .600 lift with additional clearance,

this engines going to be shifting at about 8k rpm

with a 3" stroke you have the potential to build a decent high rpm engine so you may as well take advantage of the engines true potential.

http://www.summitracing.com/parts/crn-11759-16

http://www.summitracing.com/parts/crn-110921

crane solid lifter cam

http://www.summitracing.com/parts/cro-66909x980-16

crower cool face solids

intake manifold

http://www.summitracing.com/parts/edl-7501/overview/make/chevrolet

For a Chevrolet 350, the traditional rod journal size is 2.1 inches. Engine builders have found there are numerous advantages of a smaller journal size, the most significant being that it slows the bearing speed. there are spacer rod bearings to use the 2.1" connecting rods on the 283 & 327 sbc smaller 2.0 rod journal diam.

http://www.lunatipower.com/Product.aspx?id=309

rods

http://www.jegs.com/i/Scat/942/26000716/10002/-1?parentProductId=761557

If I was building it ID want 1 5/8" long tube open headers, youll want J&E forged pistons that produce 11:1 compression

low drag rings, Id suggest a .120 valve to piston clearance on both valves.

a heat barrier piston deck coating, a .044 quench

youll want a 7-8 quart baffled oil pan with a windage tray

you'll

want a 750 cfm holley carburetor.

a manual transmission, in the lightest car available, like a T-BUCKET,

with at least a 28"-29" tire and a 4.88:1 rear gear, and your launching at about 4500 rpm off the line, internal balance and a 30 lb steel billet flywheel and sfi flywheel and clutch and blow proof bell housing, and a 200 hp wet nitrous plate system

N/A (hell yes you need race gas octane)

with race octane gas and WET 200HP nitrous plate

http://www.summitracing.com/parts/zex-82040

a 302 can be built to provide an impressive power curve but it will need to operate in the 4500 rpm-7500 rpm power band to maximize its power potential

back in the 1970s a great many of us , looking for better power in a 302 or the high performance and high compression versions of the 327 ,swapped the valve springs out for much better valve springs, installed rocker stud girdles, extra tall valve covers, on mildly ported fuelie heads or if you were bucks up you bought CRANE fireball PORTED heads , (usually Casting Number 3890462) CANDFIELD OR or brownfield aluminum heads and installed long tube headers, and low restriction exhaust systems in Z28"s, and VEGAS with 4 speed transmissions and used 11:1 compression 302-327 and a few 377 engines and we used a 780 cfm holley or dual 500 cfm carter carb dual quads, we installed a 4.11:1 -4.56:1 rear gear's we used the bigest slicks that would fit the cars, and used a crane 110921 solid lifter cam and 1.6:1 roller rockers (that was a very well respected combo) (a few of us used SMOKEY RAM INTAKES) and we had very noticeable improvements in the cars performance.

keep in mind that youll want a 7-8 quart capacity , baffled oil pan with a windage tray thats been carefully installed with the correct clearances anda balanced rotating assembly with ideally 6" connecting rods and forged components for the crank rods and pistons and use of ARP 7/16" rod bolts, and a manual transmission, SFI certified billet flywheel and a blow proof bell housing, too maintain consistent oil pressure, and keep your toes attached to your feet, and increase durability as stock O.E.M. components will not last forever if your spinning the engine north of 7500 rpm consistently

if you could tune and set up a suspension, had decent traction bars ,etc. , had decent slicks and you had the skills too drive well, ten second 1/4 mile time slips were occasionally seen, even back them , in a vega or lightened camaro or nova.

of course with the better cylinder heads now available like the 215CC large port vorted or 210cc AFR or 215cc BRODIX adding an aditional 60 hp-100hp to those older engines would be rather easy.

http://garage.grumpysperformance.com/index.php?threads/long-rod-302.12866/

http://garage.grumpysperformance.com/index.php?threads/smokeram-or-str10.3431/#post-9088

http://www.superchevy.com/how-to/project-cars/sucp-1004-high-rpm-302-engine-build/

http://www.superchevy.com/how-to/project-cars/sucp-0903-302-small-block-engine-build/

http://www.superchevy.com/how-to/project-cars/sucp-0903-302-small-block-engine-build/

Last edited: