SenderoMan

Member

My faithful 350 finally gave up the ghost this fall after many good years of service. The logical choice seems to be a 383, so I've started my research and am needing help selecting a camshaft.

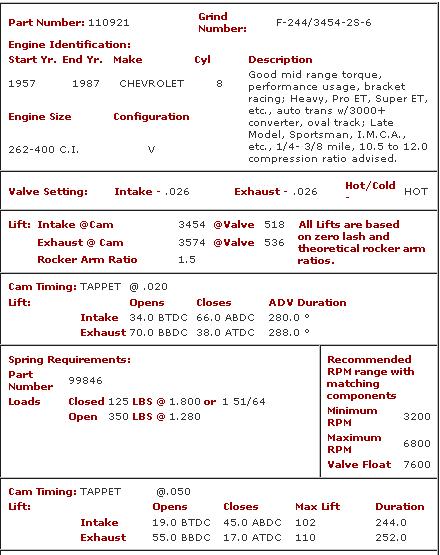

My friend and engine builder Jerry Coon in St. Joe, Missouri would like me to go with a full roller assembly, but finances dictate that will not happen. So that leaves either a hydraulic or solid flat tappet to fit the budget.

This is going into a 1976 Camaro, which happens to be my first car that was many years ago!

It has fiberglass hood and bumpers and weighs about 3250 lbs with me and a quarter tank of gas. Turbo 350, 10" converter (stall 2800) and 4.10 gears with posi unit. Has Nitto Drag Radials 275/60/15 on rear, Competition Engineering traction bars and sub frame connectors.

The only parts from the 350 that are available for the 383:

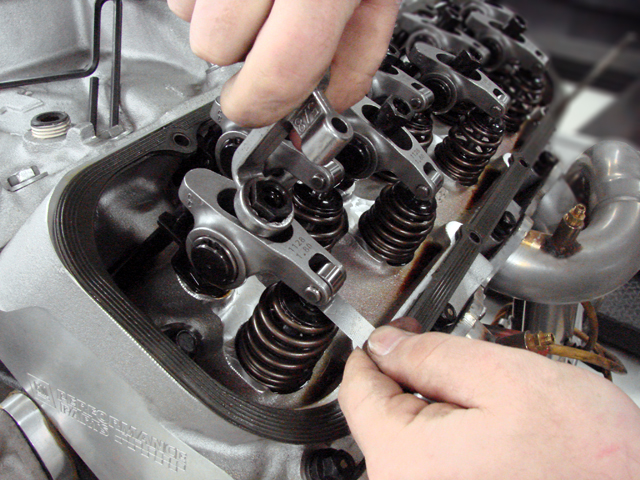

are a set of Dart Iron Eagle heads (original ones, not the Platnium) 200 cc intake, 64 cc chambers, 2.02 intake and 1.60 valves. Crane Energizer roller rockers

Victor Jr. intake with Holley 3310-2 750 with adjustable vacuum secondary spring kit. Also have a 1" inch plastic four hole spacer.

Moroso Outlaw II 6 qt. pan with screen.

This is mainly a street, fair weather car that gets driven 500 miles or less a year. Will probably make it to the drag strip once or twice a year. The previous 350 had TRW forged flattops (four valve relief) pistons, with a Lunati 284/507 hydraulic flat tappet. 1.6 rockers were on the exhaust side, it ran 13.3's at 101-102 mph on some old, hard BF Goodrich TA radials.

Never got a chance to run it with the Nitto's.

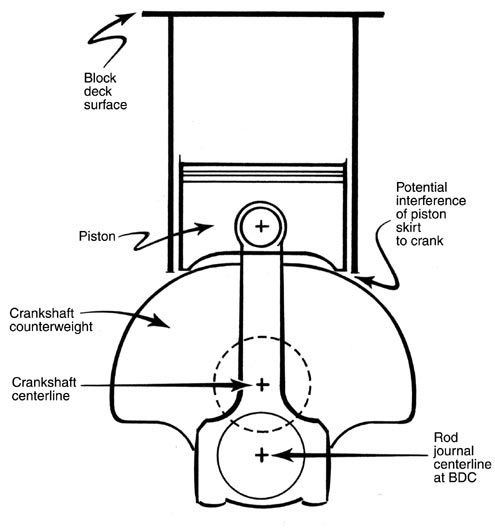

Was looking at Skip White's rotating assembly with the 7.5 cc dish Wiseco pistons and 6" rods, which says will make 10.77 compression ratio. Will this be too high for my heads? Does anyone have personal use with this company and these rotating assemblies?

Thanks for your help!

My friend and engine builder Jerry Coon in St. Joe, Missouri would like me to go with a full roller assembly, but finances dictate that will not happen. So that leaves either a hydraulic or solid flat tappet to fit the budget.

This is going into a 1976 Camaro, which happens to be my first car that was many years ago!

It has fiberglass hood and bumpers and weighs about 3250 lbs with me and a quarter tank of gas. Turbo 350, 10" converter (stall 2800) and 4.10 gears with posi unit. Has Nitto Drag Radials 275/60/15 on rear, Competition Engineering traction bars and sub frame connectors.

The only parts from the 350 that are available for the 383:

are a set of Dart Iron Eagle heads (original ones, not the Platnium) 200 cc intake, 64 cc chambers, 2.02 intake and 1.60 valves. Crane Energizer roller rockers

Victor Jr. intake with Holley 3310-2 750 with adjustable vacuum secondary spring kit. Also have a 1" inch plastic four hole spacer.

Moroso Outlaw II 6 qt. pan with screen.

This is mainly a street, fair weather car that gets driven 500 miles or less a year. Will probably make it to the drag strip once or twice a year. The previous 350 had TRW forged flattops (four valve relief) pistons, with a Lunati 284/507 hydraulic flat tappet. 1.6 rockers were on the exhaust side, it ran 13.3's at 101-102 mph on some old, hard BF Goodrich TA radials.

Never got a chance to run it with the Nitto's.

Was looking at Skip White's rotating assembly with the 7.5 cc dish Wiseco pistons and 6" rods, which says will make 10.77 compression ratio. Will this be too high for my heads? Does anyone have personal use with this company and these rotating assemblies?

Thanks for your help!

Last edited: