IF YOU DON,T YET HAVE A FACTORY SHOP MANUAL FOR YOUR CAR YOUR WORKING AT A DISADVANTAGE

it is always helps to post your location,when posting questions, at least the city & state your located in because theres a good chance an experienced hobbyist or mechanic on this site may be reading this, located local to you, who is willing to help either for free or at low cost! or at least post advices and places to get parts locally

Ive been building engines for over 47 years now, and yeah,eventually even my hard head learned, a few things, but I,m sure willing too learn and ask questions, and use any new info posted

can a few of you gentlemen explain to me why??

when I suggest isolating and testing each separate potential component of both the fuel and ignition, systems and checking the engines valve train and checking compression, fuses, and sensors and pulling trouble codes and using the factory shop manual and a few tools like a mufti-meter and compression gauge, IR TEMP THERMOMETER,VACUUM GAUGE, and listed tests, even when I supply rather extensive links showing extensive detailed info, the majority of the guys reading thru the threads obviously ignore the info that could be used too locate the source, in most cases youll need too, isolate it test it and fix it rather than making random wild guesses without any facts or testing?

look if you don,t isolate the problem to its source through accurate testing there,s almost no other logical way to locate and fix the problem.

GUYS I NEVER SAID I,M A GREAT MECHANIC, BUT I HAVE LEARNED THAT IF YOU TAKE THE TIME TO BREAK THINGS DOWN INTO THE SIMPLEST PART AND DO A BIT OF RESEARCH, FINDING ANSWERS IS FAR LESS INTIMIDATING OR DIFFICULT,

youll need to isolate any problem to its source, be it engine, drive train, suspension,fuel system, electric, cooling, exhaust, etc. then further logically isolate it to the defective component, or part needing adjustment or replacement

like the old saying how do you eat an elephant......one little bite at a time!

all the answers are readily available, theres known testing procedures and listed test results you can expect, and procedures listed in the shop manual for isolating and testing components, you don,t need to be a genius, you just need to be logical and persistent and not afraid to learn new things while getting your hands dirty at times

THE FASTEST AND EASY ROUTE IS TO ISOLATE AND TEST< NOT RANDOM GUESS WORK

buy a CHEVY SHOP MANUAL FOR YOUR YEAR CORVETTE!

set and verify your ignition timing, pull trouble codes,set your tps and iac,, then check for vacuum leaks on the lines and intake,then get out your multi meter and verify all the sensors, chances are good its a defective heat sensor or defective o2 sensor, a logical step by step approach will lead you to the problem, youll be amazed at what youll learn reading links. use of a shop manual and multi meter can be very helpful

http://www.harborfreight.com/5-in-1-dig ... 98674.html

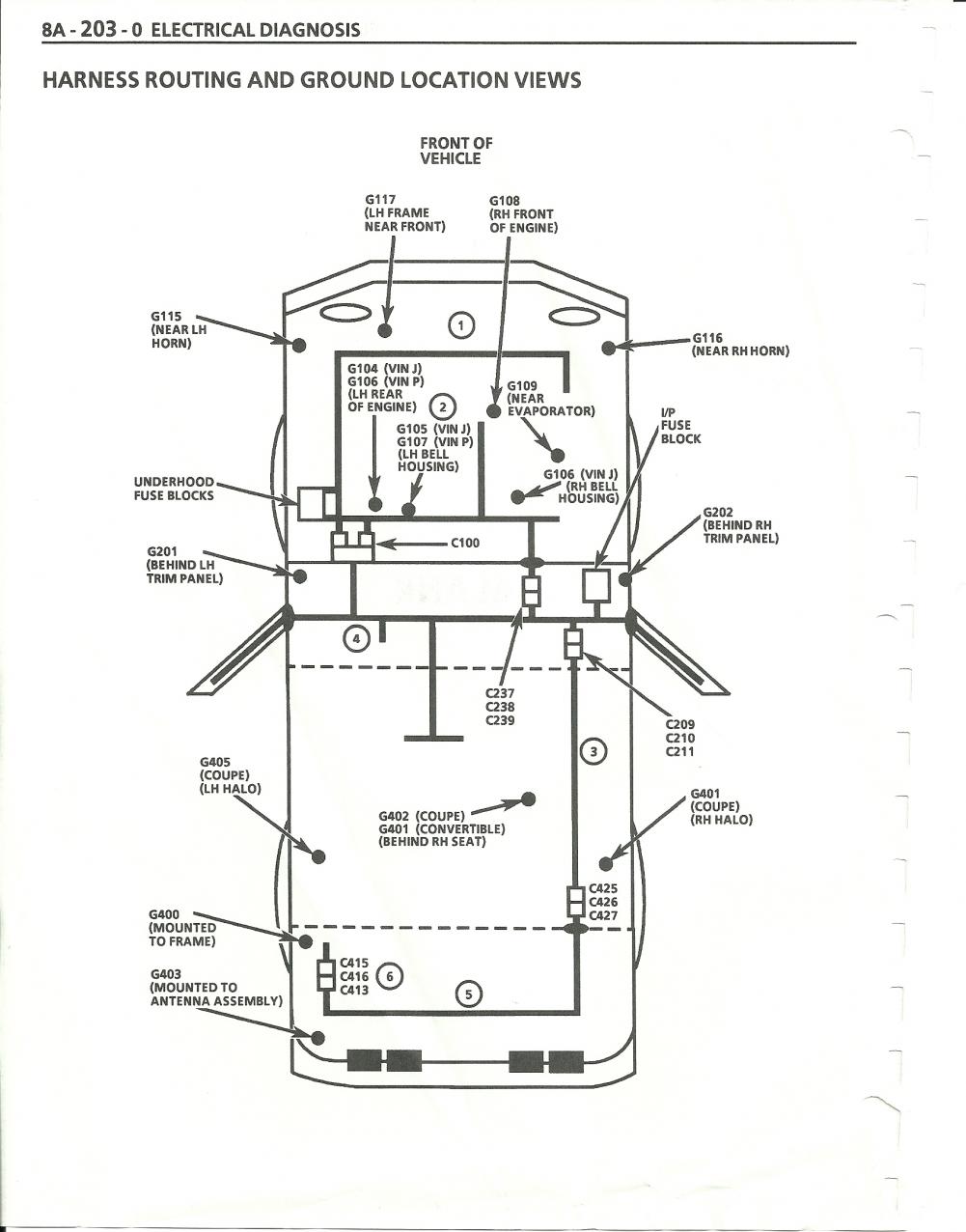

learn to use the factory shop manual, and a multi meter and LISTEN to the engine closely, tapping and high pitch whines can indicate defective injectors or fuel pressure regulators, fuel pumps,mis- adjusted valve train components, worn distributor parts, check all the fuses and electrical grounds and corrosion on connections thats something thats frequently over looked etc.

http://www.chevythunder.com/Flow chart index.htm

http://www.professionalequipment.com/ex ... ermometer/

having a good cross check tool like a quality IR temp gun, and a decent multi meter, sure helps find the truth as far as a defective gauge or sensor

READ THESE LINKs

viewtopic.php?f=50&t=10012&p=38779#p38779

viewtopic.php?f=36&t=63

rule one

if your installing a new component ,read the manufacturers instructions carefully and call the tech guys if ANYTHINGS not 110% clear

RULE two

IF something won,t fit or function....STOP, call the the tech guys ,after you re-read the manufacturers instructions carefully and measure carefully so you sound at least 1/2 way like you know what talking about, then call the tech guys if ANYTHINGS not 110% clear

RULE three

STOP AND DO THE REQUIRED RESEARCH if youve got questions

I never mind sounding dumb as long as I get the correct answers, so I won,t LOOK dumb by doing something wrong

rule four

isolate the problem to a lack of or Mal -function in,engine compression,ignition,lubrication,cooling, fuel supply,drive-train,or suspension, or a mechanical or electrical fault as soon as you can, this can only be done by testing and verification, don,t guess or assume anythings correct until you verify it yourself

yes reading the sub linked info is mandatory if you want answers

http://www.helminc.com/helm/welcome_sel ... M2S049ETF8

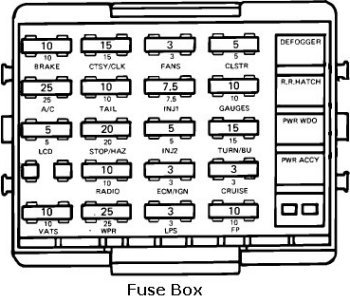

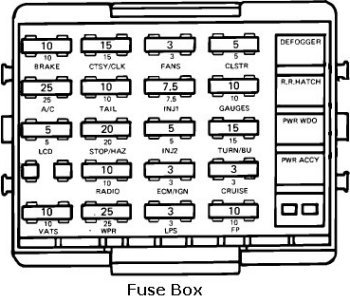

CHECK ALL YOUR FUSES WITH A MULTI METER

http://www.clarks-garage.com/shop-manua ... tm#oil-low

http://www.davidfarmerstuff.com/

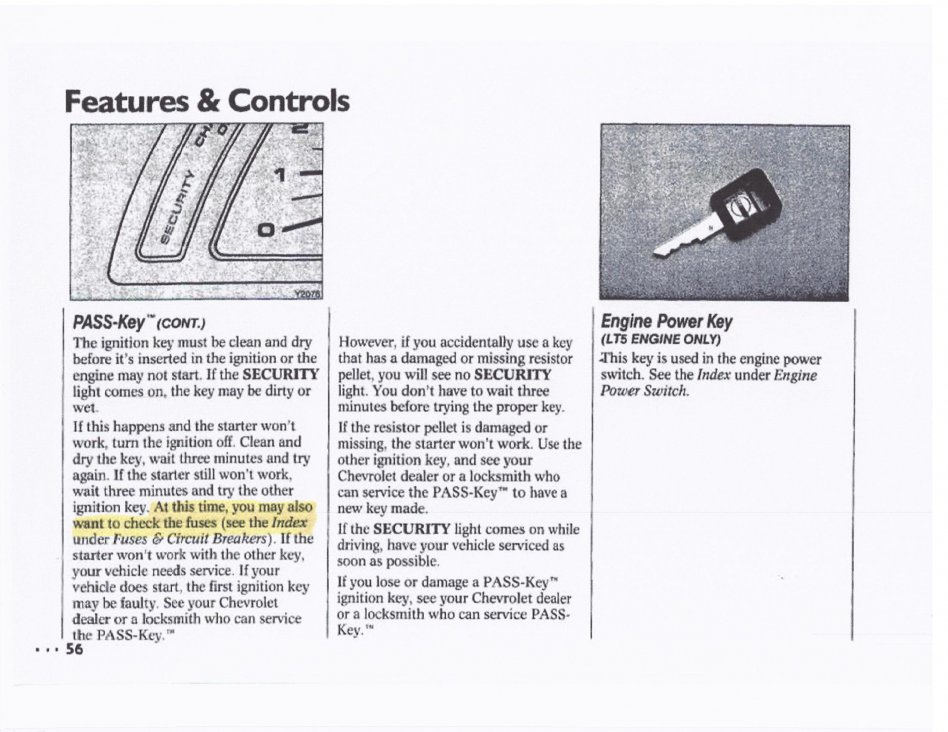

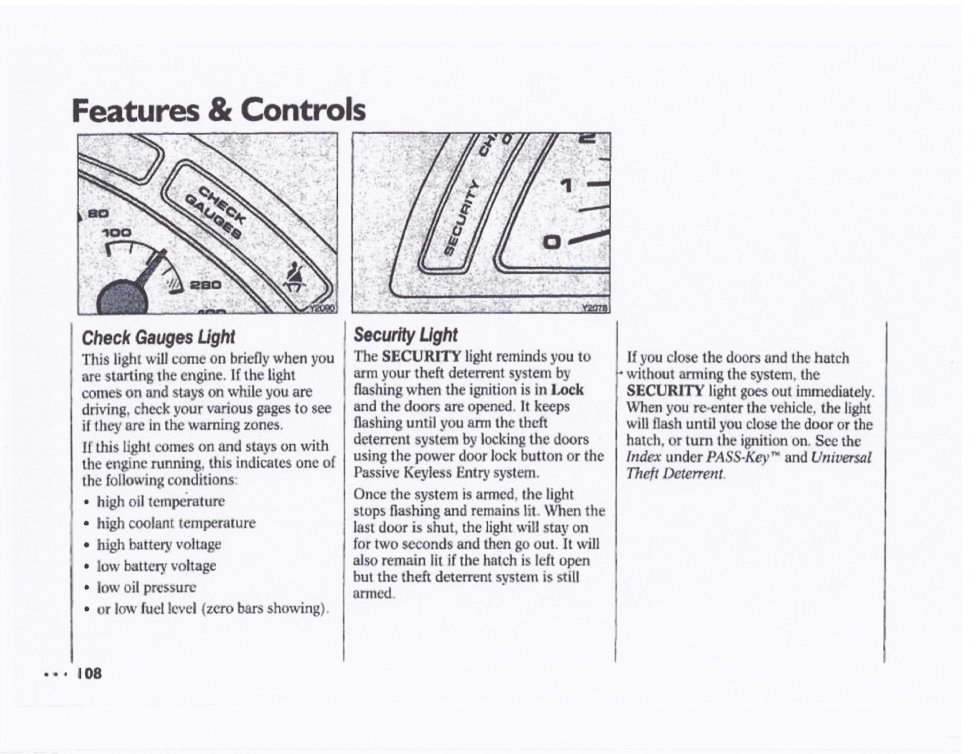

when ever you get into unexplained symptoms the answer remains the same....in every case,.... you drop back to the basics and do a few tests, get out a multi meter and verify every fuse is good, and you have 13 volts at the battery and youve got at least a 1/2 tank of fresh fuel, before you start chasing your tail, thinking about more complicated problems

find the cause, you isolate, each function or system or malfunction to its related components then test, each individually, use of the shop manual is almost mandatory

erase old trouble codes and pull new codes after each change, made.

read the codes, and follow the FACTORY SHOP MANUAL INFO

there could be several reasons and a few tests will limit the potential problem areas,valve float, restricted fuel pressure,or volume, badly adjusted carb floats, wrong jets, wrong power valves, dirty or restricted air filter, cam timing, ignition timing, carb being badly adjusted,valves being badly adjusted, ignition advance curve not correct, timing tab or damper, not correctly indicating TDC, etc. ignition spark should be bright blue and impressive, if its, weak,narrow, yellow or red theres a problem so research the cause, verify the coil and voltage

you start by dropping back to the basics , adjusting or verifying or correcting each potential problem area and eliminating it as the cause, then and only then moving on to the next area, guessing will drive you nuts and cause you to throw large amounts of un-necessary parts at the problem with little resulting improvements. a logical step bye step approach is best, youll need to verify cylinder compression, ignition, strength and timing and fuel and air delivery, ID also suggest a compression test and a general checking over,each potential engine and drive line sub-system carefully, with a timing light,vacuum gauge, fuel pressure gauge, VOM meter , ETC. and adjusting valves, checking for vacuum leaks, check fuel pressure and post clear pictures of spark plugs as they give a ton of info if you know how to read them, etc.it helps a great deal to know what your working with ,ID suggest starting, by verifying TDC and having the correct timing tape on your damper then,start with 8 degrees btdc and verifying the full advance of 36 degrees total is all in at 3200rpm as a base line, once youve got that, as a standard you can tune and run the car and eventually try tweaks to the basic ignition curve if needed, once you have an ignition base line, move on to the carbs tuning, you also need to keep in mind that what goes in as a fuel /air mix needs to go out as a much expended volume of hot gases and a restrictive exhaust will effectively block most attempts to get more power from an engine, so measure exhaust back pressure. you might be amazed at what a couple hours research into the subject will do to help you build a much more durable engine, and actually reading thru links and sub-links and asking questions helps a great deal

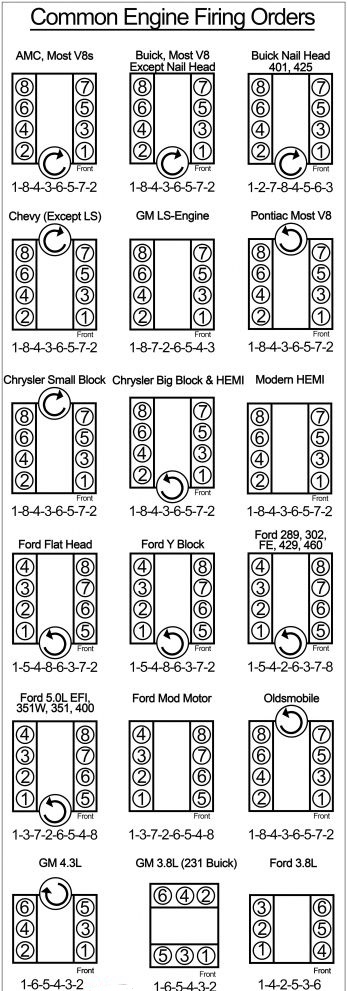

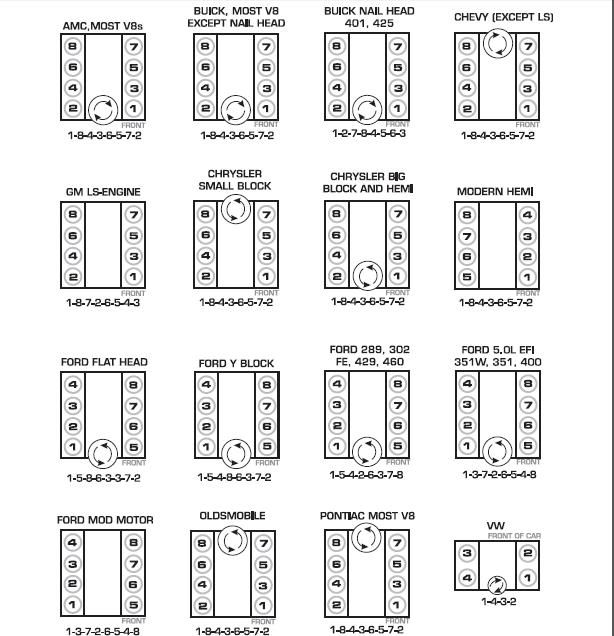

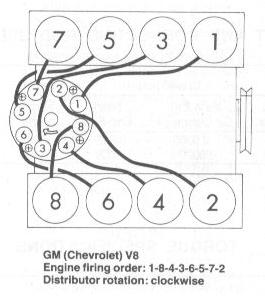

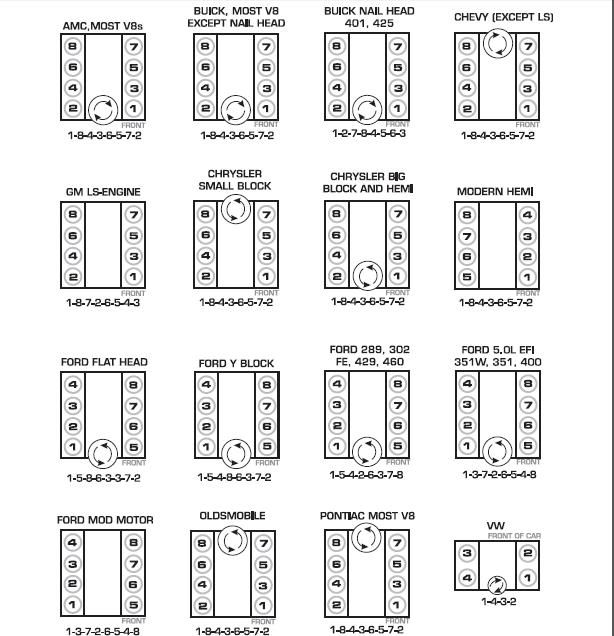

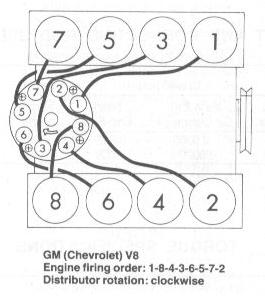

you might be amazed at the number of times "CARBURETOR PROBLEMS" are cured with getting the IGNITION, TIMING AND ADVANCE CURVE WORKING CORRECTLY, and check out the simply things your 100% sure you did correctly, because I can,t begin to tell you how many times I see guys who have the firing order on the ignition wrong, or guys that install a 4/7 swap cam and still use the standard ignition firing order or guys that never verify TDC and ignition advance curves.

get an IR temp gun and check for wild variations in exhaust temps, get a compression test done, do a logical check to verify each cylinder fires etc.

Id also be pulling and changing the oil filter and inspecting the old one for metallic debris indicating a worn cam lobe, assume EVERY SUB SYSTEM could be miss adjusted or defective EVEN if you just replaced parts recently

basically an in depth tune-up and system verification is whats needed

viewtopic.php?f=54&t=4611

viewtopic.php?f=70&t=202

viewtopic.php?f=55&t=109

can,t get it started? these bits of info should help

always drop back to basics

check your battery cable connections

check your fuses and get out your shop manual.

IF you have the option pull trouble codes.

have you verified TDC on the damper and timing tab?

have you done a compression test?

are all the spark plugs firing correctly?

did you degree in the cam or just DOT-to-dot install it?

whats your fuel pressure?

have you verified the carbs float levels?

does fuel run out the site holes at idle?

are the needle& seat valves working correctly?

whats your ignition timing?

do you have voltage at the coil?

whats your plenum vacuum?

have you verified the engine got no vacuum leaks?

whats the oil pressure?(did you check the dip stick?)

have you adjusted the valves at idle?

does the distributor timing advance with rpm increases?

have you tried a different carb?

what are the plugs gaped at?

does this happen without an air filter?

have you verified you've have functioning power valves?

what jets are you using?

is there visible fuel flow from the boosters?

whats your battery voltage?

whats your exhaust back pressure?

are you totally sure the fuel free of water and fresh?

have you pulled trouble codes?

drop back to basics, don,t assume you did anything correctly until you verify, its been done correctly.

first remove plug #1 and your valve covers and the distributor cap

stick a large ratchet/socket on the crank bolt and stick your thumb over the #1 plug hole rotate the engine until you feel compression building the rotor on the distributor should be approaching the #1 plug, now watch the timing tab and damper mark, it should line up at the TDC (TOP DEAD CENTER) marks , if its lined up with #6 and you get no compression on the #1 cylinder when the TDC lines up the engine needs another rotation,if you get compression on the #1 cylinder when the TDC lines up with rotor pointing at #6 the distributor 180 out) and the distributor needs to be pulled rotated 180 and re installed.

If your running a carb, now verify you have 4-5 psi of fuel pressure and your getting spark at the plugs once the distributor cap and wires are installed, verify the firing order and once it starts back off each rocker nut at idle until the rocker clicks than tighten slowly just to the point it stops clicking and then add 1/4 turn of preload. verify your exhaust is not clogged, a partly melted catalytic converter can kill off power fast

READ THRU these links, and the sub linked info in them, should help

viewtopic.php?f=55&t=109

viewtopic.php?f=70&t=202

viewtopic.php?f=70&t=875

viewtopic.php?f=56&t=495&p=26600&hilit=clogged+converter#p26600

viewtopic.php?f=70&t=3301

viewtopic.php?f=44&t=773

http://forum.grumpysperformance.com/viewtopic.php?f=70&t=1411

http://forum.grumpysperformance.com/viewtopic.php?f=70&t=967

viewtopic.php?f=81&t=1189&p=2447#p2447

http://forum.grumpysperformance.com/viewtopic.php?f=70&t=270

viewtopic.php?f=32&t=1401&p=3104#p3104

viewtopic.php?f=55&t=1475&p=3325&hilit=testing+sensor#p3325

http://forum.grumpysperformance.com/viewtopic.php?f=70&t=1015

http://forum.grumpysperformance.com/viewtopic.php?f=55&t=1115

http://forum.grumpysperformance.com/viewtopic.php?f=52&t=196

http://forum.grumpysperformance.com/viewtopic.php?f=62&t=882&p=1390&hilit=+propane#p1390

viewtopic.php?f=44&t=773&p=1123#p1123

viewtopic.php?f=44&t=808&p=1180#p1180

viewtopic.php?f=44&t=808

viewtopic.php?f=44&t=777

all it takes to find out why your not making the hp you think you should be is actual testing to find out what your dealing with and what needs improving or changes

be fore you make changes you need to have a base line your working from

do these tests

did you verify TDC or just install the cam dot-to-dot?

whats your compression read?

whats the battery voltage read when the engines running?

post very clear pictures of all 8 plugs?

whats your EXACT ignition advance curve?

whats the plenum vacuum read at wide open throttle?

whats the exhaust system pressure in the collector pipe read at wide open throttle?

viewtopic.php?f=56&t=495

viewtopic.php?f=55&t=109

viewtopic.php?f=70&t=202

viewtopic.php?f=70&t=1809

viewtopic.php?f=70&t=4683

watch the video

http://www.youtube.com/watch?v=YdIGZ-tV ... re=related

is it mechanical?

look for broken parts, loose connections, leaky hoses

are the CATS clogged or the O2 sensors faulty

check the compression in all cylinders

re-adjust the valves

look for vacuum leaks

look for loose serpentine belts

look for cooling system problems

check the trans fluid level and condition

check oil and fuel levels

check the rear differentials fluid level and condition

check the engines oil level and condition

check the brake fluid level and condition

change the filters

check the throttle body is opening completely

verify the TPS and IAC are set correctly, and use some carb/throttle body cleaner to clean up the TB.

what are the engines oil pressure, fuel pressure and cooling system temps?

if somethings wrong there's usually symptoms that point to the source!

IS it electrical?

verify the MAT, MAP, and or MAF sensors are working correctly

verify the coolant temp sensor and knock sensor are working

set the ignition timing

install new plugs with a .045 gap

verify the O2 sensors ok

look for loose grounds, on the engine,gauges,battery

check the battery voltage

check the fuel pump and relays

use a V.O.M. to verify plug wire resistance

check/replace the distrib cap.

VERIFY ALL SENSORS and FUSES and CONNECTIONS are ok, verify the voltage on the systems correct

IS it fuel related

verify the pressure and flow

verify the injectors are functioning correctly

read the old plugs

use a ir temp gun to verify exhaust temps

throw a couple cans of injector cleaner and 8 oz of MARVEL MYSTERY OIL into a fresh tank of fuel, it can clean out lots of minor varnish in the system

when you try to track down any problem with a cars engine you need to start with the basics of

fuel pressure,

and a compression check,

checking for vacuum leaks,

checking the valves are adjusted correctly,

verify the battery has a minimum of 12.5 volts

and the alternator boosts that while running to over 13 volts

verifying that your timing marks are at T.D.C,on the damper

verify that the timing tab indicates true T.D.C.

have a quality timing light and know how its used

and your ignition timing curve is correct, and smoothly advancing as the rpms build.

verify the timing is close to the shop manual suggestions

check all the fuses and engine grounds,

and get out a infrared temp gun and look for marked changes in the exhaust temperatures, indicating non-firing cylinders or fuel distribution issues

verify the oil temperature and pressure

verify the engines got less than 2 psi of exhaust back pressure

learn to read spark plugs as they are a great indicator of conditions in the combustion chamber

learn to use a vacuum gauge

if you have one a fuel/air ratio meters a big help

BUT HAVE A SHOP MANUAL and take the time to READ IT!

tools you really need

SHOP MANUAL

timing light

vacuum gauge

IR temp gun

degree wheel

dial indicator and stand

fuel pressure gauge

V.O.M. meter

torque wrench

magnifying spark plug reader

lift or (4) 12 ton jack stands

basic mechanic hand tools

floor jack

90% of your problems will be found just running thru the check list and following the shop manual suggestions, yes diagnostic software , and owning a scanner is a very good idea!

yes I know your 100% sure the ignition timing and the plug wires are correctly installed..CHECK THEM AGAIN CAREFULLY SEVERAL TIMES

The first thing ID do is VERIFY the CAUSE, OF THE PROBLEM FOR THAT, THRU ISOLATING AND TESTING, COMPONENTS AND SYSTEMS

A SHOP MANUAL IS ALMOST MANDATORY,

THESE LINKS should help

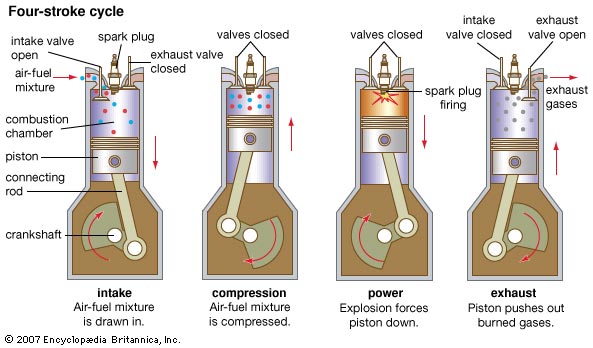

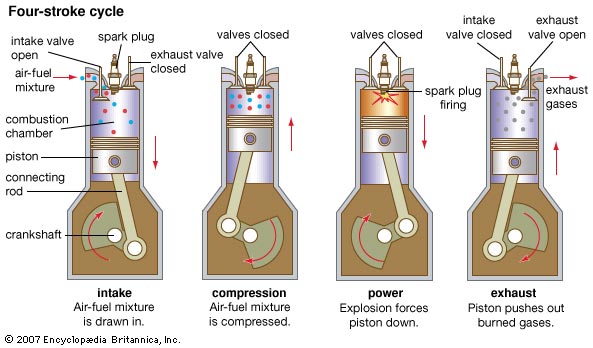

remember most problems come down to the basics of DO YOU HAVE FUEL?, IGNITION, OR COMPRESSION?, OR IS THERE SOMETHING MECHANICALLY WRONG,? once youve isolated the basic problem its source will become rather obvious in many cases

viewtopic.php?f=80&t=728

viewtopic.php?f=55&t=1241&p=3037&hilit=+sensor#p3037

do a compression test and inspect the rocker movement very carefully on EACH CYLINDER and POST THE RESULTS to insure your not fighting a mechanical issue before we start, verify the rockers are adjusted and verify TDC on the damper and timing tab ARE REALLY INDICATING TDC on the engine, then verify your ignition advance starts at about 10 degrees BTDC at idle and smoothly advances to about 36 degrees at 3200rpm, use a VOM or multi meter to verify each spark plug wire reads UNDER 2000 ohms per foot,and that youve got 13 volts at the coil with the engine running at idle

check for vacuum leaks

verify your float levels,if you have a carb and fuel pressure with either a carb or injectors

while your at it post clear pictures of each spark plug labeled with the cylinder it came from

pictures like this tell a great deal

viewtopic.php?f=50&t=10623&p=45691#p45691

you really need to purchase a multi meter and a SHOP MANUAL and look thru the schematics

without testing theres almost no way to locate the source of your problem,, testing will tell you

http://www.helminc.com/helm

http://www.harborfreight.com/5-in-1-dig ... 98674.html

it is always helps to post your location,when posting questions, at least the city & state your located in because theres a good chance an experienced hobbyist or mechanic on this site may be reading this, located local to you, who is willing to help either for free or at low cost! or at least post advices and places to get parts locally

Ive been building engines for over 47 years now, and yeah,eventually even my hard head learned, a few things, but I,m sure willing too learn and ask questions, and use any new info posted

can a few of you gentlemen explain to me why??

when I suggest isolating and testing each separate potential component of both the fuel and ignition, systems and checking the engines valve train and checking compression, fuses, and sensors and pulling trouble codes and using the factory shop manual and a few tools like a mufti-meter and compression gauge, IR TEMP THERMOMETER,VACUUM GAUGE, and listed tests, even when I supply rather extensive links showing extensive detailed info, the majority of the guys reading thru the threads obviously ignore the info that could be used too locate the source, in most cases youll need too, isolate it test it and fix it rather than making random wild guesses without any facts or testing?

look if you don,t isolate the problem to its source through accurate testing there,s almost no other logical way to locate and fix the problem.

GUYS I NEVER SAID I,M A GREAT MECHANIC, BUT I HAVE LEARNED THAT IF YOU TAKE THE TIME TO BREAK THINGS DOWN INTO THE SIMPLEST PART AND DO A BIT OF RESEARCH, FINDING ANSWERS IS FAR LESS INTIMIDATING OR DIFFICULT,

youll need to isolate any problem to its source, be it engine, drive train, suspension,fuel system, electric, cooling, exhaust, etc. then further logically isolate it to the defective component, or part needing adjustment or replacement

like the old saying how do you eat an elephant......one little bite at a time!

all the answers are readily available, theres known testing procedures and listed test results you can expect, and procedures listed in the shop manual for isolating and testing components, you don,t need to be a genius, you just need to be logical and persistent and not afraid to learn new things while getting your hands dirty at times

THE FASTEST AND EASY ROUTE IS TO ISOLATE AND TEST< NOT RANDOM GUESS WORK

buy a CHEVY SHOP MANUAL FOR YOUR YEAR CORVETTE!

set and verify your ignition timing, pull trouble codes,set your tps and iac,, then check for vacuum leaks on the lines and intake,then get out your multi meter and verify all the sensors, chances are good its a defective heat sensor or defective o2 sensor, a logical step by step approach will lead you to the problem, youll be amazed at what youll learn reading links. use of a shop manual and multi meter can be very helpful

http://www.harborfreight.com/5-in-1-dig ... 98674.html

learn to use the factory shop manual, and a multi meter and LISTEN to the engine closely, tapping and high pitch whines can indicate defective injectors or fuel pressure regulators, fuel pumps,mis- adjusted valve train components, worn distributor parts, check all the fuses and electrical grounds and corrosion on connections thats something thats frequently over looked etc.

http://www.chevythunder.com/Flow chart index.htm

http://www.professionalequipment.com/ex ... ermometer/

having a good cross check tool like a quality IR temp gun, and a decent multi meter, sure helps find the truth as far as a defective gauge or sensor

READ THESE LINKs

viewtopic.php?f=50&t=10012&p=38779#p38779

viewtopic.php?f=36&t=63

if your installing a new component ,read the manufacturers instructions carefully and call the tech guys if ANYTHINGS not 110% clear

RULE two

IF something won,t fit or function....STOP, call the the tech guys ,after you re-read the manufacturers instructions carefully and measure carefully so you sound at least 1/2 way like you know what talking about, then call the tech guys if ANYTHINGS not 110% clear

RULE three

STOP AND DO THE REQUIRED RESEARCH if youve got questions

I never mind sounding dumb as long as I get the correct answers, so I won,t LOOK dumb by doing something wrong

rule four

isolate the problem to a lack of or Mal -function in,engine compression,ignition,lubrication,cooling, fuel supply,drive-train,or suspension, or a mechanical or electrical fault as soon as you can, this can only be done by testing and verification, don,t guess or assume anythings correct until you verify it yourself

yes reading the sub linked info is mandatory if you want answers

http://www.helminc.com/helm/welcome_sel ... M2S049ETF8

CHECK ALL YOUR FUSES WITH A MULTI METER

http://www.clarks-garage.com/shop-manua ... tm#oil-low

http://www.davidfarmerstuff.com/

when ever you get into unexplained symptoms the answer remains the same....in every case,.... you drop back to the basics and do a few tests, get out a multi meter and verify every fuse is good, and you have 13 volts at the battery and youve got at least a 1/2 tank of fresh fuel, before you start chasing your tail, thinking about more complicated problems

find the cause, you isolate, each function or system or malfunction to its related components then test, each individually, use of the shop manual is almost mandatory

erase old trouble codes and pull new codes after each change, made.

read the codes, and follow the FACTORY SHOP MANUAL INFO

there could be several reasons and a few tests will limit the potential problem areas,valve float, restricted fuel pressure,or volume, badly adjusted carb floats, wrong jets, wrong power valves, dirty or restricted air filter, cam timing, ignition timing, carb being badly adjusted,valves being badly adjusted, ignition advance curve not correct, timing tab or damper, not correctly indicating TDC, etc. ignition spark should be bright blue and impressive, if its, weak,narrow, yellow or red theres a problem so research the cause, verify the coil and voltage

you start by dropping back to the basics , adjusting or verifying or correcting each potential problem area and eliminating it as the cause, then and only then moving on to the next area, guessing will drive you nuts and cause you to throw large amounts of un-necessary parts at the problem with little resulting improvements. a logical step bye step approach is best, youll need to verify cylinder compression, ignition, strength and timing and fuel and air delivery, ID also suggest a compression test and a general checking over,each potential engine and drive line sub-system carefully, with a timing light,vacuum gauge, fuel pressure gauge, VOM meter , ETC. and adjusting valves, checking for vacuum leaks, check fuel pressure and post clear pictures of spark plugs as they give a ton of info if you know how to read them, etc.it helps a great deal to know what your working with ,ID suggest starting, by verifying TDC and having the correct timing tape on your damper then,start with 8 degrees btdc and verifying the full advance of 36 degrees total is all in at 3200rpm as a base line, once youve got that, as a standard you can tune and run the car and eventually try tweaks to the basic ignition curve if needed, once you have an ignition base line, move on to the carbs tuning, you also need to keep in mind that what goes in as a fuel /air mix needs to go out as a much expended volume of hot gases and a restrictive exhaust will effectively block most attempts to get more power from an engine, so measure exhaust back pressure. you might be amazed at what a couple hours research into the subject will do to help you build a much more durable engine, and actually reading thru links and sub-links and asking questions helps a great deal

you might be amazed at the number of times "CARBURETOR PROBLEMS" are cured with getting the IGNITION, TIMING AND ADVANCE CURVE WORKING CORRECTLY, and check out the simply things your 100% sure you did correctly, because I can,t begin to tell you how many times I see guys who have the firing order on the ignition wrong, or guys that install a 4/7 swap cam and still use the standard ignition firing order or guys that never verify TDC and ignition advance curves.

get an IR temp gun and check for wild variations in exhaust temps, get a compression test done, do a logical check to verify each cylinder fires etc.

Id also be pulling and changing the oil filter and inspecting the old one for metallic debris indicating a worn cam lobe, assume EVERY SUB SYSTEM could be miss adjusted or defective EVEN if you just replaced parts recently

basically an in depth tune-up and system verification is whats needed

viewtopic.php?f=54&t=4611

viewtopic.php?f=70&t=202

viewtopic.php?f=55&t=109

can,t get it started? these bits of info should help

always drop back to basics

check your battery cable connections

check your fuses and get out your shop manual.

IF you have the option pull trouble codes.

have you verified TDC on the damper and timing tab?

have you done a compression test?

are all the spark plugs firing correctly?

did you degree in the cam or just DOT-to-dot install it?

whats your fuel pressure?

have you verified the carbs float levels?

does fuel run out the site holes at idle?

are the needle& seat valves working correctly?

whats your ignition timing?

do you have voltage at the coil?

whats your plenum vacuum?

have you verified the engine got no vacuum leaks?

whats the oil pressure?(did you check the dip stick?)

have you adjusted the valves at idle?

does the distributor timing advance with rpm increases?

have you tried a different carb?

what are the plugs gaped at?

does this happen without an air filter?

have you verified you've have functioning power valves?

what jets are you using?

is there visible fuel flow from the boosters?

whats your battery voltage?

whats your exhaust back pressure?

are you totally sure the fuel free of water and fresh?

have you pulled trouble codes?

drop back to basics, don,t assume you did anything correctly until you verify, its been done correctly.

first remove plug #1 and your valve covers and the distributor cap

stick a large ratchet/socket on the crank bolt and stick your thumb over the #1 plug hole rotate the engine until you feel compression building the rotor on the distributor should be approaching the #1 plug, now watch the timing tab and damper mark, it should line up at the TDC (TOP DEAD CENTER) marks , if its lined up with #6 and you get no compression on the #1 cylinder when the TDC lines up the engine needs another rotation,if you get compression on the #1 cylinder when the TDC lines up with rotor pointing at #6 the distributor 180 out) and the distributor needs to be pulled rotated 180 and re installed.

If your running a carb, now verify you have 4-5 psi of fuel pressure and your getting spark at the plugs once the distributor cap and wires are installed, verify the firing order and once it starts back off each rocker nut at idle until the rocker clicks than tighten slowly just to the point it stops clicking and then add 1/4 turn of preload. verify your exhaust is not clogged, a partly melted catalytic converter can kill off power fast

READ THRU these links, and the sub linked info in them, should help

viewtopic.php?f=55&t=109

viewtopic.php?f=70&t=202

viewtopic.php?f=70&t=875

viewtopic.php?f=56&t=495&p=26600&hilit=clogged+converter#p26600

viewtopic.php?f=70&t=3301

viewtopic.php?f=44&t=773

http://forum.grumpysperformance.com/viewtopic.php?f=70&t=1411

http://forum.grumpysperformance.com/viewtopic.php?f=70&t=967

viewtopic.php?f=81&t=1189&p=2447#p2447

http://forum.grumpysperformance.com/viewtopic.php?f=70&t=270

viewtopic.php?f=32&t=1401&p=3104#p3104

viewtopic.php?f=55&t=1475&p=3325&hilit=testing+sensor#p3325

http://forum.grumpysperformance.com/viewtopic.php?f=70&t=1015

http://forum.grumpysperformance.com/viewtopic.php?f=55&t=1115

http://forum.grumpysperformance.com/viewtopic.php?f=52&t=196

http://forum.grumpysperformance.com/viewtopic.php?f=62&t=882&p=1390&hilit=+propane#p1390

viewtopic.php?f=44&t=773&p=1123#p1123

viewtopic.php?f=44&t=808&p=1180#p1180

viewtopic.php?f=44&t=808

viewtopic.php?f=44&t=777

all it takes to find out why your not making the hp you think you should be is actual testing to find out what your dealing with and what needs improving or changes

be fore you make changes you need to have a base line your working from

do these tests

did you verify TDC or just install the cam dot-to-dot?

whats your compression read?

whats the battery voltage read when the engines running?

post very clear pictures of all 8 plugs?

whats your EXACT ignition advance curve?

whats the plenum vacuum read at wide open throttle?

whats the exhaust system pressure in the collector pipe read at wide open throttle?

viewtopic.php?f=56&t=495

viewtopic.php?f=55&t=109

viewtopic.php?f=70&t=202

viewtopic.php?f=70&t=1809

viewtopic.php?f=70&t=4683

watch the video

http://www.youtube.com/watch?v=YdIGZ-tV ... re=related

is it mechanical?

look for broken parts, loose connections, leaky hoses

are the CATS clogged or the O2 sensors faulty

check the compression in all cylinders

re-adjust the valves

look for vacuum leaks

look for loose serpentine belts

look for cooling system problems

check the trans fluid level and condition

check oil and fuel levels

check the rear differentials fluid level and condition

check the engines oil level and condition

check the brake fluid level and condition

change the filters

check the throttle body is opening completely

verify the TPS and IAC are set correctly, and use some carb/throttle body cleaner to clean up the TB.

what are the engines oil pressure, fuel pressure and cooling system temps?

if somethings wrong there's usually symptoms that point to the source!

IS it electrical?

verify the MAT, MAP, and or MAF sensors are working correctly

verify the coolant temp sensor and knock sensor are working

set the ignition timing

install new plugs with a .045 gap

verify the O2 sensors ok

look for loose grounds, on the engine,gauges,battery

check the battery voltage

check the fuel pump and relays

use a V.O.M. to verify plug wire resistance

check/replace the distrib cap.

VERIFY ALL SENSORS and FUSES and CONNECTIONS are ok, verify the voltage on the systems correct

IS it fuel related

verify the pressure and flow

verify the injectors are functioning correctly

read the old plugs

use a ir temp gun to verify exhaust temps

throw a couple cans of injector cleaner and 8 oz of MARVEL MYSTERY OIL into a fresh tank of fuel, it can clean out lots of minor varnish in the system

when you try to track down any problem with a cars engine you need to start with the basics of

fuel pressure,

and a compression check,

checking for vacuum leaks,

checking the valves are adjusted correctly,

verify the battery has a minimum of 12.5 volts

and the alternator boosts that while running to over 13 volts

verifying that your timing marks are at T.D.C,on the damper

verify that the timing tab indicates true T.D.C.

have a quality timing light and know how its used

and your ignition timing curve is correct, and smoothly advancing as the rpms build.

verify the timing is close to the shop manual suggestions

check all the fuses and engine grounds,

and get out a infrared temp gun and look for marked changes in the exhaust temperatures, indicating non-firing cylinders or fuel distribution issues

verify the oil temperature and pressure

verify the engines got less than 2 psi of exhaust back pressure

learn to read spark plugs as they are a great indicator of conditions in the combustion chamber

learn to use a vacuum gauge

if you have one a fuel/air ratio meters a big help

BUT HAVE A SHOP MANUAL and take the time to READ IT!

tools you really need

SHOP MANUAL

timing light

vacuum gauge

IR temp gun

degree wheel

dial indicator and stand

fuel pressure gauge

V.O.M. meter

torque wrench

magnifying spark plug reader

lift or (4) 12 ton jack stands

basic mechanic hand tools

floor jack

90% of your problems will be found just running thru the check list and following the shop manual suggestions, yes diagnostic software , and owning a scanner is a very good idea!

yes I know your 100% sure the ignition timing and the plug wires are correctly installed..CHECK THEM AGAIN CAREFULLY SEVERAL TIMES

The first thing ID do is VERIFY the CAUSE, OF THE PROBLEM FOR THAT, THRU ISOLATING AND TESTING, COMPONENTS AND SYSTEMS

A SHOP MANUAL IS ALMOST MANDATORY,

THESE LINKS should help

remember most problems come down to the basics of DO YOU HAVE FUEL?, IGNITION, OR COMPRESSION?, OR IS THERE SOMETHING MECHANICALLY WRONG,? once youve isolated the basic problem its source will become rather obvious in many cases

viewtopic.php?f=80&t=728

viewtopic.php?f=55&t=1241&p=3037&hilit=+sensor#p3037

do a compression test and inspect the rocker movement very carefully on EACH CYLINDER and POST THE RESULTS to insure your not fighting a mechanical issue before we start, verify the rockers are adjusted and verify TDC on the damper and timing tab ARE REALLY INDICATING TDC on the engine, then verify your ignition advance starts at about 10 degrees BTDC at idle and smoothly advances to about 36 degrees at 3200rpm, use a VOM or multi meter to verify each spark plug wire reads UNDER 2000 ohms per foot,and that youve got 13 volts at the coil with the engine running at idle

check for vacuum leaks

verify your float levels,if you have a carb and fuel pressure with either a carb or injectors

while your at it post clear pictures of each spark plug labeled with the cylinder it came from

pictures like this tell a great deal

viewtopic.php?f=50&t=10623&p=45691#p45691

you really need to purchase a multi meter and a SHOP MANUAL and look thru the schematics

without testing theres almost no way to locate the source of your problem,, testing will tell you

http://www.helminc.com/helm

http://www.harborfreight.com/5-in-1-dig ... 98674.html

Last edited by a moderator: