C4 Larger Intake Runners L98 TPI

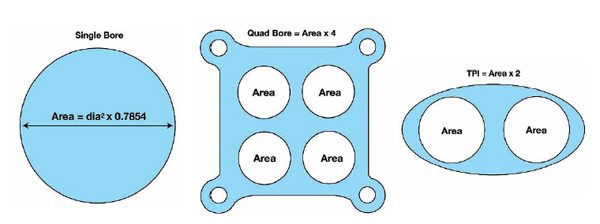

Intake......runner length .... port in...... out

Stock GM Base----- 6.375"------------- 1.47"------- 1.96x1.20

TPIS base------------6.125"------------- 1.75"------- 2.09x1.28

Accel base-----------6.125"------------- 1.75"---------2.09x1.28

Holley base--------- 6.000" ------------ 2.30â€-------- 1.90x1.23 (2.337 sq inches)

Runners

Stock TPI-------- 7.250"------1.470" round(1.70 sq inches)

SLP -------------- 6.625"------1.600" round (2.01 sq inches)

Accel LTR------- 6.625"------1.615" round (2.05 sq inches)

TPiS-------------- 7.625"------1.660" round (2.168 sq inches)

Mini ram --------3.500â€

stock MRII with 1204 (AFR 195) ports, 58MM - 265 cfm

stock MRII with 1206 (AFR 220) ports, 58MM - 281 cfm

MRII clean-up, 1206 ports, 58MM - 292 cfm

MRII cut, weld, port, etc, 58MM - 321 cfm

LT1 ----------3.000â€

Runners (measured individually)

Stock........................................................................................................................................203.17 cfm

ACCEL.....................................................................................................................................242.02 cfm

Extrude/ACCEL........................................................................................................................275.83 cfm

Super Ram................................................................................................................................289.18 cfm

Intake manifold with 3/8 inch radiused inlet .............................................................................222.45 cfm

Holley stealth ram ………..........................................................................................................275.00 cfm

Stock intake manifold with runner

Stock.........................................................................................................................................198.72 cfm

ACCEL......................................................................................................................................213.52 cfm

Extrude/ACCEL.........................................................................................................................217.11 cfm

Super Ram.................................................................................................................................220.67 cfm

Holley stealth ram ….................................................................................................................275.00 cfm

ACCEL Hi-Flow intake manifold with 3/8 inch radiused inlet.....................................................251.51 cfm

ACCEL Hi-Flow intake manifold with runner Stock...................................................................215.83 cfm

ACCEL......................................................................................................................................232.53 cfm

Extrude/ACCEL.........................................................................................................................243.21 cfm

Super Ram.................................................................................................................................240.24 cfm

Extrude-Honed ACCEL Hi-Flow intake manifold with 3/8 inch radiused inlet.............................275.83 cfm

Extrude-Honed ACCEL Hi-Flow intake manifold with ACCEL runner.......................................266.94 cfm

Edelbrock Performer RPM manifold (Stock)...............................................................................286.51 cfm

Edelbrock Victor Jr....................................................................................................................275.24 cfm

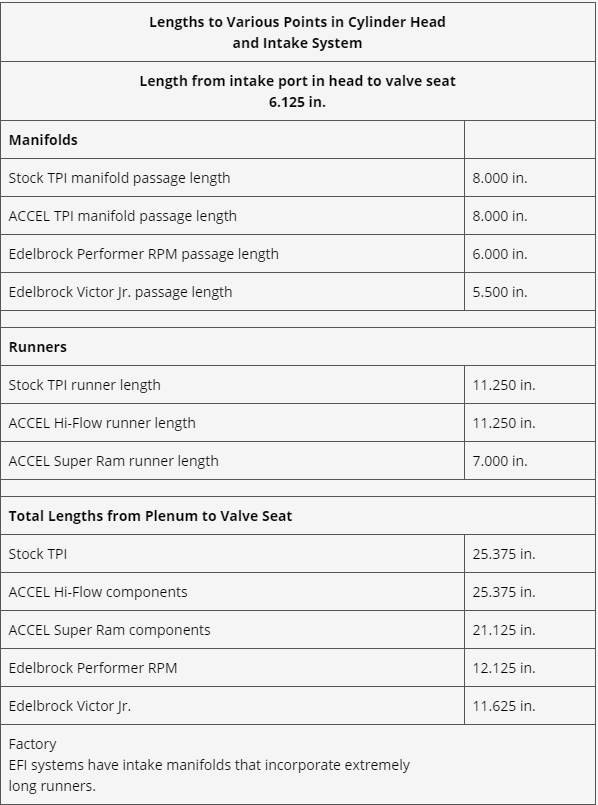

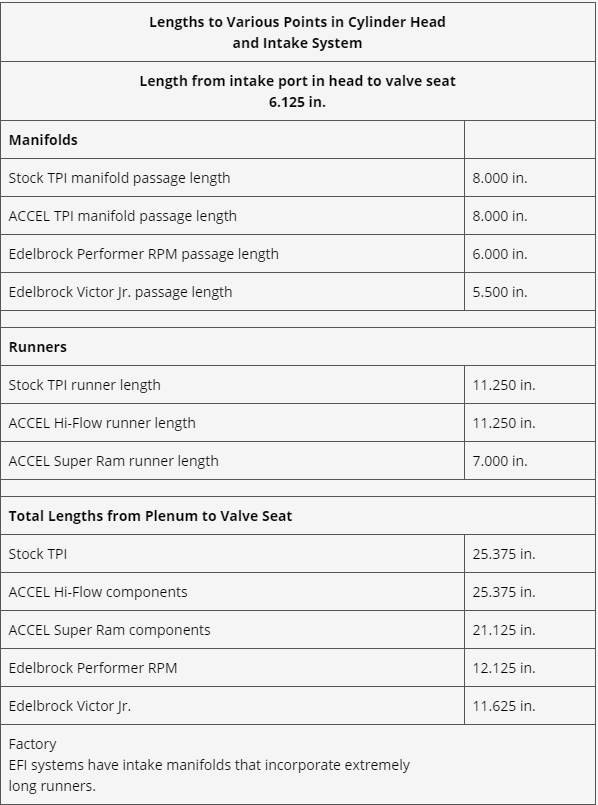

Runner Length

Stock TPI manifold ...................8†...............runners 11.25â€............... cylinder head 6â€.............total 25.25â€

Accel super ram manifold........ 8â€................runners 7.00â€............... cylinder head 6â€............ total 21.00â€

Holley stealth ram manifold .....6.26†................................................. cylinder head 6â€............ total 12.26â€

Edelbrock performer RPM ...........................runners 6.00â€................ cylinder head 6â€............ total 12.00â€

Edelbrock Victor Jr .......................................runners 5.50â€................ cylinder head 6â€............ total 11.50â€

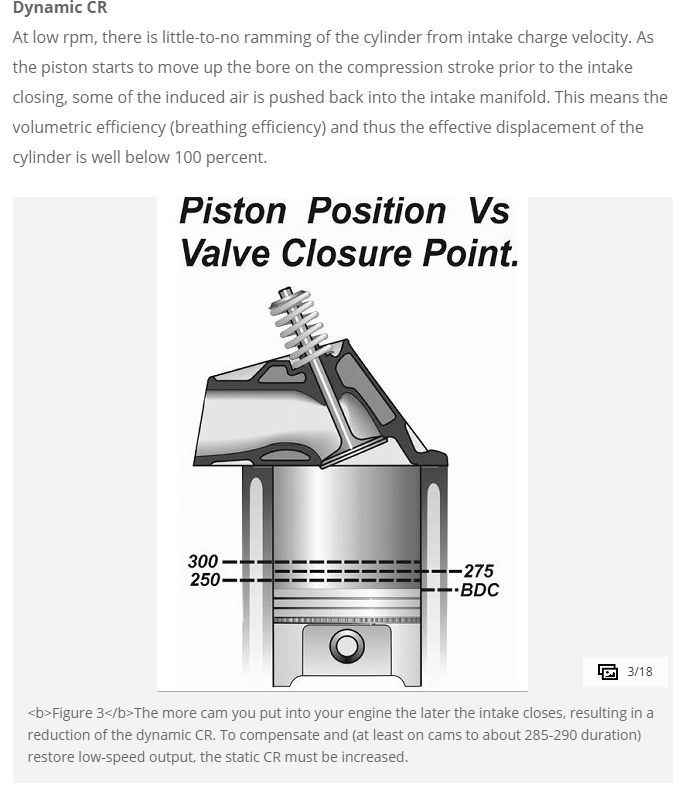

Now playing with the figure in the calculators below, what you'll find is that if your using a 350 size engine as a guide, the tpi runner length is ideal for peak tq 3427rpm and 2700-4000rpm for peak hp.

The Accel Super Ram is ideal for peak tq at 4032rpm and 3300rpm-4800rpm for peak hp.

Holley's Stealth Ram runner length is ideal at 4700 for peak tq and 5618rpm to 6282rpm for peak hp.

The TPIS Mini Ram and LT1 intakes are ideal for peak tq at about 5200rpm and 7244rpm to 8101rpm for peak hp.

By hp peak, in the above lists, I'M REFERRING TO THE RPM RANGE WHERE combination of cross sectional area MATCHED TO THE plenum to INTAKE valve distance WHERE THE internal AIRFLOW HARMONICS TEND TO INCREASE THE CYLINDER FILLING EFFICIENCY (WHERE THE INTAKE WILL TEND TO PULL THE MOST HP). Now KEEP FIRMLY IN MIND the engines tend to enter valve float and get close to engine red line by 6300-6700rpm depending on your combo. After running all the available combos, I've found a HOLLEY STEALTH RAM has been EXTREMELY EFFECTIVE on several engines tested. CURRENTLY THE STEALTH RAM SEEMS TO

BE THE CHOICE, ESPECIALLY IF MATCHED TO GOOD CYLINDER HEADS AND THE CORRECT

CAM.

https://www.firstfuelinjection.com/services.html

http://garage.grumpysperformance.com/index.php?threads/can-you-get-there-with-tpi.10494/#post-44299

http://garage.grumpysperformance.co...ther-efi-intake-manifold-info.431/#post-48733

http://garage.grumpysperformance.co...-well-thought-through-1985-vette-combo.14289/

http://garage.grumpysperformance.com/index.php?threads/tbucket-engine-project-dart-shp.3814/

http://garage.grumpysperformance.com/index.php?threads/porting-can-help.462/

http://garage.grumpysperformance.com/index.php?threads/tpi-throttle-body-size-48mm-52mm-58mm.546/

http://garage.grumpysperformance.co...gine-to-match-the-cam-specs.11764/#post-55651

http://garage.grumpysperformance.com/index.php?threads/port-speeds-and-area.333/

http://garage.grumpysperformance.co...on-building-a-383-sbc-stroker.428/#post-57879

http://garage.grumpysperformance.com/index.php?threads/what-to-look-for-in-a-good-engine-combo.9930/

http://garage.grumpysperformance.com/index.php?threads/stroker-tips-by-len-emanuelson.1249/

http://garage.grumpysperformance.co...s-for-a-383-with-170-cc-edelbrocks-now.13243/

http://garage.grumpysperformance.com/index.php?threads/dynamic-vs-static-compression.727/

http://garage.grumpysperformance.co...-the-extra-cost-vs-a-flat-tappet-design.3802/

http://garage.grumpysperformance.co...-parking-lot-car-show-today.13996/#post-71265

http://garage.grumpysperformance.com/index.php?threads/is-backpressure-hurting-your-combo.495/

http://garage.grumpysperformance.com/index.php?threads/building-a-s̶t̶r̶o̶n̶g̶-̶3̶5̶0̶-383-for-frank-the-tank….11173/

Here's some flow figures, right off the manufactures sites in many cases. Keep in mind the concept of the chains weakest link. It does ABSOLUTELY no good to match a base or runners on a TPI intake that flows 250cfm if the other part flows 200cfm. You'll still only flow 200cfm. The HOLLEY STEALTH RAM FLOWS at 275cfm out of the box,(minor port clean-up work) and can easily reach 300cfm with minor port work. The stock TPI has a hard time flowing 230cfm even with minor port work. Look here. Most of this info is right off the Accel, Holley, Edelbrock, and TPIS sites. Add a little math and the results become much clearer!!!Hi guys, I'm new to the forum have had my 85 Greenwood Corvette for five years and have started to look for more power, was thinking of upgrading the inlet runners in between the intake manifold and the plenumn, i believe there is a larger set available, was hoping someone could direct me to a second hand or reasonably priced set. Also thoughts from experienced members Cheers Chris

Wallace Racing HP Calculator For Finding Cross Sectional Area of Ports From RPM

www.wallaceracing.com

Intake......runner length .... port in...... out

Stock GM Base----- 6.375"------------- 1.47"------- 1.96x1.20

TPIS base------------6.125"------------- 1.75"------- 2.09x1.28

Accel base-----------6.125"------------- 1.75"---------2.09x1.28

Holley base--------- 6.000" ------------ 2.30â€-------- 1.90x1.23 (2.337 sq inches)

Runners

Stock TPI-------- 7.250"------1.470" round(1.70 sq inches)

SLP -------------- 6.625"------1.600" round (2.01 sq inches)

Accel LTR------- 6.625"------1.615" round (2.05 sq inches)

TPiS-------------- 7.625"------1.660" round (2.168 sq inches)

Mini ram --------3.500â€

stock MRII with 1204 (AFR 195) ports, 58MM - 265 cfm

stock MRII with 1206 (AFR 220) ports, 58MM - 281 cfm

MRII clean-up, 1206 ports, 58MM - 292 cfm

MRII cut, weld, port, etc, 58MM - 321 cfm

LT1 ----------3.000â€

Runners (measured individually)

Stock........................................................................................................................................203.17 cfm

ACCEL.....................................................................................................................................242.02 cfm

Extrude/ACCEL........................................................................................................................275.83 cfm

Super Ram................................................................................................................................289.18 cfm

Intake manifold with 3/8 inch radiused inlet .............................................................................222.45 cfm

Holley stealth ram ………..........................................................................................................275.00 cfm

Stock intake manifold with runner

Stock.........................................................................................................................................198.72 cfm

ACCEL......................................................................................................................................213.52 cfm

Extrude/ACCEL.........................................................................................................................217.11 cfm

Super Ram.................................................................................................................................220.67 cfm

Holley stealth ram ….................................................................................................................275.00 cfm

ACCEL Hi-Flow intake manifold with 3/8 inch radiused inlet.....................................................251.51 cfm

ACCEL Hi-Flow intake manifold with runner Stock...................................................................215.83 cfm

ACCEL......................................................................................................................................232.53 cfm

Extrude/ACCEL.........................................................................................................................243.21 cfm

Super Ram.................................................................................................................................240.24 cfm

Extrude-Honed ACCEL Hi-Flow intake manifold with 3/8 inch radiused inlet.............................275.83 cfm

Extrude-Honed ACCEL Hi-Flow intake manifold with ACCEL runner.......................................266.94 cfm

Edelbrock Performer RPM manifold (Stock)...............................................................................286.51 cfm

Edelbrock Victor Jr....................................................................................................................275.24 cfm

Runner Length

Stock TPI manifold ...................8†...............runners 11.25â€............... cylinder head 6â€.............total 25.25â€

Accel super ram manifold........ 8â€................runners 7.00â€............... cylinder head 6â€............ total 21.00â€

Holley stealth ram manifold .....6.26†................................................. cylinder head 6â€............ total 12.26â€

Edelbrock performer RPM ...........................runners 6.00â€................ cylinder head 6â€............ total 12.00â€

Edelbrock Victor Jr .......................................runners 5.50â€................ cylinder head 6â€............ total 11.50â€

Now playing with the figure in the calculators below, what you'll find is that if your using a 350 size engine as a guide, the tpi runner length is ideal for peak tq 3427rpm and 2700-4000rpm for peak hp.

The Accel Super Ram is ideal for peak tq at 4032rpm and 3300rpm-4800rpm for peak hp.

Holley's Stealth Ram runner length is ideal at 4700 for peak tq and 5618rpm to 6282rpm for peak hp.

The TPIS Mini Ram and LT1 intakes are ideal for peak tq at about 5200rpm and 7244rpm to 8101rpm for peak hp.

By hp peak, in the above lists, I'M REFERRING TO THE RPM RANGE WHERE combination of cross sectional area MATCHED TO THE plenum to INTAKE valve distance WHERE THE internal AIRFLOW HARMONICS TEND TO INCREASE THE CYLINDER FILLING EFFICIENCY (WHERE THE INTAKE WILL TEND TO PULL THE MOST HP). Now KEEP FIRMLY IN MIND the engines tend to enter valve float and get close to engine red line by 6300-6700rpm depending on your combo. After running all the available combos, I've found a HOLLEY STEALTH RAM has been EXTREMELY EFFECTIVE on several engines tested. CURRENTLY THE STEALTH RAM SEEMS TO

BE THE CHOICE, ESPECIALLY IF MATCHED TO GOOD CYLINDER HEADS AND THE CORRECT

CAM.

bytor said:Came across this info while doing some research and thought I'd share.

http://www.hobracing.com/tech/tpi_flow.asp

TPI Intakes and runners

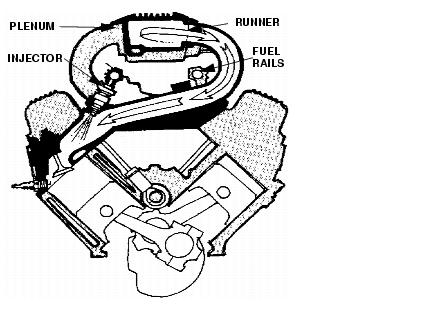

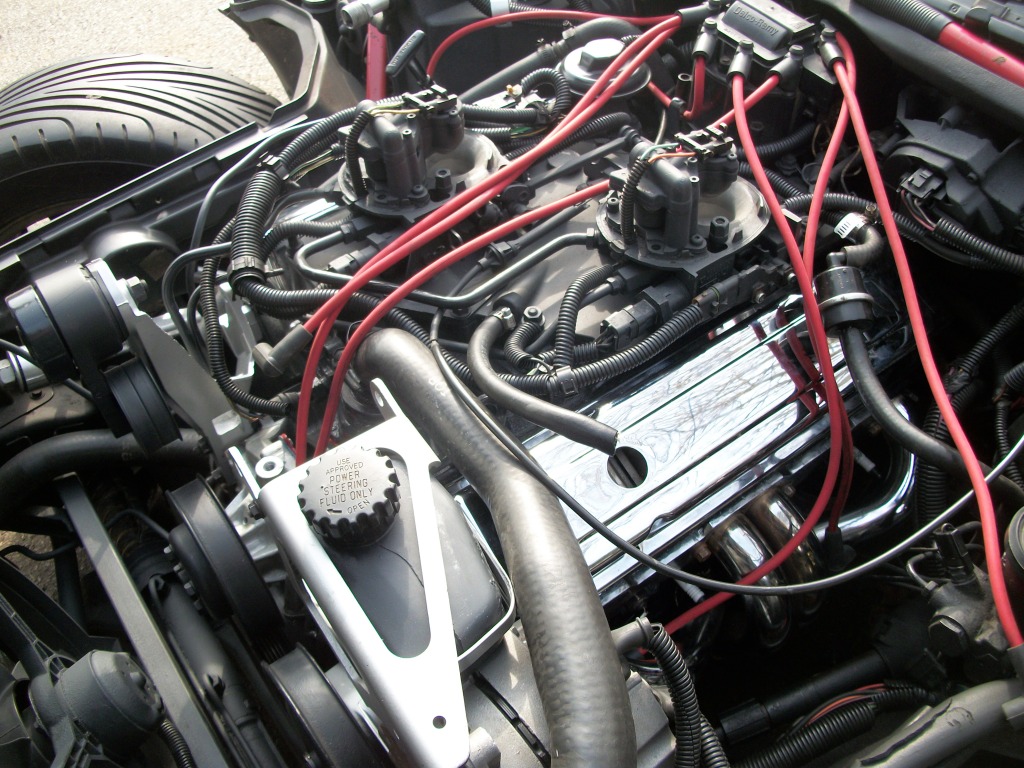

typical 1986 tuned port corvette engine

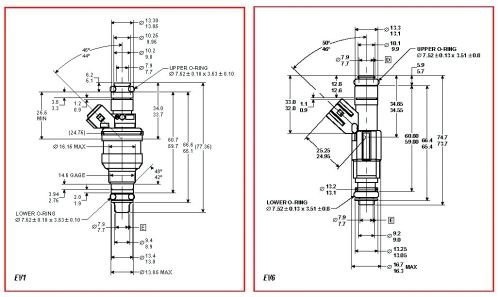

The following airflow tests were performed on the University of Northwestern Ohio's SuperFlow SF600 Flow Bench. All CFM values are corrected for airflow at 28 inches of water. Injector flow rates are flowed at 43.5 PSI on an injector flow bench using test fluid with same density as gasoline.

heres a bit of advice! so many times I get called over to help in some project, only to find the problems the guys hoping I can solve could have been avoided entirely ,

if the guy whos at this point is going partially insane, had only bothered to carefully read the details or installation instructions.

many times youll see the guy ordered the wrong part number, and theres a very similar component that exactly matches the concept ,

hes currently waist deep into, only to find the component he ordered is not compatible with the rest of the parts, hes working with.

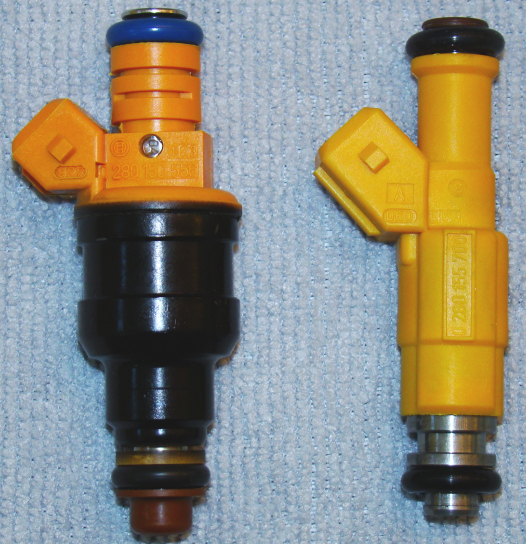

Ive seen guys order high impedance injectors that are installed on a controller designed for low impedance injectors

http://fuelinjectorclinic.com/faqs

You can measure the resistance across the two electrical terminals of the injector. If the resistance is between 1.5 and 4.0 Ohm you have low impedance injectors. If the resistance is between 8 and 16 Ohm you have high impedance injectors.

https://www.hotrod.com/articles/hrdp-1211-low-impedance-vs-high-impedance-fuel-injectors/

Low impedance (peak and hold) injectors have a resistance of between 2 and 4 ohms. High impedance(saturated) injectors have a resistance of between 10 and 14 ohms. Low impedance and high impedance injectors cannot be used interchangeably without modification of the injector drivers.

What are the differences between low impedance/peak & hold and high impedance/saturated injectors?

The older fat body style low impedance injectors (1.5 to 4.0 Ohm) used to have faster open and close times due to the type of electrical signal pattern emitted by an ECU equipped with proper P&H signal transmitters. This “Peak and Hold” injector signal typically uses a high (4 amp) initial current to open the injector, and which reduces to a lower (1 amp) current to keep the injector open until the pulse ends. Since this method put less total current into the coil, the coil heated up less and was therefore more reliable. Since the “hold” or lower current part of the signal has created a weaker magnetic field, the injector will also close more quickly.

High impedance injectors (10 to 16 Ohm) are triggered by a low (typically around 1.2 amps) constant current signal and kept open by the same constant (saturated) current for the entire cycle. Most OEM injectors today are high impedance injectors being driven by saturated injector signals from the ECU since car manufacturers are most interested in the simpler saturated signal which is more cost effective to produce when building ECU’s, especially where there is no apparent loss of drivability or performance.

https://www.summitracing.com/parts/...MIsMryyOf_3gIVjoTICh1o7wzhEAQYAiABEgKO9fD_BwE

https://www.summitracing.com/parts/...MInIGXief_3gIVy-DICh1rpgH3EAYYAiABEgJLafD_BwE

AirFlow

Stock TPI/LT1 48mm Throttle Body w/o airfoil -- 783.0 cfm

Stock TPI/LT1 48mm Throttle Body w/ airfoil -- 821.9 cfm

TPI/LT1 52mm Throttle Body w/o airfoil -- 848.9 cfm

TPI/LT1 52mm Throttle Body w/ airfoil -- 898.8 cfm

Stock 98 Camaro 3800 II Throttle Body -- 554.3 cfm

Stock TPI Bosch MAF sensor w/ screens -- 517.8 cfm

Stock TPI Bosch MAF sensor w/o screens -- 658.4 cfm

Stock 87 GN 3.8L Turbo AC MAF sensor w/ screen -- 584.2 cfm

Stock 86 2.8L AC 5-wire MAF sensor w/ screen -- 576.2 cfm

Stock 96-up AC 3100 V6 MAF sensor w/ screen -- 616.4 cfm

Stock 96-up AC 3100 V6 MAF sensor w/o screen -- 670.7 cfm

Stock 94-up LT1 MAF Sensor w/o screen -- 719.0 cfm

Stock 85-87 Firebird TPI airbox mid piece -- 499.3 cfm

Stock 4.3/5.0/5.7 2bbl TBI complete -- 574.1 cfm (dry)

Stock 4.3/5.0/5.7 2bbl TBI w/o injectors -- 584.7 cfm

Stock 3800 vin L throttle body w/ screen -- 419.1 cfm

Stock 3800 vin L throttle body w/o screen -- 444.8 cfm

4bbl MPFI Holley Throttle Body -- 1287.6 cfm

Another source sent in these flow numbers

Flow and HP ratings for Throttle-bodies:

Flow (cfm) Max. NA HP

Stock 668 300

Stock w/airfoil 710 350

52MM w/airfoil 835 400

54MM (AS&M) 900 450

58MM 1050 500

TPI Intakes and runners flow rates

Stock intake manifold with runner

Stock....................198.72 cfm

ACCEL................213.52 cfm

Extrude/ACCEL....217.11 cfm

Super Ram............220.67 cfm

the stock TPI has a hard time flowing 230cfm even with minor port work, look here

most of this info is right off the accel,holley,edelbrock, and TPIS sites, add a little math and the results become much clearer!!!

Intake....... length ....... port in -- out

Stock GM Base--- 6.375"------ 1.47"- 1.96x1.2

TPiS base------ -6.125"------ 1.75"- 2.09x1.28

Accel base----- -6.125"------ 1.75"- 2.09x1.28

Holley base------- 6” runner 2.3”- 1.9”x 1.23 (2.337 sq inches)

Runners

Stock TPI----- -- 7.250"------1.470" round(1.70 sq inchs)

SLP ----------- - 6.625"------1.600" round (2.01 sq inchs)

Accel LTR------- 6.625"------1.615" round (2.05 sq inchs)

TPiS----------- 7.625"------1.660" round (2.168 sq inchs)

Mini ram -----3.5”

LT1 ----------3”

Runners (measured individually)

Stock....................203.17 cfm

ACCEL................242.02 cfm

Extrude/ACCEL...275.83 cfm

Super Ram............289.18 cfm

Intake manifold with 3/8 inch radiused intlet.............................222.45 cfm

Holley stealth ram ………..275cfm

Stock intake manifold with runner

Stock....................198.72 cfm

ACCEL................213.52 cfm

Extrude/ACCEL....217.11 cfm

Super Ram............220.67 cfm

Holley stealth ram …..275cfm

ACCEL Hi-Flow intake manifold with 3/8 inch radiused inlet.........251.51 cfm

ACCEL Hi-Flow intake manifold with runner

Stock....................215.83 cfm

ACCEL................232.53 cfm

Extrude/ACCEL....243.21 cfm

Super Ram............240.24 cfm

Extrude-Honed ACCEL Hi-Flow intake manifold with 3/8 inch radiused inlet ...............275.83 cfm

Extrude-Honed ACCEL Hi-Flow intake manifold with ACCEL runner ..............266.94 cfm

Edelbrock Performer RPM manifold (Stock)..........286.51 cfm

Edelbrock Victor Jr. ............275.24 cfm

HOLLEY STEALTH RAM

the HOLLEY STEALTH RAM FLOWS at 275cfm out of the box, and has the potential when matched to the correct heads and cam to totally out flow most other intakes available,can easily reach 300cfm with minor port work and costs much less

Stock…………………………… 275cfm

Ported…………………………..300cfm

Runner lengths

Stock tpi manifold 8” runners 11.25”, cylinder head 6” total 25.25”

Accel super ram manifold 8” runners 7” cylinder head 6” total 21”

Holley stealth ram manifold 6.26” ” cylinder head 6” total 12.26”

Edelbrock performer RPM runners 6” ” cylinder head 6” total 12”

Edelbrock vic jr , runner length 5.5” ” ” cylinder head 6” total 11.5”

Also interesting TPI mods. Not so sure I agree with the one on bumping up the initial timing.

http://www.hobracing.com/tech/tpi_mods.asp

keep in mind that an engine is a group of interacting sub systems,

adding larger intake runners will do little,

unless the new cylinder heads, and intake base, and runners allow significantly improved air flow rates, flow thats significantly more than the O.E.M. heads,

and the cam you use has enough duration and lift,

to allow significantly more air flow , properly mixed with the correct fuel to air ratio,too enter the cylinders,

and allow the engine to operate at a higher average rpm,EFFICIENTLY, all through its intended operational rpm range,

thus produce a higher average power band.

adding a high performance longer duration cam that opens the valves higher and longer will do little except to reduce your effective working compression,

the very minor issue here is simply that you won,t have a valid before & after dyno result to compare between the two, intake manifold prep levels,if you install a modified and cleaned-up improved intake manifold without first using a stock as cast version,

thus you won,t have the ability to truly feel , or see on a dyno the DIFFERENCE,

your effort to increased efficiency had, on those improvements to the air flow rates, or the real measurable effect that had , had on the engine.

but I can assure you there is a measurable improvement , simply from similar pass intake port work.

Ive regularly seen power increases in the 15-20 hp range with similar work you've displayed,

but I know that gains in power from similar port & runner clean-up work, of over 25-30 hp are rather common.

http://garage.grumpysperformance.com/index.php?threads/port-speeds-and-area.333/

http://garage.grumpysperformance.co...h-ram-and-other-efi-intake-manifold-info.431/

http://www.superchevy.com/how-to/vemp-1010-edelbrock-pro-flo-xt-intake/

http://garage.grumpysperformance.co...o-flow-firsts-tpi-intake-etc.1052/#post-37126

unless the ports feeding those valves can flow more fuel & air mix to fill the cylinder efficiently.

that extra air flow the engine can use, but the extra air flow, requires,

the whole system from throttle body to exhaust tip to flow better than the restrictive stock components.

a good set of headers and a low restriction exhaust increase scavenging efficiency,

this of course requires larger injectors as more air flow will require more fuel,

the more fuel you can burn efficiently will provide potentially more power,

and one of the best ways to further increase the engines potential in a stroker crank,

and more displacement and compression,

a 383 will generally produce 40-50 more ft lbs and 50 more hp than a similar 350.

a well designed and carefully assembled 350-406 sbc with an aftermarket set of better heads,

and a better intake can easily produce well in excess of double the original TPI engines power.

obviously your choices in components selected, and the care taken during the assembly process ,

will have a marked effect on the power produced.

below youll find several links, and sub links,

that may take you several hours to read through,

but it will save you a great deal of time and money to do so carefully.

read through all the linked info it contains a good deal of related info youll need to look through and understand to boost the TPI engines power effectively.

Knowing what your dealing with, what the stock parts can do, and what should be modified or replaced, and what you can do to enhance , increase and broaden, the power is 1/2 the battle here.

watch the video, and like I stated many times,

its the combo of the engines,

compression,

displacement ,

cam timing

and the exhaust scavenging ,

and the intake manifold design,

NOT the intake port cross sectional area,

that are the most critical factors, in the engines lower rpm and mid rpm torque.

but for damn sure an intake runner port can be small enough to noticeably restrict upper mid range and peak power significantly,

For 5 decades I've heard endlessly about how installing larger free flowing cylinder heads would devastate the engines ability to make any low or mid rpm torque.

especially when Id suggest using a set of smaller 300cc-320cc, aluminum,rectangle port heads on a 496 BBC, or 200 cc-210cc heads on a 406 sbc, I was asked to build

yet on every engine I've ever had built or had some guy ask me to look at, to see why it ran a great deal less impressively than he expected it too,

they brought into my shop its was very obvious (at least to me) that it was the combo of low compression, too little displacement, with too much cam duration ,

a restrictive exhaust or some guy who was trying to save money and continuing to use a stock stall speed torque converter, or retain a badly mis-matched 2.87:1-3.08:1 rear gear ratio,

with an engine that he miss matched components by slapping a large carburetor , and a single plane intake on,an engine that will rarely exceed 6000 rpm, that was the major reason.

if you want an engine combo to run your first step is to logically match the list of components you,ll use to the application,

and that requires you stop, engage the brain and think things through carefully,

and the most common way to screw up the process is to over cam a low compression engine,

have a restrictive exhaust or mis-match the drive train gearing to the engines power band.

(take notes and ask questions)

http://www.hobracing.com/tech/tpi_flow.asp

Stealth TPI Induction - L98 Stroker Installation - Super Chevy Magazine

This Chevrolet L98 TPI engine has its displacement stroked to 383 cubic inches and has stealth mods installed including a new cam and an extrude honed tuned port injection system to make 458 HP - Super Chevy Magazinewww.motortrend.com

TPI Intakes and runners

The following airflow tests were performed on the University of Northwestern Ohio's SuperFlow SF600 Flow Bench. All CFM values are corrected for airflow at 28 inches of water. Injector flow rates are flowed at 43.5 PSI on an injector flow bench using test fluid with same density as gasoline.

AirFlow

Stock TPI/LT1 48mm Throttle Body w/o airfoil -- 783.0 cfm

Stock TPI/LT1 48mm Throttle Body w/ airfoil -- 821.9 cfm

TPI/LT1 52mm Throttle Body w/o airfoil -- 848.9 cfm

TPI/LT1 52mm Throttle Body w/ airfoil -- 898.8 cfm

Stock 98 Camaro 3800 II Throttle Body -- 554.3 cfm

Stock TPI Bosch MAF sensor w/ screens -- 517.8 cfm

Stock TPI Bosch MAF sensor w/o screens -- 658.4 cfm

Stock 87 GN 3.8L Turbo AC MAF sensor w/ screen -- 584.2 cfm

Stock 86 2.8L AC 5-wire MAF sensor w/ screen -- 576.2 cfm

Stock 96-up AC 3100 V6 MAF sensor w/ screen -- 616.4 cfm

Stock 96-up AC 3100 V6 MAF sensor w/o screen -- 670.7 cfm

Stock 94-up LT1 MAF Sensor w/o screen -- 719.0 cfm

Stock 85-87 Firebird TPI airbox mid piece -- 499.3 cfm

Stock 4.3/5.0/5.7 2bbl TBI complete -- 574.1 cfm (dry)

Stock 4.3/5.0/5.7 2bbl TBI w/o injectors -- 584.7 cfm

Stock 3800 vin L throttle body w/ screen -- 419.1 cfm

Stock 3800 vin L throttle body w/o screen -- 444.8 cfm

4bbl MPFI Holley Throttle Body -- 1287.6 cfm

Another source sent in these flow numbers

Flow and HP ratings for Throttle-bodies:

Flow (cfm) Max. NA HP

Stock 668 300

Stock w/airfoil 710 350

52MM w/airfoil 835 400

54MM (AS&M) 900 450

58MM 1050 500

TPI Intakes and runners flow rates

Stock intake manifold with runner

Stock....................198.72 cfm

ACCEL................213.52 cfm

Extrude/ACCEL....217.11 cfm

Super Ram............220.67 cfm

the stock TPI has a hard time flowing 230cfm even with minor port work, look here

most of this info is right off the accel,holley,edelbrock, and TPIS sites, add a little math and the results become much clearer!!!

Intake....... length ....... port in -- out

Stock GM Base--- 6.375"------ 1.47"- 1.96x1.2

TPiS base------ -6.125"------ 1.75"- 2.09x1.28

Accel base----- -6.125"------ 1.75"- 2.09x1.28

Holley base------- 6” runner 2.3”- 1.9”x 1.23 (2.337 sq inches)

Runners

Stock TPI----- -- 7.250"------1.470" round(1.70 sq inchs)

SLP ----------- - 6.625"------1.600" round (2.01 sq inchs)

Accel LTR------- 6.625"------1.615" round (2.05 sq inchs)

TPiS----------- 7.625"------1.660" round (2.168 sq inchs)

Mini ram -----3.5”

LT1 ----------3”

Runners (measured individually)

Stock....................203.17 cfm

ACCEL................242.02 cfm

Extrude/ACCEL...275.83 cfm

Super Ram............289.18 cfm

Intake manifold with 3/8 inch radiused intlet.............................222.45 cfm

Holley stealth ram ………..275cfm

Stock intake manifold with runner

Stock....................198.72 cfm

ACCEL................213.52 cfm

Extrude/ACCEL....217.11 cfm

Super Ram............220.67 cfm

Holley stealth ram …..275cfm

ACCEL Hi-Flow intake manifold with 3/8 inch radiused inlet.........251.51 cfm

ACCEL Hi-Flow intake manifold with runner

Stock....................215.83 cfm

ACCEL................232.53 cfm

Extrude/ACCEL....243.21 cfm

Super Ram............240.24 cfm

Extrude-Honed ACCEL Hi-Flow intake manifold with 3/8 inch radiused inlet ...............275.83 cfm

Extrude-Honed ACCEL Hi-Flow intake manifold with ACCEL runner ..............266.94 cfm

Edelbrock Performer RPM manifold (Stock)..........286.51 cfm

Edelbrock Victor Jr. ............275.24 cfm

HOLLEY STEALTH RAM

the HOLLEY STEALTH RAM FLOWS at 275cfm out of the box, and has the potential when matched to the correct heads and cam to totally out flow most other intakes available,can easily reach 300cfm with minor port work and costs much less

Stock…………………………… 275cfm

Ported…………………………..300cfm

Runner lengths

Stock tpi manifold 8” runners 11.25”, cylinder head 6” total 25.25”

Accel super ram manifold 8” runners 7” cylinder head 6” total 21”

Holley stealth ram manifold 6.26” ” cylinder head 6” total 12.26”

Edelbrock performer RPM runners 6” ” cylinder head 6” total 12”

Edelbrock vic jr , runner length 5.5” ” ” cylinder head 6” total 11.5”

Also interesting TPI mods. Not so sure I agree with the one on bumping up the initial timing.

http://www.hobracing.com/tech/tpi_mods.asp

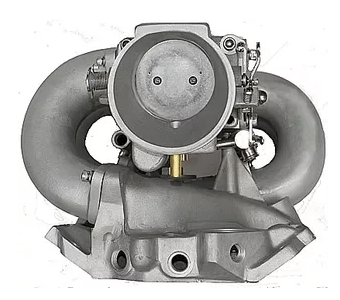

Basic TPI modifications

Friday, May 23, 2014

READ THIS

no mater what cam you select, retaining the stock cylinder heads and stock TPI intake will be a HUGE potential restriction to potential power levels you could otherwise reach, a cam will help, but your leaving 50-80 hp on the table that better heads a better intake, larger injectors (needed to keep the intended fuel/air ratio, required, to make increased power) and a low restriction exhaust with tuned headers would allow you to easily access the higher rpm range.

and installing a cam will require better valve springs checking clearances and ideally a 3.54"1-3.73:1 rear gear ratio to get the full potential out of the higher average operational rpm range and increased air flow rates

a couple hours spent reading links will help here!

yes you can upgrade the cam and see gains, but correctly matching all the components to provide the required air flow and fuel delivery at the higher rpm range and matching that too a low restriction tune exhaust will provide noticeably improved results.

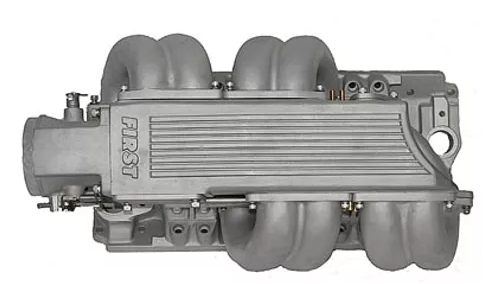

theres several 190cc-200 cc heads that would produce very noticeable power improvements over the stock cylinder heads and the stock TPI intake is a huge restriction, a http://www.firstfuelinjection.com

TPI intake with a set of brodix, AFR or trickflow or similar heads would provide much better power than the stock intake and cylinder heads will.

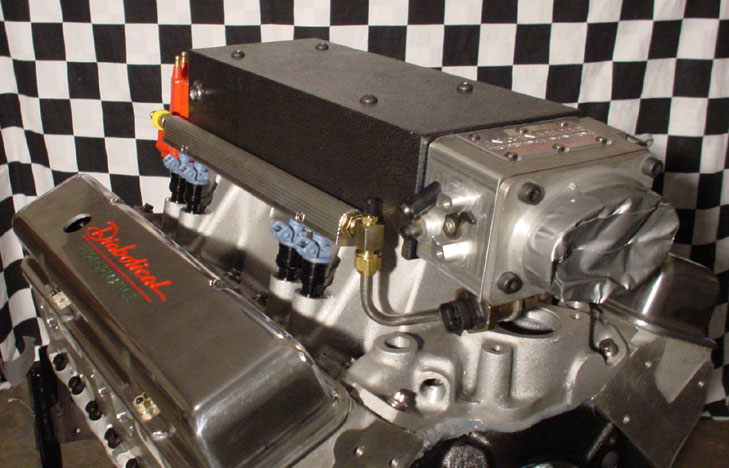

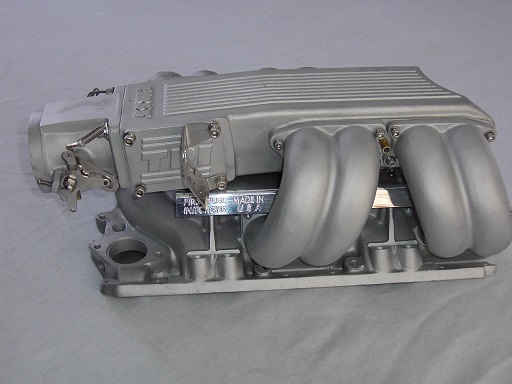

I,ve found THIS IS THE BEST TPI STYLE INTAKE AVAILABLE

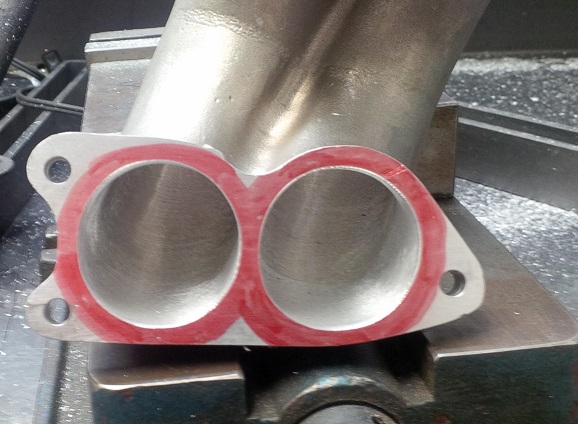

heres a few pictures I found posted of a FIRST intake being ported

rough and smooth are fairly relative terms, smooth in an intake runner generally refers,

too the mirror like surfaces that were almost thought too be mandatory in the 1950s-early 1960s

but you certainly can,t get a "smooth surface texture "

with anything in a flapper wheel of 80 grit or larger grit

http://www.thepolishingshop.co.uk/acatalog/Flap_Wheels_Long_Reach_.html

http://www.thepolishingshop.co.uk/acatalog/Flap-Wheel-10mm-x-10mm-x-3mm-Shank-Std.html

http://garage.grumpysperformance.com/index.php?threads/where-to-buy-abrasives.3422/#post-9070

http://garage.grumpysperformance.com/index.php?threads/porting-can-help.462/page-3#post-72525

http://garage.grumpysperformance.co...-by-step-guide-with-pictures.5378/#post-71848

Last edited: A moment ago

http://www.firstfuelinjection.com

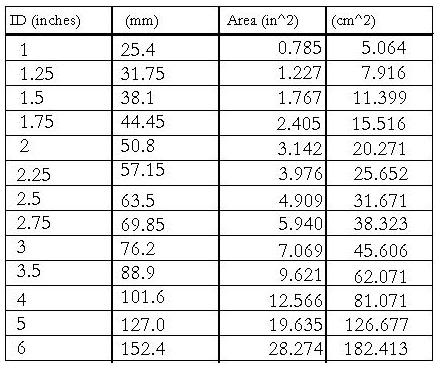

THE larger 1.75" (2.45 sq inch cross sectional area)of the FIRST intake design, vs the STOCK 1.47" diameter runner cross section (1.7 sq inch cross sectional area), of the stock G.M. tpi, intake adds at least 1200 rpm to the engines potential IF properly matched to the correct components, like 42lb injectors, un-ported this runner should provide peak power in the 4500rpm-6000rpm range, while the stock TPI intake runners peak at least 1200rpm lower, near 3400rpm where they tend too start restricting flow compared to the larger runner size of the ,

FIRST TPI INTAKE DESIGNS LARGER RUNNERS CROSS SECTIONAL AREA

Id select decent flowing heads like these

http://www.airflowresearch.com/index.php?cPath=24_33

these 1.6:1 ratio roller rockers

http://www.summitracing.com/parts/cca-1605-16

a cam like this, if your goal is max peak power (and low speed drive-ability is not much of a concern)

https://www.summitracing.com/parts/crn-119651

a cam like this, if your goal is good driveability on the street with good power

http://www.summitracing.com/parts/crn-119661

http://www.airflowresearch.com/super-chevy-sep-2013-195cc-sbc.php

http://www.summitracing.com/search?Sort ... er%2000471

a cam like this, (crower above)if your goal is good driveability on the street with good power, but your willing to put up with some low speed driveability issues to get more power (it basically splits the difference,I tried all three and went with the smaller crane roller

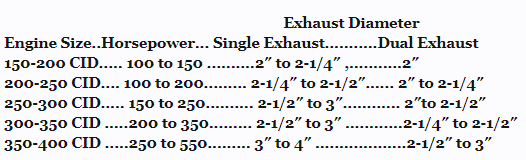

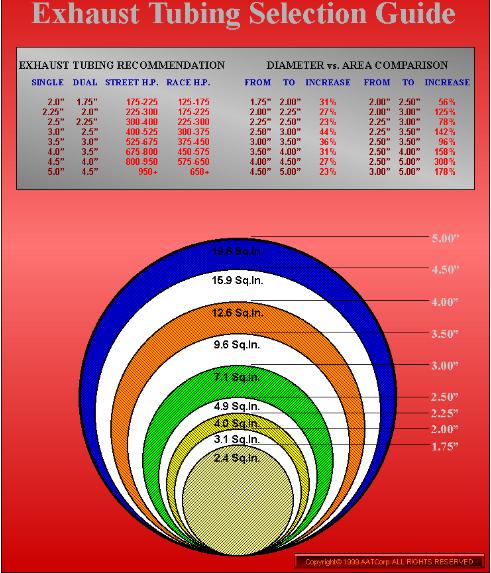

in the ideal exhaust system youll want to have less than .5

(thats 1/2 a PSI of back pressure) at the engines peak rpm

http://www.exhaustvideos.com/faq/how-to-calculate-muffler-size-pipe-diameter/

http://www.mk5cortinaestate.co.uk/calculator5.php

3" o.d = 2.87" diam. inside--approximately 6.5 sq inches of area

2.75 o.d = 2.62"diam. inside--approximately 5.4 sq inches of area

2.5 o.d = 2.37" diam. inside--approximately 4.4 sq inches of area

2.25 o.d = 2.12" diam. inside--approximately 3.5 sq inches of area

well worth reading

http://www.popularhotrodding.com/engine ... ndex1.html

http://garage.grumpysperformance.com/index.php?threads/exhaust-components.361/

http://garage.grumpysperformance.com/index.php?threads/calculating-required-exhaust-pipe-size.11552/

http://garage.grumpysperformance.co...-exhaust-pipe-diam-for-your-application.1730/

http://garage.grumpysperformance.com/index.php?threads/is-backpressure-hurting-your-combo.495/

http://garage.grumpysperformance.com/index.php?threads/building-an-exhaust-system-for-your-car.1166/

http://garage.grumpysperformance.co...-calculators-and-basic-math.10705/#post-72061

http://www.wallaceracing.com/Calculators.htm

a good quality 7-8 quart oil pan with windage tray

http://www.race-mart.com/Milodon-MIL-31516.html

these valve covers

http://www.proformparts.com/product-exe ... ory_id/249

a high flow water pump

calculate horse power from intake port flow rates

http://www.wallaceracing.com/calcafhp.php

http://www.wallaceracing.com/calchpaf.php

http://www.wallaceracing.com/ca-calc.php

http://www.wallaceracing.com/max-rpm.php

http://www.wallaceracing.com/lpv.php

http://www.wallaceracing.com/chokepoint.php

http://www.wallaceracing.com/chokepoint-rpm.php

http://www.wallaceracing.com/area-under-curve.php

http://www.wallaceracing.com/piston-speed-velocity.php

http://www.wallaceracing.com/header_length.php

http://garage.grumpysperformance.com/index.php?threads/can-you-get-there-with-tpi.10494/#post-44284

http://garage.grumpysperformance.com/index.php?threads/c4-larger-intake-runners-l98-tpi.13785/

http://garage.grumpysperformance.co...m-dyno-results-and-other-info.433/#post-37683

http://garage.grumpysperformance.com/index.php?threads/hey-grumpy-do-i-need-bigger-injectors.5583/

http://garage.grumpysperformance.com/index.php?threads/port-speeds-and-area.333/

http://garage.grumpysperformance.com/index.php?threads/ideal-tpi-build.12203/

http://garage.grumpysperformance.co...sure-hurting-your-combo.495/page-2#post-35063

http://garage.grumpysperformance.com/index.php?threads/a-caveat-about-profiler-cylinder-heads.10065/

http://garage.grumpysperformance.com/index.php?threads/a-well-designed-c4-exhaust.786/#post-57392

http://garage.grumpysperformance.co...ther-efi-intake-manifold-info.431/#post-32491

http://garage.grumpysperformance.com/index.php?threads/tpi-throttle-body-size-48mm-52mm-58mm.546/

http://garage.grumpysperformance.com/index.php?threads/sources-for-tpi-parts-and-info.590/

http://garage.grumpysperformance.com/index.php?threads/bits-of-383-build-info.18/

http://garage.grumpysperformance.com/index.php?threads/my-current-corvettes-383-combo.430/

https://www.firstfuelinjection.com/services.html

http://garage.grumpysperformance.com/index.php?threads/can-you-get-there-with-tpi.10494/#post-44299

http://garage.grumpysperformance.co...ther-efi-intake-manifold-info.431/#post-48733

http://garage.grumpysperformance.co...-well-thought-through-1985-vette-combo.14289/

http://garage.grumpysperformance.com/index.php?threads/tbucket-engine-project-dart-shp.3814/

http://garage.grumpysperformance.com/index.php?threads/porting-can-help.462/

http://garage.grumpysperformance.com/index.php?threads/tpi-throttle-body-size-48mm-52mm-58mm.546/

http://garage.grumpysperformance.co...gine-to-match-the-cam-specs.11764/#post-55651

http://garage.grumpysperformance.com/index.php?threads/port-speeds-and-area.333/

http://garage.grumpysperformance.co...on-building-a-383-sbc-stroker.428/#post-57879

http://garage.grumpysperformance.com/index.php?threads/what-to-look-for-in-a-good-engine-combo.9930/

http://garage.grumpysperformance.com/index.php?threads/stroker-tips-by-len-emanuelson.1249/

http://garage.grumpysperformance.co...s-for-a-383-with-170-cc-edelbrocks-now.13243/

http://garage.grumpysperformance.com/index.php?threads/dynamic-vs-static-compression.727/

http://garage.grumpysperformance.co...-the-extra-cost-vs-a-flat-tappet-design.3802/

http://garage.grumpysperformance.co...-parking-lot-car-show-today.13996/#post-71265

http://garage.grumpysperformance.com/index.php?threads/is-backpressure-hurting-your-combo.495/

http://garage.grumpysperformance.com/index.php?threads/building-a-s̶t̶r̶o̶n̶g̶-̶3̶5̶0̶-383-for-frank-the-tank….11173/

Last edited: