http://www.holley.com/HiOctn/ProdLine/Products/ES/ESHHSCH/Sidemnt.html

http://www.youtube.com/watch?v=6grztIXf ... re=related

http://www.classicchambered.com/classic/products.html

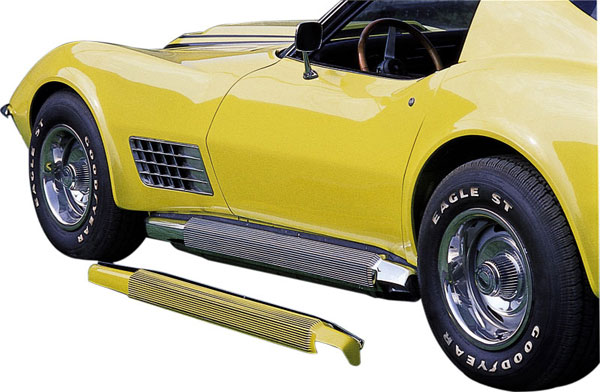

I had zero problem with exhaust gases getting into the car but I did notice they were louder than stock (LIKE I CHOSE THEM FOR THEIR QUITE, SOUND LEVELS! SHEESSS!) I chose them because they were lighter in weight and had long primairys for excellent low rpm torque while having easily removable internal mufflers for quick removal at the track!

personally I would prefer the hooker headers and side pipes, on any c3 big block corvette after having them on my 1968 corvette for over a decade, the MUFFLER inserts are a totally different deal thou , I found those factory inserts to be very very restrictive...and yes youll learn very fast that synthetic fiber in slacks or shorts is a huge NO! NO! , cotton base jeans can touch hot side pipes buts most synthetics melt almost instantly as does SKIN in direct contact with side pipes so gals won,t like them

I truely wish they were available for the 1985 corvette, and (Im sure I will make a custom set when I build my final version,exhaust for my engine swap,bbc 1985 custom corvette)

personally I think they add something to the cars appeal/appearance but be aware your girlfriend/wife may detest them as they tend to leave bad burns on girls ankles as they exit the car and allow their leg to contact the exhaust, guys don't tend to have the same problem except if your wearing shorts because brief contact with blue jeans goes un-notice unless they are synthetic blend that tends to melt, cotton tends to insulate well enough without burning that you'll barely notice brief contact. however the wife will [censored] constantly if burnt, so be advised you'll need to both point the potential burn hazard out before and after she enters/exits the car each and every time, and if she still manages to burn herself its still YOUR FAULT! :crazy:

we guys tend to look at it as "IF YOUR GOING TO BE DUMB YOU BETTER BE TOUGH!" and overlook that minor potential problem! :grin:

if the muffler inserts get rusted or stuck into the outer exhaust side tubes

a couple good whacks to loosen the insert and the solvent mix below should allow the insert to slide out

they can get wedged with rust and corrosion,if you coat them with oil on the outside surface of the insert muffler before the insert mufflers are installed, it tends to come out easier later, if not, pour a cup of 50% diesel fuel/50% acetone mix in and lit sit for 15 minutes to loosen corrosion then while waiting buy a 6" long 5/16" hook bolt and a short section of 1" electrical conduit to fabricate a removal tool, and yes if you do coat the muffler insert with oil it will tend to take all day before it stops smoking very slightly.

stock hooker baffles are restrictive

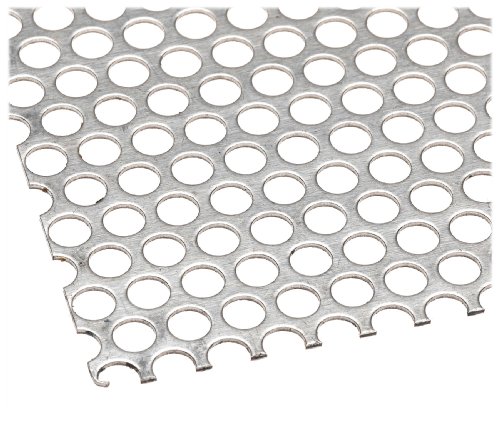

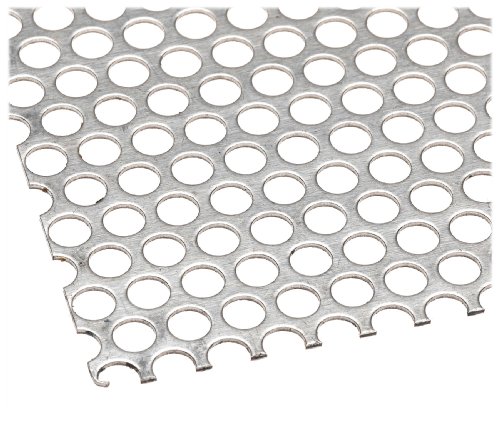

I eventually threw my muffler inserts in a dumpster and fabricated my own from preforated stainless sheet steel as they proved to be far less restrictive

here once again is where having the ability to weld and fabricate is a huge plus, the factory baffle inserts are very restrictive

you can and really should fabricate a set of spiral baffles from perforated steel tube and sheet, it will significantly reduce any restriction to exhaust

http://www.spiralturbobaffles.com/

http://www.macsmufflers.co.nz/cs/prodLi ... Category=9

http://www.metalgeek.com/static/cope.pcgi

I know when I had my 13.7:1 compression,496 big block , I had hooker side pipe headers installed , we noticed a big difference in MPH with the inserts in place (something like a 3mph reduction) so we simply cut about 12 3.9" diam. circular baffles out of perforated stainless sheet metal

and spaced, 6 of them in each side pipe, spaced out with a threaded rod and 24 nuts and washers spaced about every 6" on a 3 foot long section of 1/2" threaded rod, inserted in the center of each perforated stainless baffle plate,and we inserted them in each side pipe ,this perforated sheet we used had about 1/4" holes and about 50% coverage ,and worked reasonably well,at reducing the noise compared to open headers,and allowed us to make decent power , much better than the hooker inserts did, but the insert we made was not as well designed as i would make now, as back then, I had far less understanding of what we were really trying to accomplish, but still it worked.

IF YOU HAVE A DECENT MIG OR TIG WELDER and access to some metal fabrication equipment I think youll be far ahead if you take the time and effort to use perforated steel sheet and tube or pipe too custom build side pipe insert mufflers, similar to the spiralturbobaffles out of perforated steel sheet and steel tube, as the perforated steel tube and sheet material lends it self quite well to the application while allowing both good flow rates and good sound wave disruption, a custom pattern made from cardboard, for the baffles and the perforated central 1"-1.5" pipe would not be dirt cheap but would be available if you shop carefully and flow better than the spiralturbobaffles

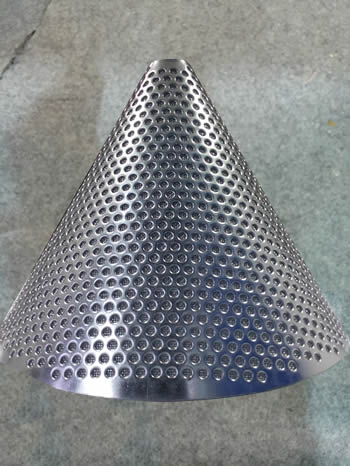

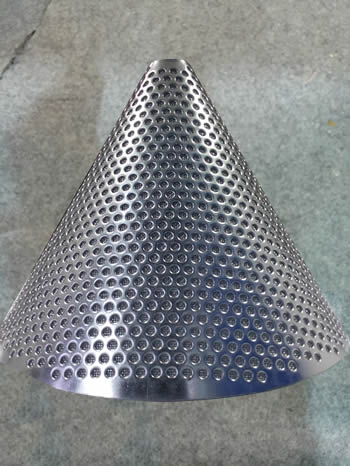

theres also exhaust insert cones whose total open surface area exceeds the diameter , because the geometry of the surface area of a cone allows a greater surface area on the surface than the base but I think the smallest is 3" diam.

that you can fabricate something similar much cheaper,if you weld, these cones are expensive if you buy them, but hardly difficult to fabricate,

it certainly would not be all that difficult to fabricate an exact fit pattern out of poster board then use that to cut perforated sheet steel to make your own, custom, perfect fitting, muffler insert baffle, versions, that easily out flow the standard insert mufflers.

If your not into fabricating you could make a poster board pattern and have a local sheet metal shop fabricate them for you, obviously not as cost effective but still most likely a bit cheaper

stuff 2-to-4 of the cones equally spaced on a threaded rod with washers and nuts to maintain spacing inside the corvettes side exhaust pipe instead of the restrictive factory inserts , and you'll have very low exhaust flow restriction, good sound wave disruption a WIN/WIN situation.

viewtopic.php?f=80&t=793&p=1150&hilit=baffle+exhaust#p1150

viewtopic.php?f=44&t=1518&p=12667&hilit=exhaust+baffle#p12667

brngrhd has a really nice vette with side exhaust headers

http://www.spiralturbobaffles.com/

http://www.cruisercustomizing.com/la-ch ... LA-1210-24

IF your semi skilled with a welder you can fabricate baffles similar to this (above) from preforated tube and sheet stainless that will do a MUCH better job and be far less restrictive so you won,t loose nearly as much hp to the inserts, THERE was a 78 hp difference (reduction) between having the provided inserts installed and open collectors on my old 496 BBC combo, with hooker side pipes

I built similar baffles and they only reduced power about 17hp vs 78hp

I didn,t say I was replacing STS baffles

(which didn,t exist at the time)

I installed a custom design that was very similar to the current sts design

to replace the hooker glass pack inserts

to replace the hooker glass pack inserts

the basic well proven fact is that almost all the commercial headers were and are designed with fit and ease of fabrication as the primary design parameters and max performance far down the list.

low cost and ease of manufacture , and designing a single header too fit as many applications as possible to simplify inventory issues, has almost always been the manufacturers goal.

longer primary tub length has frequently proven to provide both more mid rpm torque and more average torque, and its the torque within 2000-rpm-3000 -rpm of the peak torque that moves the car during almost all the time in performance use.

longer tubes cost more money and make the header harder to design too fit well, so most manufactures rather design a shorter headers that may fit several similar cars rather than the ideal longer header for a single application.

4 into two, into one collector designs (LIKE BELOW)have also proven to be excellent performers,

but the generally work best if the cam timing and high compression are well matched

one of the rather well established racer tricks has always been to run open collectors too reduce back pressure, as

( headers scavenge best, with zero back pressure)

and in many cases, where clearances allowed, we cut the collectors of commercial headers , and welded on pre made extensions

(LIKE THESE BELOW)and almost always saw a boost in performance

https://www.summitracing.com/parts/FLO-C134218234/

one reason side exhaust on corvettes were and are used is the design allowed decent ground clearance AND long efficient header primary tube header designs.

pictured above

the only major differences in my design was the use of PERFORATED STAINLESS STEEL as the BAFFLES and drilling a perpendicular 1/2" hole thru the center of the 1"center pipe every few inches between the baffles

IT never occurred to me their might be a market for them at the time

http://www.onlinemetals.com/merchant.cfm?pid=13528&step=4&id=1002&top_cat=1

http://forum.grumpysperformance.com/viewtopic.php?f=62&t=1518&p=3473#p3473

keep in mind hooker street exhaust baffles are designed to quite the exhaust down and for street use in the 1000rpm-4000rpm power band , your EXPECTED to remove the inserts when you race, as they are a restriction to flow at higher rpms

those hooker muffler inserts are VERY restrictive at anything over about 3500rpm, their exit cross section is less than a single primary on the typical sbc headers, and your trying to force 4 cylinders on a bbc to exit thru that, LIKE I stated I lost 78hp over open side pipes to the inserts and IM sure the restriction could easily get worse on some combos

http://www.youtube.com/watch?v=6grztIXf ... re=related

http://www.classicchambered.com/classic/products.html

I had zero problem with exhaust gases getting into the car but I did notice they were louder than stock (LIKE I CHOSE THEM FOR THEIR QUITE, SOUND LEVELS! SHEESSS!) I chose them because they were lighter in weight and had long primairys for excellent low rpm torque while having easily removable internal mufflers for quick removal at the track!

personally I would prefer the hooker headers and side pipes, on any c3 big block corvette after having them on my 1968 corvette for over a decade, the MUFFLER inserts are a totally different deal thou , I found those factory inserts to be very very restrictive...and yes youll learn very fast that synthetic fiber in slacks or shorts is a huge NO! NO! , cotton base jeans can touch hot side pipes buts most synthetics melt almost instantly as does SKIN in direct contact with side pipes so gals won,t like them

I truely wish they were available for the 1985 corvette, and (Im sure I will make a custom set when I build my final version,exhaust for my engine swap,bbc 1985 custom corvette)

personally I think they add something to the cars appeal/appearance but be aware your girlfriend/wife may detest them as they tend to leave bad burns on girls ankles as they exit the car and allow their leg to contact the exhaust, guys don't tend to have the same problem except if your wearing shorts because brief contact with blue jeans goes un-notice unless they are synthetic blend that tends to melt, cotton tends to insulate well enough without burning that you'll barely notice brief contact. however the wife will [censored] constantly if burnt, so be advised you'll need to both point the potential burn hazard out before and after she enters/exits the car each and every time, and if she still manages to burn herself its still YOUR FAULT! :crazy:

we guys tend to look at it as "IF YOUR GOING TO BE DUMB YOU BETTER BE TOUGH!" and overlook that minor potential problem! :grin:

if the muffler inserts get rusted or stuck into the outer exhaust side tubes

a couple good whacks to loosen the insert and the solvent mix below should allow the insert to slide out

they can get wedged with rust and corrosion,if you coat them with oil on the outside surface of the insert muffler before the insert mufflers are installed, it tends to come out easier later, if not, pour a cup of 50% diesel fuel/50% acetone mix in and lit sit for 15 minutes to loosen corrosion then while waiting buy a 6" long 5/16" hook bolt and a short section of 1" electrical conduit to fabricate a removal tool, and yes if you do coat the muffler insert with oil it will tend to take all day before it stops smoking very slightly.

stock hooker baffles are restrictive

I eventually threw my muffler inserts in a dumpster and fabricated my own from preforated stainless sheet steel as they proved to be far less restrictive

here once again is where having the ability to weld and fabricate is a huge plus, the factory baffle inserts are very restrictive

you can and really should fabricate a set of spiral baffles from perforated steel tube and sheet, it will significantly reduce any restriction to exhaust

http://www.spiralturbobaffles.com/

http://www.macsmufflers.co.nz/cs/prodLi ... Category=9

http://www.metalgeek.com/static/cope.pcgi

I know when I had my 13.7:1 compression,496 big block , I had hooker side pipe headers installed , we noticed a big difference in MPH with the inserts in place (something like a 3mph reduction) so we simply cut about 12 3.9" diam. circular baffles out of perforated stainless sheet metal

and spaced, 6 of them in each side pipe, spaced out with a threaded rod and 24 nuts and washers spaced about every 6" on a 3 foot long section of 1/2" threaded rod, inserted in the center of each perforated stainless baffle plate,and we inserted them in each side pipe ,this perforated sheet we used had about 1/4" holes and about 50% coverage ,and worked reasonably well,at reducing the noise compared to open headers,and allowed us to make decent power , much better than the hooker inserts did, but the insert we made was not as well designed as i would make now, as back then, I had far less understanding of what we were really trying to accomplish, but still it worked.

IF YOU HAVE A DECENT MIG OR TIG WELDER and access to some metal fabrication equipment I think youll be far ahead if you take the time and effort to use perforated steel sheet and tube or pipe too custom build side pipe insert mufflers, similar to the spiralturbobaffles out of perforated steel sheet and steel tube, as the perforated steel tube and sheet material lends it self quite well to the application while allowing both good flow rates and good sound wave disruption, a custom pattern made from cardboard, for the baffles and the perforated central 1"-1.5" pipe would not be dirt cheap but would be available if you shop carefully and flow better than the spiralturbobaffles

theres also exhaust insert cones whose total open surface area exceeds the diameter , because the geometry of the surface area of a cone allows a greater surface area on the surface than the base but I think the smallest is 3" diam.

that you can fabricate something similar much cheaper,if you weld, these cones are expensive if you buy them, but hardly difficult to fabricate,

it certainly would not be all that difficult to fabricate an exact fit pattern out of poster board then use that to cut perforated sheet steel to make your own, custom, perfect fitting, muffler insert baffle, versions, that easily out flow the standard insert mufflers.

If your not into fabricating you could make a poster board pattern and have a local sheet metal shop fabricate them for you, obviously not as cost effective but still most likely a bit cheaper

stuff 2-to-4 of the cones equally spaced on a threaded rod with washers and nuts to maintain spacing inside the corvettes side exhaust pipe instead of the restrictive factory inserts , and you'll have very low exhaust flow restriction, good sound wave disruption a WIN/WIN situation.

viewtopic.php?f=80&t=793&p=1150&hilit=baffle+exhaust#p1150

viewtopic.php?f=44&t=1518&p=12667&hilit=exhaust+baffle#p12667

brngrhd has a really nice vette with side exhaust headers

http://www.spiralturbobaffles.com/

http://www.cruisercustomizing.com/la-ch ... LA-1210-24

IF your semi skilled with a welder you can fabricate baffles similar to this (above) from preforated tube and sheet stainless that will do a MUCH better job and be far less restrictive so you won,t loose nearly as much hp to the inserts, THERE was a 78 hp difference (reduction) between having the provided inserts installed and open collectors on my old 496 BBC combo, with hooker side pipes

I built similar baffles and they only reduced power about 17hp vs 78hp

I didn,t say I was replacing STS baffles

(which didn,t exist at the time)

I installed a custom design that was very similar to the current sts design

the basic well proven fact is that almost all the commercial headers were and are designed with fit and ease of fabrication as the primary design parameters and max performance far down the list.

low cost and ease of manufacture , and designing a single header too fit as many applications as possible to simplify inventory issues, has almost always been the manufacturers goal.

longer primary tub length has frequently proven to provide both more mid rpm torque and more average torque, and its the torque within 2000-rpm-3000 -rpm of the peak torque that moves the car during almost all the time in performance use.

longer tubes cost more money and make the header harder to design too fit well, so most manufactures rather design a shorter headers that may fit several similar cars rather than the ideal longer header for a single application.

4 into two, into one collector designs (LIKE BELOW)have also proven to be excellent performers,

but the generally work best if the cam timing and high compression are well matched

one of the rather well established racer tricks has always been to run open collectors too reduce back pressure, as

( headers scavenge best, with zero back pressure)

and in many cases, where clearances allowed, we cut the collectors of commercial headers , and welded on pre made extensions

(LIKE THESE BELOW)and almost always saw a boost in performance

https://www.summitracing.com/parts/FLO-C134218234/

one reason side exhaust on corvettes were and are used is the design allowed decent ground clearance AND long efficient header primary tube header designs.

pictured above

the only major differences in my design was the use of PERFORATED STAINLESS STEEL as the BAFFLES and drilling a perpendicular 1/2" hole thru the center of the 1"center pipe every few inches between the baffles

IT never occurred to me their might be a market for them at the time

http://www.onlinemetals.com/merchant.cfm?pid=13528&step=4&id=1002&top_cat=1

http://forum.grumpysperformance.com/viewtopic.php?f=62&t=1518&p=3473#p3473

keep in mind hooker street exhaust baffles are designed to quite the exhaust down and for street use in the 1000rpm-4000rpm power band , your EXPECTED to remove the inserts when you race, as they are a restriction to flow at higher rpms

those hooker muffler inserts are VERY restrictive at anything over about 3500rpm, their exit cross section is less than a single primary on the typical sbc headers, and your trying to force 4 cylinders on a bbc to exit thru that, LIKE I stated I lost 78hp over open side pipes to the inserts and IM sure the restriction could easily get worse on some combos

Last edited by a moderator: