octanejunkie said:I'm sure we've all been at the point where we want more from our current builds and and start looking in all directions - inevitably we all look at the cam since it is the heart of the engine and everything else is based around it.

I'm currently looking for a bit more performance from the truck in my signature, I'm considering cam and rear gears; one at a time though...

I was a bit conservative when I built the motor that's in my truck and opted for a mild cam, a supposed clone of the famous "lazy ZZ4" cam according to the salesman at long-gone PAW. The cam and lifters came in at a whopping $109 so I figured I didn't have much to lose and I could always change it later.

Though I've long since lost the cam card I did manage to write down the specs, somewhere... can't find them now of course. The highlights are:

260/260 advertised duration, 214/224 duration, .443/.465 lift @50, 112 LSA

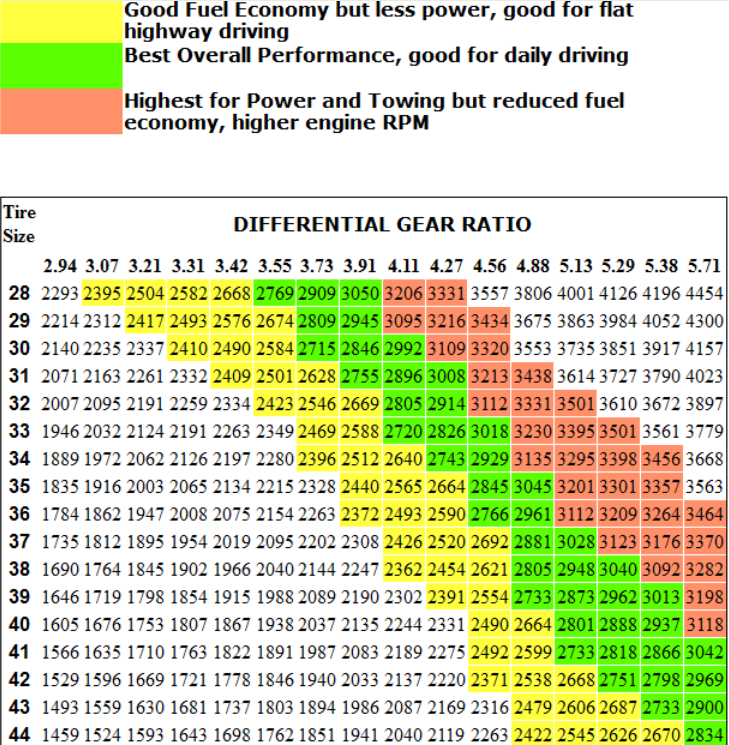

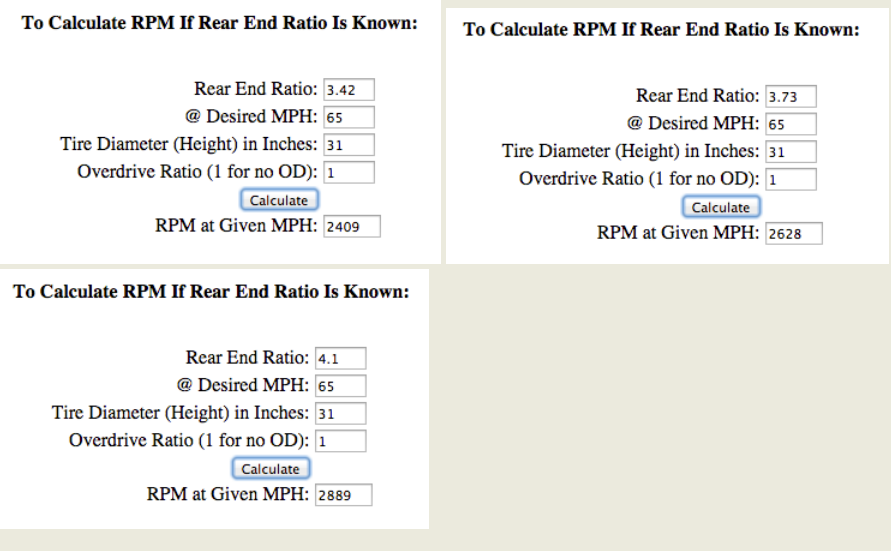

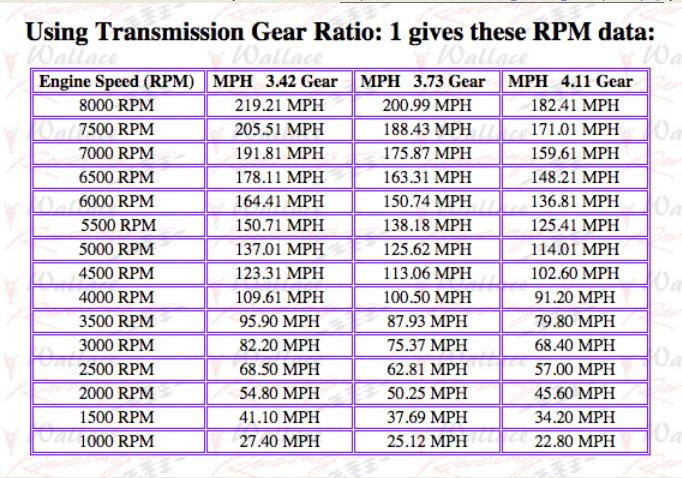

IIRC, the cam was "rated" at Idle-5500 RPM performance range. In my experience, my truck pulls well off-idle and up to about 2500-3000 RPM, then falls off. I am not sure how much of this is the cam or my gearing but I suspect most of this is the cam, which is why I feel a rear gear ratio change to lower gears won't net all of what I am looking for.

Off the line, in the 0-25% throttle range is where this truck seems to have the most power. Even with 3.42 gears and 31.5" tires I can spin the rear wheels through first and into second gear - so there is plenty of power, plus the rear end is light being a truck. Idle quality is pretty tame, no lope to it, but not quite a factory-steady idle too. With my current tune after installing EFI I have 18" Hg of vacuum at idle with a steady needle.

Being conservative, I originally backed down from 3.73 rear gears when I had a 3-speed trans in the truck, now with a 700R4 I regret that compromise but that's easily fixed (see my other thread on rear gear swap, what to get) - now I wonder if 3.73 is enough gear to make the swap with the coin with 31.5" tires.

Back to the cam, I am again leaning towards the conservative side and looking at Comp Cams XE268H (12-242-2) and hence the reason for this topic; how do we decide what cam to put in?

I've spoken to other folks with similar trucks, and folks with this exact cam in different vehicles.

I've called Comp Cams and been told "this will work for you," I've also used the CamQuest online, but it did not recommend this cam at all.

At this point it seems like I'm looking at a $400 gamble unless I can figure out how to make an intelligent, calculated decision so I decided to post this thread and perhaps this information (a real world cam selection criteria) can benefit everyone.

Any thoughts or wisdom? Grumpy?

taved said:Folks,

I thought that this would be of interest to some.

I have a mild 383 sbc with GMPP Bowtie Vortech 185cc heads (25534421) and a GMPP Hotcam in a 1972 Chevelle (TH350).

Static compression is calculated at 9.6:1. Cranking compression is 185 psi.

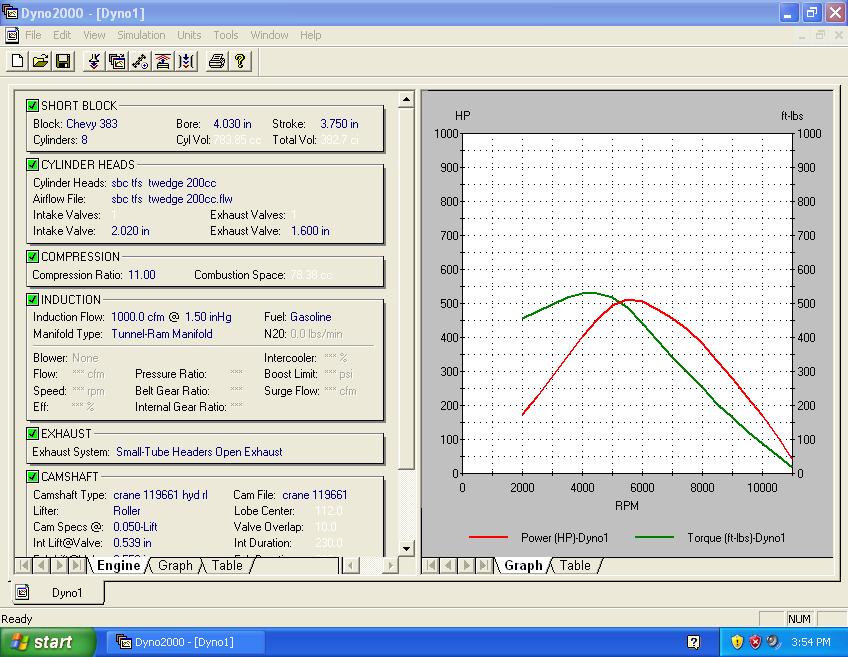

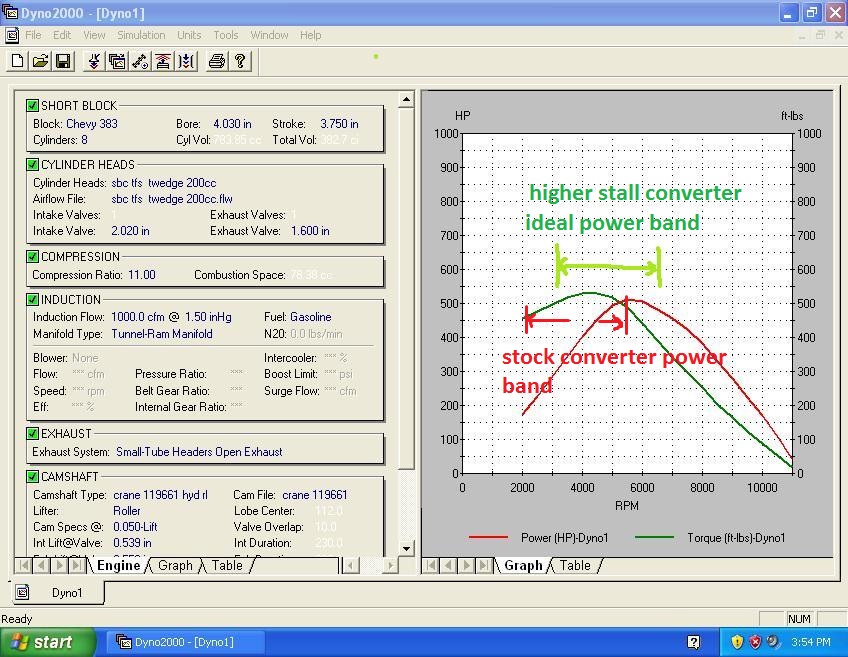

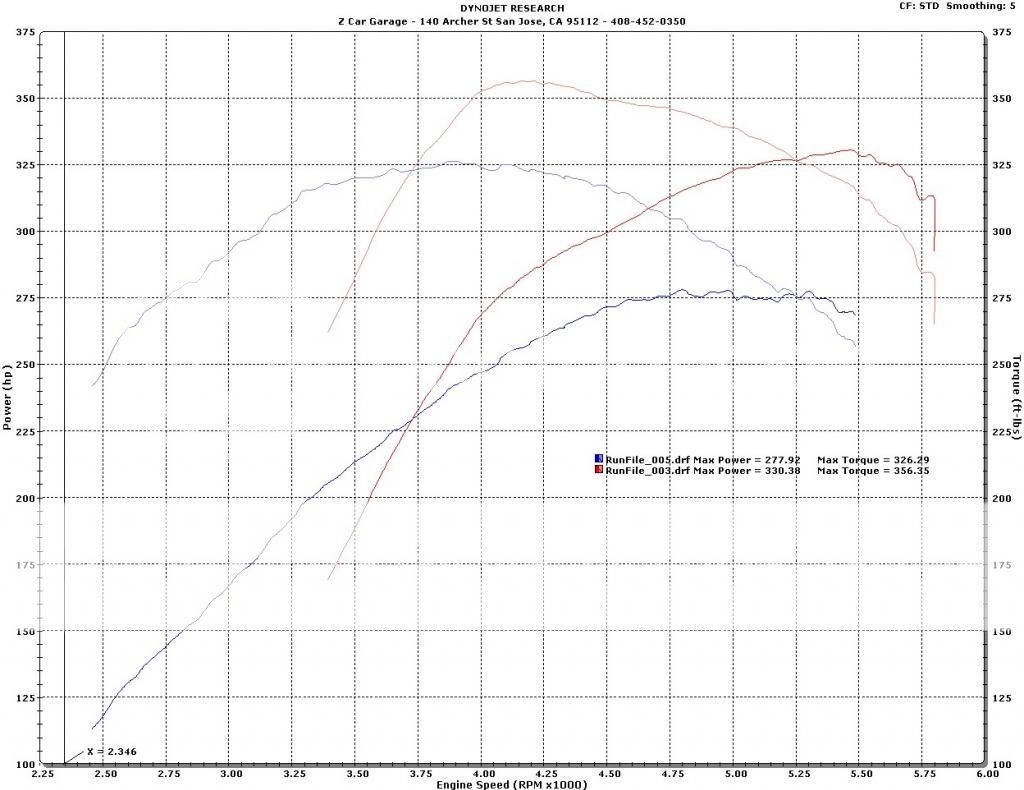

The dyno plots in blue- old exhaust system and stock convertor

stock iron exhaust manifolds, 2.5" true-dual pipes, Summit Turbo mufflers, tips to bumper

The dyno plots in red- new exhaust system and 2400 stall converter

Hooker sbc headers, 2.5" Pypes X-over pipe, 2.5: pipes, Pypes Race Pro MVR30 18" case mufflers, tips to bumper

I wish that I could take the converter off the comparison but it's too late.

Dave

video:

IF YOU LOOK CLOSELY THE VORTEC HEADS AND HOT CAM ON THAT 383 < OBVIOUSLY PEAKED IN THE 4000rpm-4500rpm RANGE, AS THE TORQUE CURVE DROPS NOTICABLY AFTER THAT RPM, WHICH WOULD BE EXPECTED WITH THOSE HEADS RESTRICTING A 383 , MUCH OVER 4500RPM

as always it really helps as great deal to do some research into what has proven to be successful, in the past, HERES WHAT I WOULD DO!.

Id suggest making 100% sure the current engines running correctly, verify the exhaust back pressure at wide open throttle remains under 3 psi and your ignition advance and fuel pressure remain where you intend them to be, Id verify the TDC and cam timing, do a compression test and get a fuel/air ratio meter and an IR temp gun, and vacuum/pressure gauge to verify the exhaust gases are showing the correct fuel ratio, and your not dealing with a restrictive or partly clogged exhaust

I'd be trying to duplicate the proven successful design vs randomly matching components and hoping the results will be successful., stock vortec heads heads will start to become flow restrictive on a 350 engine at about 4500rpm, and become very restrictive by 5700rpm, so your unlikely to get good power at over 5500rpm so cam it accordingly, do the tune so your running at about 14:1 fuel/air ratio at idle to about 2800rpm then slowly transition to a richer 12.7:1 ratio by 4500rpm, yes this might require larger injectors

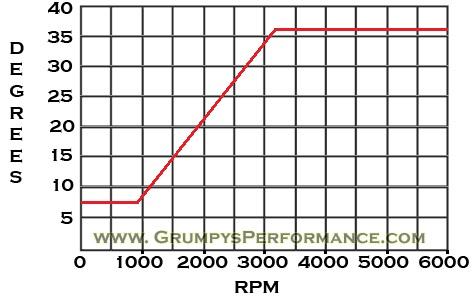

a cam like this, LUNATI HYDRAULIC FLAT TAPPET LINKED BELOW, with a 2800rpm stall converter , and 1.6:1 ratio roller rockers will wake up that combo (obviously you need to verify your clearances and use the correct valve springs (stock heads have about a .470 lift clearance youll need springs and clearance for a .550 lift) and verify your exhaust back pressure is LESS than 2 psi at WOT at 5500rpm, set the ignition advance curve to start near 14 degrees advance at idle then steadily advance to about 36 total at about 3200rpm

LUNATI tech line

Tech Line: 662-892-1500 TALK TO THESE GUYS< ASK QUESTIONS GET THEIR INPUT,DISCUSS YOUR APPLICATION, BEFORE YOU BUY ANYTHING

http://www.lunatipower.com/Product.aspx?id=2929

YES ID USE rhoads lifters (yes they tick like solids at idle)

http://www.rhoadslifters.com/Pages/OriginalFT.html

viewtopic.php?f=70&t=4683

viewtopic.php?f=71&t=555

viewtopic.php?f=52&t=82

viewtopic.php?f=52&t=10162

viewtopic.php?f=52&t=10705&p=46769&hilit=+using+charts#p46769

viewtopic.php?f=52&t=1070

viewtopic.php?f=52&t=333

viewtopic.php?f=52&t=8460

Last edited by a moderator: