Ken

Member

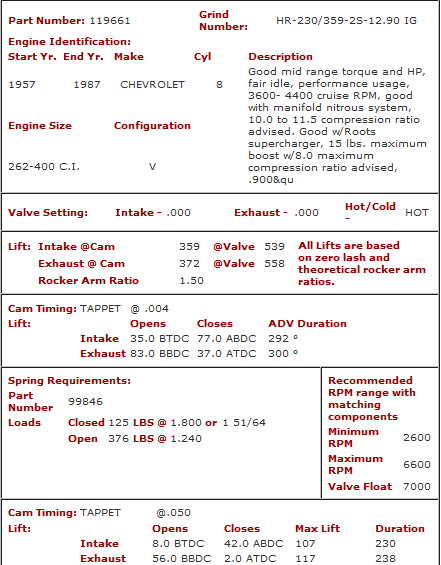

Many Updated done 1994 GMC 4x4 Yukon Two Door and I am thinking the cam may need to be changed, I tried to go to COMP Cam's and use there chart but keep getting an error when I go to finish it ..... INFO and the cam in it now in pictures >>>

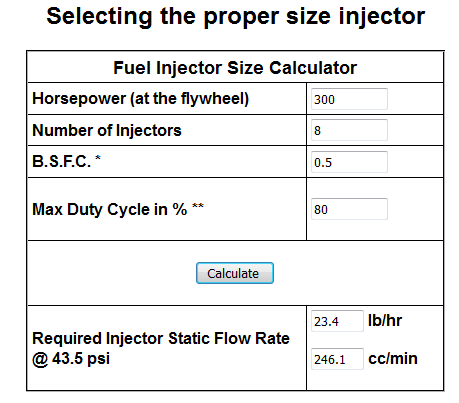

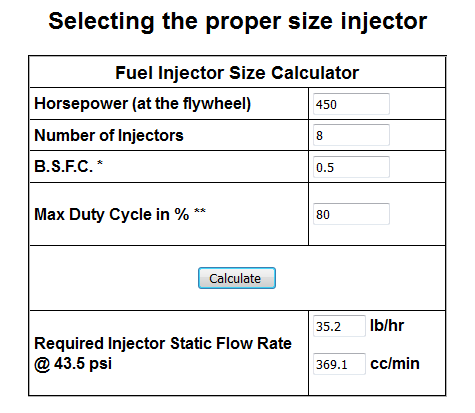

Also going to upgrade throttle body to a 58mm on a Holly Stealth Ram Jet. 383 forged & Bal. 4bolt main,1pc rear seal, roller cam & roller tipped 1.6 rockers, lift comes in at about 510/520, AEM Controller/ECM & Engine Position Module LS-1 coil on plug, JBA shorty stainless Headers, 4L80E Trans 3/4ton 8lugs 4.11 axles

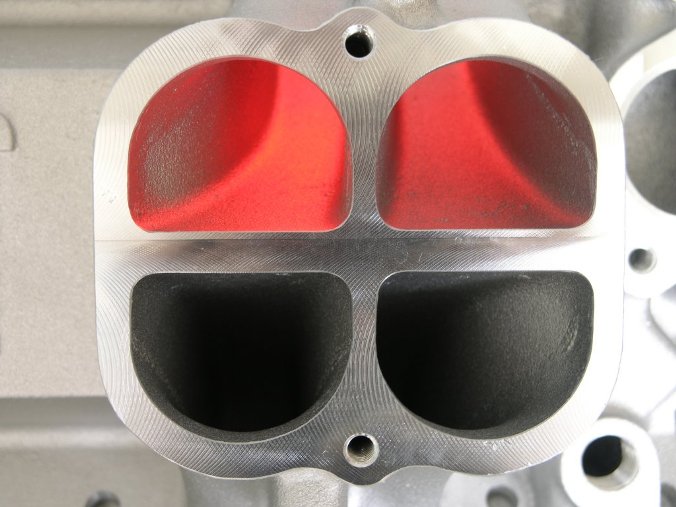

Note... On the TrickFlow G1 Twisted Wedge Heads the Intake valve is cantered to 13 deg's, 180cc intake port, 64cc chambers, 13* intake / 23* exhaust valve , ported polished and flowed and valve seats upgraded... This Cam is the same one from the original 2bll TBI Fuel injection system... gear has gone from 3.08 to 4.11 and tires went from 235/70 R16 to 225/75R16. Weight is about 4800Lbs. I have been trying to get trans shift points right learning about the AEM controller, not much luck, looking to go to a TCI EZ trans controller. But this thing won't even spin the tires unless there dusty or wet IT Just Hook's... I would think even with the CalTracs Bar's It should still spin the tires off the light, The lowering keys are backed way off and it allows the front end to come WAY UP and transfers the weight to the read end...

After this get's right on to the front steering... maybe rack and pinion

Also going to upgrade throttle body to a 58mm on a Holly Stealth Ram Jet. 383 forged & Bal. 4bolt main,1pc rear seal, roller cam & roller tipped 1.6 rockers, lift comes in at about 510/520, AEM Controller/ECM & Engine Position Module LS-1 coil on plug, JBA shorty stainless Headers, 4L80E Trans 3/4ton 8lugs 4.11 axles

Note... On the TrickFlow G1 Twisted Wedge Heads the Intake valve is cantered to 13 deg's, 180cc intake port, 64cc chambers, 13* intake / 23* exhaust valve , ported polished and flowed and valve seats upgraded... This Cam is the same one from the original 2bll TBI Fuel injection system... gear has gone from 3.08 to 4.11 and tires went from 235/70 R16 to 225/75R16. Weight is about 4800Lbs. I have been trying to get trans shift points right learning about the AEM controller, not much luck, looking to go to a TCI EZ trans controller. But this thing won't even spin the tires unless there dusty or wet IT Just Hook's... I would think even with the CalTracs Bar's It should still spin the tires off the light, The lowering keys are backed way off and it allows the front end to come WAY UP and transfers the weight to the read end...

After this get's right on to the front steering... maybe rack and pinion