THE cam gear rotates exactly once for each two times the crank rotates,the cam gear lines up at the 12 o'clock crank and 6 o'clock cam gear orientation when the #6 cylinders on the compression stroke, rotate the engine one complete revolution and the cranks again at 12 o'clock but the cam gears index mark is now at 12 o'clock, indicating the #1 cylinders at the compression stroke, you use the 12/6 index to install cams simply because its easier to align correctly ,visually, but you need to rotate the engine to the 12/12 orientation before dropping the distributor back in, the distributor won,t fully seat unless the oil pump drive shaft seats up into the distributor gear, as you remove the distributor the helical gear interface tends to turn the pump drive shaft slightly, you can use a long flat tip screw driver to turn that back to the correct location and with a bit of practice you'll learn to gauge the amount the rotor rotates as it seats into the cam gear.

http://www.summersbrothersracing.co...LF-CUT-DRIVE-FLANGE-BIG-BLOCK-CHEVY_p_30.html

watch video

http://www.youtube.com/watch?v=UYGU7mTw ... r_embedded

http://garage.grumpysperformance.co...ng-cam-and-shifting-the-lca.10553/#post-44949

http://garage.grumpysperformance.com/index.php?threads/cam-degreeing.9010/#post-35474

http://garage.grumpysperformance.com/index.php?threads/precision-measuring-tools.1390/#post-12997

http://garage.grumpysperformance.co...hanics-of-adv-ret-a-camshaft.4532/#post-12050

http://garage.grumpysperformance.com/index.php?threads/degreeing-in-a-cam-correctly.3097/#post-8240

http://garage.grumpysperformance.com/index.php?threads/cam-degree-equipment-tools.1759/#post-4440

http://garage.grumpysperformance.co...rect-custom-length-pushrods.14241/#post-72355

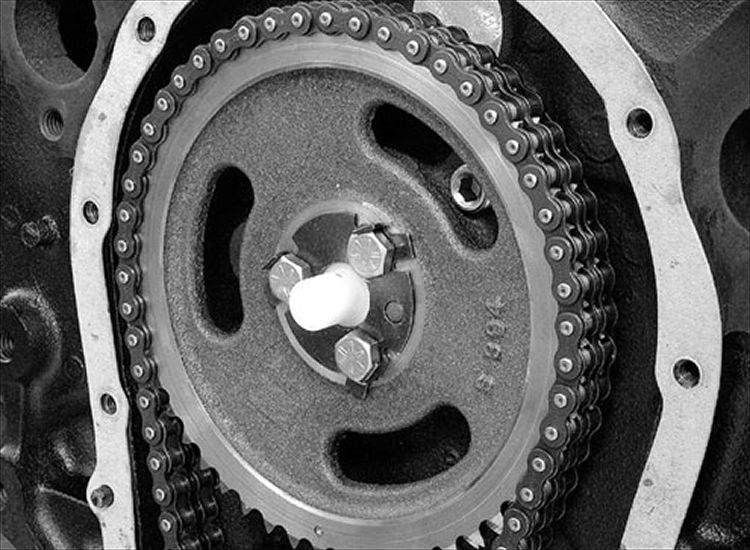

The CLOYES true roller style is vastly superior to the factory link belt design

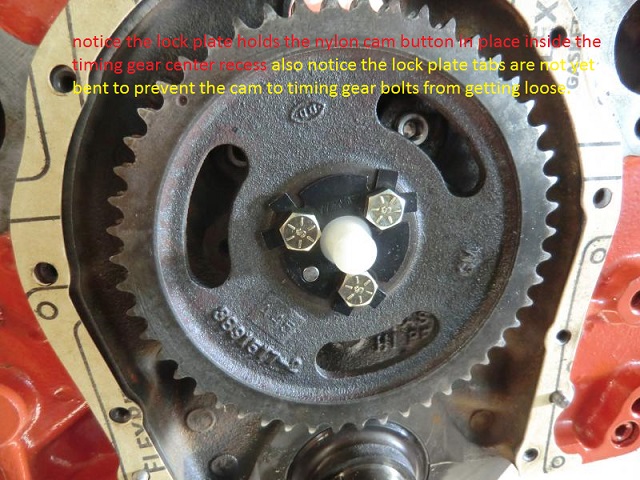

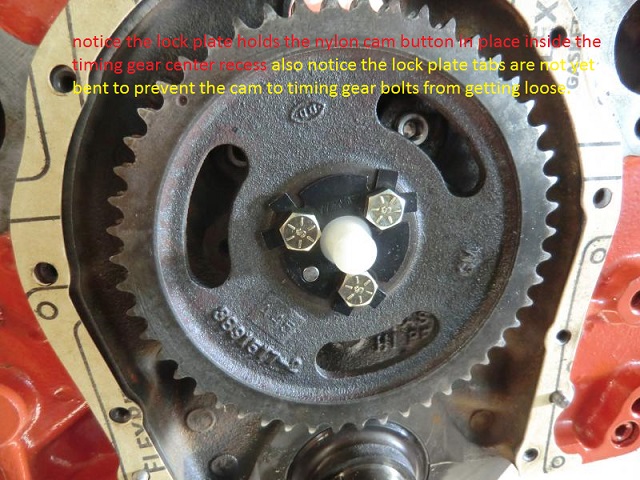

use loc-tite on the threads and a cam button and cam button retainer plate , if its the early style with out the step nose and retainer plate design

I've seen a good many chevy cams ,

but I have yet to see one where they failed to thread the timing chain gear bolt holes, obviously you could drill and tap that cam core,

but I would ask for a replacement simply because if the manufacturers quality control team missed that, check on the cams fabrication,

theres a chance they also missed other quality control checks, clearances etc.

http://garage.grumpysperformance.com/index.php?threads/cam-degreeing.9010/#post-32126

http://garage.grumpysperformance.com/index.php?threads/cam-gear-and-timing-marks-etc.724/#post-1021

http://garage.grumpysperformance.com/index.php?threads/degree-in-that-cam-correctly.27/#post-35

http://garage.grumpysperformance.co...ng-cam-and-shifting-the-lca.10553/#post-44949

http://garage.grumpysperformance.co...hanics-of-adv-ret-a-camshaft.4532/#post-12048

http://garage.grumpysperformance.com/index.php?threads/cam-spacer-buttons.1793/

http://www.jonkaaseracingengines.com/pr ... rives.html

how come its 180 degs out of phase?

I get this question all the time, well here’s something I see lots of guys don’t understand, ONCE YOU'VE INSTALLED A CAM WITH THE TIMING MARKS YOU MUST ROTATE THE CRANK 360 DEGREES BEFORE DROPPING IN THE DISTRIBUTOR, while its true that if the, timing marks are positioned so the crank is at 12 o,clock and the cam gear is at 6 o,clock that the cam lobes will be in the position that fires #6 cylinder that HAS NO EFFECT AT ALL (on finding TDC,) for aligning the degree wheel with TDC,or THE timing tab pointer, for degreeing in the cam, the piston passes thru TDC TWICE in every firing cycle once on the firing/power stroke and once on the exhaust stroke, the cam rotates at exactly 1/2 the speed of the crank so to make it easy to line up the marks they install it with the marks at the closest point 6/12 for easy indexing, rotate the engine 360 degrees to the #1 TDC power stroke and the crank gear will still be at 12 o'clock 12/12 but the cam will be at 12 o,clock also, rotate another 360 degrees and your back where you started. its simply easier to index the cam at the point where the index marks align closely. look at how the cam lobes themselves open the valves when the cam is just installed the #1 cylinder valves are slightly open and the #6 are closed per "Lunati" ‘’YES YOU ARE RIGHT - WHEN CRANK IS AT TWELVE AND CAM IS AT SIX THEN #6 CYL IS FIRING AFTER YOU LINE UP YOUR MARKS AND INSTALL GEAR THEN ROTATE YOUR CRANK ONE REVOLUTION AND THEN DROP THE DIST. IN - AT THAT POINT

http://boxwrench.net/specs/chevy_sb.htm

look here

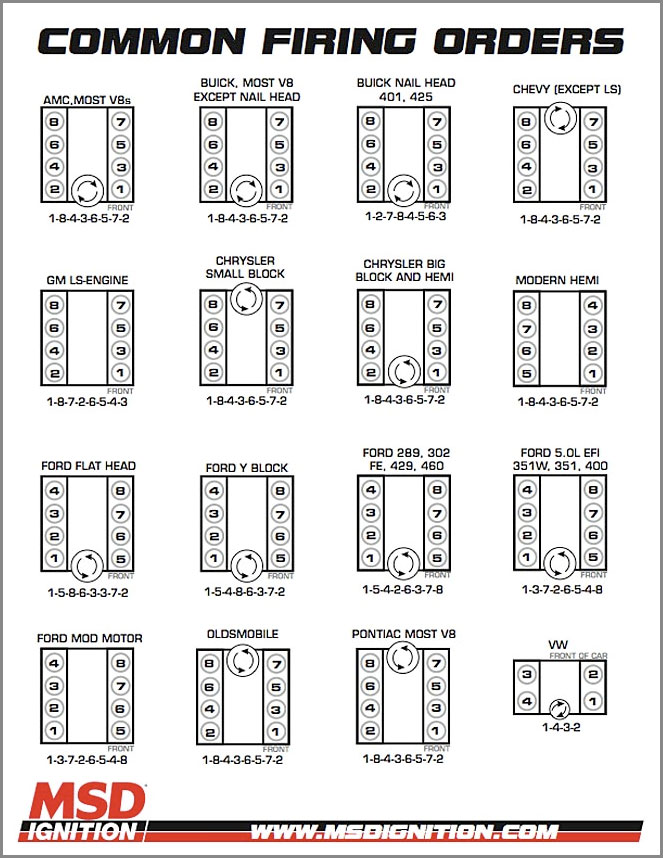

drop the distributor in with the rotor pointing at the #1 cylinder, and YEAH! it physically possible to get the distributors rotor to point at any place you want it too by changing the oil pump drive shaft alignment with a large flat blade screw driver while the distributors out of the engine and that's easily changed, but to do it correctly,you want the rotor to point at the #1 cylinder on the compression stroke, so pull the #1 plug, get a large ratchet/socket on the damper and put your finger over the open plug hole and slowly rotate the engine by hand in its normal rotational direction until you see pressure build under your finger as the rotor approaches #1 cylinder location on the distributor base which you should have marked as its supposed to be in direct alignment between the distributor and the number 1 cylinder on the engine, remember the distributor and cam gears are helical and the rotor turns as it seats so compensate slightly. and the rotor should be just coming into alignment as pressure builds under your finger, once that's done re-install the distributor cap and plug and use a timing light to set the timing, you normally want about 6-12 degrees BTDC at idle and watch it advance to about 37 degrees as the rpms build to about 3000rpm

a couple times Ive seen imported cam timing chain sets that were machined WAAAYY off from being correct, if you didn,t DEGREE IN your current CAM, and just used the index marks on the timing set, chances are good that your cams indexed incorrectly, as a first step Id strongly suggest verifying the cams degreed in correctly

you'll need a few basic tools and a good understanding of what your doing, but its certainly not all that difficult.

I was asked where to get a CHEAP degree wheel

heres one you can print out and save for engine builds on the engine stand

(put curser on and click)

http://savetheledges.org/test/AVS/image ... eWheel.png

http://store.summitracing.com/partdetai ... toview=sku

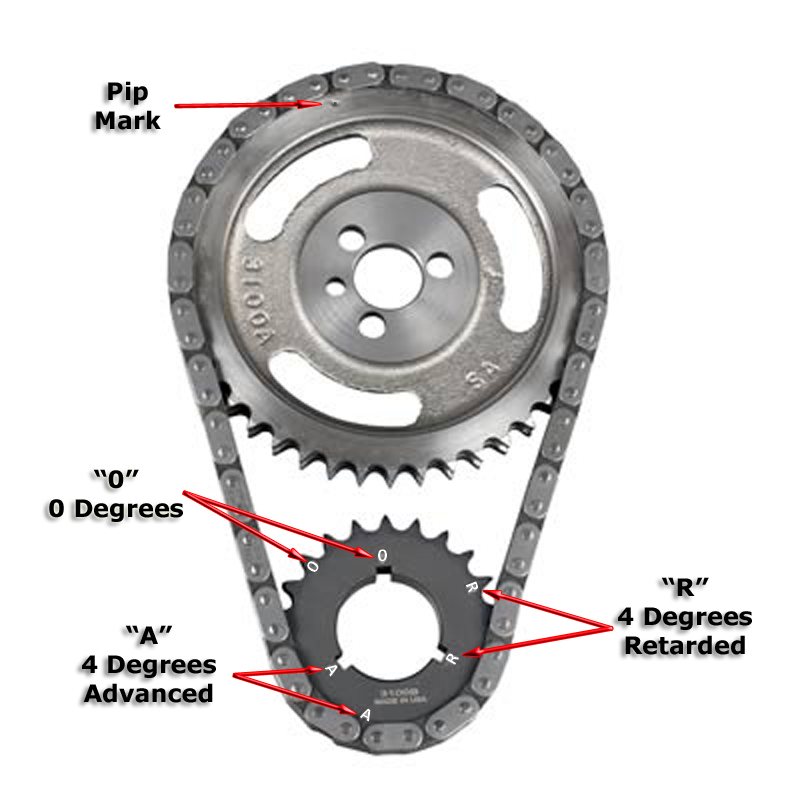

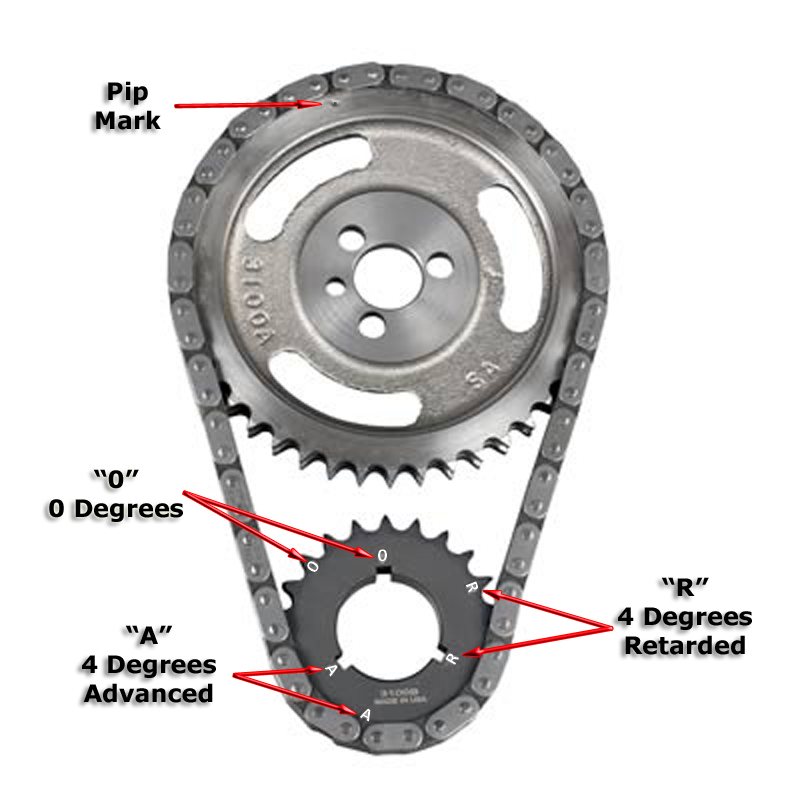

BTW you CAN advance or retard the roller timing chain its done bye drilling out the cam index pin hole in the timing gear and installing an off set bushing

http://store.summitracing.com/partdetai ... toview=sku

there are fully adjustable timing gear sets available

http://www.usaperform.com/timing-chain- ... =4d&page=1

you could buy these from summit racing or similar parts from jegs

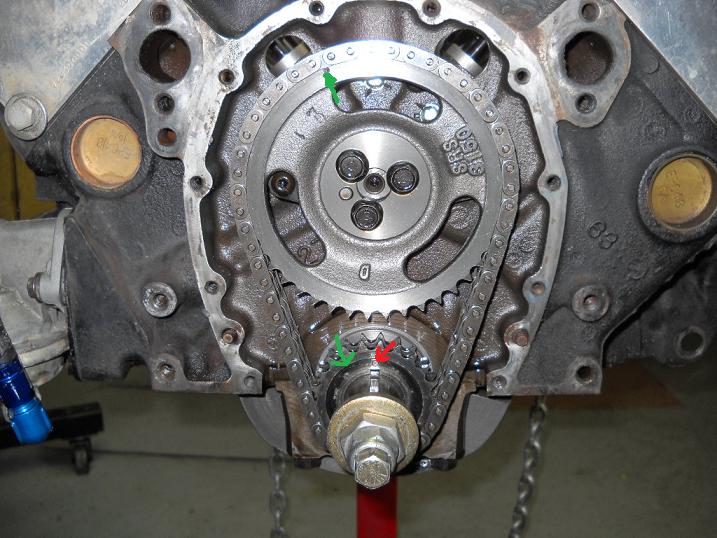

this is 180 degrees out (the distributor rotor points at cylinder #6, so before you drop in the distributor rotate the crank 360 degrees bring both marks to the 12 o-clock location, then drop in the distributor pointing to cylinder #1, and adjust ignition timing from that point

this is 180 degrees out (the distributor rotor points at cylinder #6, so before you drop in the distributor rotate the crank 360 degrees bring both marks to the 12 o-clock location, then drop in the distributor pointing to cylinder #1, and adjust ignition timing from that point

http://www.summitracing.com/

http://www.jegs.com sells this KIT

Comp Cams #249-4796

http://www.jegs.com/i/Comp Cams/249/4796/10002/-1

and you can buy these

MOR-62191 $44 (wheel)

MOR-61755 $47 (SBC)

MOR-61756 $47.(BBC)crank sockets

SUM-900188 $17 (piston stop, head off)

SUM-900189 $6.95(piston stop, head on)

TFS-90000 $94.95 (degree kit)

youll also want two flat tappet solid lifters and two weak check springs

http://store.summitracing.com/partdetai ... toview=sku

instructions

http://www.iskycams.com/camshaft.html

http://www.thedirtforum.com/degree.htm

http://www.ridgenet.net/~biesiade/camdegree.htm

http://www.hotrodder.com/kwkride/degree.html

http://www.cranecams.com/pdf/803.pdf

http://www.pontiacstreetperformance.com ... shaft.html

http://www.compcams.com/Technical/Instr ... es/145.pdf

this charts based on a 350-383 Chevy or similar size engine, but its a good rough guide on most engines under 400cid displacement on matching the duration to the intended operational rpm band

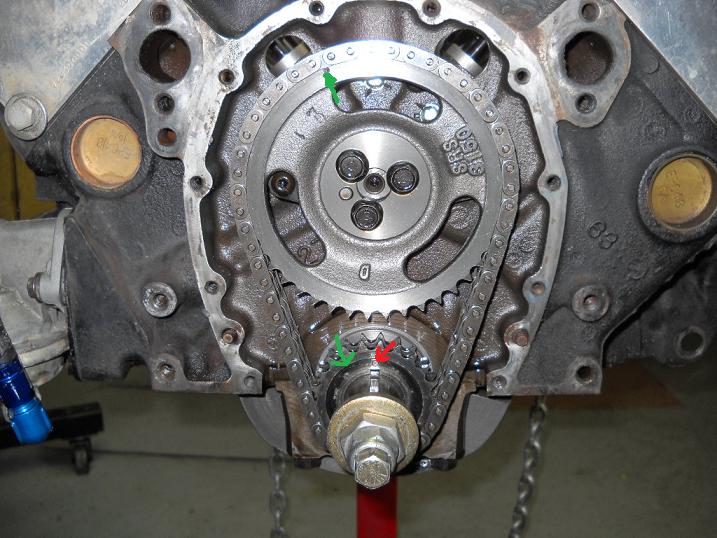

when you go to install a cam, a fairly common new guy screw-up is if you index the upper and larger cam gear (0) index mark,on the smaller and lower crank gear 0 over the KEY-WAY slot,

I,D be amazed if it RUNS at all, installed indexed that way, but guys do occasionally screw up and index the upper larger cam gear to the 0 directly over the key-way slot on the smaller, lower , crank gear, which SHOULD in stead be in approximately in the 2 O'CLOCK location when the index marks ARE correctly aligned on both the crank at 12 o'clock and the cam gear at 6 o'clock

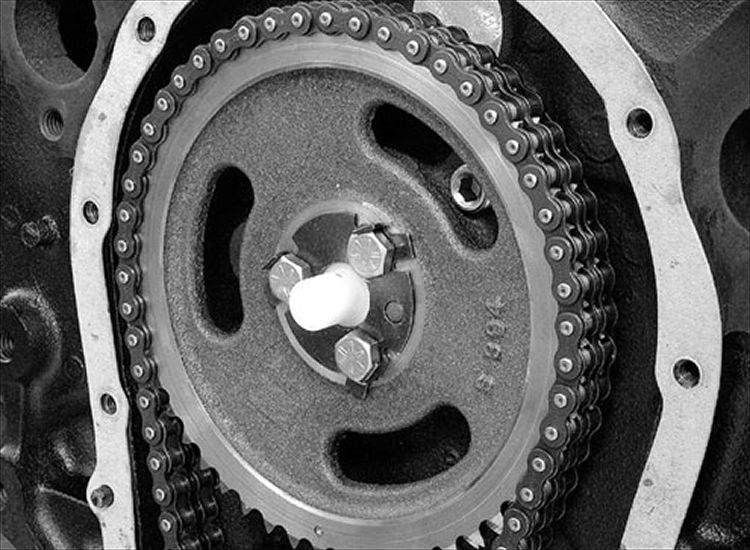

the timing chain picture above illustrates the off set from the KEY-WAY slot,to its related index mark that must be lined up with the cam gear above it

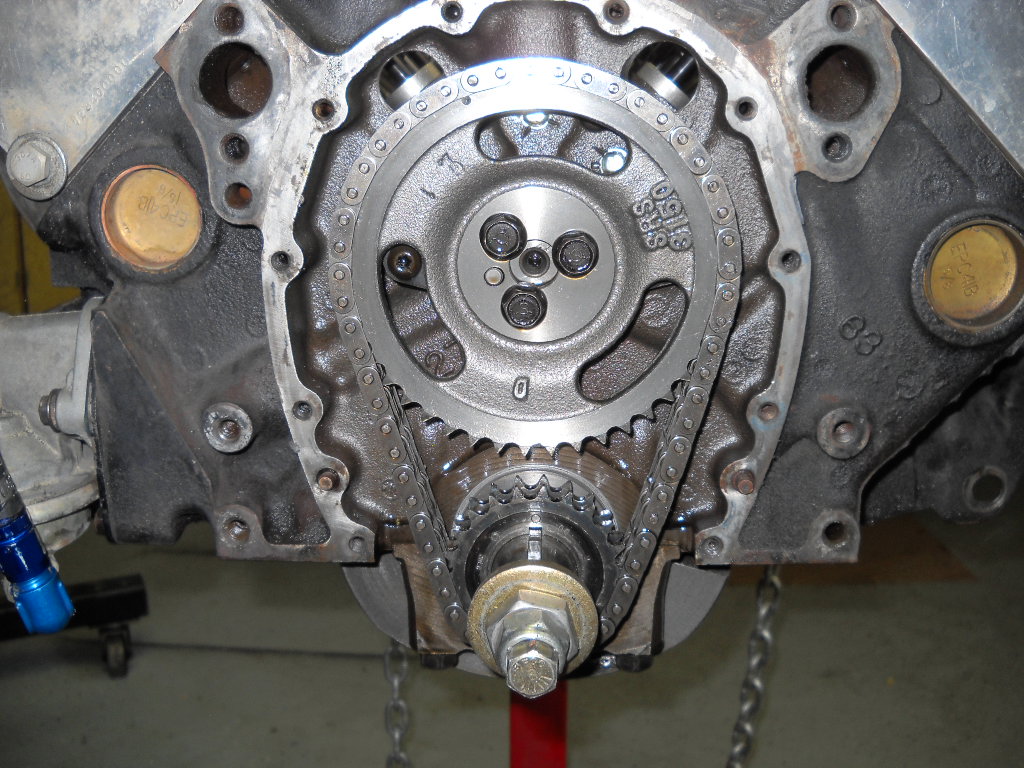

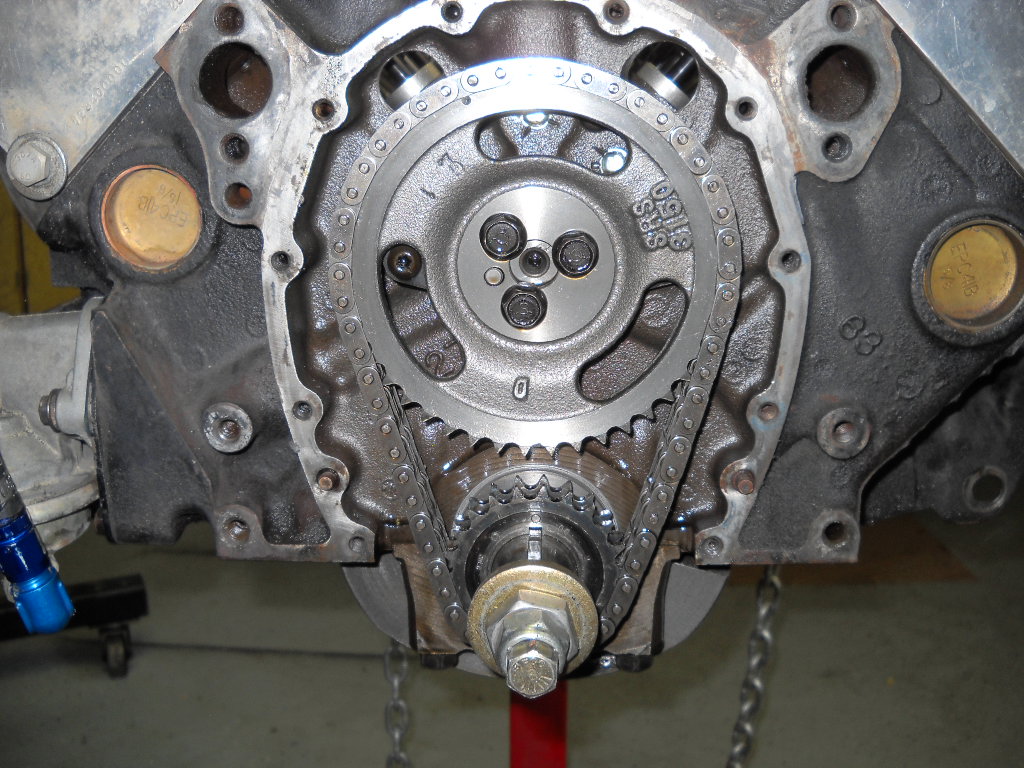

this picture below is a good place to point out "a common NEW GUY SCREW-UP"

the two green arrow indicated dots are normally lined up with the upper cam gear at 6 o'clock and the lower crank gear at 12 o'clock during a dot-to-dot install, where guys don,t bother to degree in a cam, but occasionally I see guys use the KEY- WAY slot marked lower crank gear to line up with the upper cam gear, notice the key way slot has a (O) , that can be confusing if you've never bothered to do this before. theres also frequently an (A) or (R) key way slot and a index mark (A) or (R)

IF the lower crank gear index mark on the lower cam gear is correctly indexed (which its NOT yet rotated enough to do in the picture above)

the top cam gear is exactly twice the size of the lower crank gear,it rotates at exactly 1/2 speed or once for each TWO crank gear rotations ,if the cam gear and lower crank gear are correctly indexed the timing as they rotate will place the cam gear at EITHER 12 o'clock, or at 6 o'clock, exactly as the crank gear hits 12 o'clock on each rotation

notice in the lower picture the crank key way is at about the 2 o'clock position

http://www.summersbrothersracing.co...LF-CUT-DRIVE-FLANGE-BIG-BLOCK-CHEVY_p_30.html

watch video

degree it in correctly and get it to last,cam install info,

IM frequently asked (why bother degreeing in a cam, the timing set comes with index marks to install it?) it basically comes down to, a question of do you accept a random install where the timing can be almost any place randomly or do you insist on maximizing the engines potential and know...

garage.grumpysperformance.com

http://www.youtube.com/watch?v=UYGU7mTw ... r_embedded

http://garage.grumpysperformance.co...ng-cam-and-shifting-the-lca.10553/#post-44949

http://garage.grumpysperformance.com/index.php?threads/cam-degreeing.9010/#post-35474

http://garage.grumpysperformance.com/index.php?threads/precision-measuring-tools.1390/#post-12997

http://garage.grumpysperformance.co...hanics-of-adv-ret-a-camshaft.4532/#post-12050

http://garage.grumpysperformance.com/index.php?threads/degreeing-in-a-cam-correctly.3097/#post-8240

http://garage.grumpysperformance.com/index.php?threads/cam-degree-equipment-tools.1759/#post-4440

http://garage.grumpysperformance.co...rect-custom-length-pushrods.14241/#post-72355

The CLOYES true roller style is vastly superior to the factory link belt design

use loc-tite on the threads and a cam button and cam button retainer plate , if its the early style with out the step nose and retainer plate design

I've seen a good many chevy cams ,

but I have yet to see one where they failed to thread the timing chain gear bolt holes, obviously you could drill and tap that cam core,

but I would ask for a replacement simply because if the manufacturers quality control team missed that, check on the cams fabrication,

theres a chance they also missed other quality control checks, clearances etc.

http://garage.grumpysperformance.com/index.php?threads/cam-degreeing.9010/#post-32126

http://garage.grumpysperformance.com/index.php?threads/cam-gear-and-timing-marks-etc.724/#post-1021

http://garage.grumpysperformance.com/index.php?threads/degree-in-that-cam-correctly.27/#post-35

http://garage.grumpysperformance.co...ng-cam-and-shifting-the-lca.10553/#post-44949

http://garage.grumpysperformance.co...hanics-of-adv-ret-a-camshaft.4532/#post-12048

http://garage.grumpysperformance.com/index.php?threads/cam-spacer-buttons.1793/

http://www.jonkaaseracingengines.com/pr ... rives.html

how come its 180 degs out of phase?

I get this question all the time, well here’s something I see lots of guys don’t understand, ONCE YOU'VE INSTALLED A CAM WITH THE TIMING MARKS YOU MUST ROTATE THE CRANK 360 DEGREES BEFORE DROPPING IN THE DISTRIBUTOR, while its true that if the, timing marks are positioned so the crank is at 12 o,clock and the cam gear is at 6 o,clock that the cam lobes will be in the position that fires #6 cylinder that HAS NO EFFECT AT ALL (on finding TDC,) for aligning the degree wheel with TDC,or THE timing tab pointer, for degreeing in the cam, the piston passes thru TDC TWICE in every firing cycle once on the firing/power stroke and once on the exhaust stroke, the cam rotates at exactly 1/2 the speed of the crank so to make it easy to line up the marks they install it with the marks at the closest point 6/12 for easy indexing, rotate the engine 360 degrees to the #1 TDC power stroke and the crank gear will still be at 12 o'clock 12/12 but the cam will be at 12 o,clock also, rotate another 360 degrees and your back where you started. its simply easier to index the cam at the point where the index marks align closely. look at how the cam lobes themselves open the valves when the cam is just installed the #1 cylinder valves are slightly open and the #6 are closed per "Lunati" ‘’YES YOU ARE RIGHT - WHEN CRANK IS AT TWELVE AND CAM IS AT SIX THEN #6 CYL IS FIRING AFTER YOU LINE UP YOUR MARKS AND INSTALL GEAR THEN ROTATE YOUR CRANK ONE REVOLUTION AND THEN DROP THE DIST. IN - AT THAT POINT

http://boxwrench.net/specs/chevy_sb.htm

look here

drop the distributor in with the rotor pointing at the #1 cylinder, and YEAH! it physically possible to get the distributors rotor to point at any place you want it too by changing the oil pump drive shaft alignment with a large flat blade screw driver while the distributors out of the engine and that's easily changed, but to do it correctly,you want the rotor to point at the #1 cylinder on the compression stroke, so pull the #1 plug, get a large ratchet/socket on the damper and put your finger over the open plug hole and slowly rotate the engine by hand in its normal rotational direction until you see pressure build under your finger as the rotor approaches #1 cylinder location on the distributor base which you should have marked as its supposed to be in direct alignment between the distributor and the number 1 cylinder on the engine, remember the distributor and cam gears are helical and the rotor turns as it seats so compensate slightly. and the rotor should be just coming into alignment as pressure builds under your finger, once that's done re-install the distributor cap and plug and use a timing light to set the timing, you normally want about 6-12 degrees BTDC at idle and watch it advance to about 37 degrees as the rpms build to about 3000rpm

a couple times Ive seen imported cam timing chain sets that were machined WAAAYY off from being correct, if you didn,t DEGREE IN your current CAM, and just used the index marks on the timing set, chances are good that your cams indexed incorrectly, as a first step Id strongly suggest verifying the cams degreed in correctly

you'll need a few basic tools and a good understanding of what your doing, but its certainly not all that difficult.

I was asked where to get a CHEAP degree wheel

heres one you can print out and save for engine builds on the engine stand

(put curser on and click)

http://savetheledges.org/test/AVS/image ... eWheel.png

http://store.summitracing.com/partdetai ... toview=sku

BTW you CAN advance or retard the roller timing chain its done bye drilling out the cam index pin hole in the timing gear and installing an off set bushing

http://store.summitracing.com/partdetai ... toview=sku

there are fully adjustable timing gear sets available

http://www.usaperform.com/timing-chain- ... =4d&page=1

you could buy these from summit racing or similar parts from jegs

http://www.summitracing.com/

http://www.jegs.com sells this KIT

Comp Cams #249-4796

http://www.jegs.com/i/Comp Cams/249/4796/10002/-1

and you can buy these

MOR-62191 $44 (wheel)

MOR-61755 $47 (SBC)

MOR-61756 $47.(BBC)crank sockets

SUM-900188 $17 (piston stop, head off)

SUM-900189 $6.95(piston stop, head on)

TFS-90000 $94.95 (degree kit)

youll also want two flat tappet solid lifters and two weak check springs

http://store.summitracing.com/partdetai ... toview=sku

instructions

http://www.iskycams.com/camshaft.html

http://www.thedirtforum.com/degree.htm

http://www.ridgenet.net/~biesiade/camdegree.htm

http://www.hotrodder.com/kwkride/degree.html

http://www.cranecams.com/pdf/803.pdf

http://www.pontiacstreetperformance.com ... shaft.html

http://www.compcams.com/Technical/Instr ... es/145.pdf

this charts based on a 350-383 Chevy or similar size engine, but its a good rough guide on most engines under 400cid displacement on matching the duration to the intended operational rpm band

when you go to install a cam, a fairly common new guy screw-up is if you index the upper and larger cam gear (0) index mark,on the smaller and lower crank gear 0 over the KEY-WAY slot,

I,D be amazed if it RUNS at all, installed indexed that way, but guys do occasionally screw up and index the upper larger cam gear to the 0 directly over the key-way slot on the smaller, lower , crank gear, which SHOULD in stead be in approximately in the 2 O'CLOCK location when the index marks ARE correctly aligned on both the crank at 12 o'clock and the cam gear at 6 o'clock

the timing chain picture above illustrates the off set from the KEY-WAY slot,to its related index mark that must be lined up with the cam gear above it

this picture below is a good place to point out "a common NEW GUY SCREW-UP"

the two green arrow indicated dots are normally lined up with the upper cam gear at 6 o'clock and the lower crank gear at 12 o'clock during a dot-to-dot install, where guys don,t bother to degree in a cam, but occasionally I see guys use the KEY- WAY slot marked lower crank gear to line up with the upper cam gear, notice the key way slot has a (O) , that can be confusing if you've never bothered to do this before. theres also frequently an (A) or (R) key way slot and a index mark (A) or (R)

IF the lower crank gear index mark on the lower cam gear is correctly indexed (which its NOT yet rotated enough to do in the picture above)

the top cam gear is exactly twice the size of the lower crank gear,it rotates at exactly 1/2 speed or once for each TWO crank gear rotations ,if the cam gear and lower crank gear are correctly indexed the timing as they rotate will place the cam gear at EITHER 12 o'clock, or at 6 o'clock, exactly as the crank gear hits 12 o'clock on each rotation

notice in the lower picture the crank key way is at about the 2 o'clock position

Last edited by a moderator: