From the desk of the Junkman, another how to for dummies!

First of all, is

https://www.dropbox.com/s/bjhqwvv3iykx7 ... _noise.wav"]this what you hear , when your lights go down? How about this: you turn on your parking lights and the headlights raise! If so, then you've come to the right thread!

There are a couple of threads that show how to do this but what scared me about the job was the lack of pictures. Thus, I kinda blindly walked around the car and scratched my head until I figured some things out. After completing the job I also realized how many tips that I could pass on for us "not mechanically inclined." And so, I've created this super detailed version of the instructions for people like me.

Now there are two ways to do this. You can remove just the motor itself (which is a tough job for those with large hands), or you can remove the entire headlight assembly. I thought about doing just the motor but when I picked up the first Torx bit to see what size I needed, it conveniently slipped out of my fingers and into the headlight cavity. Great. It looks like I'll be removing the headlight assembly. This was the better decision in the long run because I also learned how to change my headlight bulbs, my fog lamps, and I found out where water was entering the running lights and blowing the lamps.

Whatever you do, don't take both headlight assemblies out at the same time. You'll probably need to look at the other one to see how the wiring is run behind the lights. If you don't run the harness exactly as it is installed from the factory, then you won't be able to put everything back exactly as it was. Plus, you could end up chopping the harness in half when the lights go up and down enough times. That advice saved my butt big time on this job.

With that said, dial up users beware. Lots of pictures!

Let's Get Started!

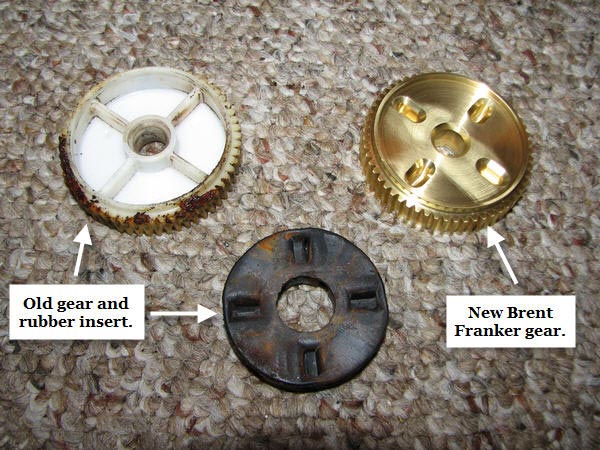

The main secret to this fix is to fix it right away! As soon as you hear that dreaded jack hammer going off under the hood, you need to get the gear(s) ordered and take Saturday off to fix it. I got my gears from Brent Franker and here's why. Other gears being sold require you to re-use the rubber insert inside the gear housing.

Brent's gear is not hollowed out like the stock gear is and thus does not require the re-use of the rubber insert. This is good because I've seen pictures posted by a forum member where the rubber insert was all chewed up. Since you can't buy the rubber insert by itself, you're kinda up a creek unless you have a gear like Brent's. You can learn all about his gear and order it at

http://www.bfranker.badz28.com/headlightfix/index.htm . This same gear fits the 1993 -2002 Firebird but trust me, it also fits the C5 Corvette headlight motor perfectly.

Tools

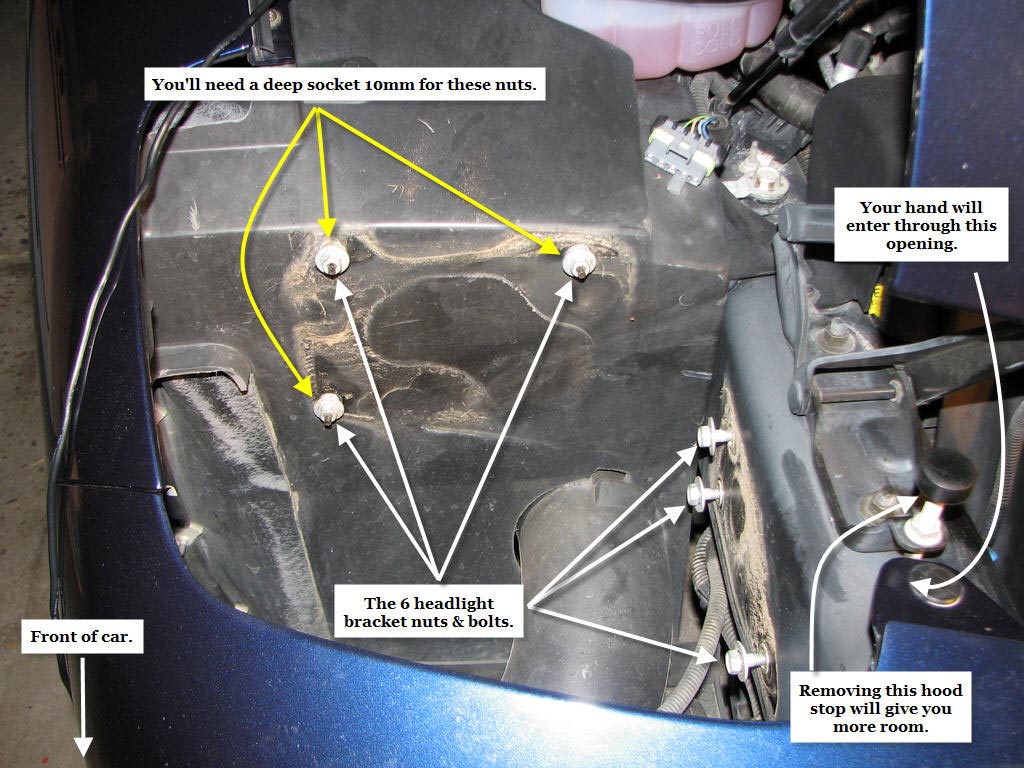

The tool list that you'll need is not that long. You will need a 10mm deep socket, preferably a quarter-inch drive and ratchet. You'll also need a Phillips screwdriver and a small flathead one too. There is another standard socket that you'll need but I can't for the sake of me remember the size. I think it was a 1/2 inch, but don't quote me on that. It doesn't have to be a deep socket though. You'll be able to figure it out when you get to those bolts. The last thing is a T-15 torx bit and some clamps

The first thing that you'll need to establish is whether or not you have "Popeye arms". If you do, you're going to have to access the headlight mounting screws from the bottom of the car. That's a little more work. Here's how to tell. First, open your hood and raise the headlight that has the stripped gear. If you are addressing this problem early enough, you can simply turn on your headlights. If not, you'll need to crank the offending headlight up manually. To do this, remove this cap if it is still on the headlight motor (the headlight motor is located just to the side of the headlight).

Next, you will need to crank the headlight to it's fully up position. You can do so by turning the knob on the back of the motor. Counter-clockwise for up, clockwise for down. It may take a few turns before you see the headlight begin to rise so just keep cranking away.

If the knob is hard to turn, then you've reached the fully up or fully down position.

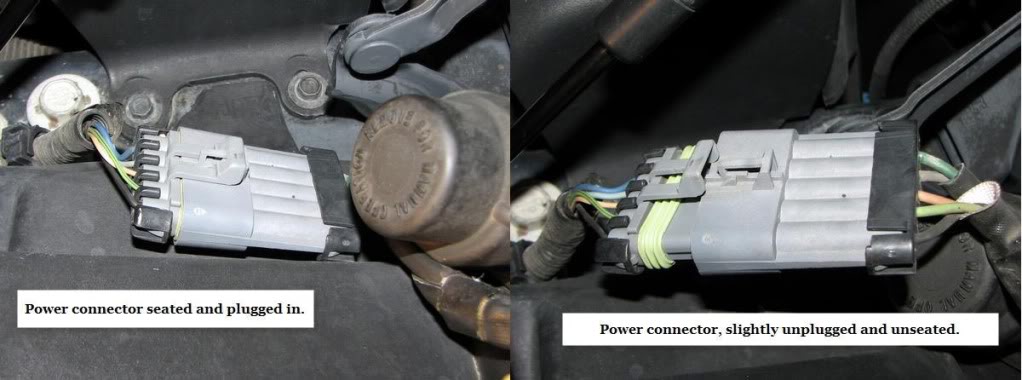

IMPORTANT! At this point, you should disconnect the power to the headlight. I have read a couple of post where guys have had their hands "eaten" by these headlights and they said it was really painful, days later. Don't take a chance. Unplug the power to the headlights.

This will also be the very last thing you plug up at the end of the job.

Here's how: Locate the connector in the pictures below.

This is what I mean by seated and unseated in the pictures. There is a small tab that holds the power connector in place. Removing the power connector or unseating it from that tab is pretty easy. Once you get everything put back together, re-seating the connector is a major pain! I spent 20 minutes bent over the car trying to line the connector and that tab up. My back was hurting when I finally got it connected. Well, I'm going to tell you how to avoid that fiasco later.

Those connectors always confuse me as to how they separate so I also included a picture above of what it looks like once you take it apart.

Here's that tab I'm talking about:

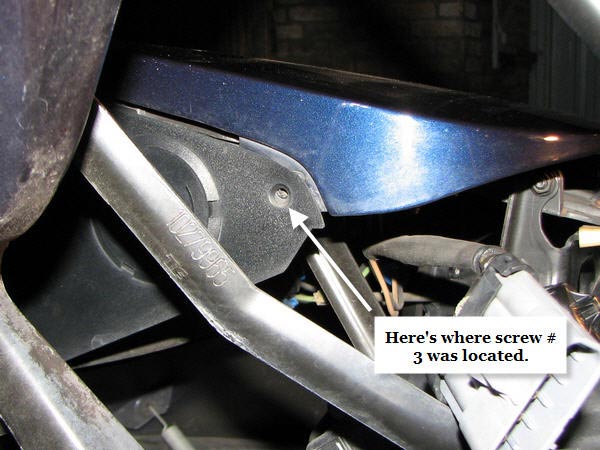

Once the headlight is completely raised, you'll need to remove the 3 Phillips head screws that hold the black trim on surrounding the headlight.

The 3rd one is hiding in the back.

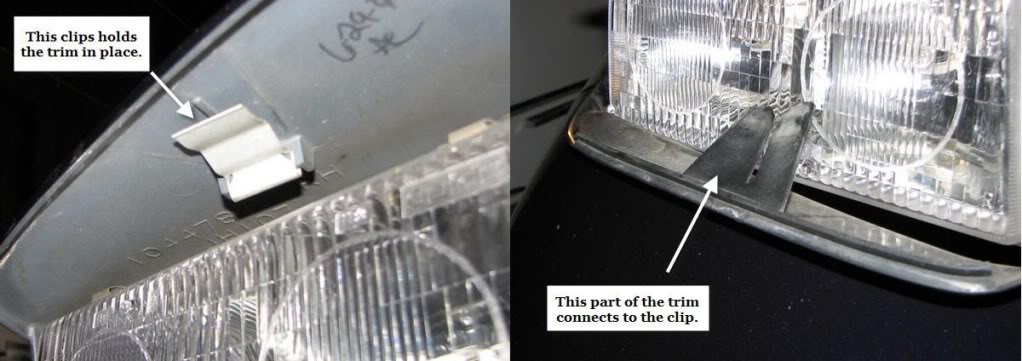

Now that you have removed those screws, the black trim should slide forward and off the car. There a piece at the top of the headlight that helps hold it on. You'll need to work the trim off of that piece in order to remove it. Check out the picture below.

Now here's a tip for those of us who seem to have parts left over after the job is complete. Take the 3 screws you removed and place them back into the holes that they came out of. You can put them back into the headlight assembly or the black trim (if you put them into the trim, tape them in place with masking tape). This way, you'll know which screws go in which holes when you go to put everything back together. Talk about a life saver...if there are more than 2 screws, I'll forget where they go later.

I also removed the painted headlight cover so that it wouldn't get scratch up during the repair. It’s easy to do. There are 4 T-15 Torx screws that you remove and the thing pops right off. Two in the back and 1 on each side. You can see the two in the back with the headlight raised. You'll see the ones on the side once you remove the black trim. Remember to place the screws back in their respective holes during the repair!

Now here's where you find out if you have Popeye arms. Here's a picture of the headlight cavity with the headlight assembly removed.

If you can get your hand into the cavity and touch all 6 of the bracket nuts and bolts, then you don't have Popeye arms and you should be able to remove all 6 nuts and bolts without raising the car and going in from the bottom. Removing the hood stop post will give you a little more room if necessary. As you can see, I didn't have to remove the hood stop and although it was a tight squeeze, I didn't have to go through the bottom of the car either. Lucky me! If you do have to remove the hood stop post, be sure and mark it somehow so that you know how far to put it back in during reassembly.

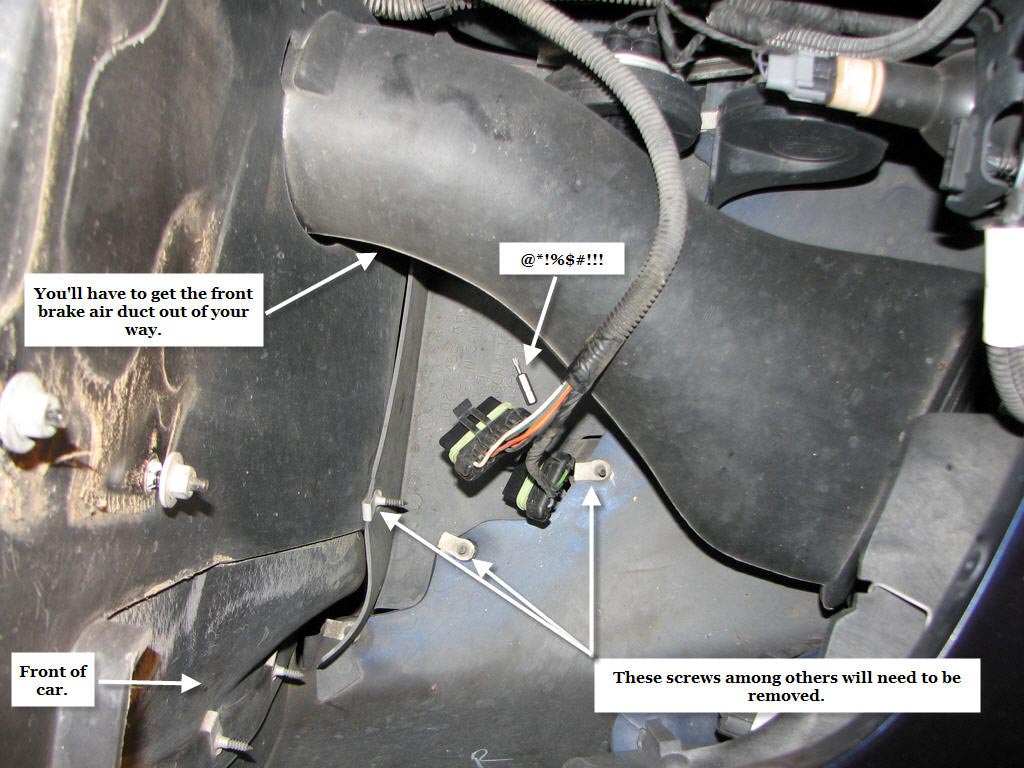

If you do have to go in from the bottom, here's a photo that may help you figure out which screws to remove. Yea, there's that stinkin' Torx bit.

Once you get the bolts and nuts removed: If you're working on the driver's headlight, you're ready to remove the assembly. Just bring it forward and lift it out. Be very careful not to chip up the front of the headlight opening. This is why I always put a cloth down so that I don't scratch it up.

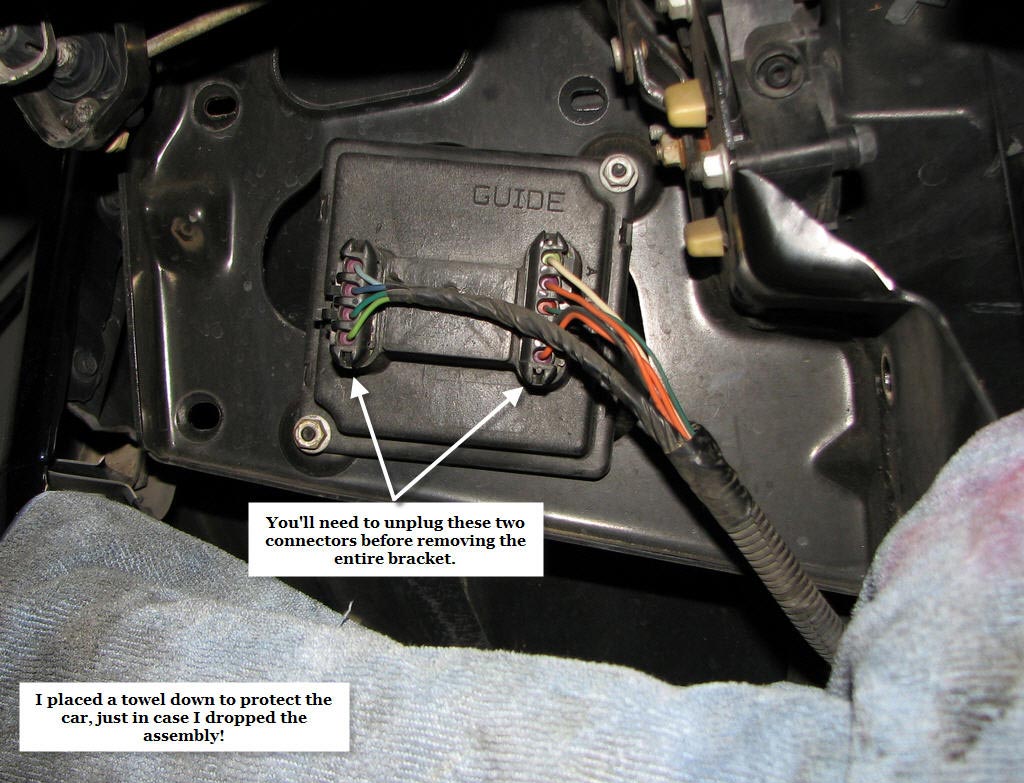

If you're working on the passenger's headlight, you're almost ready to lift the assembly out of the car. However, you'll first need to disconnect an additional harness. Here's a picture:

Here's what you should be staring at now.

At this point if your garage in not heated or air conditioned, you can now retire to the confines of your home.

Remember that tab that held the power connector in place? Remove it now! You can use some needle nose pliers to squeeze its base and remove it from the car by going through the wheel well. Then, plug it into the underside of the power connector so you don't loose it. Do this now, or you'll have a backache later trying to remount that connector.

Now check out the picture below:

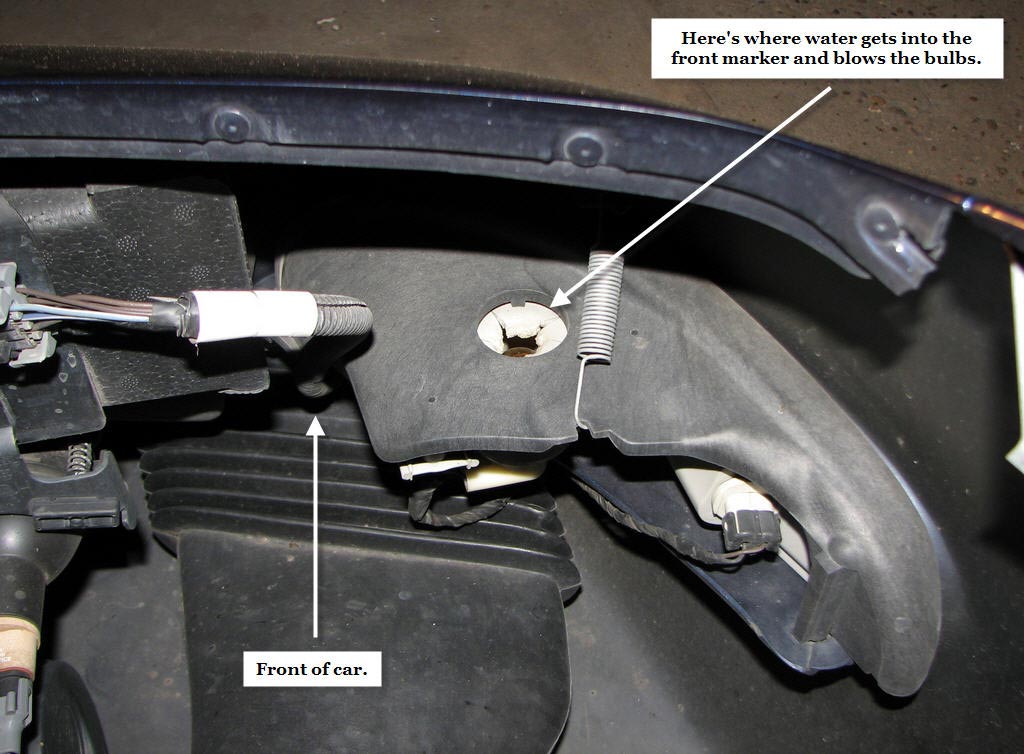

If you're wondering how water gets to your front marker and blows the bulb all the time, now you know. The bulb has actually burned through the housing. GM left this other gaping hole which I am going to cover with some heat resistant tape.

The other picture here just shows were your fog lamps and horn are in case you were wondering.

Part II, The Motor Repair

At this point you should take the time to do something that saved me a major headache when reinstalling the headlight. Remove the bulbs. If this has never been done in your car before, this the time to try it. Once the headlight is mounted back in the car, getting those things loose (especially if they've never been replaced) is a major PITA! I had to rearrange my harness after getting everything reinstalled and this meant unplugging the headlight harness. Had I not done this while the assembly was out of the car, I probably would have busted my knuckles and kicked the car in frustration (okay, maybe I would have kicked my other car but my knuckles would have been a mess).

These lights come out like most car lights, with a twist and a pull. The trick is, they don't both twist the same way. I fussed with these things for 20 minutes, scared I was going to break something but I finally got them out. Here's the solution. The high beam bulb twists counter-clockwise to remove while the low beam bulb twists clockwise. Mine were stubborn as hell but they finally came out. Learn how to do it now and save yourself a headache later.

Note: Unplug the harness from the bulbs before doing this.

Now you're ready to remove the motor from the headlight assembly. There are 3 screws and 4 nuts that hold it together. Pretty self-explanatory.

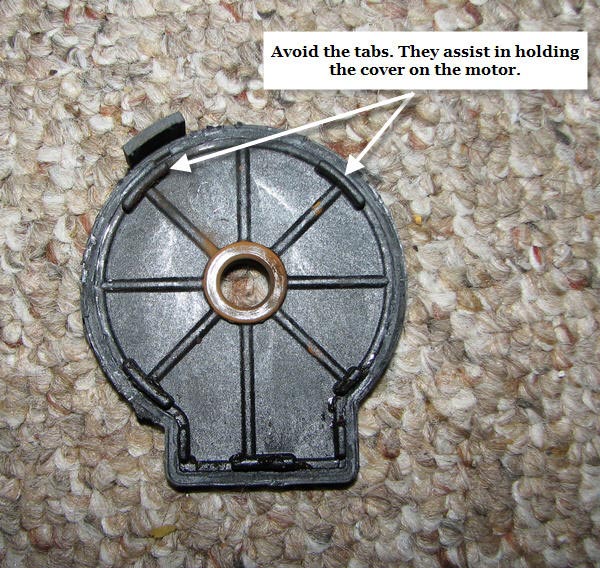

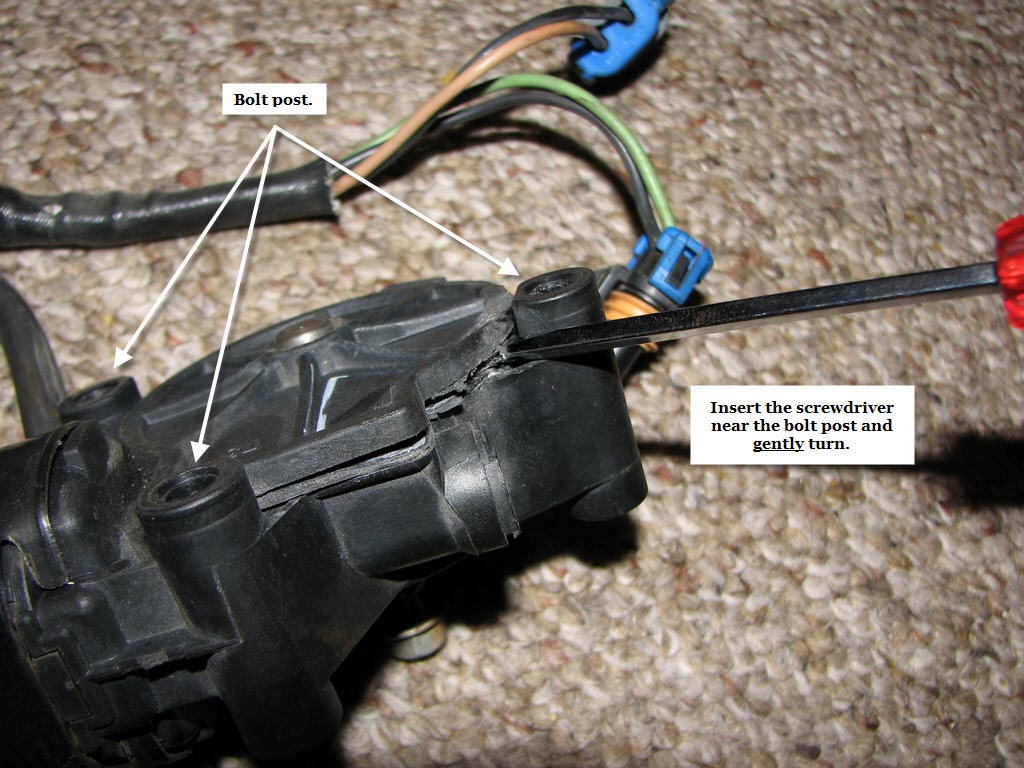

Now you're ready to disassemble the motor. This was kinda tricky but I lucked up and had some pretty good success. First look at this picture of the cover removed.

As you can see, there are tabs that are located around the cover. Using a very thin flathead screwdriver, work the tip into the areas where there are no tabs. If this repair has never been done to your motor, you'll find that the cover will slowly come off. Just take your time and don't get in a hurry. This is the part of the job that requires the most patience. I found that starting at the bolt post and prying gently in that area produced the best results.

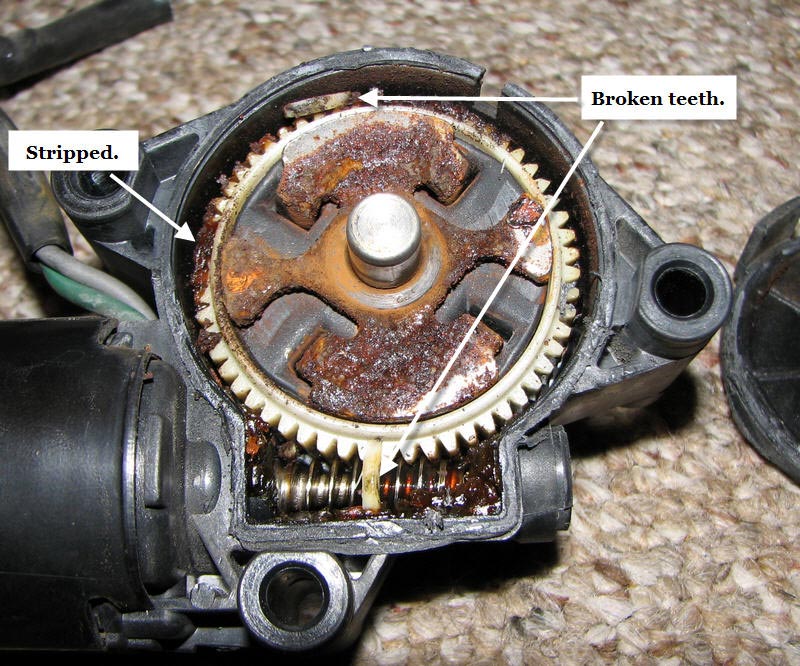

Once you get the cover off, you'll be greeted by this:

Not only can you see the missing teeth and the stripped gear, you can also see that water had obviously been getting inside the housing, thus all the rust (this is also why my cover was pretty easy to get off). Go ahead and pop out the old gear and clean all the chewed up teeth and old gear grease out of the housing. Get some fresh grease and lay it on the shaft of the motor. I used some multi-purpose super white grease from my local auto supply store.

If you're using Brent's gear as I suggested above, then you won't need the rubber bushing that comes with the factory design. If yours is in good shape, keep it and offer it up to the forum members who might need it. Like I said, you can't buy just the rubber insert by itself.

As you reassemble the housing, pay attention to the way the shaft sits on the gear. Make sure that it is flush with the face of the new gear. Once you get it orientated correctly, it will sat flush.

One thing that Brent talks about on his website in great detail is the possibility of having this failure happen a second time because of the tabs that hold the motor assembly together. This is something that you need to check at this time so that you are not a victim of a second failure. Look at the picture below.

There are 4 tabs that you need to check to ensure that the motor is being held together. Check them and give them a tap to make sure that they are tightly seated. Don't go beating on them a lot, just a few taps to make sure that they are flush up against the housing.

Brent's gear kit includes some Double/Bubble Epoxy for reattaching the cover to the motor housing. In his instructions, it states that you will need to wait at least 24 hours for this stuff to fully set. Now being the impatient one that I am, I wanted no part of waiting 24 hours so I asked him if I could use something else. He said he was sure something else would work fine and off to O'riley's I went. This is what I came up with.

This stuff sucked. My cover came off the next day. Use the glue that comes with the kit. I put that stuff on and that cover hasn't budged yet.

Now reattach that puppy back to the headlight bracket and head for the garage! There are some key things that you must ensure before reattaching the headlight bracket to the car so pay attention to the next section.

Part III, Reattaching the Headlight Bracket

The first thing you want to do is look at the other set of headlights. Notice how the harness is run. Notice what the harness goes around, goes behind, and goes over and under. This very important because if you run the harness the wrong way, it won't sit properly and you could end up chopping the thing up with your bracket arms. This is why you only disassembled 1 headlight. The other being properly mounted is your template to go by. I hope if you're reading this, that you paid attention at the beginning of the post and didn't remove both headlights. This saved my but big time because I couldn't get any good pictures of how the cable is run.

WARNING!!! As you put everything back together, THE LAST THING YOU SHOULD DO BEFORE TURNING ON THE LIGHTS AND SEEING IF YOUR REPAIR HAS WORKED IS PLUG UP THE POWER TO THE HEADLIGHTS!!!

A couple of forum members have posted incidents about the headlights closing while they had their hand in the cavity. Do not plug that power cable in until the very last possible moment. If you need to readjust the harness or for any reasons have to stick your hand back inside that cavity, you don't want that headlight coming down on your hand. I hear it is painful as hell and not a pleasant experience. Plug the power to the headlights up as the very last step!

Well folks, that brings us to the end of "War & Peace", the Junkman's version. For those of you who know what you're doing, this was probably the longest waste of your time ever spent. For us shade tree mechanics, I hope that it was the motivation that you needed to tackle this job yourself. DON'T PAY A STEALER TO DO THIS! It was rather easy now that I know how to do it and my second gear order has now been placed. Heck, I might need to read my own instructions again!