Loves302Chevy

"One test is worth a thousand expert opinions."

This post was prompted by Jimmy Duncan's post, Frank the Tank: http://garage.grumpysperformance.com/index.php?threads/building-a-s̶t̶r̶o̶n̶g̶-̶3̶5̶0̶-383-for-frank-the-tank….11173/page-26#post-61098

On page 17, as he is taking measurements of his 383 SBC short block to enter into the DCR calculator, he learns that with his 5cc EDV pistons and 64cc heads, his DCR will be too high. Fortunately, he hasn't bought his heads or camshaft yet.

Specifically, I'm looking to discuss in more detail:

On page 17, as he is taking measurements of his 383 SBC short block to enter into the DCR calculator, he learns that with his 5cc EDV pistons and 64cc heads, his DCR will be too high. Fortunately, he hasn't bought his heads or camshaft yet.

Specifically, I'm looking to discuss in more detail:

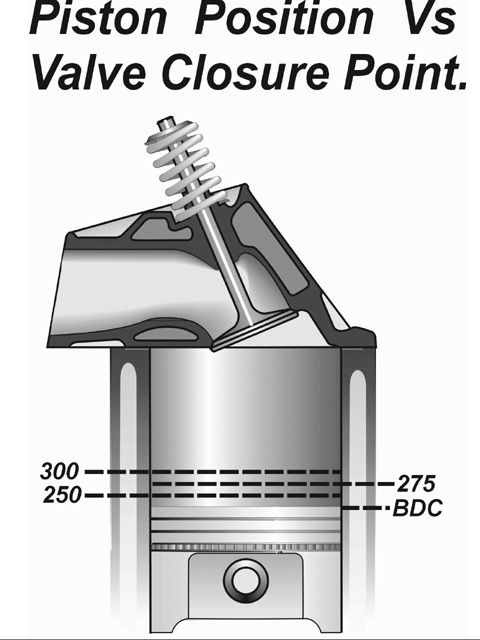

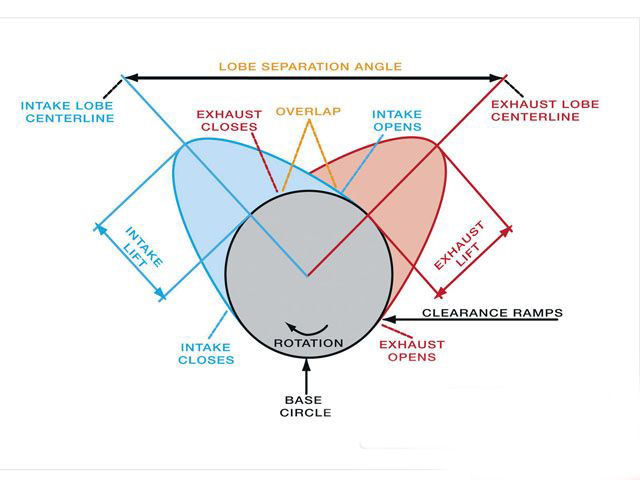

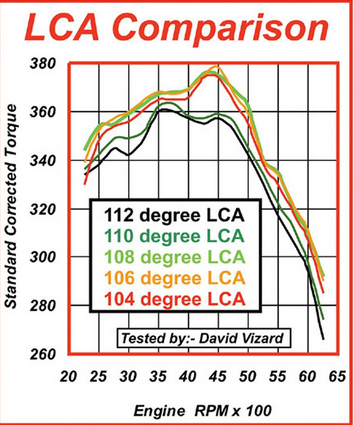

- advancing or retarding the camshaft to adjust your DCR

- why do nearly all manufacturers grind their camshafts "dual-pattern" with more lift & duration on the exhaust side?

- why most cams are ground 4 degrees advanced and under what conditions should we install 4 degrees retarded to "undo" this

- when using the DCR, how do you use it with SOLID lifter camshafts?

- CompCams THUMPER line of camshafts for more of that "rumpity-rump" sound