Grumpy, I have a 1996 corvette with an LT1 engine and I wanted to use roller rockers with a rocker stud, girdle, and swap to CHROME VALVE COVERS, at a semi reasonable cost, valve covers I find are all well over $150, that seems to be a problem, in both availability and cost, because the stock valve covers don,t have the required clearance, and are not CHROME, so what can I do here?

thinking about putting roller rockers on my 327.

IM seriously considering/ thinking about putting roller rockers on my 327.do i have room to put 1.6 ratio or just stay with 1.5s http://garage.grumpysperformance.com/index.php?threads/louis-tool-swapping-to-1-6-1-ratio-rockers.14761/...

garage.grumpysperformance.com

Links, links and more links!

I'm new here but getting lost in the links and sub links and their links is time well spent. I've recently replaced the blown 305 in my 85 K-10 with a mystery 383, I say that because I don't know it's history. It's an odd build and I would have liked to tear into it more before dropping it in my...

garage.grumpysperformance.com

first gen SBC valve cover spacers

http://brodix.com/heads-2/small-block-chevrolet-compatible-heads/ik-series

http://www.jegs.com/i/Brodix/158/1021001/10002/-1

brodix ph# 1-479-394-1075 (ALWAYS VERIFY PART NUMBERS SEVERAL,

TIMES FROM AT LEAST TWO SOURCES, BEFORE ORDERING PARTS)

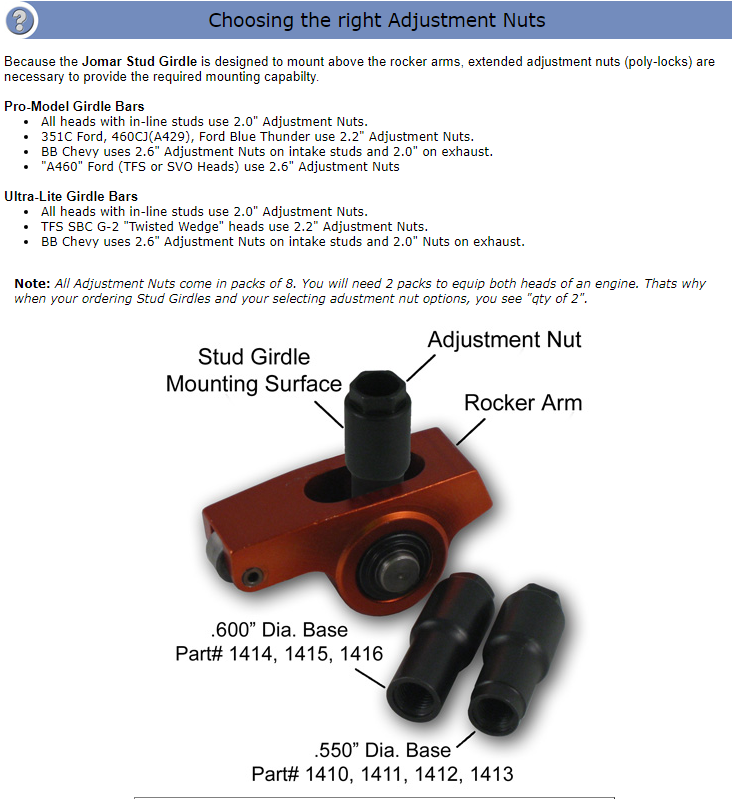

the brodix rock stud girdle is part # BR-6435 and LIST price is about $230 you can get it for less if you shop carefully

BE AWARE that the I.K. 200 heads were shipped with BOTH 3/8" and 7/16" rocker studs ,

and the poly locks for the 7/16" rocker studs ONLY fit that rocker stud girdle

obviously you need to verify what your heads have before you order the matching rocker stud girdle

KEEP IN MIND, MANY PEOPLE THAT HAVE BROKEN ROCKER STUDS HAVE FAILED TO VERIFY THE PISTON TO VALVE, CLEARANCES, ROCKER STUD TO ROCKER SLOT CLEARANCES,AND SPRING BIND CLEARANCES, etc.

it takes hundreds of pounds of force to bust rocker studs and or bend push rods, if you have those issues STOP AND LOCATE the geometry or CLEARANCE ISSUES CAUSING THE PROBLEM

theres several manufacturers and models available , heres a basic 1.5:1 ratio SBC version.

http://www.summitracing.com/parts/lun-85025

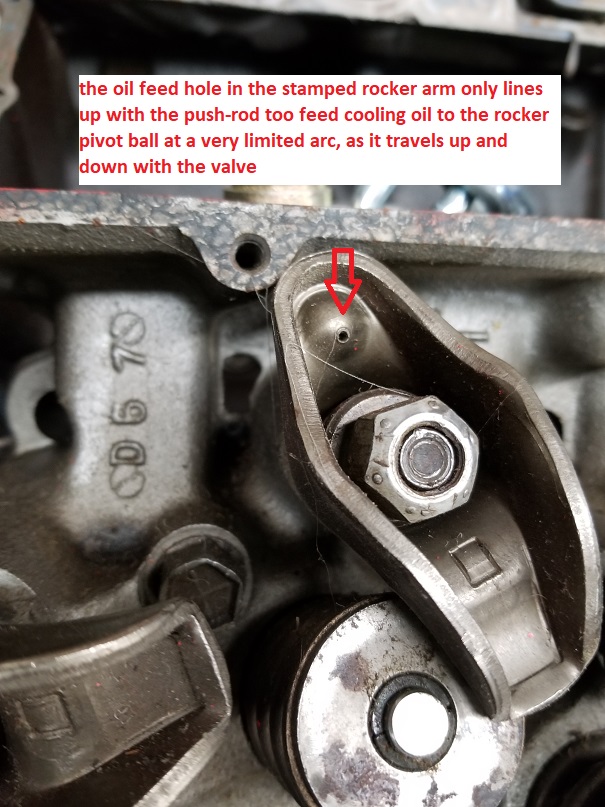

the grooved rocker pivot ball design was an effort by G.M. engineering to economically solve the issue of marginal oil flow causing rocker ball galling, and resulting noisy, or broken valve trains

http://www.summitracing.com/parts/mrg-9415/overview/make/chevrolet

http://www.summitracing.com/parts/mrg-9847/overview/make/chevrolet

http://www.summitracing.com/parts/trd-9460/overview/make/chevrolet

once you start looking for TALL CHROME CENTER BOLT VALVE COVERS youll generally find the price jumps to $180-$300 and

NARROW SELF ALIGNING ROLLER ROCKERS

http://www.jegs.com/p/Scorpion-Raci...dy-Self-Aligning-Rocker-Arms/2416814/10002/-1

BEEHIVE SPRINGS AND THE SMALLER MATCHING RETAINERS ADD ADDITIONAL VALVE TRAIN CLEARANCE

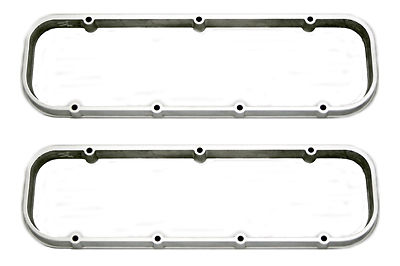

they do make a center bolt to perimeter bolt valve cover adapter.s

that allows you to run the earlier perimeter bolt valve tall valve covers on the center bolt heads

PROFORM MAKES A NICE FUNCTIONAL SET with a removable top

(NOT CHROME BUT RATHER INGENIOUS NONE THE LESS)

Got around to installing the Harland Sharp (G1100) stud girdles yesterday.

Initially I put the stud girdles on so that they were above the shoulder on the adjusting nuts. Then I put

to the top of the valve cover on with the oil baffle touching the girdle, then pushed it down until the top

was seated. This left the girdle just slightly above the shoulder. From there I tapped it with a plastic

hammer until it was just below the shoulder, giving me about 1/8 inch between the girdle and oil baffle.

Before setting the valve lash I tightened all four girdle bolts until it was getting difficult to turn the

adjusting nuts. You can see this in the video of me setting the lash on cylinder #4. After setting the valve

lash I torqued the the four bolts to 30 ft/lbs.

My aluminum plate to block the oil splash off the rocker still fit just under the new stud girdles. I was

surprised there was not a problem. It seemed with all the extra aluminum material it made it harder to

hear the clicking of the lifters when the lash was opened up until there was a clearance between the rocker

and valve stem.

or why some less expensive rocker studs break, keep in mind the rocker and push rods,

are under hundreds of ft lbs of valve spring pressure and the rocker studs deflect significantly under load,

as the lifter rides up on the cam lobe and the valve spring deflects under load,

its really a miracle more rockers and rocker studs don,t snap off.

and the video, shows clearly why rocker stud girdles add considerable valve train stability

big block chevy valve cover spacers

its very common to find you'll gain a couple horsepower with the addition of a rocker stud girdle employed,

as youll have both more precise valve train control and less deflection, Ive seen guys instantly gain an extra 150 rpm-200 rpm,

before they started feeling valve float or loss of valve train control and its certainly less stress on the cylinder head casting and rocker studs.

the one thing ID suggest is that before you buy any rocker stud girdle you ask questions, many cylinder head designs use non-standard rocker stud spacing.

CENTER BOLT SBC VALVE COVER SPACERS, LIKE

LT1/4 and vortec heads use.

THE ADAPTER ADDS ENOUGH EXTRA HEIGHT THAT MANY NARROW ROLLER ROCKERS WITH A STUD GIRDLE MAY FIT

http://www.speedwaymotors.com/Valve-Cover-Adapter-for-Center-Bolt-Heads,1890.html

http://garage.grumpysperformance.co...s-and-valve-cover-install-info.946/#post-1615

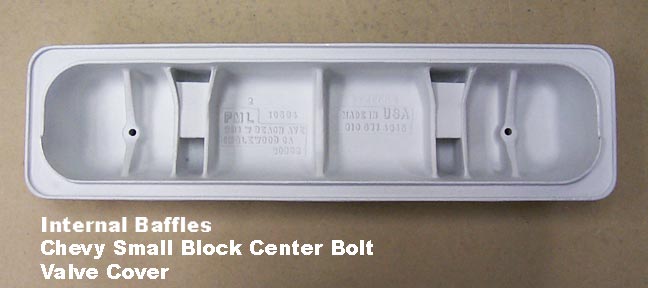

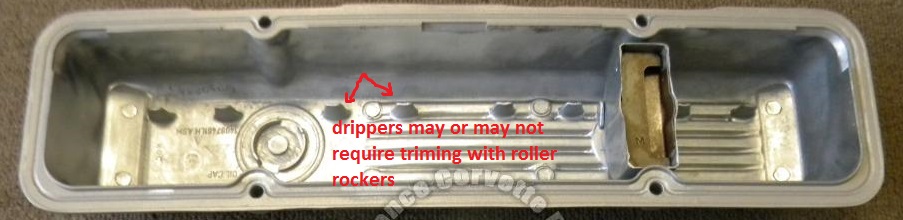

yes the steel roller rockers and the jam nuts will work, but drawmains correct the internal drippers on some cast valve covers will need to be removed , and are not necessary with roller rockers, obviously the type of valve cover dripper extension.s cast into the valve cover, and the roller rockers and jam nuts you use, or you select can vary so you.ll need to check clearances to see if any work needs to be done to add required clearance IF ITS REQUIRED

steel roller rockers like COMP CAMS AND CROWER CAMS SELL generally are stronger and smaller in size making those easier to fir and clearance and steel has at least 2-3 plus times the fatigue strength of most aluminum

http://www.harborfreight.com/10-inch-heavy-duty-end-nipper-38496.html

http://www.grumpysperformance.com/dremel.com

a set of 10" nippers and a cutting disc on a dremel tool and a careful cleaning after the modification is all thats required

http://garage.grumpysperformance.co...fit-under-stock-valve-covers.6641/#post-21035

Last edited: