8

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Building a S̶t̶r̶o̶n̶g̶ ̶3̶5̶0̶ 383 for Frank the Tank…

- Thread starter JimmyDuncan

- Start date

JimmyDuncan

Well-Known Member

Hmmm, seems to be tough to find here too....

One bottle from within Oz will cost me about $50-60... Or, I can buy it from US for $28 + $55 postage.... ha!

Maybe Ill try some more wallet friendly air + solvent cleaning as Bob suggested.... If I'm not happy with results I'll pick up a stand alone trans cooler...

Whats the chances that the current radiator will not be up to cooling duties for the new engine..? Maybe a new radiator will be in my future too?

I currently don't have a shroud... which I know will likely be a help..

One bottle from within Oz will cost me about $50-60... Or, I can buy it from US for $28 + $55 postage.... ha!

Maybe Ill try some more wallet friendly air + solvent cleaning as Bob suggested.... If I'm not happy with results I'll pick up a stand alone trans cooler...

Whats the chances that the current radiator will not be up to cooling duties for the new engine..? Maybe a new radiator will be in my future too?

I currently don't have a shroud... which I know will likely be a help..

8

87vette81big

Guest

Plan on a new upgraded radiator & electric fan Jimmy.

Unless you have the Optional factory 4-core brass copper radiator.

Unless you have the Optional factory 4-core brass copper radiator.

busterrm

solid fixture here in the forum

Might be a good idea to look at summit racing, they have OEM replacements in 3-4 core, I got a 3 core for my nova for 275 bux, but it may be good to stick with what you have and wait till after your move to buy a new radiator, mine slipped in and bolted up in OEM configuration. If your current radiator is still good and can do a easy enough cleaning of the trans cooler you may not need a new one.Plan on a new upgraded radiator & electric fan Jimmy.

Unless you have the Optional factory 4-core brass copper radiator.

JimmyDuncan

Well-Known Member

Might be a good idea to look at summit racing, they have OEM replacements in 3-4 core, I got a 3 core for my nova for 275 bux, but it may be good to stick with what you have and wait till after your move to buy a new radiator, mine slipped in and bolted up in OEM configuration. If your current radiator is still good and can do a easy enough cleaning of the trans cooler you may not need a new one.

True. Hopefully Summit and Jegs will ship at a reasonable price to NZ...

Waiting to see if its broke before fixing it is sound advice...

JimmyDuncan

Well-Known Member

Quick question... (I'll update on the overall progress soon..) Can any damage be done to a new build 383, driving about a handful of times over the course of a month with an under size exhaust, until exhaust shop can fit in building a new one..?

I have 1 3/4" headers into a 2" exhaust that is obviously not great, as it sounds a bit strangled and crackles when I rev it (no crossover).. Can I go for the occasional cruise and run in the engine without fear of damage..? End of month a new system will go on..

I have 1 3/4" headers into a 2" exhaust that is obviously not great, as it sounds a bit strangled and crackles when I rev it (no crossover).. Can I go for the occasional cruise and run in the engine without fear of damage..? End of month a new system will go on..

power will be down noticeably once the rpms increase over about 3000rpm,

but for the short term I don,t think you have ANYTHING,

to worry about running a restrictive exhaust short term,

your simply not allowing the engine to breath efficiently under stress,

thats a bit like taping your mouth shut with duct tape,

and asking you to run a 200 yard sprint breathing only through your nose....

its just not likely youll turn in your best effort ever,

but youll likely just learn to take things a bit slower in either case.

but for the short term I don,t think you have ANYTHING,

to worry about running a restrictive exhaust short term,

your simply not allowing the engine to breath efficiently under stress,

thats a bit like taping your mouth shut with duct tape,

and asking you to run a 200 yard sprint breathing only through your nose....

its just not likely youll turn in your best effort ever,

but youll likely just learn to take things a bit slower in either case.

JimmyDuncan

Well-Known Member

Great. Thanks Grumpy. I'm glad... I just got it registered to drive on the road here in New Zealand last night.. It's been a couple of months and I'm keen to cruise about..power will be down noticeably once the rpms increase over about 3000rpm,

but for the short term I don,t think you have ANYTHING,

to worry about running a restrictive exhaust short term

JimmyDuncan

Well-Known Member

Verifying TDC....

So, long story short... (I'll write up the long story another day..) I do not have confidence in the TDC mark on my balancer..

My new 383 has a larger 400 size (8") balancer and I'm not confident that my marker (I don't know what it came off.. ) is positioned correctly and/or if when the mark on the balancer is on zero that I am at TDC... I understand that different years and balancer sizes require different positions for the pointer..

) is positioned correctly and/or if when the mark on the balancer is on zero that I am at TDC... I understand that different years and balancer sizes require different positions for the pointer..

I need to confirm TDC.. I have a piston stop. I tried to use it, however it seems like it may not be hitting the piston.... I think maybe the angle of the plugs is such that it sits in the compression chamber in the head and misses the piston? Which also has me worried it may contact the valves? With the stop screwed all the way out, the engine just kept rotating without showing any sign of stopping... Is there another method, engine in car to verify TDC...? I've seen a few posts about purpose bent piston stops..?

http://www.promaxxperformance.com/index.php/racing-parts/sbc/sbc-small-block-chevy-2112.html

So, long story short... (I'll write up the long story another day..) I do not have confidence in the TDC mark on my balancer..

My new 383 has a larger 400 size (8") balancer and I'm not confident that my marker (I don't know what it came off..

I need to confirm TDC.. I have a piston stop. I tried to use it, however it seems like it may not be hitting the piston.... I think maybe the angle of the plugs is such that it sits in the compression chamber in the head and misses the piston? Which also has me worried it may contact the valves? With the stop screwed all the way out, the engine just kept rotating without showing any sign of stopping... Is there another method, engine in car to verify TDC...? I've seen a few posts about purpose bent piston stops..?

http://www.promaxxperformance.com/index.php/racing-parts/sbc/sbc-small-block-chevy-2112.html

JimmyDuncan

Well-Known Member

No hints, tips or suggestions...?

sorry I just missed this

(btw when using a spark plug in the cylinder head style piston stop tool

if your standard strait probe/stop tool is not touching the piston due to the shallow enterance angle

youll want to remove ALL the spark plugs and back off ALL the rockers

on not only cylinder number one ,

but all the cylinders ,

so you can feel the engine as it moves/rotates

yes youll need to adjust valve when your done finding TDC

http://garage.grumpysperformance.com/index.php?threads/adjusting-valves.196/

and make sure the cars not in gear so that the engine can be rotated much more easily when done manually,

this prevents the valves in cylinder number one from opening and removing the other spark plugs greatly reduces resistance due to compression.

yes your problem, is FAR from rare and in fact its very common most guys simply take an old spark plug,

put it in a vise and bust out the old porcilian center and re-thread the interior of the remaining metal hex.

or buy a tool like comps

https://www.summitracing.com/parts/...-_-comp-cams&gclid=CJ3wuuyJ8tACFYOFswodCKYKvw

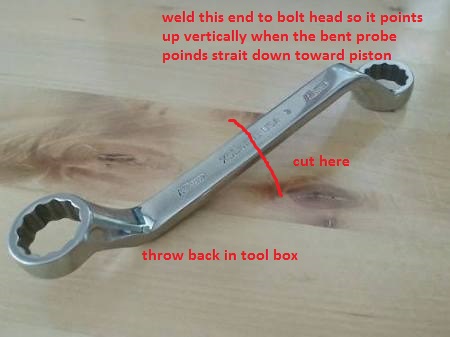

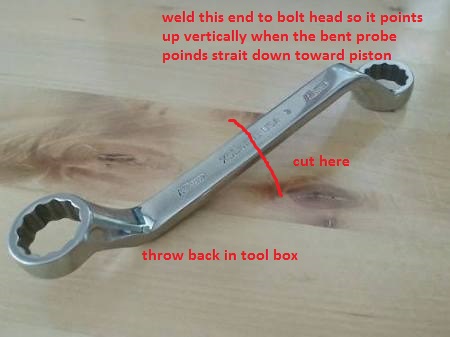

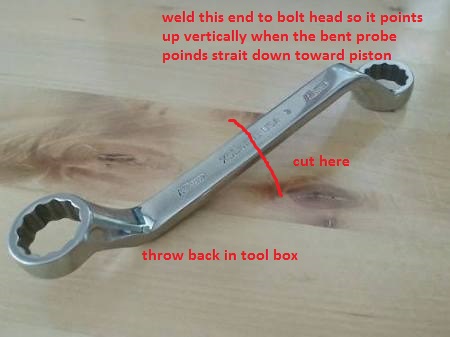

you then buy a 6" threaded bolt, screw it into the plug body

IF THAT BOLT IN THE PISTON STOP EXTENDED AN ADDITIONAL 1.5"FURTHER INTO THE CYLINDER

I'M FAIRLY SURE IT WOULD HAVE BEEN HITTING THE PISTON AND THUS FUNCTIONING AS DESIGNED

you buy a 6" threaded bolt, screw it into the plug body

with similar thread pitch and thread, that fully threaded bolt about 3" of that bolt extending past the spark plug base,into the cylinder, at that shallow angle, it would be preventingthe piston from reaching TDC

and heat and bend it with your propane or acetylene torch in a shallow curve,

now BRAZE or weld a cheap socket head wrench to the bolt head so it can,t move off the bolt and indexed so ,

its pointing strait up when the bent internal part of the piston stop points strait down ward

RELATED THREADS

http://garage.grumpysperformance.com/index.php?threads/cam-degreeing.9010/#post-35474

http://garage.grumpysperformance.co...et-it-to-last-cam-install-info.90/#post-31431

http://garage.grumpysperformance.co...ter-1-for-timing-ignition-cam.966/#post-18999

http://garage.grumpysperformance.com/index.php?threads/turning-your-crank-manually.5933/#post-18274

http://garage.grumpysperformance.com/index.php?threads/cam-degree-equipment-tools.1759/#post-4441

now you can stick the bent bolt into the cylinder, thread the bolt body into the head and once its seated in the head,

you can easily index the bent part to point down into the cylinder where it will contact the piston as it rotates

which a strait bolt would not do due to the shallow enterance angle

be aware that you need to be able to feel the engine stop when it contacts the probe tip, if you don,t manually turn the engine fter first removing the other spark plugs ,

and backing off the rockers the resistannce to rotation the valve train and compression have will make felling the piston contacting the piston stop difficult,

and you damn sure don,t want to bend or break the piston stop.

(btw when using a spark plug in the cylinder head style piston stop tool

if your standard strait probe/stop tool is not touching the piston due to the shallow enterance angle

youll want to remove ALL the spark plugs and back off ALL the rockers

on not only cylinder number one ,

but all the cylinders ,

so you can feel the engine as it moves/rotates

yes youll need to adjust valve when your done finding TDC

http://garage.grumpysperformance.com/index.php?threads/adjusting-valves.196/

and make sure the cars not in gear so that the engine can be rotated much more easily when done manually,

this prevents the valves in cylinder number one from opening and removing the other spark plugs greatly reduces resistance due to compression.

yes your problem, is FAR from rare and in fact its very common most guys simply take an old spark plug,

put it in a vise and bust out the old porcilian center and re-thread the interior of the remaining metal hex.

or buy a tool like comps

https://www.summitracing.com/parts/...-_-comp-cams&gclid=CJ3wuuyJ8tACFYOFswodCKYKvw

you then buy a 6" threaded bolt, screw it into the plug body

IF THAT BOLT IN THE PISTON STOP EXTENDED AN ADDITIONAL 1.5"FURTHER INTO THE CYLINDER

I'M FAIRLY SURE IT WOULD HAVE BEEN HITTING THE PISTON AND THUS FUNCTIONING AS DESIGNED

you buy a 6" threaded bolt, screw it into the plug body

with similar thread pitch and thread, that fully threaded bolt about 3" of that bolt extending past the spark plug base,into the cylinder, at that shallow angle, it would be preventingthe piston from reaching TDC

and heat and bend it with your propane or acetylene torch in a shallow curve,

now BRAZE or weld a cheap socket head wrench to the bolt head so it can,t move off the bolt and indexed so ,

its pointing strait up when the bent internal part of the piston stop points strait down ward

RELATED THREADS

http://garage.grumpysperformance.com/index.php?threads/cam-degreeing.9010/#post-35474

http://garage.grumpysperformance.co...et-it-to-last-cam-install-info.90/#post-31431

http://garage.grumpysperformance.co...ter-1-for-timing-ignition-cam.966/#post-18999

http://garage.grumpysperformance.com/index.php?threads/turning-your-crank-manually.5933/#post-18274

http://garage.grumpysperformance.com/index.php?threads/cam-degree-equipment-tools.1759/#post-4441

now you can stick the bent bolt into the cylinder, thread the bolt body into the head and once its seated in the head,

you can easily index the bent part to point down into the cylinder where it will contact the piston as it rotates

which a strait bolt would not do due to the shallow enterance angle

be aware that you need to be able to feel the engine stop when it contacts the probe tip, if you don,t manually turn the engine fter first removing the other spark plugs ,

and backing off the rockers the resistannce to rotation the valve train and compression have will make felling the piston contacting the piston stop difficult,

and you damn sure don,t want to bend or break the piston stop.

Last edited:

JimmyDuncan

Well-Known Member

sorry I just missed this

(btw when using a spark plug in the cylinder head style piston stop tool

if your standard strait probe/stop tool is not touching the piston due to the shallow enterance angle

youll want to remove ALL the spark plugs and back off ALL the rockers

on not only cylinder number one ,

but all the cylinders ,

so you can feel the engine as it moves/rotates

yes youll need to adjust valve when your done finding TDC

http://garage.grumpysperformance.com/index.php?threads/adjusting-valves.196/

and make sure the cars not in gear so that the engine can be rotated much more easily when done manually,

this prevents the valves in cylinder number one from opening and removing the other spark plugs greatly reduces resistance due to compression.

yes your problem, is FAR from rare and in fact its very common most guys simply take an old spark plug,

put it in a vise and bust out the old porcilian center and re-thread the interior of the remaining metal hex.

or buy a tool like comps

https://www.summitracing.com/parts/...-_-comp-cams&gclid=CJ3wuuyJ8tACFYOFswodCKYKvw

you then buy a 6" threaded bolt, screw it into the plug body

with similar thread pitch and thread that fully threaded bolt about 3" of that bolt entending past the spark plug base,

and heat and bend it with your propane or acetolene torch in a shallow curve,

now BRAZE or weld a cheap socket head wrench to the bolt head so it can,t move off the bolt and indexed so ,

its pointing strait up when the bent internal part of the piston stop points strait down ward

RELATED THREADS

http://garage.grumpysperformance.com/index.php?threads/cam-degreeing.9010/#post-35474

http://garage.grumpysperformance.co...et-it-to-last-cam-install-info.90/#post-31431

http://garage.grumpysperformance.co...ter-1-for-timing-ignition-cam.966/#post-18999

http://garage.grumpysperformance.com/index.php?threads/turning-your-crank-manually.5933/#post-18274

http://garage.grumpysperformance.com/index.php?threads/cam-degree-equipment-tools.1759/#post-4441

now you can stick the bent bolt into the cylinder, thread the bolt body into the head and once its seated in the head,

you can easily index the bent part to point down into the cylinder where it will contact the piston as it rotates

which a strait bolt would not do due to the shallow enterance angle

be aware that you need to be able to feel the engine stop when it contacts the probe tip, if you don,t manually turn the engine fter first removing the other spark plugs ,

and backing off the rockers the resistannce to rotation the valve train and compression have will make felling the piston contacting the piston stop difficult,

and you damn sure don,t want to bend or break the piston stop.

Ah yes, I've seen the bent piston stop on other forums.. I'll look into that some more. Thanks..

I like the idea of attaching a wrench to the tool, but a line scribed/drawn on the end of the bolt with an arrow will do the same job yes? It will be a tool that gets used rarely I am imagining..?

Maybe replacing the threaded part of the comp piston stop I have with a longer bolt, bending and marking that will do? Would there be occasions when the bent stop won't work..?

Last edited by a moderator:

Ah yes, I've seen the bent piston stop on other forums.. I'll look into that some more. Thanks..

I like the idea of attaching a wrench to the tool, but a line scribed/drawn on the end of the bolt with an arrow will do the same job yes? It will be a tool that gets used rarely I am imagining..?

I guess it depends on how often you check TDC (my cylinder head mounted piston stop tool gets used about 7-8 times a year)

yes a scribed arrow will work but in dim light or crampped engine compartments the welded on short wrench seems to work best for me!

Maybe replacing the threaded part of the comp piston stop I have with a longer bolt, bending and marking that will do?

YES IT SHOULD

Would there be occasions when the bent stop won't work..?

NONE THAT IVE FOUND YET

I like the idea of attaching a wrench to the tool, but a line scribed/drawn on the end of the bolt with an arrow will do the same job yes? It will be a tool that gets used rarely I am imagining..?

I guess it depends on how often you check TDC (my cylinder head mounted piston stop tool gets used about 7-8 times a year)

yes a scribed arrow will work but in dim light or crampped engine compartments the welded on short wrench seems to work best for me!

Maybe replacing the threaded part of the comp piston stop I have with a longer bolt, bending and marking that will do?

YES IT SHOULD

Would there be occasions when the bent stop won't work..?

NONE THAT IVE FOUND YET

JimmyDuncan

Well-Known Member

Ah yes, I've seen the bent piston stop on other forums.. I'll look into that some more. Thanks..

I like the idea of attaching a wrench to the tool, but a line scribed/drawn on the end of the bolt with an arrow will do the same job yes? It will be a tool that gets used rarely I am imagining..?

I guess it depends on how often you check TDC (my cylinder head mounted piston stop tool gets used about 7-8 times a year)

yes a scribed arrow will work but in dim light or crampped engine compartments the welded on short wrench seems to work best for me!

Maybe replacing the threaded part of the comp piston stop I have with a longer bolt, bending and marking that will do?

YES IT SHOULD

Would there be occasions when the bent stop won't work..?

NONE THAT IVE FOUND YET

Cheers again grumpy.

Strictly Attitude

solid fixture here in the forum

I bent mine to do mine

Loves302Chevy

"One test is worth a thousand expert opinions."

With the stop screwed all the way out, the engine just kept rotating without showing any sign of stopping...

??? You either ran the engine with the piston stop screwed in, or cranked it with the starter motor ??? Not good.

JimmyDuncan

Well-Known Member

Ha! No no no no....??? You either ran the engine with the piston stop screwed in, or cranked it with the starter motor ??? Not good.

JimmyDuncan

Well-Known Member

Actually, question - if I start with the TDC mark at the current (maybe not correct) zero mark, how many turns of the balancer should it be till the piston stop stops the piston..? Just one yes??