Cam Break-in Procedure

viewtopic.php?f=52&t=282

http://www.compcams.com/Community/Artic ... 1578676008

viewtopic.php?f=54&t=1334&p=2910#p2910

http://www.gmpartsdirect.com/results.cfm?partnumber=EOS

http://www.gmpartsdirect.com/results.cf ... number=EOS

http://www.hotrod.com/techarticles/engi ... index.html

http://www.cam-shield.com/index.html

http://www.corvetteactioncenter.com/tech/oil/index.html

http://www.pbm-erson.com/uploads/cat%5B ... CEDURE.pdf

you might want to read thru this

preventing cam & lifter break-in failures

viewtopic.php?f=62&t=1515

http://www.pbm-erson.com/uploads/cat%5B ... CEDURE.pdf

http://www.corvetteactioncenter.com/tech/oil/index.html

OPTIONS

it should be rather obvious that theres options, cam failures are usually the result of incorrect CLEARANCES or too much SPRING PRESSURE or LACK of ADEQUATE LUBRICATION,USE DECENT MOLY CAM LUBE, and decent quality oil, adding MAGNETS to trap metallic CRUD HELPS, be sure to change your oil filter and oil after the first 3-4 hours or 100 miles as theres bound to be crud and assembly lube trapped in the oil and filter

obviously youll want to verify the correct distributor gear material to use with the cam manufacturer, before using it and providing extra oil flow, to the gears should help reduce wear

http://www.summitracing.com/parts/LUN-89027LUN/

• Have a high quality service manual available, such as the factory service manual, or the vehicle specific manuals published by Chiltons, Motors, or Haynes. You will need these for the basic information regarding engine disassemble and reassemble along with the torque settings for the various fasteners.

• Read and understand the manual completely, along with these instructions before you begin working. We highly recommend you also have the assistance of a knowledgeable friend to assist you, especially during the initial fire-up and break-in period.

In addition to the normal installation procedure, installing a performance camshaft requires you to check for several extra items to insure long life and optimum performance.

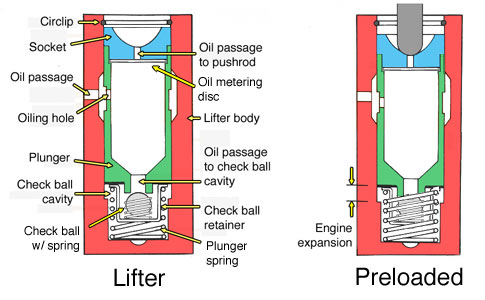

• New Lifters Are A Must- There is no such thing as a good used lifter! Any flat faced lifter establishes a wear pattern almost immediately with the cam lobe it is riding on and cannot be used on any other cam lobe, let alone a different cam. Should you have a need to disassemble the engine, make sure you keep the lifters in order so they go back on to the exact same lobes.

• Valve Spring Pressure and Travel- We highly recommend purchasing the matching valve springs recommended in our catalog. This insures you will have the proper pressures, both closed and open, and sufficient travel to get the maximum rpm, performance and life from your new cam.

• Piston to Valve Clearance- While many performance cams will work just fine with stock pistons, there are many factors that effect your engine and the clearance available. Things such as factory tolerances, normal machine work such as head and block surfacing, aftermarket components such as cylinder heads, higher ratio rocker arms, etc. all effect your engines ability to handle a performance camshaft.

• Valve Train Interference- In addition to valve spring travel and piston-to-valve clearance, a commonly overlooked area is that of retainer to seal clearance. The other common area of interference is rocker arm to stud clearance along with rocker arm travel. The best way to check these is by physically opening both a intake and an exhaust valve on each cylinder head to the gross lift of the cam plus and additional .030". It is easiest to do this by pressing down on the rocker arm with one of the many tools available. Do not simply rotate the engine to the maximum lift point for a given valve. This does not work when engines are hydraulic lifter equipped, or even allow any margin of safety when you are using a mechanical lifter cam.

• Valve Adjustment- The easiest way to insure proper adjustment is to adjust the rocker arms as you install them, one cylinder at a time. Adjust the intake valve as the exhaust valve is just starting to open and adjust the exhaust valve when the intake valve is almost closed. It is simplest to do this with the intake manifold off and watching the lifter’s movement.

• Hydraulic Lifter Valve Adjustment- All engines, regardless of manufacture, require correct valve adjustment. Some engines, such as Chevrolet V-8’s, are equipped with stud mounted rocker arms can easily be adjusted to compensate for changes incurred during engine assembly. Never just torque the rocker arm into place and assume that the lifter preload will automatically be correct. Various engine manufacturers use multiple length pushrods, shims, and spacers to compensate for changes in preload. Hydraulic lifters cannot compensate for all changes. Ideal lifter preload is .020" to .080". Do not attempt to fill the lifters full of oil prior to installation. They will fill automatically once started and manually filling them makes adjusting the preload a difficult task.

• Mechanical Lifter Valve Adjustment- Adjusting mechanical lifters should be done the same way as outlined above, one valve at a time. For an initial setting, we recommend .003" to .005" than listed on the cam’s specification card. Once broken in and with the engine fully warmed up, re set the rocker arms to the cam’s specification sheet.

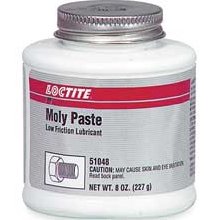

• Installation Lubricants- All flat faced (non-roller) camshafts require the use of high pressure lubricant supplied with your Erson cam on the bottom of the lifters, the lobes of the cam and on the distributor drive gear. Do not use this lube on the tips of the pushrods, the sides of the lifters or on the rocker arms. Use a quality oil when installing roller tappets.

BEFORE YOU TURN THE KEY

• Fill All of the Engine’s Fluids- Using a minimum of a SAE API SD, SE or better fresh clean mineral based oil, fill the engine to the proper level. Do not use synthetic oil during break-in. Fill the coolant system and follow the instructions on purging air from the system. With carburetor equipped engines, fill the carburetor to insure fuel is available immediately. Make sure that the ignition timing is properly set to insure immediate starting, without excess cranking of the engine.

• Pre-Lube the Engine- Using a oil pump priming tool such as those available from Mallory, spin the engine’s oil pump until you see pressure on the gauge or have oil at the rocker arms. Do not attempt to prime the engine using the starter motor!

• Proper Ventilation- Make sure that you do not start the engine without good airflow. That means have the overhead garage door open and the exhaust vented to the outside. If you have any doubts about sufficient airflow to the engine, push the car out of the garage to make sure the radiator can draw in plenty of air. Having a fan to blow fresh air through the garage is a plus.

• Exhaust System- If at all possible, start the car with a muffled exhaust system hooked up and operational. It makes it much easier to hear what is going on.

• Resist the Urge- Take a minute before you try to start the engine for the first time and double check that you are ready to go. Don’t take any short cuts or leave parts such as fan shrouds, air cleaner, wire looms, etc. off. Clean up the are around and especially under your vehicle. Pick up your tools and wipe up the floor so you can easily spot even a minor leak.

• Be Prepared- Have extra coolant or a hose handy, clean rags, tools for tightening clamps, connections, etc. just in case. They need to be in place to make sure you have an uneventful break-in of the camshaft.

WHEN THE ENGINE STARTS

• Have a Helper- Now is the time for a helper. They can check the coolant level, check for oil and fluid leaks, and proper operation of underhood accessories. Air pockets in the coolant system are common so make sure the recovery bottle is checked and filled as necessary. You cannot count on the temperature gauge. Temperature gauges are only accurate if the sensor is submerged in coolant and will not give an accurate reading if in an air pocket.

• Do Not Idle the Engine- As soon as the engine starts, raise the rpm to 2,000 rpm. You should also constantly vary the RPM between 2,000 and 3,000 RPM for the first 20 minutes. This is the only way to insure proper lubrication during this critical period since the camshaft to lifter contact area relies almost exclusively on oil splash from the crank and connecting rods. Make sure that you run the engine for a full 20 minutes using this procedure. It will seem like forever, but it is one of the most important steps to insure long, dependable performance.

Once Break-in is Complete- Drain and replace the engine oil and filter with new, fresh oil and a new filter. Recheck for any fluid leaks and check all fluid levels. If you installed a mechanical lifter style camshaft, flat faced or roller style, the valve adjustment should be rechecked at this time with the engine fully warmed up. Hydraulic lifter equipped engines should not require any readjustment.

Proper maintenance is important for any vehicle. Frequent oil changes, with a new filter is one of the easiest ways to insure your vehicle will deliver the performance you want for many long happy miles.

ID ADD, USE a GOOD MOLY BASE ASSEMBLY LUBE AND A HIGH ZINC CONTENT OIL AND SOME G.M. E.O.S. TO THE OIL

MARVEL MYSTER OIL is a good high detregent oil designed to aid valve train and rings ETC. cleaning, I almost always add about 10% marvel mstery oil to my engines, but if your running flat tappet lifters Id point out that many current oils are designed for roller lifter engines so Id sellect an oil thats designed for the older design with the higher zinc content, and adding a can of E.O.S. to the oil and moly assembly lube on the lifters and cam, sure won,t hurt on that first break in, if your breaking in the engine in your driveway, have a running hose and a fan handy, water running thru the radiators cooling fins and a fan blowing air helps prevent over heating, have a timing light and USE IT, check your fluid levels and watch your gauges

GM’S RECOMMENDED CRATE ENGINE START-UP PROCEDURE

Print this page out and check off boxes below (in the printed copy) when each step is completed.

Step Box

1) Safety first! If the car is on the ground, be sure the emergency brake is set, the wheels are chocked, and the transmission cannot fall into gear. Next verify that all hoses are tight and that both the radiator and radiator over flow jar/tank are full and have been filled with the proper anti-freeze and water mix.

2) Before starting your engine for the first time, add one pint of engine oil supplement ( EOS¹) to the crankcase oil and then check the oil level. Once this has been done, prime the oil system with an oil pump primer tool. Make sure number 1 cylinder is on TDC compression stroke, and install the distributor.

3) Adjust the distributor timing roughly by hand for a quick start up and smoothest idle possible.

4) When the engine first starts, verify that the engine rpm is at a safe level and that the timing is set near or at 30° before top dead center (BTDC). Run the engine speed between 1,500 and 2,500 RPM’s, varying the engine speed up and down with-in this range, to prevent overheating of the exhaust valves and the exhaust system. This should be done with no-load on the engine and for the first 30 minutes of operation.

5) After the first 30 minutes of the engine running, set the ignition timing according to the timing specifications. Now would be a good time to check thoroughly for leaks.

6) Adjust the carburetor settings, if necessary.

7) Drive the vehicle with varying speeds and loads on the engine for the first 30 miles. Be sure not to use a lot of throttle or high RPM.

8) Run five or six medium-throttle accelerations to about 3,800 RPM (55 to 60 MPH), then letting off in gear and coasting back down to 20 MPH.

9) Run a couple hard-throttle accelerations up to about 3,800 RPM (55 to 60 MPH), then letting off in gear and coasting back down to 20 MPH.

10) Change the oil and filter with recommended oil (10w30SG in most cases) and filter.

11) Drive the next 500 miles normally, without high RPM’s (below 3,800 RPM), hard use, or extended periods of high loading.

12) Change oil and filter again.

13) Your engine is now ready for many happy cruising miles!

Note¹: EOS P/N 1052367 can be used any time during the life of the engine.

Technical Note: This procedure has been corrected and improved from the original GMPP procedure by GILBERT CHEVROLET.

sitting with no air other than the fan moving air thru the radiator is bound to run a bit hotter than on the road, anything under 220F is normal /expected under those conditions.

I run a water hose thru the radiators cooling fins when testing under those conditions., on the street it should run fairly consistantlly in the 180F-190F range with a 180F T-stat.

in many cases an ADDITIONAL TAURUS electric fan from a salvage yard can be installed on the other side of the radiator to run off a dash switch or sensor that will provide additional cooling when needed.(price varies but its usually very reasonable from salvage yards)

http://forums.hybridz.org/attachment.php?attachmentid=8603&d=1218835261

or

190F-210F is ABOUT NORMAL,for driving temps, and nothing to worry about, adding a seperately mounted TRANSMISSION COOLER if you have an auto trans is usually worth a 10-15 degree drop in the coolant temp,MINIMUM, if the current trans fluids cooled in the lower radiator, adding an 8 qt baffled oil pan is usually good for an additional 7F-10F degrees reduction in oil temp alone

A great deal of the heat is transfered to the oil and trans fluids long before the radiator and coolant sees it,routing the hot trans fluid to an aux cooler and adding a high capacity oil pan significantly reduces the heat the radiator needs to transfer from the coolant to the air flow thru it.

http://store.summitracing.com/partd...&part=PRM-12318&N=700+400006+115&autoview=sku

http://www.4secondsflat.com/Hydraulic_lifter_cams.html

viewtopic.php?f=52&t=282

http://www.compcams.com/Community/Artic ... 1578676008

viewtopic.php?f=54&t=1334&p=2910#p2910

http://www.gmpartsdirect.com/results.cfm?partnumber=EOS

http://www.gmpartsdirect.com/results.cf ... number=EOS

http://www.hotrod.com/techarticles/engi ... index.html

http://www.cam-shield.com/index.html

http://www.corvetteactioncenter.com/tech/oil/index.html

http://www.pbm-erson.com/uploads/cat%5B ... CEDURE.pdf

you might want to read thru this

preventing cam & lifter break-in failures

viewtopic.php?f=62&t=1515

http://www.pbm-erson.com/uploads/cat%5B ... CEDURE.pdf

http://www.corvetteactioncenter.com/tech/oil/index.html

OPTIONS

it should be rather obvious that theres options, cam failures are usually the result of incorrect CLEARANCES or too much SPRING PRESSURE or LACK of ADEQUATE LUBRICATION,USE DECENT MOLY CAM LUBE, and decent quality oil, adding MAGNETS to trap metallic CRUD HELPS, be sure to change your oil filter and oil after the first 3-4 hours or 100 miles as theres bound to be crud and assembly lube trapped in the oil and filter

obviously youll want to verify the correct distributor gear material to use with the cam manufacturer, before using it and providing extra oil flow, to the gears should help reduce wear

http://www.summitracing.com/parts/LUN-89027LUN/

• Have a high quality service manual available, such as the factory service manual, or the vehicle specific manuals published by Chiltons, Motors, or Haynes. You will need these for the basic information regarding engine disassemble and reassemble along with the torque settings for the various fasteners.

• Read and understand the manual completely, along with these instructions before you begin working. We highly recommend you also have the assistance of a knowledgeable friend to assist you, especially during the initial fire-up and break-in period.

In addition to the normal installation procedure, installing a performance camshaft requires you to check for several extra items to insure long life and optimum performance.

• New Lifters Are A Must- There is no such thing as a good used lifter! Any flat faced lifter establishes a wear pattern almost immediately with the cam lobe it is riding on and cannot be used on any other cam lobe, let alone a different cam. Should you have a need to disassemble the engine, make sure you keep the lifters in order so they go back on to the exact same lobes.

• Valve Spring Pressure and Travel- We highly recommend purchasing the matching valve springs recommended in our catalog. This insures you will have the proper pressures, both closed and open, and sufficient travel to get the maximum rpm, performance and life from your new cam.

• Piston to Valve Clearance- While many performance cams will work just fine with stock pistons, there are many factors that effect your engine and the clearance available. Things such as factory tolerances, normal machine work such as head and block surfacing, aftermarket components such as cylinder heads, higher ratio rocker arms, etc. all effect your engines ability to handle a performance camshaft.

• Valve Train Interference- In addition to valve spring travel and piston-to-valve clearance, a commonly overlooked area is that of retainer to seal clearance. The other common area of interference is rocker arm to stud clearance along with rocker arm travel. The best way to check these is by physically opening both a intake and an exhaust valve on each cylinder head to the gross lift of the cam plus and additional .030". It is easiest to do this by pressing down on the rocker arm with one of the many tools available. Do not simply rotate the engine to the maximum lift point for a given valve. This does not work when engines are hydraulic lifter equipped, or even allow any margin of safety when you are using a mechanical lifter cam.

• Valve Adjustment- The easiest way to insure proper adjustment is to adjust the rocker arms as you install them, one cylinder at a time. Adjust the intake valve as the exhaust valve is just starting to open and adjust the exhaust valve when the intake valve is almost closed. It is simplest to do this with the intake manifold off and watching the lifter’s movement.

• Hydraulic Lifter Valve Adjustment- All engines, regardless of manufacture, require correct valve adjustment. Some engines, such as Chevrolet V-8’s, are equipped with stud mounted rocker arms can easily be adjusted to compensate for changes incurred during engine assembly. Never just torque the rocker arm into place and assume that the lifter preload will automatically be correct. Various engine manufacturers use multiple length pushrods, shims, and spacers to compensate for changes in preload. Hydraulic lifters cannot compensate for all changes. Ideal lifter preload is .020" to .080". Do not attempt to fill the lifters full of oil prior to installation. They will fill automatically once started and manually filling them makes adjusting the preload a difficult task.

• Mechanical Lifter Valve Adjustment- Adjusting mechanical lifters should be done the same way as outlined above, one valve at a time. For an initial setting, we recommend .003" to .005" than listed on the cam’s specification card. Once broken in and with the engine fully warmed up, re set the rocker arms to the cam’s specification sheet.

• Installation Lubricants- All flat faced (non-roller) camshafts require the use of high pressure lubricant supplied with your Erson cam on the bottom of the lifters, the lobes of the cam and on the distributor drive gear. Do not use this lube on the tips of the pushrods, the sides of the lifters or on the rocker arms. Use a quality oil when installing roller tappets.

BEFORE YOU TURN THE KEY

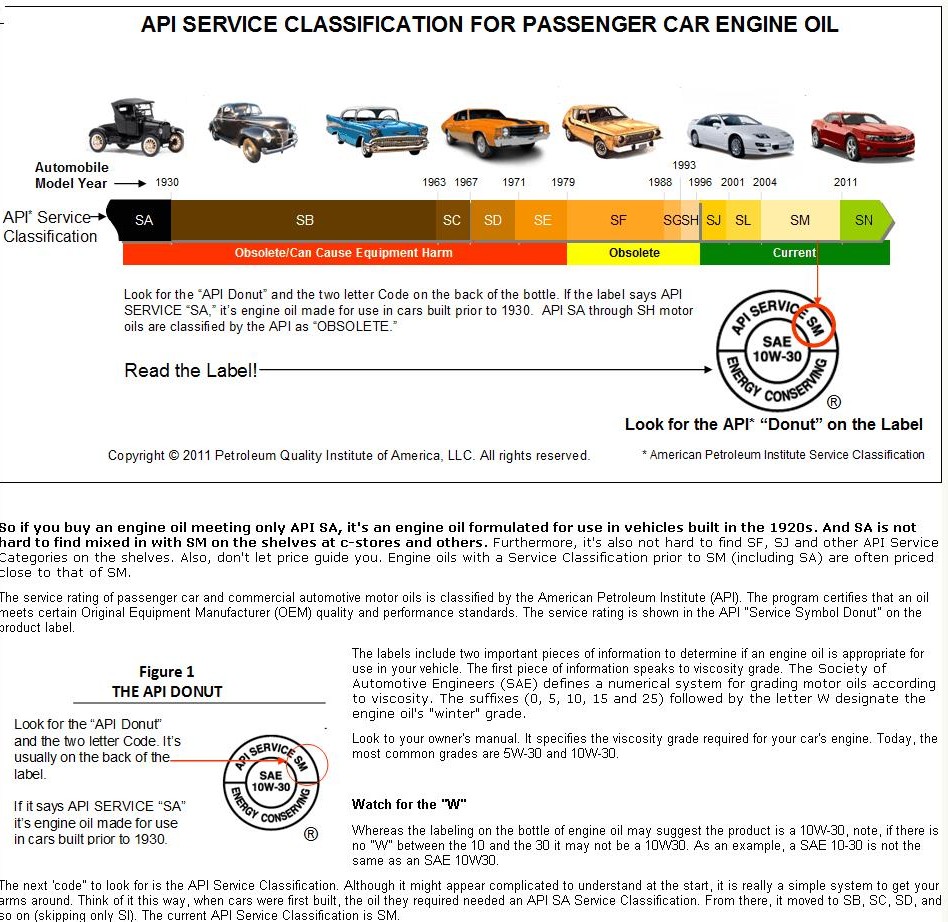

• Fill All of the Engine’s Fluids- Using a minimum of a SAE API SD, SE or better fresh clean mineral based oil, fill the engine to the proper level. Do not use synthetic oil during break-in. Fill the coolant system and follow the instructions on purging air from the system. With carburetor equipped engines, fill the carburetor to insure fuel is available immediately. Make sure that the ignition timing is properly set to insure immediate starting, without excess cranking of the engine.

• Pre-Lube the Engine- Using a oil pump priming tool such as those available from Mallory, spin the engine’s oil pump until you see pressure on the gauge or have oil at the rocker arms. Do not attempt to prime the engine using the starter motor!

• Proper Ventilation- Make sure that you do not start the engine without good airflow. That means have the overhead garage door open and the exhaust vented to the outside. If you have any doubts about sufficient airflow to the engine, push the car out of the garage to make sure the radiator can draw in plenty of air. Having a fan to blow fresh air through the garage is a plus.

• Exhaust System- If at all possible, start the car with a muffled exhaust system hooked up and operational. It makes it much easier to hear what is going on.

• Resist the Urge- Take a minute before you try to start the engine for the first time and double check that you are ready to go. Don’t take any short cuts or leave parts such as fan shrouds, air cleaner, wire looms, etc. off. Clean up the are around and especially under your vehicle. Pick up your tools and wipe up the floor so you can easily spot even a minor leak.

• Be Prepared- Have extra coolant or a hose handy, clean rags, tools for tightening clamps, connections, etc. just in case. They need to be in place to make sure you have an uneventful break-in of the camshaft.

WHEN THE ENGINE STARTS

• Have a Helper- Now is the time for a helper. They can check the coolant level, check for oil and fluid leaks, and proper operation of underhood accessories. Air pockets in the coolant system are common so make sure the recovery bottle is checked and filled as necessary. You cannot count on the temperature gauge. Temperature gauges are only accurate if the sensor is submerged in coolant and will not give an accurate reading if in an air pocket.

• Do Not Idle the Engine- As soon as the engine starts, raise the rpm to 2,000 rpm. You should also constantly vary the RPM between 2,000 and 3,000 RPM for the first 20 minutes. This is the only way to insure proper lubrication during this critical period since the camshaft to lifter contact area relies almost exclusively on oil splash from the crank and connecting rods. Make sure that you run the engine for a full 20 minutes using this procedure. It will seem like forever, but it is one of the most important steps to insure long, dependable performance.

Once Break-in is Complete- Drain and replace the engine oil and filter with new, fresh oil and a new filter. Recheck for any fluid leaks and check all fluid levels. If you installed a mechanical lifter style camshaft, flat faced or roller style, the valve adjustment should be rechecked at this time with the engine fully warmed up. Hydraulic lifter equipped engines should not require any readjustment.

Proper maintenance is important for any vehicle. Frequent oil changes, with a new filter is one of the easiest ways to insure your vehicle will deliver the performance you want for many long happy miles.

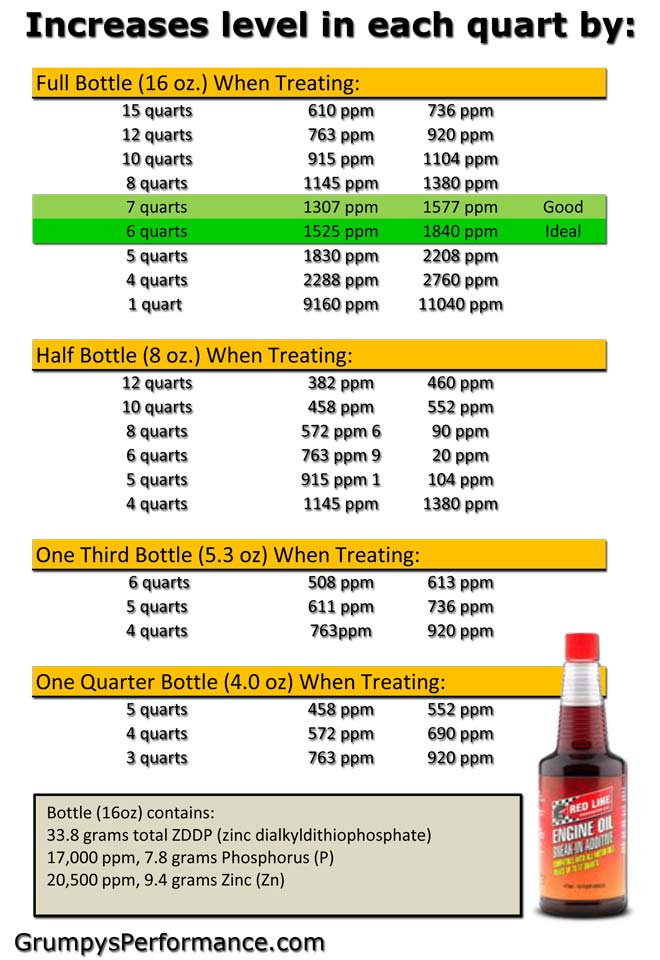

ID ADD, USE a GOOD MOLY BASE ASSEMBLY LUBE AND A HIGH ZINC CONTENT OIL AND SOME G.M. E.O.S. TO THE OIL

MARVEL MYSTER OIL is a good high detregent oil designed to aid valve train and rings ETC. cleaning, I almost always add about 10% marvel mstery oil to my engines, but if your running flat tappet lifters Id point out that many current oils are designed for roller lifter engines so Id sellect an oil thats designed for the older design with the higher zinc content, and adding a can of E.O.S. to the oil and moly assembly lube on the lifters and cam, sure won,t hurt on that first break in, if your breaking in the engine in your driveway, have a running hose and a fan handy, water running thru the radiators cooling fins and a fan blowing air helps prevent over heating, have a timing light and USE IT, check your fluid levels and watch your gauges

GM’S RECOMMENDED CRATE ENGINE START-UP PROCEDURE

Print this page out and check off boxes below (in the printed copy) when each step is completed.

Step Box

1) Safety first! If the car is on the ground, be sure the emergency brake is set, the wheels are chocked, and the transmission cannot fall into gear. Next verify that all hoses are tight and that both the radiator and radiator over flow jar/tank are full and have been filled with the proper anti-freeze and water mix.

2) Before starting your engine for the first time, add one pint of engine oil supplement ( EOS¹) to the crankcase oil and then check the oil level. Once this has been done, prime the oil system with an oil pump primer tool. Make sure number 1 cylinder is on TDC compression stroke, and install the distributor.

3) Adjust the distributor timing roughly by hand for a quick start up and smoothest idle possible.

4) When the engine first starts, verify that the engine rpm is at a safe level and that the timing is set near or at 30° before top dead center (BTDC). Run the engine speed between 1,500 and 2,500 RPM’s, varying the engine speed up and down with-in this range, to prevent overheating of the exhaust valves and the exhaust system. This should be done with no-load on the engine and for the first 30 minutes of operation.

5) After the first 30 minutes of the engine running, set the ignition timing according to the timing specifications. Now would be a good time to check thoroughly for leaks.

6) Adjust the carburetor settings, if necessary.

7) Drive the vehicle with varying speeds and loads on the engine for the first 30 miles. Be sure not to use a lot of throttle or high RPM.

8) Run five or six medium-throttle accelerations to about 3,800 RPM (55 to 60 MPH), then letting off in gear and coasting back down to 20 MPH.

9) Run a couple hard-throttle accelerations up to about 3,800 RPM (55 to 60 MPH), then letting off in gear and coasting back down to 20 MPH.

10) Change the oil and filter with recommended oil (10w30SG in most cases) and filter.

11) Drive the next 500 miles normally, without high RPM’s (below 3,800 RPM), hard use, or extended periods of high loading.

12) Change oil and filter again.

13) Your engine is now ready for many happy cruising miles!

Note¹: EOS P/N 1052367 can be used any time during the life of the engine.

Technical Note: This procedure has been corrected and improved from the original GMPP procedure by GILBERT CHEVROLET.

sitting with no air other than the fan moving air thru the radiator is bound to run a bit hotter than on the road, anything under 220F is normal /expected under those conditions.

I run a water hose thru the radiators cooling fins when testing under those conditions., on the street it should run fairly consistantlly in the 180F-190F range with a 180F T-stat.

in many cases an ADDITIONAL TAURUS electric fan from a salvage yard can be installed on the other side of the radiator to run off a dash switch or sensor that will provide additional cooling when needed.(price varies but its usually very reasonable from salvage yards)

http://forums.hybridz.org/attachment.php?attachmentid=8603&d=1218835261

or

190F-210F is ABOUT NORMAL,for driving temps, and nothing to worry about, adding a seperately mounted TRANSMISSION COOLER if you have an auto trans is usually worth a 10-15 degree drop in the coolant temp,MINIMUM, if the current trans fluids cooled in the lower radiator, adding an 8 qt baffled oil pan is usually good for an additional 7F-10F degrees reduction in oil temp alone

A great deal of the heat is transfered to the oil and trans fluids long before the radiator and coolant sees it,routing the hot trans fluid to an aux cooler and adding a high capacity oil pan significantly reduces the heat the radiator needs to transfer from the coolant to the air flow thru it.

http://store.summitracing.com/partd...&part=PRM-12318&N=700+400006+115&autoview=sku

http://www.4secondsflat.com/Hydraulic_lifter_cams.html