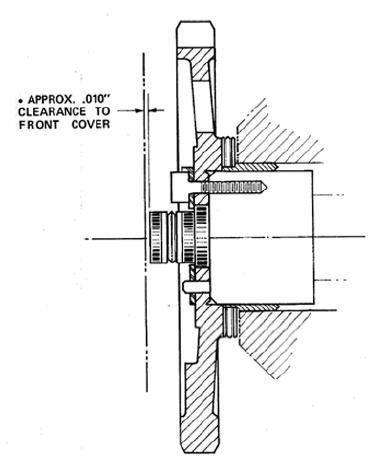

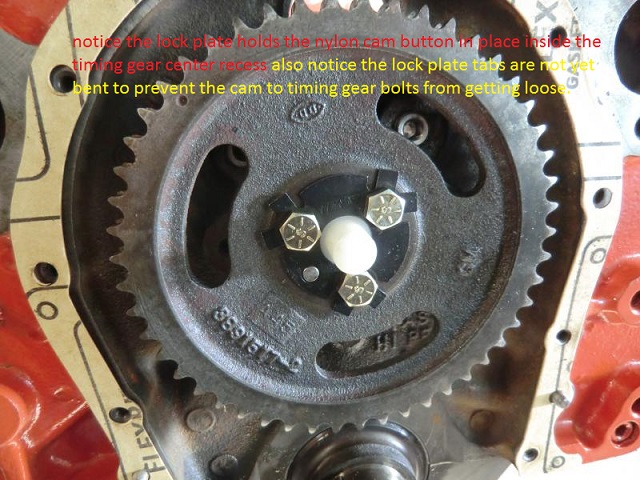

properly installed they cause zero problems, in fact Ive used a nylon cam button even on non-roller cam applications for many decades.

a thrust washer to protect the block surface is a good idea IF THE CAM GEAR is designed to use one AND if you have the .007-.005 clearance between the nylon cam button and the timing cover

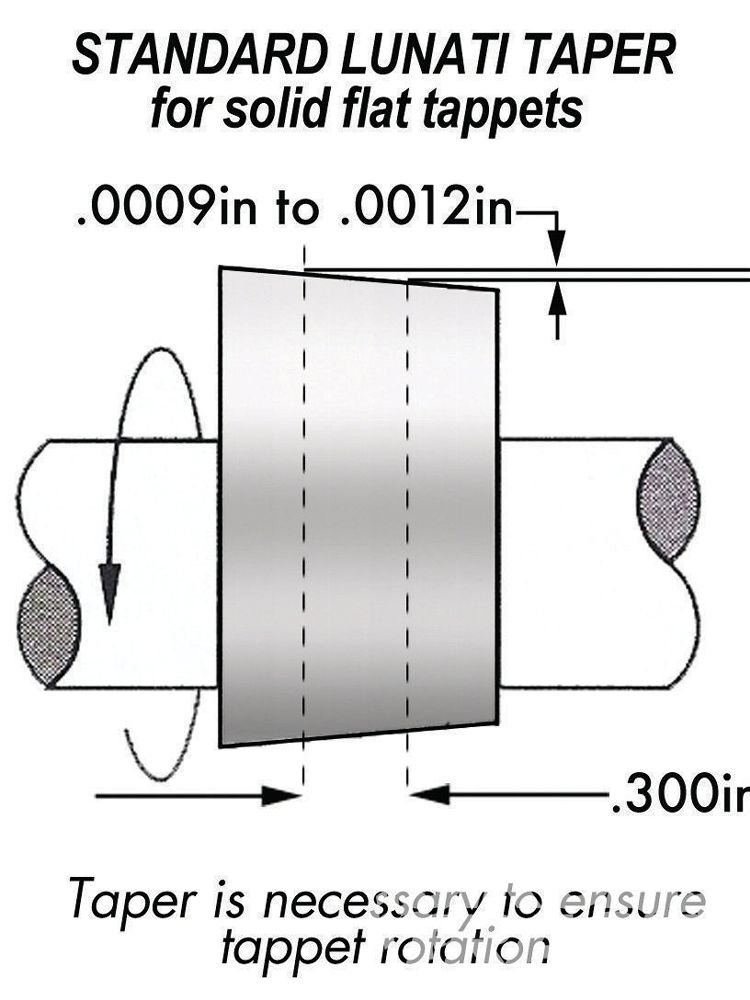

remember flat tappet cam lobes have a micro angle that tends to force the cam to the rear as it runs so theres very little chance for the cam to move forward in the block like with a roller cam, but the button does tend to eliminate and chance of that so its a good safety measure, even if its not needed most of the time.remember the rear cam journal is covered on the rear block with a freeze plug and oil pressure tends to make the cam stay a few thousands forward as theres a pressurized disc of oil flow behind the cam

READ THIS

viewtopic.php?f=52&t=3777&p=10011&hilit=nylon+button#p10011

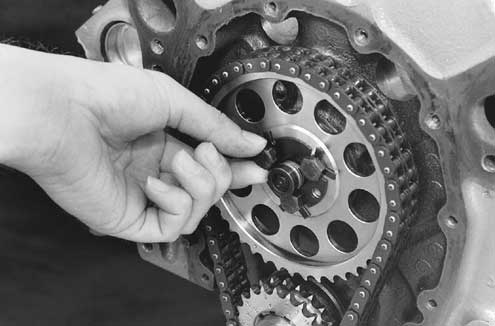

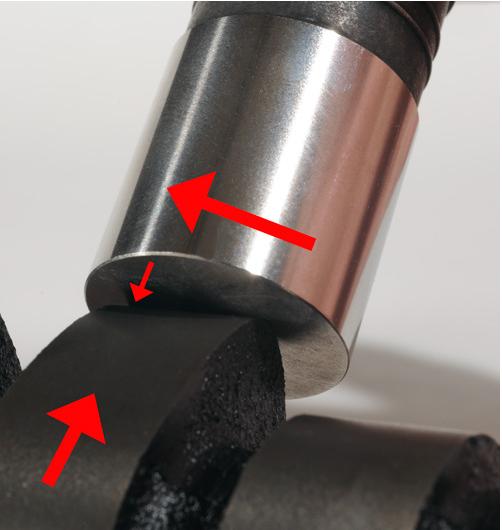

use of a camshaft install handle generally reduces the chances of damaged cam bearings

heres a bit of potentially useful info GOFAST POSTED

["quote=GOFAST"]

SBC Stepped Nose Cam in Early Block?

Just curious if anyone has devised a way to use the later SBC "stepped-nosed" cams in the early SBC's?

We are trying to eliminate the required use of any cam-buttons in the 100% stock-appearing builds on the roller platform?

Thanks, Gary in N.Y.

P.S. Open to any suggestions/recommendations. Have my own idea but like to hear some add'l possibilities/thoughts.

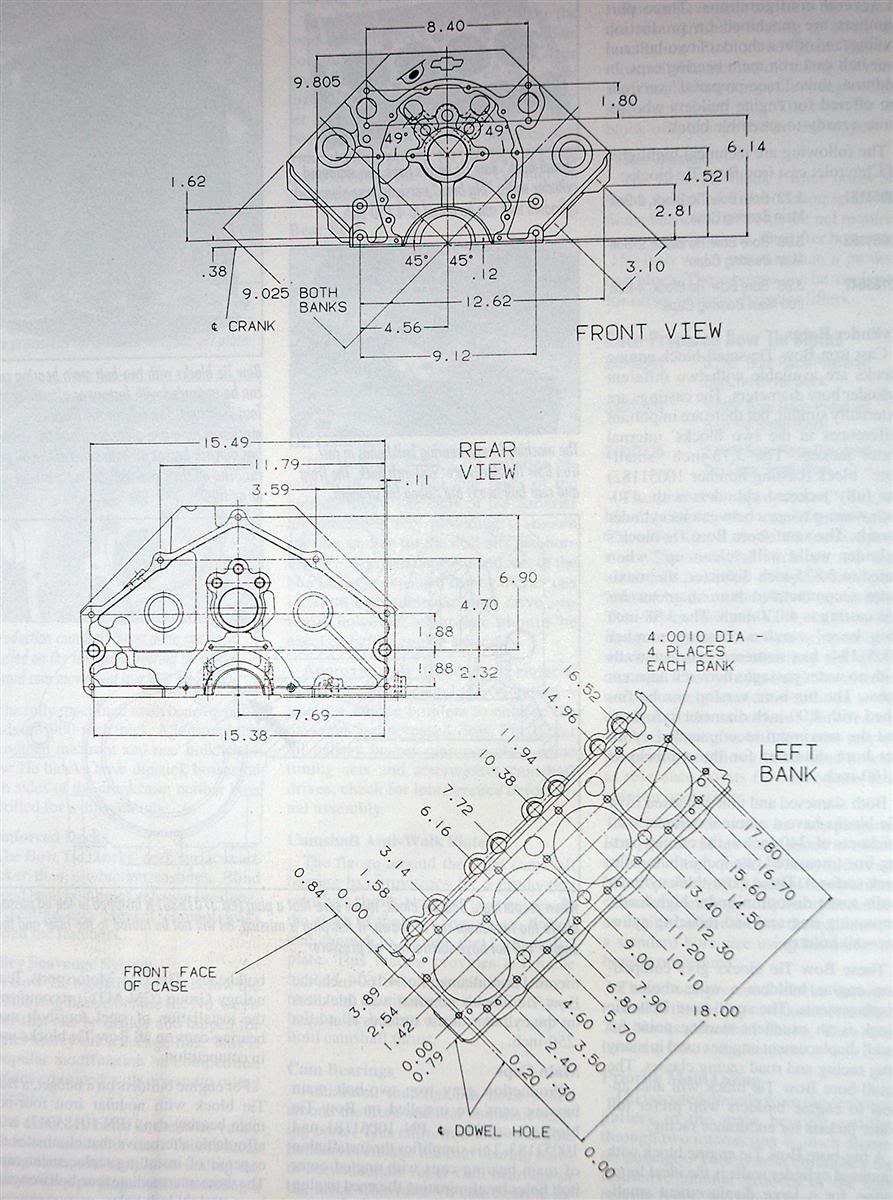

I brought this back because it turned out to be a fairly simple resolution. Wasn't sure it could be done without extensive machining, solved it easily.

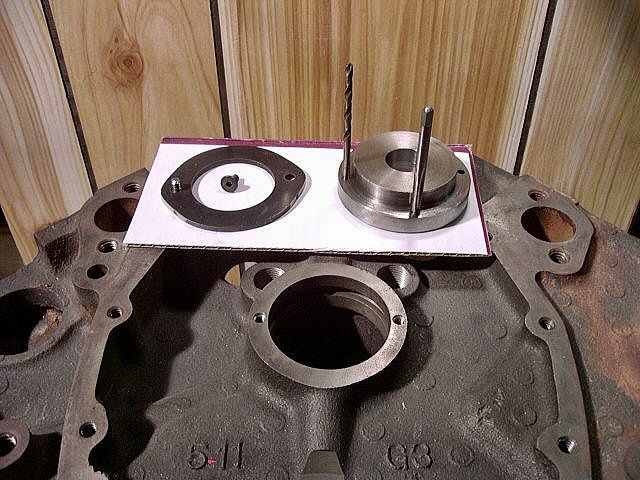

I'll put a couple shots below showing the basic's of the "fix". Takes about 30/40 minutes or so for the entire machining and can be done on a simple (decent) drill press capable of holding the block on the table.

Quote:

Originally Posted by

novaderrik View Post

just use a roller cam block... the only real striking visual difference between them and an old small block once it's in the car is the size of the pad by the water pump where the id codes are stamped.

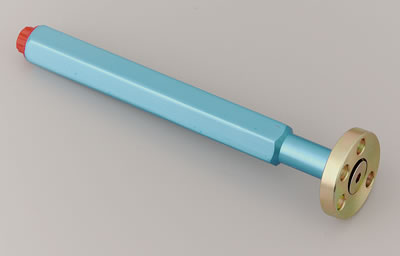

Hi nova, we do a bunch of 100% stock-appearing builds where ANY replacement block is NOT an option. Now we can set up the roller cams (mostly retro-hydraulics) with the late thrust plate. No more "playing-around" with cam buttons/end play. Much easier for us here.

Thanks, Gary in N.Y.

P.S. Anyone with any machining experience can accomplish this mod easily. With the way we designed the tool in the photo we can pick the 2 best spots on the original thrust surface to locate the 2 allen-head screws, an area that has some extra "meat" for the screw-threads.

don't need those ears on the sides anymore?

small taps in cast iron, any troubles there?

Hi Tom, correct on the "ears", they aren't needed with this method. Later today I'll put another shot here with the plate finished, "ears" removed!

No problem drilling/tapping for the fasteners, entire procedure went smoothly after devising the jig to set all the holes in place. The jig is used to locate/drill the new holes in the plate also, in the first photo you can see the "register" that holds the plate in place to back-drill these holes.

Like I stated above, was fairly easy when I finally got a handle on exactly how I was going to get it to come together.

The only potential issue on some blocks is the uniformity of the original cam-thrust surface face, many favor one side more that the other. In other words (looking at the block from the front) some castings are wider on one side making the other side narrower, we can position the 2 bolts anywhere on the surface. They don't need to be "clocked" so to speak!

(Add) This a huge breakthrough for us when doing the 100% stock-appearing builds on any roller platform. In the larger picture the cost is also less, no cam button/locking plate, just the cost of the OEM plate. Cost/labor of installing the plate is about a "wash" with the time spent on setting up the end-play with the button. We can layout the plate at the same time we drill/tap for the front (3) oil galley plugs, which are also done while on the drill press

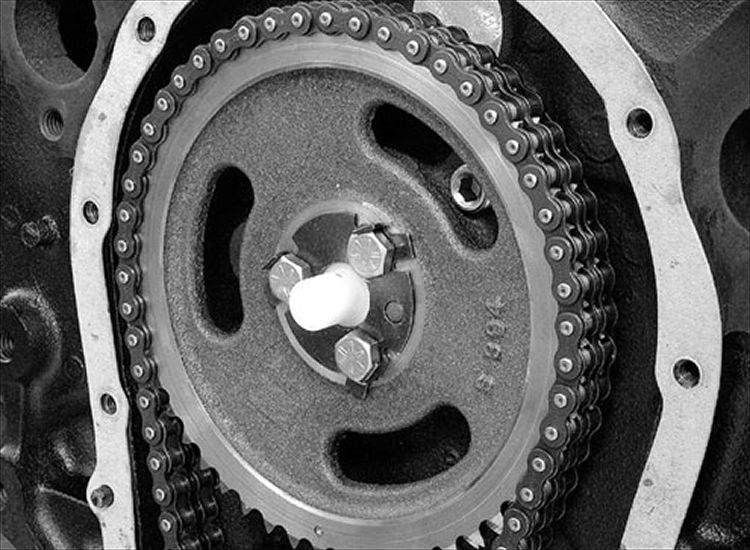

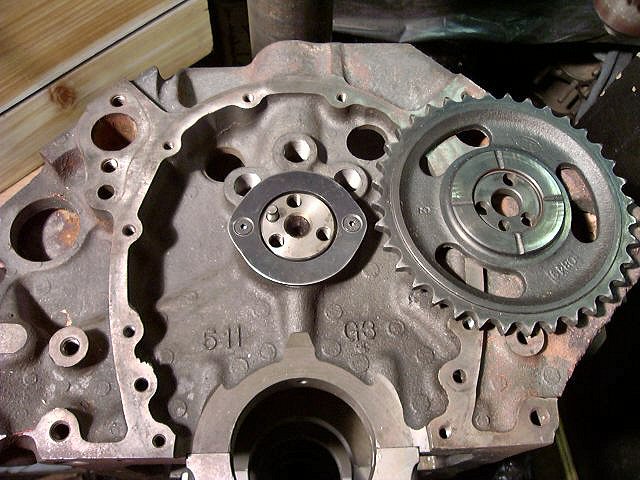

(Add) Below is a shot of the finished plate installed.

Thanks, Gary in N.Y.

P.S. On a side note, we didn't find it necessary to drill (deep enough) into the oil groove behind the cam brg but it would not have made any difference when the bolts are installed. Also, I could put 2 more fasteners in the plate if I felt it necessary. Would take about an extra 10 minutes simply by "turning" the jig 90* and drilling the 2 add'l holes.

P.S. I've already "kicked" this around with a couple local builders just for opinion's sake, all are in agreement, looks like all will be fine! I most definitely would NOT attempt this procedure by "hand", you'll most likely ruin the casting. It takes a decent lathe, the Bridgeport, and a decent rotating table to make the tooling! Also necessary is a 10-24 "bottom" tap to get every last thread possible.

ast shot, "late" cam installed, .003" (nominal) end-play.

Worked like a charm, really.

Thanks, Gary in N.Y.

P.S. Mike (Wolfplace) thanks for the support. I'll say it once more, for us here we consider this a major accomplishment. I still need to dyno test a build or two but don't anticipate any adverse effects!

http://www.jegs.com/i/JEGS-Performa...MIiNrGptbX1gIVzYJ-Ch0grAi6EAQYAiABEgKuRvD_BwE

http://paceperformance.com/i-648452...ines-chevrolet-performance-parts-engines.html

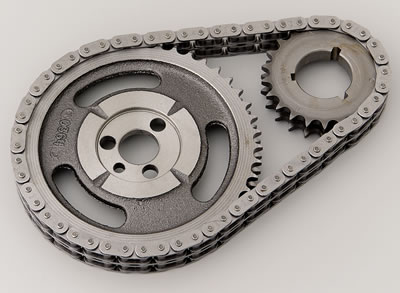

old school

http://www.jegs.com/p/COMP-Cams/Comp-Cams-Cam-Buttons-Wear-Plate/753163/10002/-1

[/quote]