Assuming you've got both good oil pressure and never allow the engine to run low on oil, its usually,the direct result of lack of good quality oil flow volume,in the valve train, usually due to crud limiting flow thru a lifter or push rod or very infrequent oil changes, or occasionally a rocker adjusted too tightly, with to much preload so the oil can,t be compressed by the lifter seat and forced up the push rod.

frequent oil changes,a lighter 10w30 synthetic, oil,or similar quality oil and good filters adding a qt of marvel mystery oil to the sump to break up crud and hold it in suspension, and only adding a 1/4 turn of lifter preload on the hydraulic flat tappet lifters, will usually prevent that problem.

Clogged lifters and push rods can cause this as can a clogged hole in the rocker that restricts oil to the rocker ball, too cool and lube the contact surfaces.

In short its usually related to a lack of constant high flow rates of clean oil flowing over the rocker ball

I know some of you gentlemen would rather dig your own eyes out of your face with a rusty fork than read links, sub-links and posted info, but amazingly there useful info , in them, like tools that let you detect cam wear early, when to swap filters

what lubes to use,how to adjust and clearance valve trains, use of magnets to trap metallic crud and limit damage, which filters to use, etc.

the total amount of assembly lube you put on the cam and rotating assembly rarely can exceed 4 OZ and that EASILY fits into an oil filter, so if your getting more crud than the first oil filter traps in the first 30 minutes during the engine brake-in process, logic says its COMING from someplace and a quick look at the filter internals with the tool linked above and the magnets you should have installed should give you a good idea as to the source

http://store.summitracing.com/partdetail.asp?autofilter=1&part=SUM-900510&N=700+115&autoview=sku

http://forum.grumpysperformance.com/viewtopic.php?f=44&t=799&p=1161#p1161

http://forum.grumpysperformance.com/viewtopic.php?f=32&t=939&p=1582&hilit=+filter+tool#p1582

http://forum.grumpysperformance.com/viewtopic.php?f=52&t=282

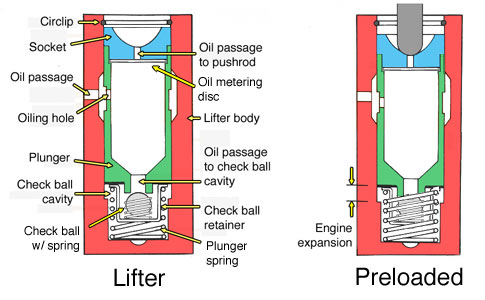

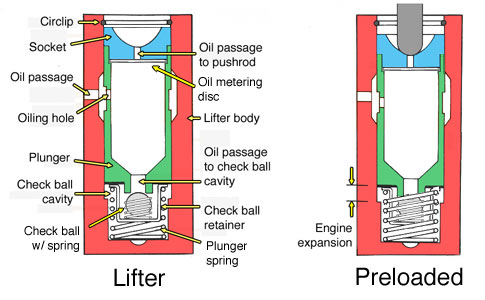

BTW EVER WONDER WHY WHEN YOU PRELOAD THE LIFTER MORE THAN ABOUT A 1/4 TURN ON THE ROCKER ADJUSTMENT NUT THE VOLUME OF OIL SQUIRTING OUT OF THE PUSH RODS DROPS OFF RAPIDLY,

thats really simple, the seat in a hydraulic lifter rides on a cushion of pressurized oil, oil that's displaced up the push-rods as the cam lobe sweeps under the lifter base, as the lifter returns to the cam lobes base circle the lifters seat is pushed back up to full height by oil pressure (one reason lifters tend to click with low oil pressure)

the potential problem is that the total distance the seat supporting the pushrod moves is usually about .055 thousands, a full turn on a rocker nut is usually .040, so the more you preload the lifter the lower the volume of oil under the lifter seat, low oil flow tends to result in low rates of valve train cooling and rapid wear

picture may help

BTW roller lifters are very similar just with a roller wheel added to the base

read these

viewtopic.php?f=52&t=2203

http://www.wallaceracing.com/runnertorquecalc.php

http://www.airflowresearch.com/index.php?cPath=75

viewtopic.php?f=52&t=333

http://www.carcraft.com/techarticles/11 ... index.html

http://www.circletrack.com/techarticles ... index.html

http://www.circletrack.com/techarticles ... index.html

http://www.circletrack.com/techarticles ... index.html

http://www.vetteweb.com/tech/vemp_0204_ ... index.html

http://www.pontiacstreetperformance.com ... rArms.html

viewtopic.php?f=52&t=181&p=215&hilit=+girdle#p215

http://www.enginebuildermag.com/Article ... itch_.aspx

viewtopic.php?f=52&t=126&p=1193&hilit=louis#p1193

frequent oil changes,a lighter 10w30 synthetic, oil,or similar quality oil and good filters adding a qt of marvel mystery oil to the sump to break up crud and hold it in suspension, and only adding a 1/4 turn of lifter preload on the hydraulic flat tappet lifters, will usually prevent that problem.

Clogged lifters and push rods can cause this as can a clogged hole in the rocker that restricts oil to the rocker ball, too cool and lube the contact surfaces.

In short its usually related to a lack of constant high flow rates of clean oil flowing over the rocker ball

I know some of you gentlemen would rather dig your own eyes out of your face with a rusty fork than read links, sub-links and posted info, but amazingly there useful info , in them, like tools that let you detect cam wear early, when to swap filters

what lubes to use,how to adjust and clearance valve trains, use of magnets to trap metallic crud and limit damage, which filters to use, etc.

the total amount of assembly lube you put on the cam and rotating assembly rarely can exceed 4 OZ and that EASILY fits into an oil filter, so if your getting more crud than the first oil filter traps in the first 30 minutes during the engine brake-in process, logic says its COMING from someplace and a quick look at the filter internals with the tool linked above and the magnets you should have installed should give you a good idea as to the source

http://store.summitracing.com/partdetail.asp?autofilter=1&part=SUM-900510&N=700+115&autoview=sku

http://forum.grumpysperformance.com/viewtopic.php?f=44&t=799&p=1161#p1161

http://forum.grumpysperformance.com/viewtopic.php?f=32&t=939&p=1582&hilit=+filter+tool#p1582

http://forum.grumpysperformance.com/viewtopic.php?f=52&t=282

BTW EVER WONDER WHY WHEN YOU PRELOAD THE LIFTER MORE THAN ABOUT A 1/4 TURN ON THE ROCKER ADJUSTMENT NUT THE VOLUME OF OIL SQUIRTING OUT OF THE PUSH RODS DROPS OFF RAPIDLY,

thats really simple, the seat in a hydraulic lifter rides on a cushion of pressurized oil, oil that's displaced up the push-rods as the cam lobe sweeps under the lifter base, as the lifter returns to the cam lobes base circle the lifters seat is pushed back up to full height by oil pressure (one reason lifters tend to click with low oil pressure)

the potential problem is that the total distance the seat supporting the pushrod moves is usually about .055 thousands, a full turn on a rocker nut is usually .040, so the more you preload the lifter the lower the volume of oil under the lifter seat, low oil flow tends to result in low rates of valve train cooling and rapid wear

picture may help

BTW roller lifters are very similar just with a roller wheel added to the base

read these

viewtopic.php?f=52&t=2203

http://www.wallaceracing.com/runnertorquecalc.php

http://www.airflowresearch.com/index.php?cPath=75

viewtopic.php?f=52&t=333

http://www.carcraft.com/techarticles/11 ... index.html

http://www.circletrack.com/techarticles ... index.html

http://www.circletrack.com/techarticles ... index.html

http://www.circletrack.com/techarticles ... index.html

http://www.vetteweb.com/tech/vemp_0204_ ... index.html

http://www.pontiacstreetperformance.com ... rArms.html

viewtopic.php?f=52&t=181&p=215&hilit=+girdle#p215

http://www.enginebuildermag.com/Article ... itch_.aspx

viewtopic.php?f=52&t=126&p=1193&hilit=louis#p1193